Understanding the intricate arrangement of components within lawn care machinery is essential for effective maintenance and repair. A clear visualization of each part’s position can significantly enhance the efficiency of troubleshooting and servicing tasks. By familiarizing oneself with these layouts, operators can ensure that their equipment runs smoothly and effectively.

In this section, we delve into the detailed representations of various elements within a specific model of lawn maintenance equipment. Each illustration serves as a guide, providing insights into the functionality and relationship between the components. This knowledge not only aids in repairs but also promotes better overall care of the machinery.

Moreover, recognizing how each piece fits into the larger system empowers users to make informed decisions regarding upgrades and replacements. With a thorough understanding of the layout, operators can enhance the performance and longevity of their equipment, ensuring it meets the demands of any landscaping task.

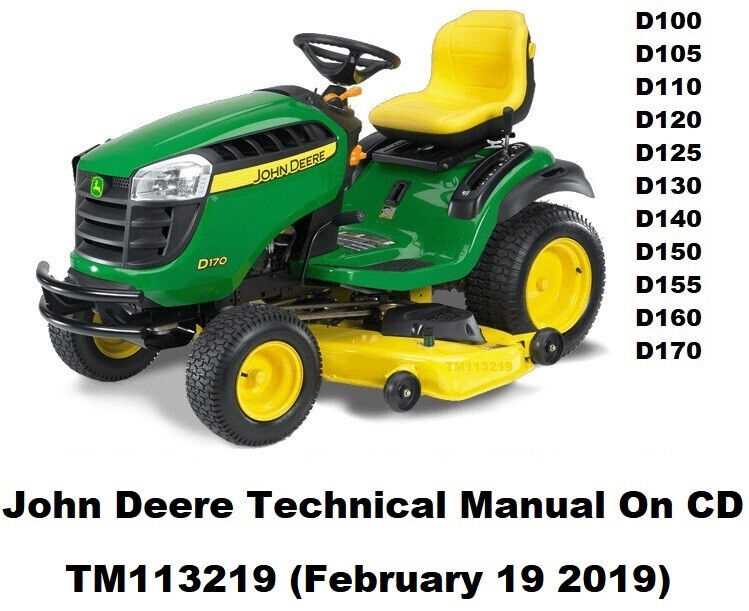

Understanding the John Deere D100

This section explores the key features and components of a popular lawn care machine designed for residential use. With its robust build and user-friendly design, this model stands out in the market for its reliability and efficiency in maintaining outdoor spaces.

Key Features

This model offers a powerful engine paired with a durable cutting deck, ensuring optimal performance for various landscaping tasks. Its ergonomic design enhances user comfort, allowing for extended periods of operation without fatigue. Additionally, the intuitive controls make it accessible for both novice and experienced users.

Maintenance Essentials

Key Components of the D100 Model

This section explores the essential elements that contribute to the functionality and performance of this specific lawn care machine. Understanding these components is vital for effective maintenance and operation.

Essential Elements

- Engine: The heart of the machine, responsible for generating power and enabling movement.

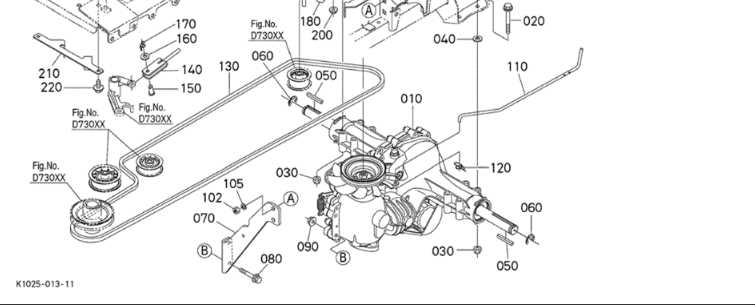

- Transmission: A crucial system that transfers power from the engine to the wheels, ensuring smooth operation.

- Deck: The cutting apparatus that determines the quality of the lawn finish.

- Wheels: Provide stability and mobility across various terrains.

- Controls: User interfaces that allow for easy navigation and adjustments during operation.

Maintenance Considerations

- Regularly check the engine oil levels and replace filters as needed.

- Inspect the transmission fluid to ensure proper functionality.

- Clean the deck after each use to prevent grass buildup.

- Examine the wheels for wear and tear to maintain safety.

- Ensure that controls are functioning smoothly for optimal user experience.

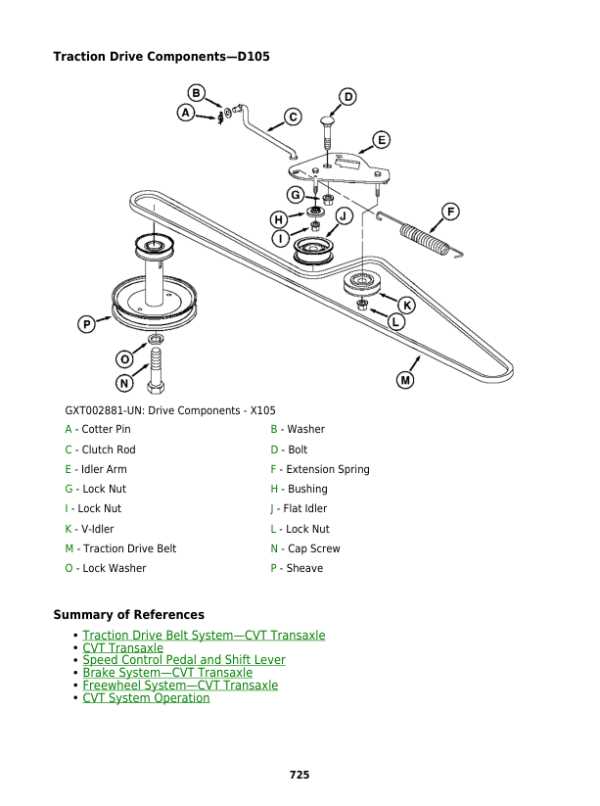

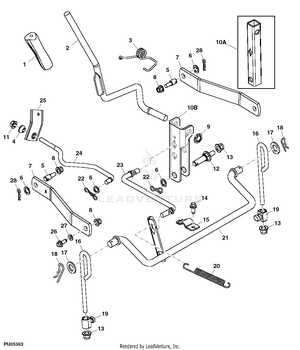

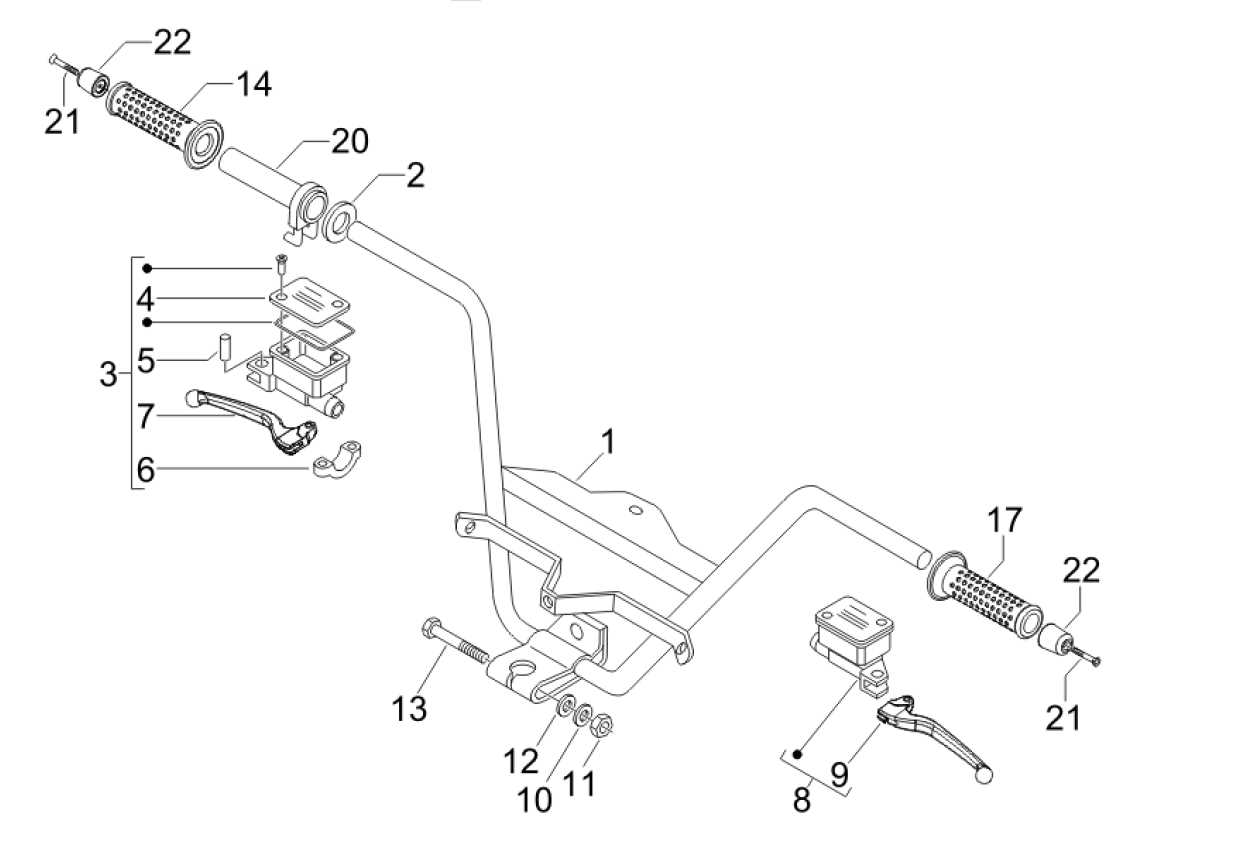

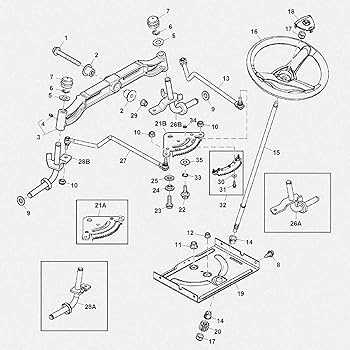

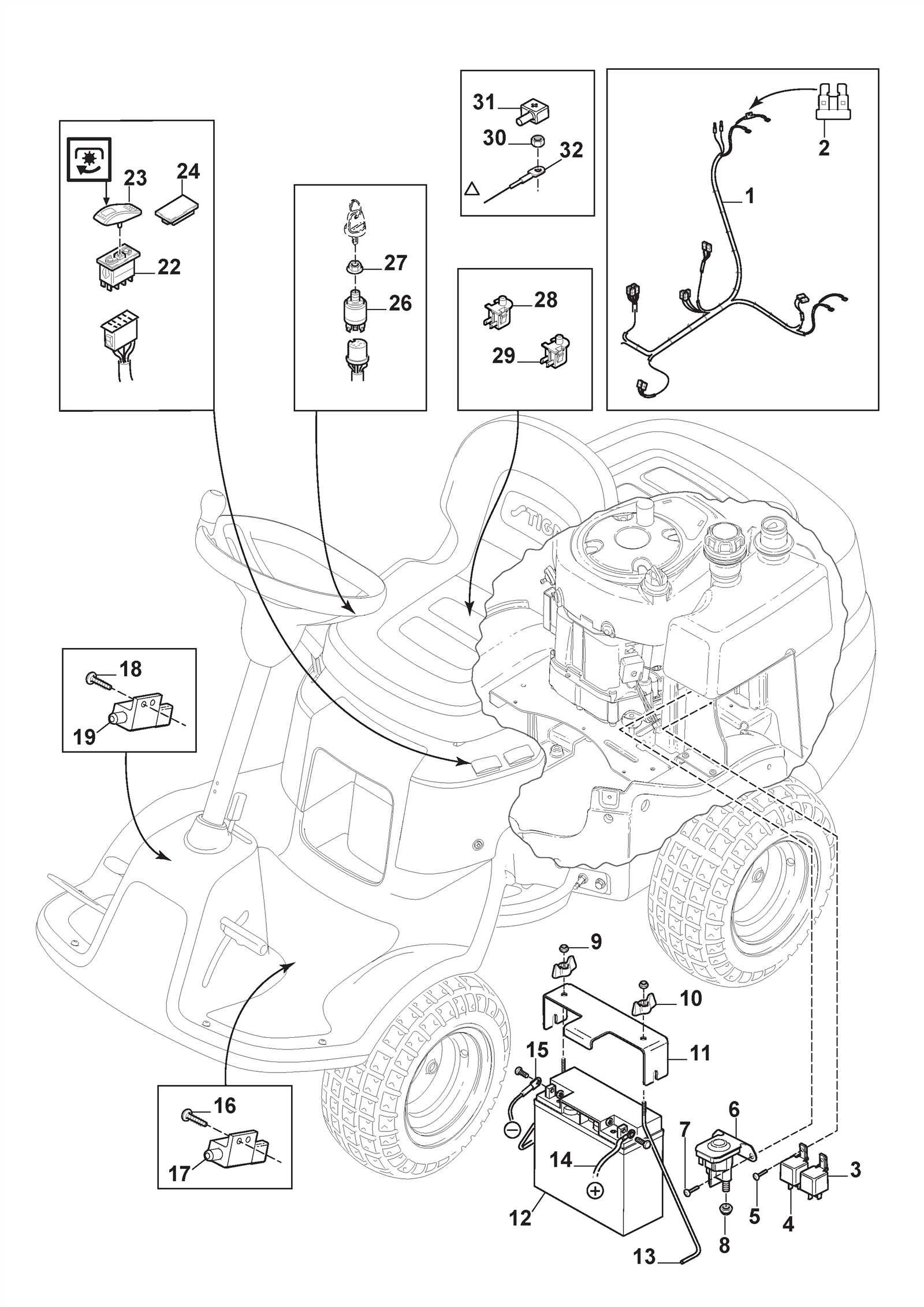

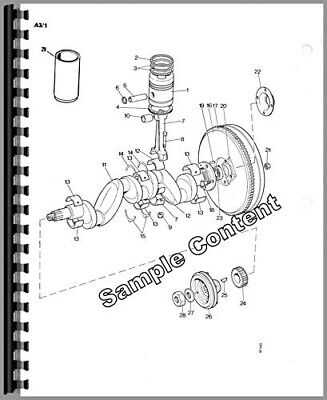

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. These illustrations offer a clear overview, enabling users to identify each element and its function within the larger system. By simplifying complex structures, they facilitate both repair and replacement processes, ensuring efficiency and accuracy.

Enhancing Maintenance Efficiency

Having a visual reference streamlines maintenance activities. It allows technicians to quickly locate the required components, reducing downtime and enhancing productivity. Additionally, it helps in preventing errors during reassembly, as each piece can be matched with its corresponding place.

Facilitating Communication

Illustrations also serve as an effective communication tool among team members. They provide a common language that transcends technical jargon, making it easier for both experienced professionals and newcomers to discuss repairs and upgrades. This clarity fosters collaboration and ensures that everyone is on the same page.

| Benefits | Description |

|---|---|

| Time Savings | Quickly identify and locate components, reducing maintenance time. |

| Accuracy | Minimizes mistakes during assembly or repair, ensuring proper functionality. |

| Team Collaboration | Enhances communication among team members, facilitating smoother operations. |

| Learning Tool | Acts as an educational resource for new technicians to understand system layouts. |

Navigating the D100 Parts Manual

Understanding the layout and information within a specific maintenance guide is essential for efficient repairs and upkeep. This section aims to simplify your exploration of the manual, providing insight into how to effectively utilize its contents to enhance your experience and ensure optimal functionality.

Key Sections to Explore

Each manual is typically divided into several distinct sections, including a comprehensive overview, component listings, and detailed schematics. Familiarizing yourself with these areas can significantly streamline your search for necessary components, ensuring you quickly locate the relevant information.

Utilizing Visual References

Visual aids often accompany textual information, making it easier to identify specific components. By studying these illustrations alongside the descriptions, you can delve deeper into the assembly and functionality, leading to more informed decisions during maintenance.

Ultimately, mastering the navigation of the guide will empower you to maintain your equipment effectively, enhancing its performance and longevity.

Common Repairs for the D100

Maintaining outdoor equipment often involves addressing frequent issues that arise during use. Understanding common repairs can help users prolong the lifespan of their machinery and ensure optimal performance. This section highlights typical maintenance tasks and fixes that may be necessary for efficient operation.

One of the most prevalent concerns is the battery system. Over time, batteries can lose charge or corrode, necessitating cleaning or replacement. Regular checks can prevent unexpected failures during operation.

Another common issue involves the cutting deck. Blades can dull or become damaged from contact with hard surfaces. Regular sharpening and occasional replacement are essential for achieving a clean cut and maintaining overall efficiency.

Fuel system maintenance is also critical. Clogged filters or stale fuel can lead to starting problems. Periodic inspection and replacement of filters, as well as using fresh fuel, can help avoid these issues.

Lastly, the drive belt may experience wear and tear, affecting power transmission. Inspecting and replacing worn belts can restore functionality and improve performance. Addressing these common repairs can significantly enhance the reliability and efficiency of your equipment.

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, ensuring you have the right components is crucial for optimal performance and longevity. Authentic replacements not only guarantee compatibility but also enhance reliability, ensuring that your machinery runs smoothly for years to come. Identifying the correct items can sometimes be a challenge, but with the right approach, you can easily navigate the options available.

Start by consulting your equipment’s manual, which often contains valuable information regarding specifications and recommended suppliers. Utilizing online resources and manufacturer websites can provide insights into where to locate genuine components. Additionally, joining forums or communities dedicated to your equipment can yield recommendations from fellow users who have faced similar challenges.

Always consider purchasing from authorized dealers or reputable retailers. This practice not only assures quality but also supports the manufacturer’s warranty. While aftermarket alternatives may seem appealing due to their lower price points, they often lack the durability and precision of original products, potentially leading to further issues down the line.

In summary, taking the time to find authentic replacements will pay off in the long run. By utilizing trusted resources and being cautious about your choices, you can ensure that your machinery remains in peak condition, ready to tackle any task at hand.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your equipment remains in optimal condition over time. By following some key practices, you can extend the lifespan of your machinery and enhance its performance, allowing it to serve you efficiently for years to come.

Routine Inspections

Conducting frequent assessments can help identify potential issues before they escalate. Look for signs of wear and tear, check fluid levels, and ensure that all components are functioning properly. Early detection is crucial for maintaining peak performance.

Proper Cleaning and Storage

Keeping your equipment clean is vital for preventing corrosion and dirt buildup. After use, remove debris and grime to protect critical areas. Additionally, when storing, choose a dry, sheltered space to shield against environmental damage. Good storage practices contribute significantly to longevity.

Upgrades for Enhanced Performance

Improving the functionality of your outdoor equipment can significantly boost its efficiency and longevity. By investing in quality enhancements, you can transform basic machinery into high-performance tools that meet your specific needs.

Key Areas for Improvement

- Engine Upgrades

- Transmission Enhancements

- Cutting Deck Modifications

Recommended Upgrades

- High-Performance Air Filters

- Improved Fuel Injectors

- Upgraded Tires for Better Traction

Each enhancement targets essential aspects of operation, allowing you to delve deeper into performance capabilities while ensuring your machinery remains reliable and effective for various tasks.