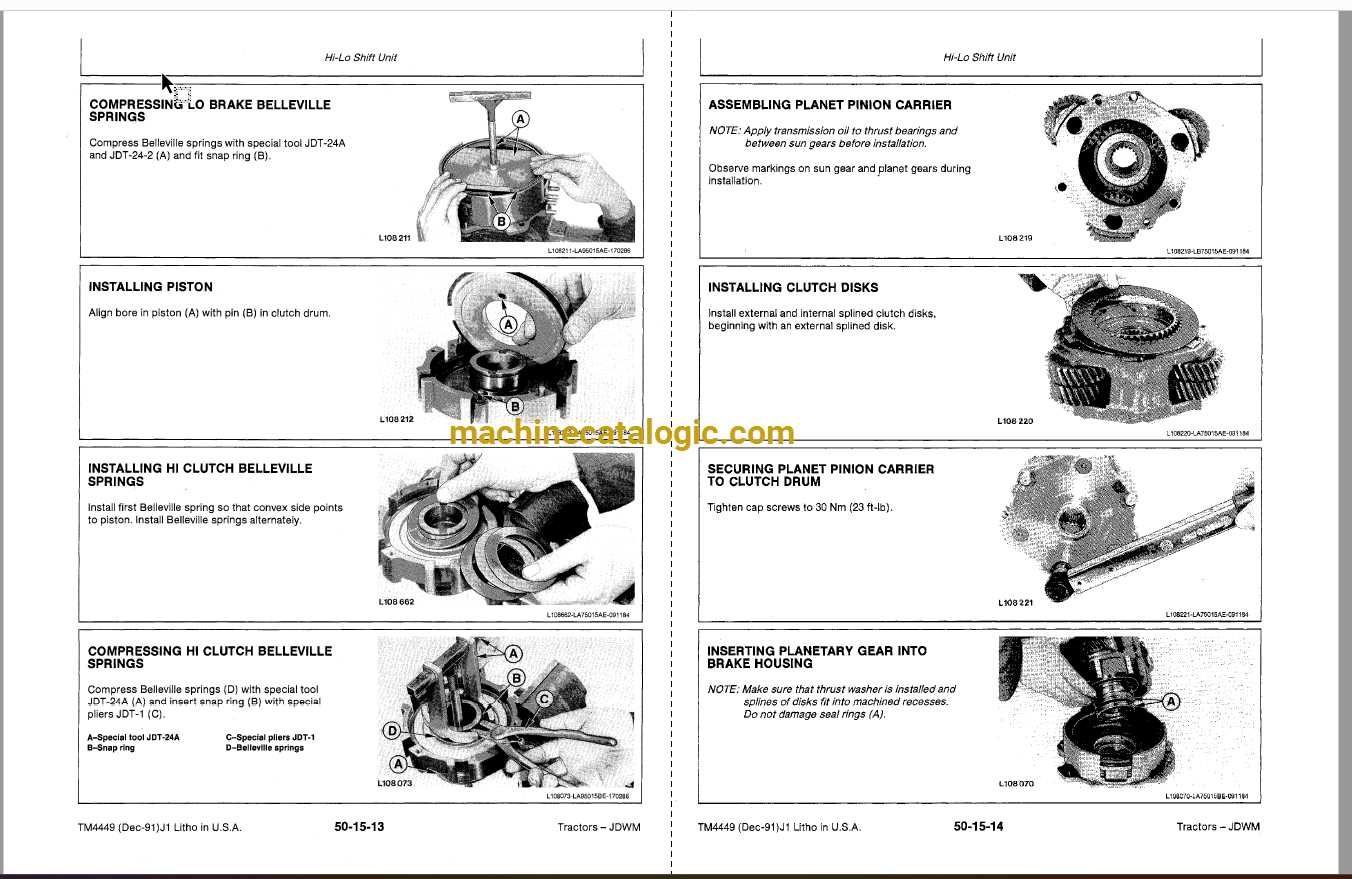

In the realm of heavy equipment, a comprehensive grasp of the various elements that constitute a machine is essential for effective maintenance and operation. Visual representations that detail the arrangement and function of each component serve as invaluable tools for both technicians and operators alike. These illustrations not only simplify complex assemblies but also enhance the efficiency of repair tasks by providing clear guidance.

Exploring the intricacies of a specific model reveals the interconnectedness of its parts. Each component plays a pivotal role in the overall functionality of the equipment, and understanding their specific placements can lead to improved performance and longevity. Whether you are a seasoned professional or a newcomer, familiarizing yourself with these layouts empowers you to troubleshoot and service machinery with confidence.

Accessing detailed schematics aids in recognizing potential issues before they escalate, thus fostering a proactive approach to maintenance. As such, utilizing these resources becomes crucial in ensuring that machinery operates smoothly, reducing downtime and enhancing productivity in various applications.

Understanding the John Deere JS26

This section explores the intricacies of a popular lawn maintenance tool known for its efficiency and reliability. Understanding its components and how they interact can significantly enhance its performance and longevity. This guide aims to provide insights into the various elements that make this tool effective in maintaining lawns and gardens.

Key Features

This machine boasts several features that cater to both amateur and professional landscapers. Its design emphasizes ease of use, durability, and adaptability to various terrains. Here are some notable characteristics:

| Feature | Description |

|---|---|

| Engine Power | Designed to deliver optimal performance, ensuring efficient cutting. |

| Cutting Width | A generous width allows for quick coverage of larger areas. |

| Adjustable Height | Users can modify the cutting height to suit their specific needs. |

| Grass Collection System | An effective system that minimizes debris on the lawn. |

Maintenance Tips

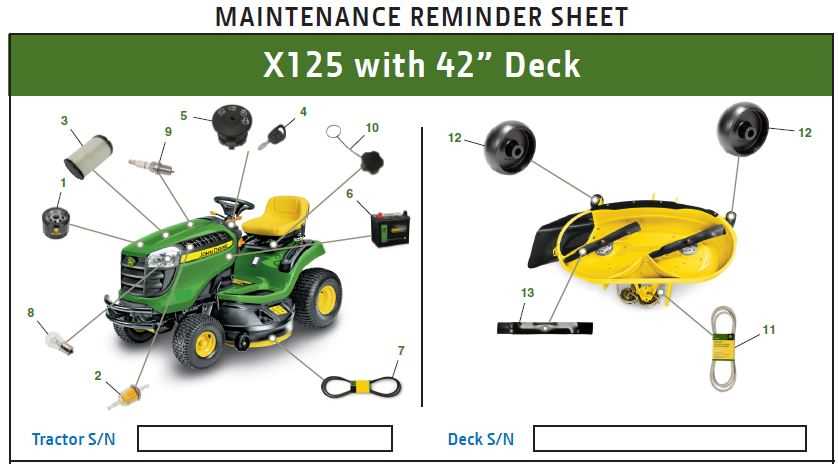

Proper upkeep is crucial for ensuring the longevity and performance of this gardening tool. Regular inspections and timely replacements of essential components can prevent potential issues. Here are some recommended maintenance practices:

- Regularly check and sharpen blades to ensure efficient cutting.

- Inspect the engine and change the oil as needed.

- Clean the undercarriage to prevent grass buildup.

- Store the equipment in a dry place to avoid rusting.

Key Features of JS26 Lawn Mower

This model stands out in the realm of gardening equipment due to its innovative design and user-friendly functionality. With a focus on efficiency and reliability, it caters to both novice and experienced users, ensuring an effortless mowing experience.

Performance and Durability

Engineered for robust performance, this mower boasts a powerful engine that delivers consistent cutting power. Its construction materials are selected for longevity, making it a dependable choice for maintaining lawns.

User Convenience

The intuitive controls and adjustable settings enhance usability, allowing for personalized mowing heights and easy maneuverability around obstacles. These features contribute to a seamless gardening experience.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for efficient cutting |

| Build Quality | Durable materials for long-lasting use |

| Adjustable Settings | Customizable height options for diverse terrains |

| Ease of Use | Simple controls for user-friendly operation |

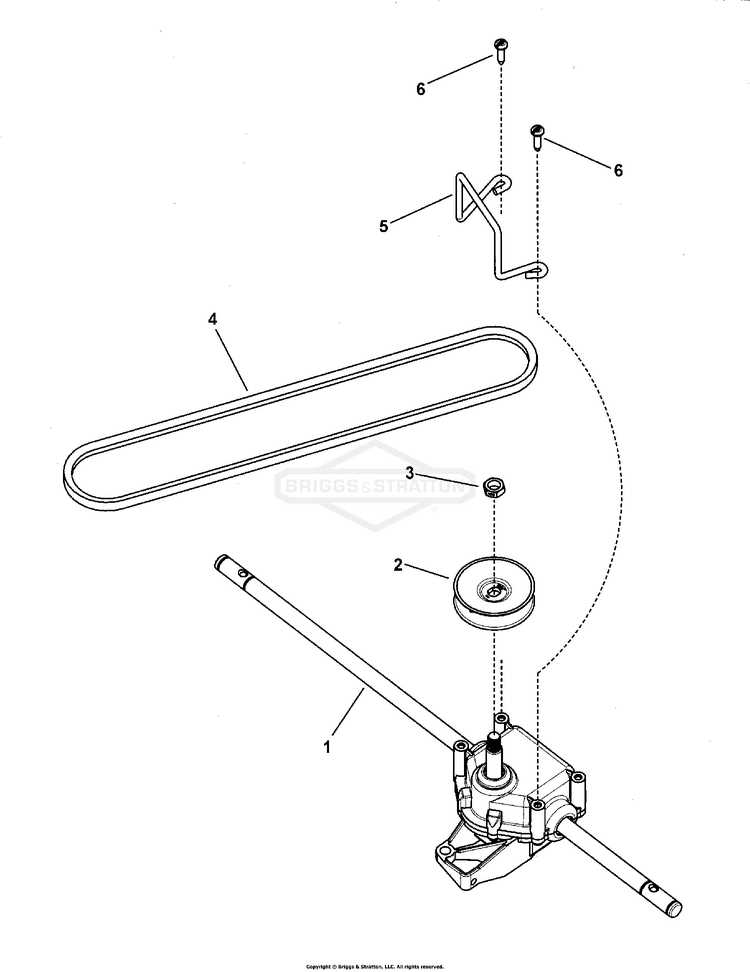

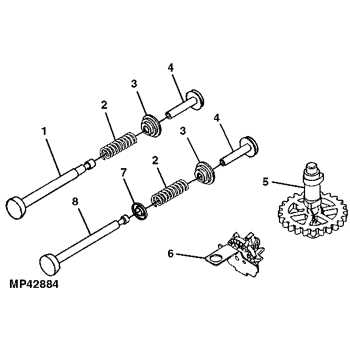

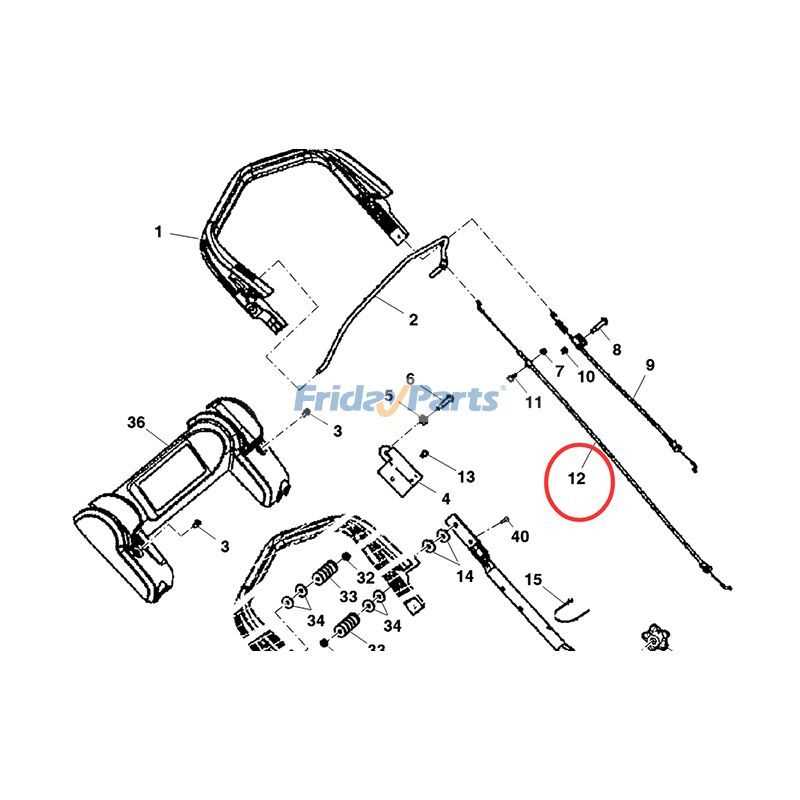

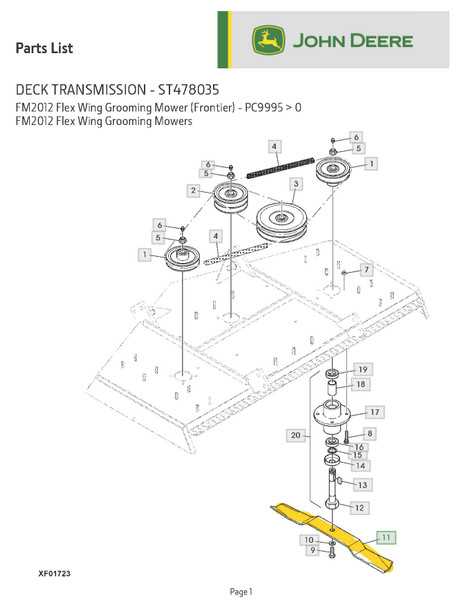

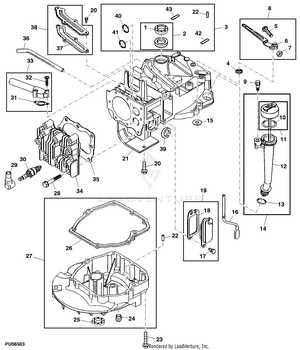

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They offer a clear insight into the structure and arrangement of various elements, allowing users to understand how each piece interacts within the system.

Here are several reasons why these visual aids are essential:

- Enhanced Understanding: Clear illustrations help users grasp complex systems more easily, facilitating efficient repairs.

- Accurate Identification: They assist in quickly locating specific components, reducing downtime during maintenance.

- Streamlined Repairs: By providing a step-by-step guide, these visuals help technicians follow procedures accurately.

- Effective Communication: Diagrams serve as a common reference point for both technical and non-technical personnel, fostering better collaboration.

- Inventory Management: Users can identify and track necessary items more effectively, ensuring they have the correct supplies on hand.

In summary, these graphical representations are invaluable tools that support efficiency, accuracy, and communication in maintenance tasks. Their role cannot be overstated in ensuring that machinery remains in optimal working condition.

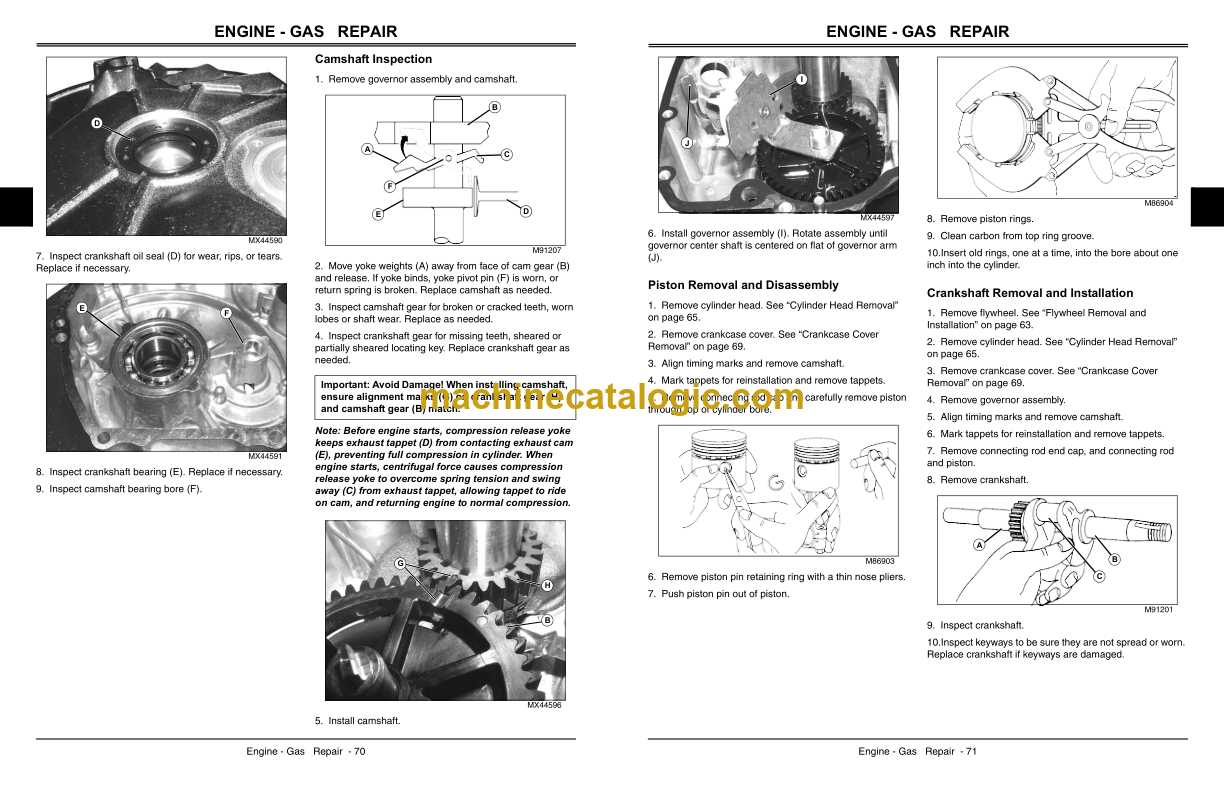

Common Issues with JS26 Components

Understanding the frequent challenges associated with various components can greatly enhance maintenance and performance. Many users encounter specific failures that, if recognized early, can prevent more significant problems down the line.

Wear and Tear: Components often suffer from regular usage, leading to reduced efficiency. Regular inspection and timely replacement can mitigate this issue, ensuring optimal functionality.

Improper Installation: Incorrect assembly of parts can lead to misalignment and malfunction. It’s crucial to follow detailed guidelines to ensure every piece is correctly fitted, thus avoiding operational disruptions.

Environmental Impact: Exposure to harsh weather conditions can accelerate damage. Protective measures, such as storage in sheltered areas, can extend the lifespan of essential components.

Lack of Maintenance: Neglecting routine upkeep can result in unforeseen failures. Implementing a regular maintenance schedule is vital for preserving performance and preventing costly repairs.

Compatibility Issues: Using incompatible components can lead to poor performance and potential breakdowns. Always ensure that any replacements meet the necessary specifications to maintain efficiency.

Where to Find Parts Diagrams

Locating technical illustrations for machinery can be crucial for efficient repairs and maintenance. Various resources are available that provide comprehensive visuals to help users identify components and their arrangements.

Online Resources

The internet is a rich source for finding detailed schematics. Websites dedicated to machinery and equipment often host extensive libraries of manuals and illustrations, allowing users to search by model or category.

Official Manuals and Distributors

Manufacturers frequently offer official guides that include valuable visuals. Additionally, authorized distributors may provide access to these resources, ensuring that users receive accurate and reliable information. Consulting these sources can enhance understanding and aid in effective troubleshooting.

Tips for Effective Maintenance

Proper upkeep of equipment is essential for ensuring optimal performance and longevity. Regular attention not only enhances functionality but also minimizes the risk of unexpected breakdowns. By implementing a systematic approach to maintenance, you can safeguard your investment and maintain efficiency.

Regular Inspections

Conducting routine checks is vital. Look for signs of wear and tear, leaks, and unusual noises. Early detection can prevent more serious issues.

Scheduled Servicing

Adhering to a maintenance schedule helps maintain peak performance. Follow manufacturer recommendations and keep a record of all service activities.

| Task | Frequency | Notes |

|---|---|---|

| Fluid Checks | Monthly | Ensure levels are adequate and clean. |

| Filter Replacement | Every 100 hours | Use manufacturer-approved filters. |

| General Cleaning | Weekly | Remove debris to avoid overheating. |

Identifying Compatible Replacement Parts

When it comes to ensuring optimal performance of your equipment, recognizing suitable substitute components is essential. Compatibility can significantly impact functionality and longevity, so understanding how to source the right elements is crucial.

Research is the first step; start by consulting manuals and online resources to identify specifications. This can provide insights into dimensions, materials, and other essential features.

Next, cross-referencing with trusted suppliers can help confirm that the items you consider will fit seamlessly. Many vendors offer tools to assist in matching components, ensuring you make informed choices.

Finally, consider user reviews and expert recommendations. Feedback from other users can highlight potential issues or confirm the reliability of specific replacements.

DIY Repairs for JS26 Users

Performing maintenance and repairs on your outdoor equipment can be a rewarding experience. By understanding the essential components and their functions, you can tackle various issues without relying solely on professional services. This guide aims to empower users to carry out simple fixes and enhancements, ensuring their machines operate efficiently and effectively.

Before diving into repairs, it’s crucial to familiarize yourself with the common problems that may arise. Issues like engine performance, blade sharpness, or electrical malfunctions can often be addressed with basic tools and a bit of know-how. Regular inspection and proactive care can also prevent minor issues from escalating into major repairs.

When conducting repairs, having a clear understanding of the structure and layout of your equipment is essential. Utilizing online resources or community forums can provide insights and valuable tips from experienced users. Always ensure you have the necessary tools and safety gear on hand to make the process smooth and safe.

Finally, document your repair process. Keeping notes or taking photos can help you track what has been done and may assist you in future maintenance tasks. Embracing a hands-on approach not only saves money but also enhances your connection to your equipment, making each outing more enjoyable.