In this section, you will find a thorough explanation of how various mechanical elements come together to ensure efficient operation. Understanding the arrangement and interplay of these components is essential for anyone aiming to maintain or repair a machine. By gaining a clear insight into how everything is connected, it becomes easier to identify potential issues and optimize performance.

We will explore the essential elements, focusing on the specific functions of each piece. Whether you’re performing routine upkeep or looking to resolve mechanical challenges, this information will provide a clear path forward. A well-organized system allows for smoother operations and reduces the likelihood of disruptions, making it crucial to familiarize yourself with the details.

Delving deeper into each section, we will cover the layout and positioning of these key elements. This will enable you to confidently navigate through complex structures, ensuring that every element is in its rightful place and functioning as intended. Proper knowledge of the system’s layout empowers you to address both routine tasks and unexpected issues with greater precision.

Comprehensive Overview of Kubota T1460 Components

In this section, we explore the various elements that contribute to the efficient operation of this popular model. Understanding the key systems and how they interact is essential for maintaining peak performance and extending the life of the machine. Each component plays a crucial role, from the power unit to the transmission, ensuring smooth functionality in a variety of tasks.

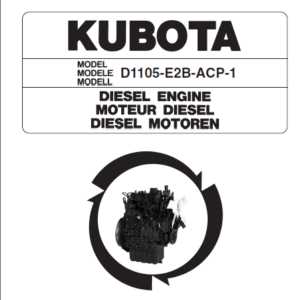

Engine Assembly is at the heart of the machinery, providing the necessary force to drive its operations. Regular inspection and maintenance of this core section can prevent major breakdowns and ensure longevity.

The drivetrain transfers power from the motor to the wheels, allowing for efficient motion control. Paying attention to this section is vital for avoiding issues with mobility, especially in rough terrain.

Another important system is the cutting mechanism, which ensures precision during tasks. Keeping this section in good condition is critical for achieving clean and consistent results.

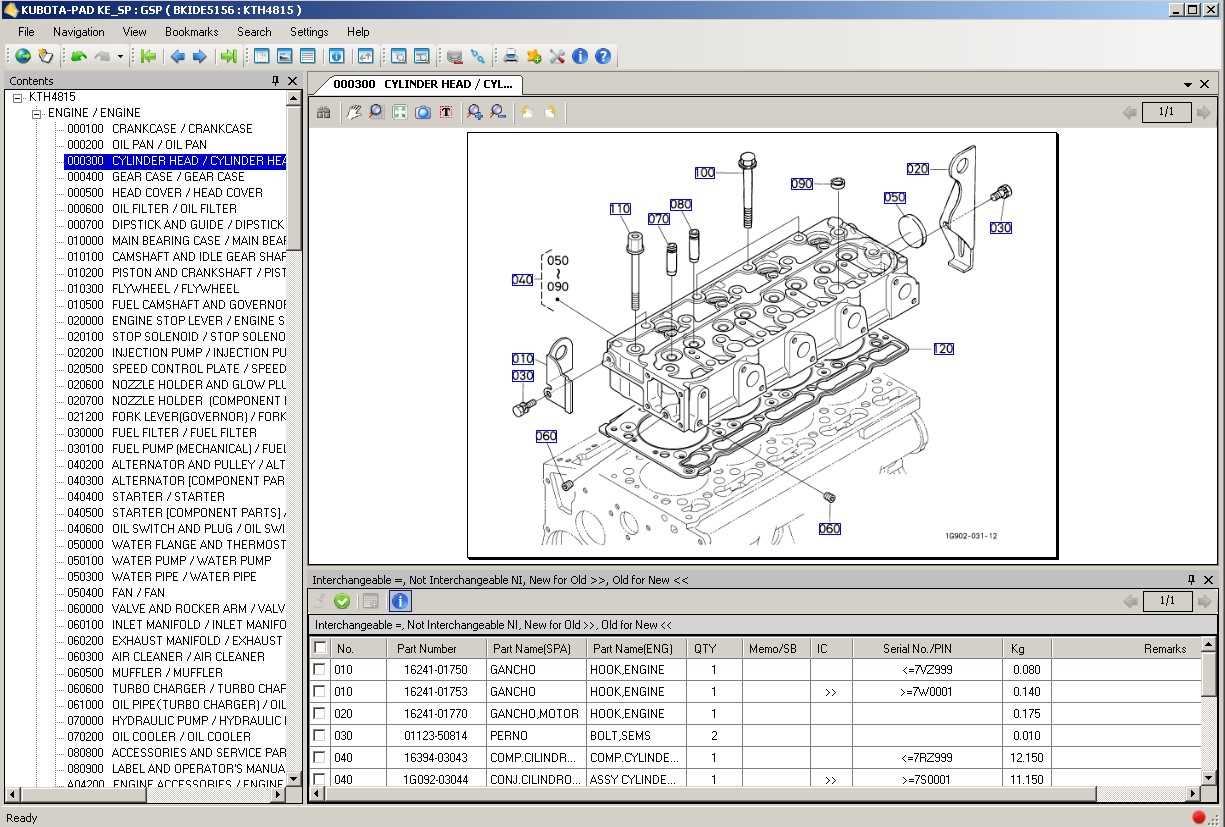

Understanding the Key Mechanical Parts

In this section, we will explore the fundamental components that contribute to the operation of a machine. Each of these elements plays a vital role in ensuring smooth functionality, and understanding their arrangement is crucial for effective maintenance and repair.

Below is a list of essential components that are commonly found in such systems:

- Engine: The core source of power, converting fuel into motion and enabling the machine to perform its primary tasks.

- Transmission: Responsible for controlling the power generated by the engine, this component regulates speed and torque.

- Steering System: A critical element for guiding the movement, allowing precise control over direction.

- Braking System: Ensures safety by enabling the operator to slow down or stop when necessary.

- Chassis: Acts as the framework, supporting the weight and structure of the entire system.

Each of these components works together, and proper maintenance of these systems is essential for optimal performance. Knowing their functions and how they interact can help prevent breakdowns and extend the life of the equipment.

Electrical System Layout and Details

The electrical system serves as the core structure for delivering power to essential components, ensuring smooth operation and efficient performance. Understanding the arrangement of these connections is crucial for maintaining and troubleshooting various issues related to power flow and control mechanisms.

Power Distribution and Components

The arrangement of wires and connectors is designed to distribute energy to multiple key components, including the ignition and lighting systems. Each element is linked through a series of circuits that allow for seamless power transfer. Proper knowledge of this network is essential for handling potential malfunctions or installing new equipment.

Wiring and Safety Considerations

When working with electrical circuits, attention to safety and proper grounding is critical. The system includes various protective measures, such as fuses and relays, which prevent overloading and potential damage. Identifying the correct paths and securing connections can help avoid short circuits and ensure stable electrical performance.

Maintenance Tips for Engine Components

Ensuring proper care of the engine is crucial for the long-term reliability and performance of any equipment. Regular inspections, timely replacements, and appropriate cleaning routines will help to maintain efficiency and prevent costly breakdowns.

One key aspect of engine maintenance is checking for wear and tear on essential components. Routine visual inspections can help identify early signs of deterioration, such as cracks or leaks, which could lead to bigger issues if not addressed promptly.

Additionally, paying attention to fluid levels and ensuring they are kept within recommended ranges is vital for preventing overheating and reducing friction between moving parts. Regular oil changes and coolant checks are simple yet effective ways to prolong the life of the engine.

Exploring the Transmission Assembly

The transmission assembly is a crucial component in ensuring the effective transfer of power within the machine. It is designed to manage speed and torque, allowing smooth operation under various conditions. Understanding how this system functions can help maintain peak performance and extend the lifespan of the equipment.

Key elements of the assembly include a series of gears, shafts, and bearings that work together to adjust the output based on the machine’s demands. Regular maintenance and inspection of these parts are essential for preventing wear and ensuring long-term reliability.

By exploring the layout and components of this system, you can gain a deeper appreciation of how it operates and what steps are necessary to keep it in optimal working condition.

Blade and Deck Structure Insights

The efficiency and performance of any cutting mechanism largely depend on the design and interaction between the blade and the underlying platform. Understanding how these elements work together is essential for ensuring smooth operation and longevity of the equipment. This section provides a detailed look into the structural aspects of the blade and deck, highlighting key considerations that impact functionality.

Blade Composition and Design: The cutting component plays a vital role in delivering precise and effective results. Its material and sharpness are crucial for achieving optimal cutting performance, while the shape influences the airflow and debris discharge. A well-maintained blade ensures even cutting and prevents undue strain on the engine.

Deck Construction and Durability: The deck serves as the foundation for the cutting mechanism. It must be robust enough to withstand the vibrations and impacts generated during use. The material used in its construction, as well as its overall design, contribute to both the protection of internal components and the efficiency of the cutting process. Proper care and regular inspection of the deck can help prevent corrosion and damage.

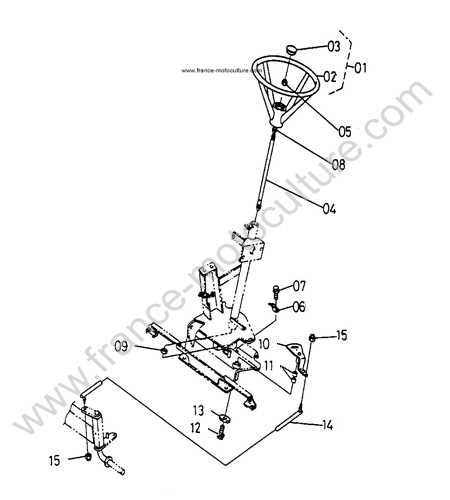

Steering System and Linkages Guide

The steering system is a crucial component that ensures the smooth maneuverability of any vehicle. This system comprises various linkages and mechanisms that work together to provide precise control over direction. Understanding the configuration and functionality of these components is essential for effective maintenance and troubleshooting.

Key Components of the Steering Assembly

The steering assembly typically consists of the steering wheel, column, gear mechanism, and connecting linkages. Each of these elements plays a significant role in translating the driver’s input into directional movement. Regular inspection and proper alignment of these components are vital to ensure optimal performance and safety.

Linkages and Their Functionality

Linkages serve as the connectors between the steering wheel and the wheels themselves. They transmit the motion generated by the steering wheel to the wheels, allowing for directional changes. Understanding how these linkages operate can help diagnose issues such as steering play or unresponsive handling, ultimately enhancing the vehicle’s reliability and efficiency.

Fuel System Configuration and Operation

The fuel system in any engine-driven equipment plays a critical role in ensuring smooth operation. By delivering the necessary fuel in the correct quantities and at the right time, the system maintains engine efficiency and performance. This section explains the key elements involved and how they interact to ensure proper functionality.

- Fuel Delivery: The system is designed to transfer fuel from the tank to the engine’s combustion chamber. This process requires a pump, which ensures a steady flow, and filters, which remove any impurities.

- Filtration: Filtration is a vital aspect, preventing contaminants from reaching sensitive components. Fuel passes through a series of filters, ensuring only clean fuel reaches the engine.

- Carburetion or Injection: Depending on the specific model, the system may utilize a carburetor or fuel injectors to mix fuel with air. Proper air-fuel mixture is essential for optimal combustion.

Understanding how each part of the system works together will help in diagnosing and resolving common issues related to performance and fuel efficiency.

Common Wear and Tear Points

Understanding the typical areas that experience degradation over time is crucial for maintaining optimal functionality. Various components of machinery are subjected to stresses that can lead to wear, impacting performance and longevity. Identifying these susceptible spots can aid in timely intervention and effective upkeep.

One frequent area of concern is the drive belts, which can become frayed or cracked due to constant exposure to tension and environmental factors. Regular inspections and replacements can prevent unexpected breakdowns.

Another vital component is the blades, which can dull or chip with use, reducing cutting efficiency. Keeping them sharp ensures smoother operation and improved results.

Additionally, the filters can accumulate dirt and debris, affecting airflow and performance. Routine cleaning or replacing of filters is essential for maintaining optimal operation.

Lastly, the battery is often overlooked but can show signs of wear through reduced charge capacity. Regular checks and maintenance can extend its life and ensure reliable performance.