The intricate design of modern farming equipment is a testament to engineering excellence. Every machine comprises numerous elements, each playing a crucial role in ensuring optimal performance. Understanding the arrangement and functionality of these components can significantly enhance maintenance and repair efforts, ultimately leading to improved efficiency in agricultural operations.

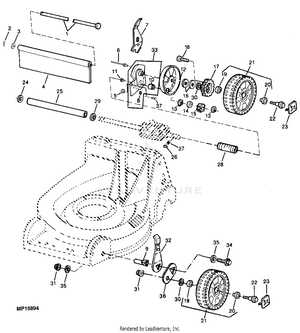

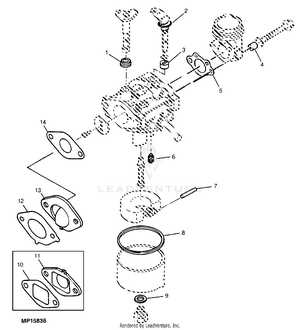

For enthusiasts and professionals alike, a comprehensive visual representation of the various segments within a specific model serves as an invaluable resource. By delving into the structural organization of machinery, operators can identify wear and tear, locate replacement components, and make informed decisions about upgrades and repairs.

In this exploration, we will focus on the detailed schematic of a particular agricultural implement. This guide aims to demystify the complexities of its assembly, allowing users to navigate the intricacies of machinery with confidence. Whether you are a seasoned technician or a novice user, familiarizing yourself with these layouts will empower you to maintain the integrity and functionality of your equipment.

Understanding the John Deere 14SE

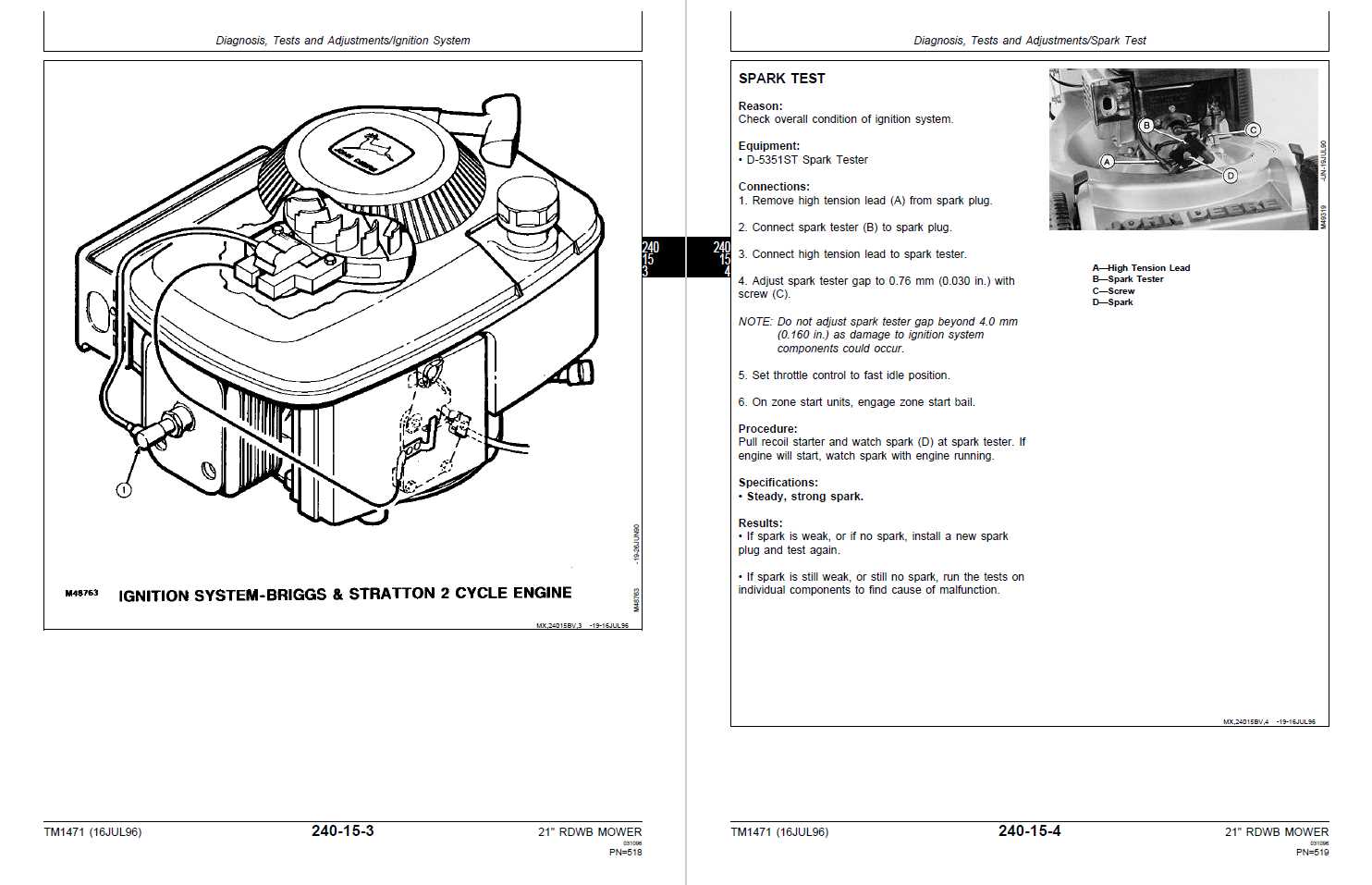

This section explores the intricacies of a well-regarded piece of machinery, highlighting its components and how they work together to deliver optimal performance. Gaining insight into the structure and functionality of this equipment is essential for maintenance and operation.

Key Features and Benefits

The model is designed with a robust framework that ensures durability and reliability. Its powerful engine and advanced technology contribute to efficient operation, making it a valuable asset for various agricultural tasks. Users often appreciate its ease of use and the ability to tackle diverse terrains with confidence.

Maintenance and Upkeep

Proper care is crucial to extending the lifespan of this machine. Regular inspections and timely replacements of essential components are recommended to avoid downtime and ensure seamless functionality. Familiarity with the internal workings can significantly aid in troubleshooting and enhancing overall performance.

In summary, understanding the mechanics of this machinery not only facilitates better usage but also empowers operators to perform necessary maintenance with confidence.

Importance of Accurate Parts Diagrams

Clear and precise illustrations play a crucial role in the maintenance and repair of machinery. These visual guides allow users to identify components accurately, ensuring that each element is recognized and addressed during servicing. The effectiveness of these references can significantly influence the efficiency of repairs and the longevity of the equipment.

Enhanced Efficiency in Maintenance

When individuals have access to well-detailed visuals, they can quickly locate necessary components, reducing the time spent searching for parts. This streamlined process not only saves time but also minimizes the risk of errors, leading to more successful repairs and servicing.

Cost-Effective Solutions

Utilizing accurate representations can lead to more informed decisions regarding replacements and repairs. By ensuring that the right elements are chosen, users can avoid unnecessary expenses related to incorrect part purchases or repeated repairs. This strategic approach fosters a more cost-effective maintenance routine, ultimately benefiting the overall operation.

Common Parts and Their Functions

Understanding the essential components of machinery is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall functionality and efficiency of the equipment. Familiarity with these key elements can aid in troubleshooting and ensuring longevity.

The engine serves as the powerhouse, converting fuel into mechanical energy, while the transmission system transfers this energy to the wheels, facilitating movement. The hydraulic system is vital for powering attachments and implements, enabling versatile operations on various terrains.

Another important component is the chassis, which provides structural support and stability, ensuring that the machine can operate effectively under load. Additionally, the electrical system manages the power distribution, starting mechanism, and lighting, enhancing safety and usability.

Finally, the control mechanisms, including levers and pedals, allow the operator to maneuver the equipment smoothly and precisely, ensuring efficient operation. Understanding these fundamental components helps in maintaining equipment and achieving optimal performance during usage.

How to Access Parts Diagrams Online

Accessing detailed schematics and component layouts for machinery has never been easier. Various online platforms offer resources that help users find the information they need to maintain and repair their equipment. This section will guide you through the steps to locate these valuable resources effectively.

Step-by-Step Guide

To find the appropriate schematics online, follow these simple steps:

| Step | Description |

|---|---|

| 1 | Visit the manufacturer’s official website or authorized dealer site. |

| 2 | Navigate to the support or resources section of the site. |

| 3 | Search for the specific model or series you need assistance with. |

| 4 | Look for a section labeled “Manuals,” “Technical Resources,” or similar. |

| 5 | Download or view the schematics in PDF or online format. |

Additional Resources

In addition to the official sites, several third-party platforms provide comprehensive information. Forums, user groups, and repair websites often host discussions and downloadable content that can enhance your understanding of specific components. Utilizing these resources can provide a more rounded view of maintenance and repair options.

Repair Tips for John Deere 14SE

Maintaining and fixing your equipment can significantly extend its lifespan and improve performance. Knowing the best practices for troubleshooting and repairs is essential for any operator. This guide provides practical suggestions to ensure your machine runs smoothly and efficiently.

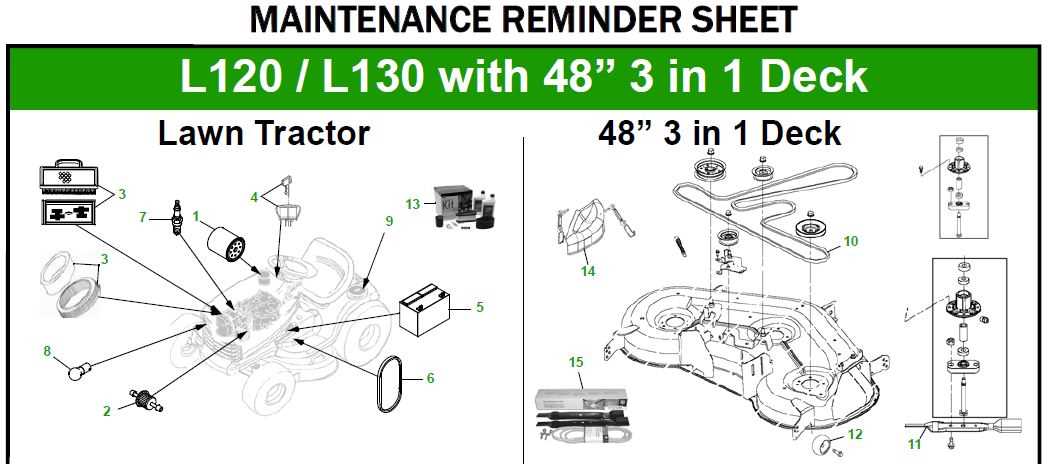

Regular Maintenance: Performing routine checks on key components can prevent larger issues down the line. Pay attention to oil levels, filters, and belts. Regular lubrication can also enhance performance and reduce wear.

Consulting the Manual: Always refer to the manufacturer’s manual for specific instructions and diagrams. This resource is invaluable for understanding assembly and disassembly, as well as identifying replacement parts.

Using Quality Components: When replacing any parts, opt for high-quality replacements that meet the original specifications. This choice can ensure compatibility and longevity.

Tools and Equipment: Invest in the right tools for the job. Proper tools not only make the process easier but also help prevent damage to the machinery during repairs.

Documenting Repairs: Keeping a log of repairs and maintenance performed can be beneficial. This documentation can help track recurring issues and serve as a reference for future maintenance.

Seeking Professional Help: If you encounter a problem beyond your expertise, don’t hesitate to seek professional assistance. This approach can save time and prevent further damage.

Identifying Compatible Replacement Parts

Finding the right components for machinery is crucial to ensure optimal performance and longevity. When looking for suitable alternatives, it’s important to understand the various factors that influence compatibility. This section will guide you through the key considerations to help you make informed decisions.

Key Considerations

- Model Specifications: Always refer to the specifications of your equipment to identify the exact requirements for each component.

- Manufacturer Recommendations: Consult the original manufacturer’s guidelines, as they often provide lists of compatible replacements.

- Quality Standards: Prioritize high-quality materials and standards that match or exceed those of the original components.

- Reviews and Feedback: Look for customer reviews and feedback regarding the performance of alternative items.

Where to Find Compatible Components

- Authorized dealers often have access to reliable replacements.

- Online marketplaces provide a wide range of options, but check seller ratings.

- Local repair shops may have insights into commonly used alternatives.

- Forums and online communities can offer valuable recommendations from experienced users.

By taking these factors into account, you can confidently select components that will meet the needs of your equipment effectively.

Maintenance Strategies for Longevity

Ensuring the enduring performance of machinery requires a thoughtful approach to upkeep. By implementing effective maintenance techniques, one can enhance the lifespan and efficiency of equipment, minimizing downtime and repair costs.

Key strategies include regular inspections, timely lubrication, and the use of high-quality replacement components. Establishing a maintenance schedule can help in identifying potential issues before they escalate, thereby safeguarding against unexpected failures.

| Strategy | Description |

|---|---|

| Regular Inspections | Conduct frequent checks to identify wear and tear early. |

| Lubrication | Apply lubricants to reduce friction and prevent damage. |

| Quality Parts | Utilize durable components for repairs and replacements. |

| Scheduled Maintenance | Establish a routine to address upkeep systematically. |

By integrating these practices, users can ultimately achieve enhanced reliability and extended service life for their machinery.

Finding a Reliable Parts Supplier

When it comes to maintaining and repairing machinery, sourcing high-quality components is essential for ensuring optimal performance and longevity. Identifying a trustworthy supplier can make all the difference in achieving seamless operations and minimizing downtime. This guide will explore key factors to consider when searching for a dependable provider of essential components.

Assessing Quality and Reliability

Quality is paramount in selecting a supplier. Investigate the materials used and the manufacturing processes employed to ensure that the components meet industry standards. Look for suppliers who offer warranties or guarantees, as this often indicates their confidence in the products they provide. Additionally, consider reading reviews or testimonials from other customers to gauge the reliability of the supplier.

Evaluating Customer Service

Excellent customer service is a crucial aspect of any successful supplier relationship. A responsive team that is willing to answer questions, provide assistance, and resolve issues promptly can significantly enhance your experience. Assess the supplier’s communication channels and ensure they are accessible and helpful, as this will facilitate smoother transactions and support in the future.

Customer Reviews and Experiences

This section highlights the insights and feedback from users who have engaged with the equipment. Their shared experiences offer valuable perspectives on performance, reliability, and overall satisfaction, helping potential buyers make informed decisions.

User Feedback Highlights

- Many customers praise the ease of use and efficiency of the machinery.

- Several users report excellent customer service support when troubleshooting issues.

- Some have noted the long-lasting durability of components, leading to fewer replacements.

Common Concerns

- A few users mentioned challenges in sourcing specific components.

- Some feedback indicated that initial setup could be complex for first-time users.

- Occasional reports of minor mechanical issues were shared, but most were easily resolved.