The intricacies of machinery often require a closer look at their individual elements. Understanding how each component fits together not only aids in maintenance but also enhances the overall performance of the machine. A well-organized representation of these parts can be invaluable for both seasoned technicians and novice users alike.

When dealing with any type of agricultural or industrial machinery, familiarity with the various segments can lead to more efficient repairs and replacements. A detailed visual reference can simplify the process, making it easier to identify issues and streamline restoration efforts. Whether you’re troubleshooting a malfunction or performing routine checks, knowing where each part is located can save time and reduce frustration.

Moreover, having access to an accurate representation of the equipment’s assembly fosters a deeper understanding of its operation. This knowledge empowers operators to make informed decisions, ensuring longevity and reliability in their tools. Exploring these elements can transform the way you interact with your machinery, making maintenance a more manageable and rewarding endeavor.

Understanding the John Deere 212

This section delves into the essential components and functionality of a renowned model known for its reliability and efficiency in various tasks. Gaining insight into its structure can enhance users’ ability to maintain and operate it effectively.

Key Features

- Robust Engine Performance

- Durable Build Quality

- Versatile Attachments for Various Tasks

Maintenance Tips

- Regularly check fluid levels and replace them as needed.

- Inspect belts and cables for wear and tear.

- Clean air filters to ensure optimal performance.

- Schedule periodic servicing to prevent major issues.

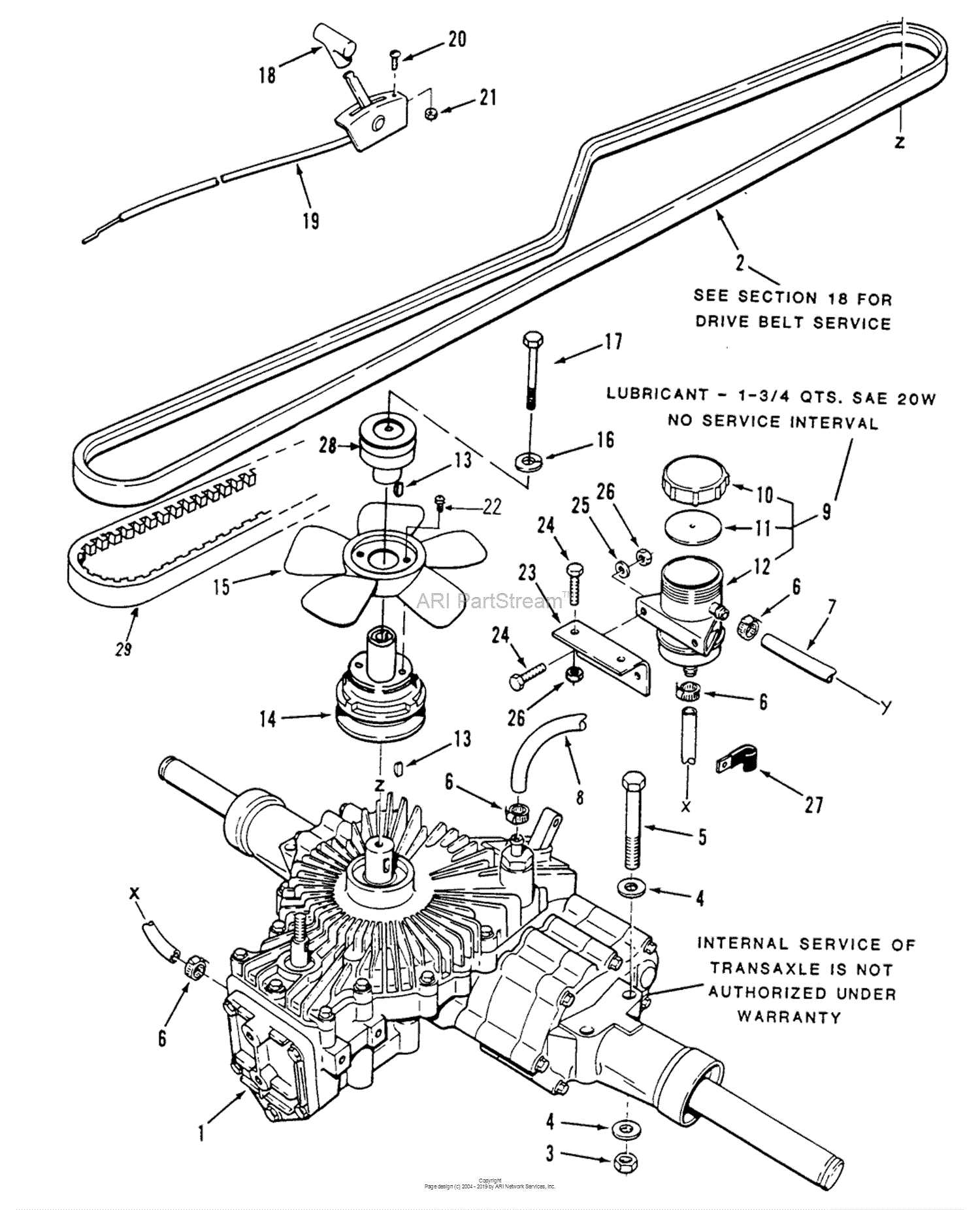

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations that detail each element enable users to identify, locate, and replace specific items with ease. Such illustrations serve as essential tools for both professionals and enthusiasts, simplifying the process of upkeep and enhancing operational efficiency.

Enhancing Repair Efficiency

When faced with mechanical issues, having a clear visual reference can significantly expedite troubleshooting. It allows individuals to pinpoint problematic areas quickly, reducing downtime and minimizing frustration. By streamlining the repair process, users can ensure their equipment remains functional and reliable.

Facilitating Accurate Ordering

When replacement components are needed, accurate identification is vital. Visual guides provide clarity, ensuring that the correct items are ordered. This accuracy helps prevent delays caused by incorrect shipments, saving both time and resources in the long run.

Common Issues with John Deere 212

When it comes to older lawn care equipment, various challenges can arise that affect performance and usability. Understanding these common problems can help owners maintain their machines effectively and ensure a longer lifespan.

Fuel System Problems: One frequent issue is related to the fuel system. Clogged filters or old fuel can lead to starting difficulties or engine stalling. Regular maintenance and timely replacement of components are essential to keep the system functioning smoothly.

Electrical Failures: Electrical components, including wiring and connectors, may deteriorate over time. Signs of trouble include erratic starting, malfunctioning lights, or an unresponsive ignition system. Inspecting these parts regularly can prevent unexpected breakdowns.

Blade Wear and Tear: The cutting blades often experience significant wear due to constant use. Dull blades can affect cutting performance and lead to uneven grass trimming. Regular sharpening and timely replacement are crucial for optimal results.

Transmission Issues: Problems with the transmission may arise, resulting in difficulty shifting gears or a complete loss of drive. Routine checks and servicing can help identify early signs of wear, allowing for timely interventions.

Overheating: Overheating can occur due to a lack of proper cooling or old coolant. This can lead to severe engine damage if not addressed. Ensuring the cooling system is functioning correctly is vital for maintaining optimal operating temperatures.

Key Components of the Lawn Tractor

The efficient operation of a garden vehicle relies on several essential elements working in harmony. Understanding these fundamental components is crucial for both maintenance and optimal performance, ensuring that the machine can handle various landscaping tasks with ease.

Engine: The heart of the machine, the engine provides the necessary power to drive the vehicle and operate attachments. It’s essential to choose an engine with the right horsepower for your mowing needs.

Transmission: This system transmits power from the engine to the wheels, allowing for smooth acceleration and deceleration. Different types of transmissions, such as automatic or manual, affect how the operator interacts with the machine.

Chassis: The framework that supports all other components, the chassis provides stability and durability. A robust chassis ensures that the tractor can withstand the rigors of outdoor use.

Cutting Deck: This component is responsible for trimming grass to the desired length. The design and size of the cutting deck significantly influence the efficiency of mowing tasks and the quality of the cut.

Wheels and Tires: These elements affect traction and maneuverability. Selecting the right type of tires is crucial for handling different terrains, ensuring that the vehicle can navigate smoothly across lawns and gardens.

Steering System: A precise steering mechanism allows for easy navigation around obstacles and tight corners. The type of steering, whether manual or power-assisted, can greatly influence the user experience.

By familiarizing yourself with these key components, you can better appreciate the functionality of your lawn tractor and ensure it remains in top working condition for years to come.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task, yet it is essential for maintaining optimal performance. Various avenues exist for acquiring the necessary items, each with its own advantages and disadvantages. Understanding these options can streamline the process and ensure that your equipment remains functional and efficient.

Online Retailers

Many individuals turn to online platforms for sourcing their required items. Numerous websites specialize in aftermarket and original equipment offerings. These digital marketplaces often provide a wide selection, competitive pricing, and the convenience of home delivery. When utilizing these services, it’s crucial to verify the authenticity and compatibility of the components with your specific model.

Local Dealerships and Repair Shops

Another effective route is visiting local dealerships or repair shops. These establishments typically have direct access to authentic components and can offer expert advice tailored to your machinery. While prices may vary, the benefit of face-to-face interaction and professional recommendations can significantly enhance your purchasing experience.

In summary, whether opting for the convenience of online shopping or the personalized service of local experts, a variety of resources are available to help you find the right items for your machinery needs.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. By following a few key practices, you can ensure optimal performance and minimize the need for costly repairs. Consistent maintenance not only enhances efficiency but also protects your investment over time.

Regular Inspections: Conduct routine checks to identify any wear and tear. Look for signs of damage, corrosion, or leaks, as early detection can prevent more significant issues down the line.

Fluid Changes: Change lubricants and fluids according to the manufacturer’s recommendations. Clean oil and fluids help to keep moving parts functioning smoothly, reducing friction and heat.

Clean Filters: Ensure that air and fuel filters are clean and replaced when necessary. Clogged filters can restrict airflow and fuel supply, leading to decreased efficiency and potential engine problems.

Keep it Clean: Regularly wash the exterior to remove dirt and debris. This helps prevent rust and other environmental damage while allowing for better visibility during inspections.

Store Properly: When not in use, store your machinery in a dry, sheltered location. Protecting it from the elements can significantly extend its operational life.

Follow the Manual: Always refer to the manufacturer’s guidelines for specific maintenance tasks and schedules. Adhering to recommended practices ensures that you are taking the right steps to maintain your equipment.

Tools Needed for Repairs

Effective maintenance and repair of machinery require a well-equipped toolbox. Having the right instruments on hand can significantly streamline the process and enhance the quality of work. This section outlines essential tools that will aid in tackling common issues, ensuring a smooth and efficient workflow.

Basic Hand Tools

First and foremost, a collection of basic hand tools is crucial. These include wrenches, screwdrivers, and pliers. Wrenches come in various sizes to accommodate different fasteners, while screwdrivers should include both flat-head and Phillips types. Pliers are also vital for gripping, twisting, and cutting tasks.

Specialized Equipment

In addition to standard tools, certain specialized equipment can make repairs more efficient. A socket set provides versatility for tightening and loosening bolts, while a torque wrench ensures that fasteners are secured to the correct specifications. Investing in a reliable multimeter is also recommended for diagnosing electrical issues, allowing for precise troubleshooting.

Upgrading Your John Deere 212

Enhancing the performance and efficiency of your machine can significantly improve its functionality and longevity. Whether you’re looking to boost power, improve comfort, or increase versatility, there are numerous ways to achieve this. Upgrades can range from simple modifications to comprehensive overhauls, depending on your needs and budget.

One of the first areas to consider is the engine. Upgrading to a more efficient model can lead to better fuel economy and increased output. Additionally, consider enhancing the cooling system to prevent overheating during extended use. This ensures that the machinery runs smoothly, even under demanding conditions.

Another key component is the transmission. Upgrading to a more advanced system can provide smoother shifting and improved power delivery. This results in a more enjoyable operation experience and can help tackle tougher tasks with ease.

Don’t overlook the importance of comfort and usability. Installing ergonomic seating and updated controls can significantly enhance your working environment. Improved visibility through upgraded lighting systems can also aid in nighttime or low-light operations.

Finally, consider accessories that expand the machine’s capabilities. Attachments like enhanced mowers, plows, or trailers can transform a standard unit into a versatile workhorse, enabling you to take on a broader range of tasks.

By focusing on these areas, you can effectively upgrade your equipment, maximizing its potential and ensuring it meets your specific needs.

Customer Reviews and Experiences

This section delves into the feedback and insights shared by users of a specific model of agricultural machinery. By highlighting individual stories and assessments, potential buyers can gain valuable perspectives on the performance, reliability, and overall satisfaction associated with this equipment.

Positive Feedback

Many customers have praised the durability and efficiency of their machinery. Users frequently note how well it handles various tasks, from routine maintenance to more demanding agricultural duties. One customer remarked, “This equipment has exceeded my expectations; it tackles my farm work effortlessly.” Such endorsements highlight the effectiveness and resilience of the machinery in diverse conditions.

Areas for Improvement

While overall satisfaction is high, some users have pointed out specific aspects that could benefit from enhancement. For instance, a few have mentioned the need for clearer instructional materials, particularly for new operators. Another user stated, “I found the manual lacking in detail, which made initial setup challenging.” Addressing these concerns could further improve user experiences and satisfaction levels.