The intricacies of machinery often hinge on a clear understanding of their various elements and how they interact. This section aims to unravel the complexities surrounding specific models of equipment, focusing on their essential constituents and how they come together for optimal performance.

By exploring the arrangement and functionality of these components, enthusiasts and professionals alike can enhance their knowledge, ultimately leading to better maintenance and troubleshooting practices. The visual representations of these assemblies serve as invaluable resources, allowing for a deeper comprehension of the equipment’s operational framework.

Whether you are a seasoned technician or a curious learner, delving into these illustrations will empower you with the insights needed to tackle any challenges that may arise, ensuring that your machinery operates at its peak efficiency.

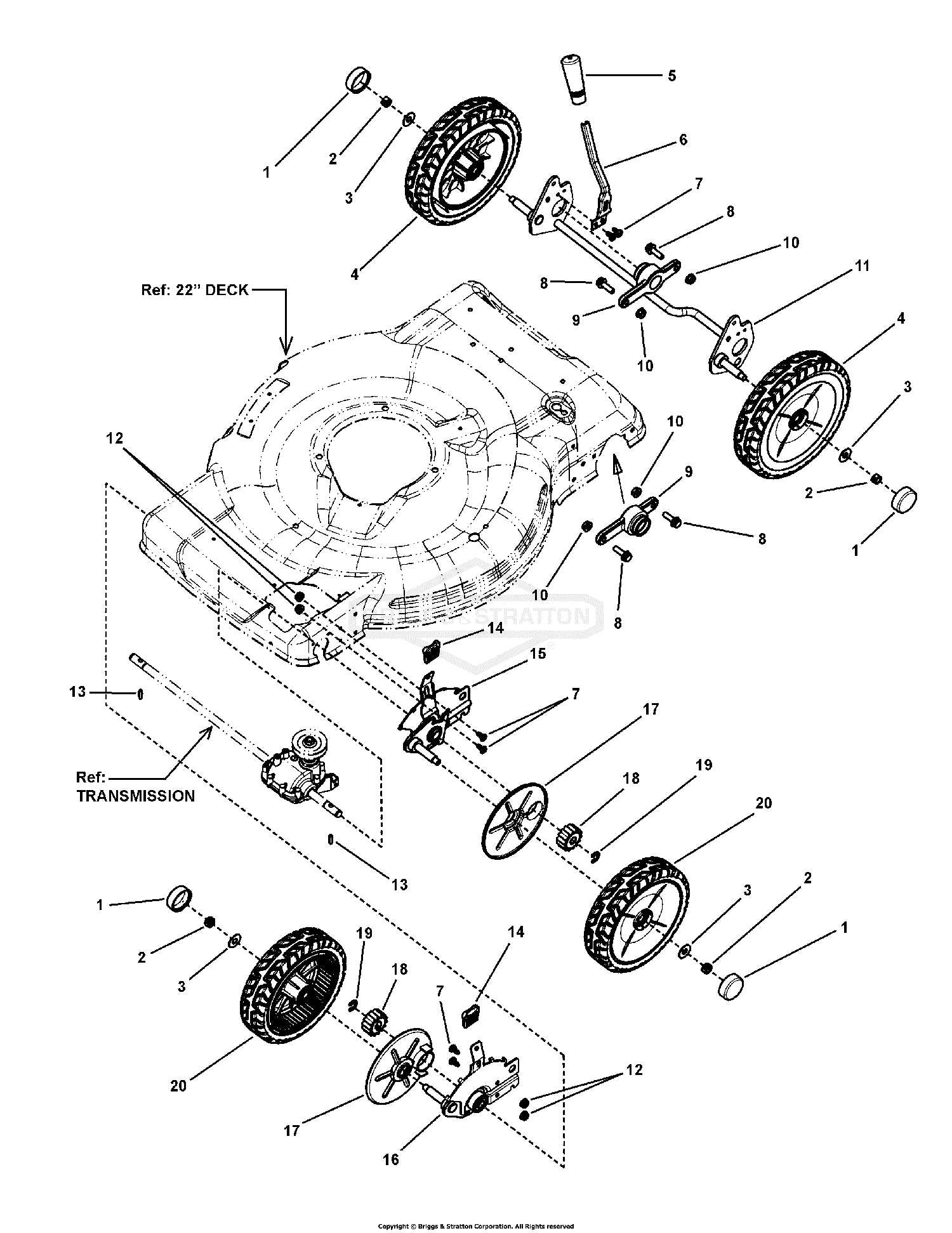

Understanding John Deere JS25 Components

When maintaining or repairing a lawn care machine, grasping the various elements that constitute its assembly is crucial. Each component plays a specific role in the overall functionality, ensuring optimal performance and durability. A comprehensive understanding of these individual parts allows for effective troubleshooting and maintenance, leading to a more efficient mowing experience.

Key Elements of the Machine

The primary components include the cutting deck, engine, and drive system. The cutting deck is responsible for achieving a clean and precise cut, while the engine powers the entire system, providing the necessary force to handle various terrains. The drive system connects these elements, allowing for smooth operation and maneuverability.

Maintenance Tips for Longevity

Regular upkeep of these crucial components can significantly enhance the longevity of the machine. Inspecting blades for sharpness and wear, ensuring the engine is properly lubricated, and checking the drive belts for any signs of damage are essential practices. Additionally, cleaning the undercarriage after each use can prevent grass buildup, which may affect performance over time.

Importance of Parts Diagrams

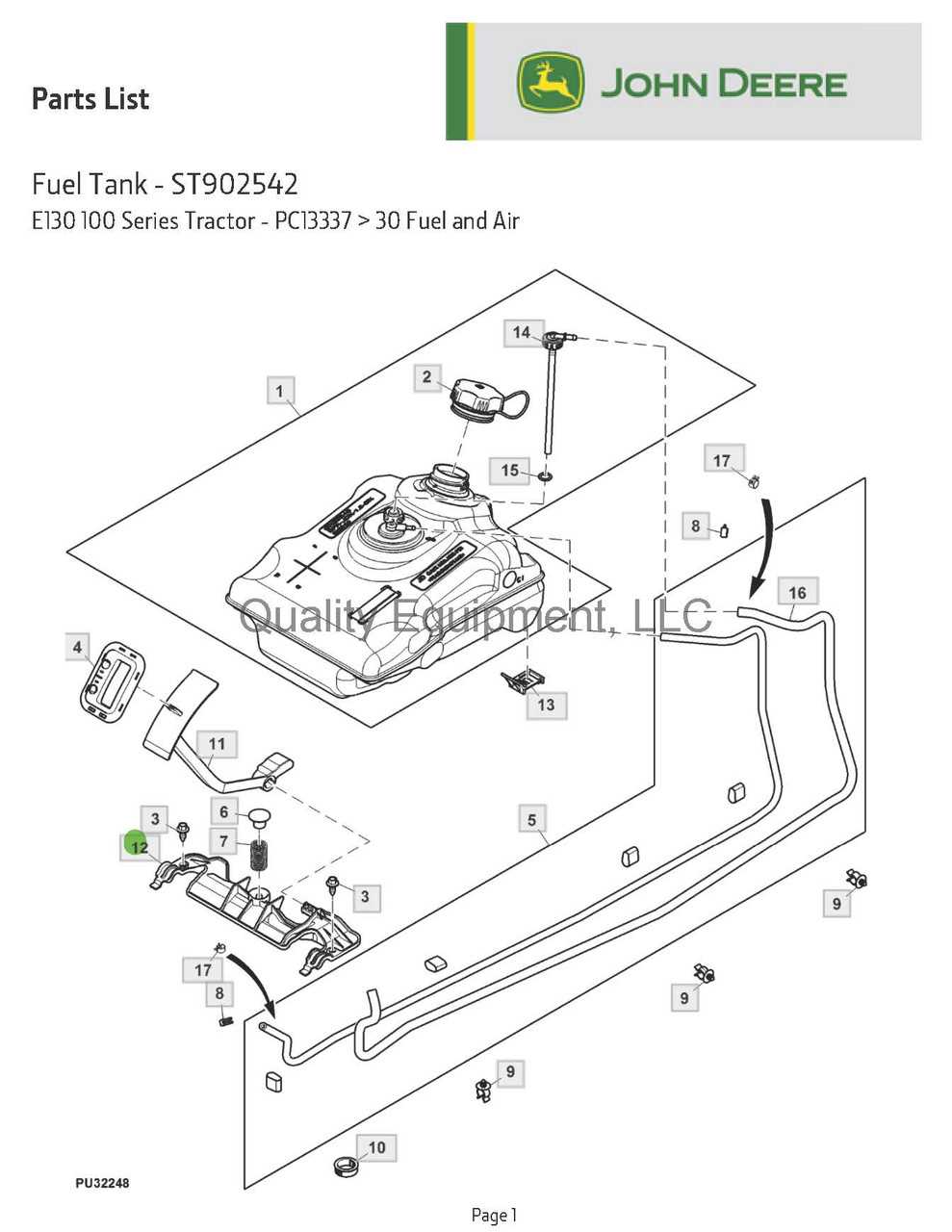

Understanding the layout of components in machinery is crucial for effective maintenance and repair. Visual representations not only simplify the identification of each element but also enhance the efficiency of service tasks. A clear illustration can prevent confusion and reduce the risk of errors during assembly or disassembly.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids provide a straightforward way to grasp complex systems. |

| Time Efficiency | Quick reference reduces downtime during repairs. |

| Improved Accuracy | Reduces the likelihood of mistakes in part selection and installation. |

| Facilitates Learning | Useful for training new technicians and users on equipment assembly. |

Common Issues with JS25 Models

Models in this category often encounter several prevalent challenges that can affect their performance and longevity. Understanding these issues can aid in maintenance and troubleshooting, ensuring a smoother operational experience.

- Engine Performance: Many users report issues related to engine power loss, which can stem from various factors such as fuel quality, air filter blockages, or spark plug wear.

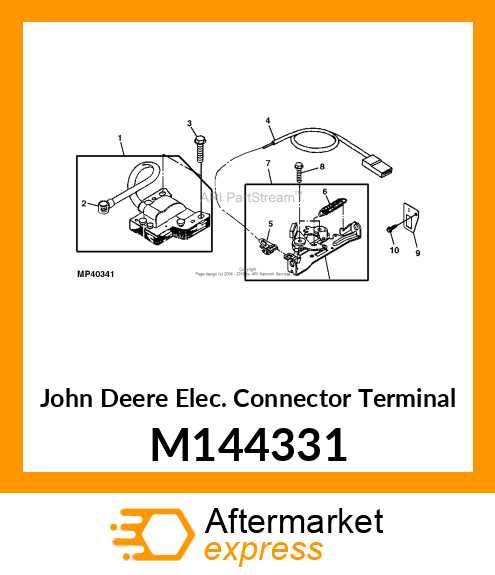

- Electrical Failures: Electrical problems, including battery drainage and faulty wiring, can lead to starting difficulties or intermittent operation.

- Blade Wear: Dull or damaged cutting blades are common complaints, affecting the overall cutting efficiency. Regular inspections and replacements are crucial.

- Transmission Issues: Problems with the transmission system can lead to shifting difficulties, often due to low fluid levels or contamination.

Addressing these common issues promptly can help maintain the equipment’s functionality and extend its operational lifespan.

How to Identify Original Parts

Ensuring the authenticity of components is crucial for maintaining equipment performance and longevity. Recognizing genuine items can prevent unnecessary costs and enhance overall functionality. This section provides essential tips to distinguish authentic parts from imitations.

Key Characteristics of Authentic Components

- Manufacturer Branding: Genuine items typically feature clear branding, logos, or model numbers etched or printed on the surface.

- Quality of Material: Original components are made from high-grade materials that often exhibit superior durability and resistance to wear.

- Packaging: Authentic products usually come in branded packaging that includes detailed information, such as part numbers and specifications.

Verification Methods

- Cross-Referencing: Check the manufacturer’s website for the specific part number to confirm its legitimacy.

- Authorized Dealers: Purchase from certified distributors or retailers known for selling genuine items.

- Expert Consultation: Consult with professionals or forums that specialize in the specific equipment type to gain insights on authenticity.

Maintenance Tips for Lawn Mowers

Regular upkeep of mowing equipment is essential for optimal performance and longevity. By following a few simple strategies, you can ensure that your machine runs smoothly, providing a pristine cut every time.

Routine Checks

Performing frequent inspections helps identify potential issues before they escalate. Check the oil level, air filter, and spark plug regularly. Cleaning the mower after each use also prevents grass buildup, which can affect efficiency.

Blade Care

Sharp blades are crucial for a clean cut. Dull blades can tear grass rather than cut it, leading to unhealthy lawns. Aim to sharpen or replace blades at least once a season, or more frequently if you mow regularly.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Air Filter Cleaning | Every 25 hours |

| Blade Sharpening | Every 25 hours |

| Fuel Check | Before each use |

Where to Find Replacement Parts

Finding suitable components for machinery can often be a daunting task. Fortunately, numerous resources are available to help you locate the necessary items to keep your equipment running smoothly. Understanding where to search is crucial for efficient maintenance and repairs.

Online Retailers

One of the most convenient options is online shopping. Numerous websites specialize in offering a wide range of components for various types of machinery. These platforms often feature detailed descriptions and specifications, making it easier to identify what you need. Additionally, customer reviews can provide insights into the reliability and quality of the items.

Local Dealerships and Stores

Visiting local dealerships or specialty stores can also be beneficial. These establishments often have knowledgeable staff who can assist you in finding the right components. Furthermore, purchasing locally supports your community and may provide quicker access to items than online shopping.

In summary, whether you choose to shop online or explore local options, a range of avenues exist for sourcing the necessary equipment components. Prioritizing quality and reliability will ensure your machinery remains in optimal condition.

Step-by-Step Repair Guide

This guide aims to assist you in effectively restoring your equipment by providing clear instructions. Whether you’re dealing with mechanical issues or requiring replacement components, following these steps will streamline the process and ensure a successful outcome.

Preparation

- Gather necessary tools: screwdriver, wrench set, pliers, etc.

- Ensure you have access to a reliable workspace with adequate lighting.

- Review safety protocols to avoid accidents during the repair process.

Repair Process

- Disconnect the power source to prevent any electrical hazards.

- Carefully remove the outer casing to access internal components.

- Identify the faulty parts by checking for wear or damage.

- Replace any damaged components with new or refurbished parts.

- Reassemble the equipment by reversing the disassembly steps.

- Reconnect the power source and perform a test run to ensure everything functions correctly.

By following these outlined steps, you can effectively troubleshoot and repair your machinery, enhancing its longevity and performance.

Benefits of Using Genuine Parts

Choosing authentic components for machinery maintenance is essential for ensuring optimal performance and longevity. Genuine items are specifically designed to meet the exact specifications of your equipment, providing reliability that aftermarket alternatives often lack.

One of the primary advantages of using original components is their compatibility. These pieces fit seamlessly, reducing the risk of malfunctions and costly repairs down the line. Furthermore, authentic parts are typically backed by a manufacturer’s warranty, offering peace of mind and protecting your investment.

Durability is another key benefit. Genuine items are made from high-quality materials, which means they withstand wear and tear better than imitations. This leads to less frequent replacements and overall lower maintenance costs over time.

Additionally, utilizing original components supports better resale value for your machinery. Prospective buyers often seek equipment that has been maintained with authentic items, as it reflects a commitment to quality and care. Investing in genuine components ultimately enhances both the performance and the value of your equipment.

Customer Reviews and Experiences

Understanding user feedback is crucial for potential buyers seeking reliable equipment. Insights from current owners provide a wealth of information about performance, durability, and overall satisfaction. This section highlights various experiences and opinions, allowing prospective users to make informed decisions.

Positive Feedback

Many users express satisfaction with their machinery, citing the following points:

- High efficiency in completing tasks

- Robust build quality that withstands rigorous use

- Ease of maintenance and availability of components

- Excellent customer support from suppliers

Common Concerns

Despite the positive aspects, some reviews mention areas for improvement:

- Initial setup can be complex for beginners

- Occasional issues with specific components

- Higher than expected operational costs

Overall, the shared experiences contribute to a comprehensive understanding of the product’s strengths and weaknesses, guiding future owners in their choices.