When it comes to maintaining agricultural machinery, a thorough grasp of the various elements involved is essential. This knowledge not only facilitates efficient repairs but also enhances the overall performance of the machinery. By examining the intricate relationships between the different components, operators can ensure their equipment runs smoothly and efficiently.

In this guide, we delve into the layout and functionality of critical elements, providing a comprehensive overview that aids in troubleshooting and repairs. Whether you’re a seasoned mechanic or a newcomer to machinery maintenance, having access to a detailed visual reference can significantly improve your understanding and approach.

Furthermore, understanding the specific roles each part plays allows for better decision-making when it comes to replacements and upgrades. With the right information at your fingertips, you can extend the lifespan of your equipment and maximize its productivity on the field.

Understanding the John Deere 185 Model

This section explores the intricacies of a specific lawn care machine, highlighting its design, functionality, and overall significance in the industry.

The machine is known for its:

- Efficient performance in residential and commercial applications

- Durable construction, ensuring longevity and reliability

- User-friendly features that enhance operation and maintenance

Key aspects include:

- Engine specifications and capabilities

- Transmission options and their benefits

- Maintenance requirements for optimal performance

Understanding these elements is crucial for anyone seeking to maximize the utility of this equipment.

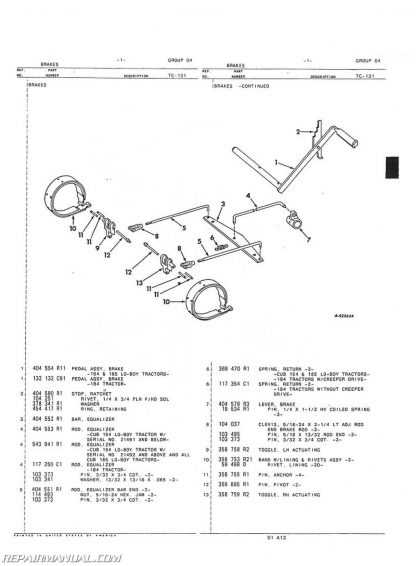

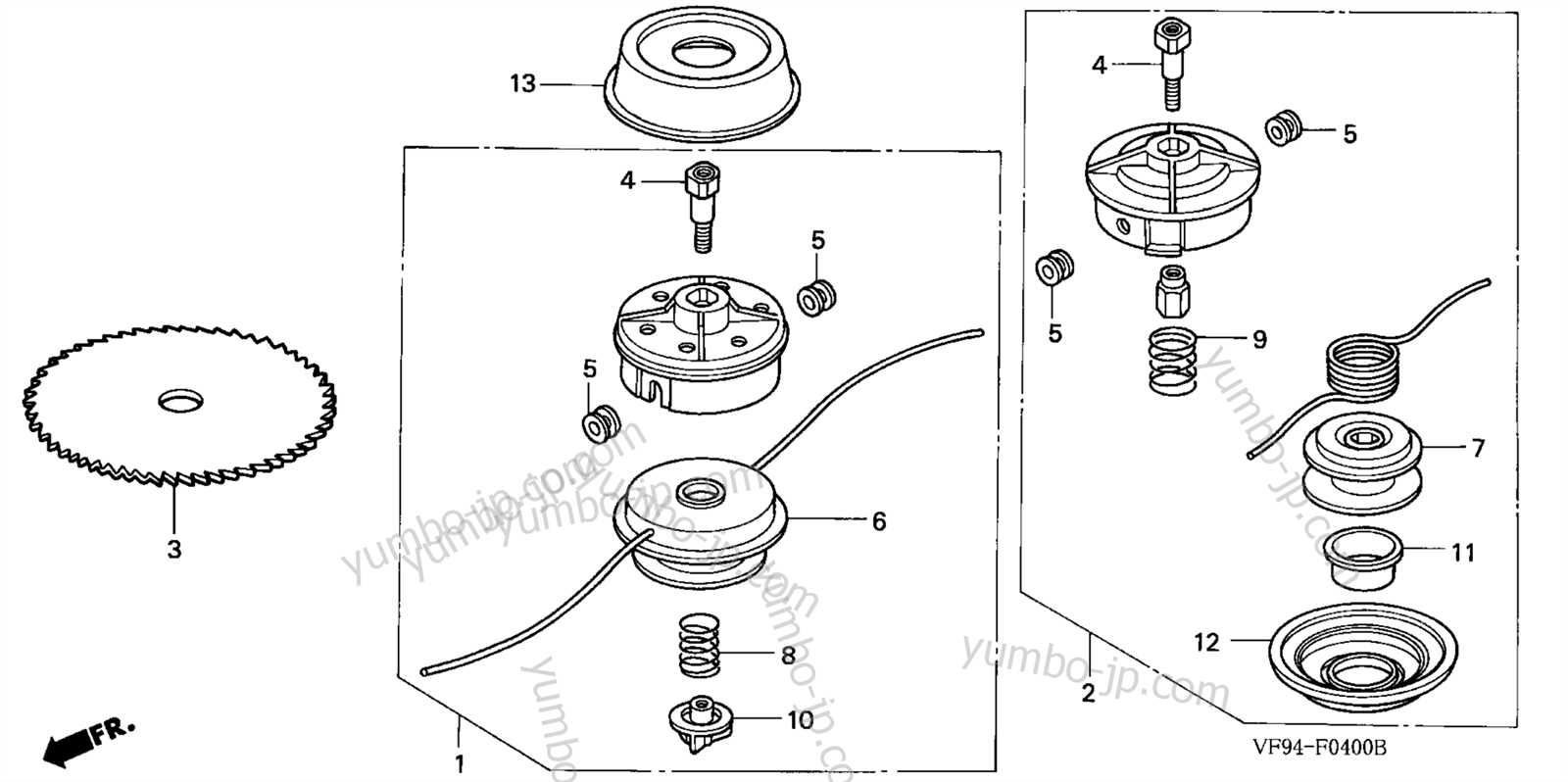

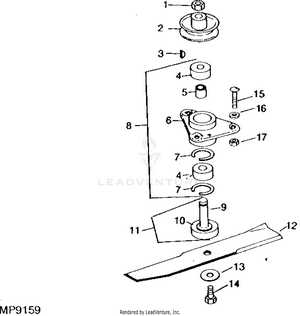

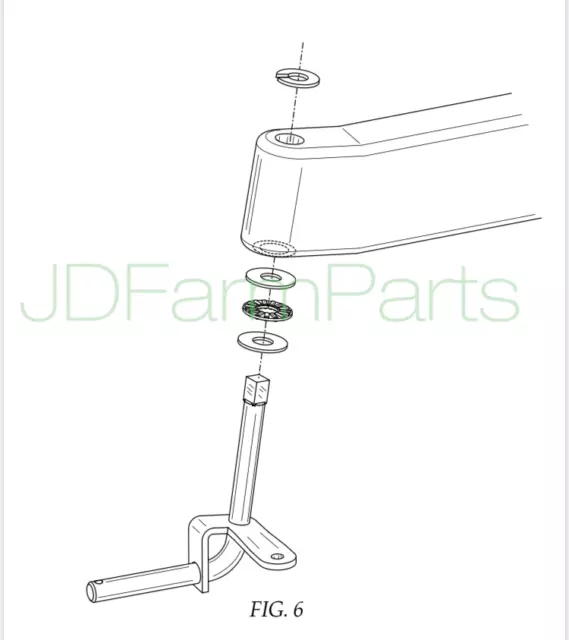

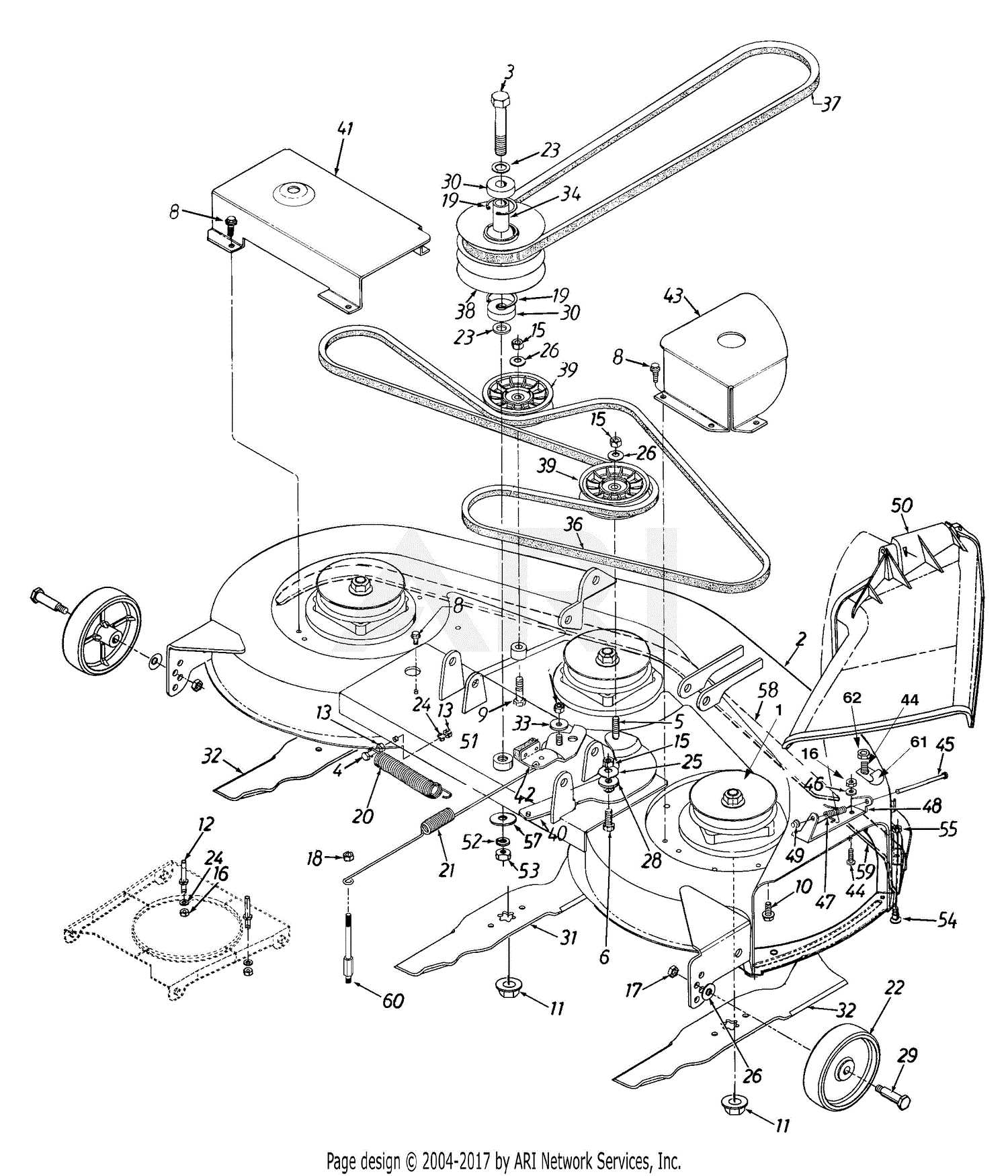

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair. Visual representations serve as valuable tools for technicians and enthusiasts, facilitating the identification and organization of individual elements. These illustrations enhance communication and streamline the repair process, ensuring that every piece is accounted for and properly managed.

Enhanced Efficiency

Using visual aids can significantly improve efficiency during repairs. When workers can quickly reference images that show the layout and placement of components, they can reduce the time spent searching for specific items or understanding assembly sequences. This clarity leads to faster troubleshooting and maintenance.

Prevention of Errors

Clear illustrations minimize the likelihood of mistakes during assembly or repair. By providing an accurate representation of how parts fit together, these resources help prevent misalignment and incorrect installations. This proactive approach not only saves time but also extends the lifespan of machinery by ensuring proper handling.

| Benefits | Description |

|---|---|

| Improved Clarity | Visual representations make it easier to understand complex assemblies. |

| Time-Saving | Quick reference aids in reducing downtime during repairs. |

| Error Reduction | Minimizes mistakes, leading to more effective maintenance. |

| Informed Decisions | Allows for better planning and resource allocation for repairs. |

Common Issues with John Deere 185

Many users experience a variety of challenges with their lawn equipment, impacting performance and efficiency. Understanding these frequent problems can help in troubleshooting and maintaining optimal functionality.

Engine Performance

- Poor starting or stalling

- Loss of power during operation

- Unusual noises from the engine

Mechanical Failures

- Worn belts and pulleys

- Leaking fluids

- Issues with the cutting deck

Addressing these common problems early can prolong the lifespan of the equipment and enhance overall satisfaction. Regular maintenance is essential for avoiding serious complications.

Identifying Parts for Replacement

Understanding the components of your equipment is crucial for effective maintenance and timely replacements. Familiarizing yourself with these elements ensures smooth operation and prolongs the lifespan of the machinery.

Here are steps to assist in recognizing what needs to be replaced:

- Consult the owner’s manual for a detailed overview of the machinery.

- Use online resources to view exploded views of components.

- Examine the machinery for visible wear and damage.

- Take note of serial numbers for accurate replacements.

Utilizing these methods will help you pinpoint the necessary components for a successful swap.

Where to Find Parts Diagrams

Accessing comprehensive visual guides for machinery components is essential for maintenance and repairs. These resources can enhance understanding and ensure that every piece is correctly identified and fitted. Numerous platforms offer these valuable illustrations, making it easier for users to navigate the intricacies of their equipment.

Online Resources: Various websites specialize in offering detailed visuals for numerous models. Searching for manufacturer-specific portals can yield authoritative information, while forums often share insights and links to helpful diagrams.

Manuals and Catalogs: Hard copies of maintenance manuals typically include essential illustrations. Checking local dealerships or libraries can uncover these informative texts that are often rich in details.

Community Support: Engaging with user communities on social media and dedicated forums can lead to discovering shared resources. Members frequently upload and discuss useful guides that may not be easily found elsewhere.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages for maintaining and enhancing the performance of machinery. These elements are designed specifically for particular models, ensuring a precise fit and reliable operation. Here are several key benefits of opting for these high-quality alternatives:

- Quality Assurance: OEM components are manufactured to meet strict quality standards, ensuring durability and longevity.

- Compatibility: These components are engineered to fit seamlessly with existing systems, minimizing the risk of malfunction or failure.

- Performance Reliability: Using original components helps maintain optimal performance levels, reducing the likelihood of breakdowns.

- Warranty Protection: Many OEM parts come with warranties, providing added peace of mind and protection against defects.

- Resale Value: Machinery equipped with original components tends to retain higher resale value due to perceived quality and reliability.

Incorporating these components into maintenance practices can lead to significant long-term savings and improved operational efficiency.

Maintenance Tips for John Deere 185

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By following a few key strategies, you can keep your equipment running smoothly and efficiently. Proper maintenance not only enhances functionality but also helps prevent costly repairs down the line.

Routine Inspections

Conducting frequent checks on various components is vital. Look for signs of wear and tear, including hoses, belts, and filters. Replace any damaged parts promptly to avoid further complications. Pay close attention to fluid levels and ensure they are maintained within the recommended ranges.

Cleaning and Lubrication

Regularly clean the exterior and interior parts to remove dirt and debris. This practice helps prevent buildup that can impair performance. Additionally, ensure that all moving parts are adequately lubricated. Using the appropriate oils and greases will reduce friction and enhance the efficiency of your machinery.

By adhering to these maintenance tips, you can significantly extend the lifespan of your equipment and ensure it remains in peak condition.

Resources for Repair and Support

Accessing the right materials and assistance is crucial for maintaining machinery efficiently. Whether you’re looking for manuals, community forums, or professional services, a variety of resources are available to help you keep your equipment in optimal condition.

Manuals and Guides

Consulting technical manuals and user guides is essential for understanding the inner workings of your machinery. These documents often provide valuable information on troubleshooting, maintenance, and repair procedures. Many manufacturers offer downloadable versions on their websites, ensuring easy access to necessary documentation.

Community Forums and Professional Help

Engaging with community forums can be a great way to share experiences and gain insights from other users. Additionally, seeking professional assistance from certified technicians can save time and ensure proper repairs. Utilizing these support avenues can enhance your equipment’s longevity and performance.