When it comes to maintaining the efficiency of lawn care equipment, comprehending the structure and components of various attachments is crucial. This section delves into the intricate relationships between different elements that contribute to optimal performance. Knowledge of these components not only aids in effective maintenance but also enhances overall functionality.

With a well-organized schematic, users can easily navigate the complexities of mower assembly. An insightful layout showcases each segment’s role, ensuring that operators can swiftly identify parts that require attention or replacement. This facilitates smoother operations and prolongs the lifespan of the equipment.

By examining a comprehensive illustration of attachment elements, users gain valuable insights into assembly processes. Such understanding empowers owners to make informed decisions regarding upkeep, ensuring their machinery remains in peak condition for all landscaping endeavors.

Understanding John Deere Auto Connect 60D

This section delves into the innovative attachment system designed for seamless integration with various agricultural machinery. It focuses on the efficient coupling mechanism that enhances productivity and simplifies the process of implementing implements, ensuring that users can maximize their equipment’s potential.

Key Features

One of the standout characteristics of this system is its ability to facilitate quick and straightforward connections. Users can effortlessly attach or detach equipment without the need for extensive manual effort. This not only saves time but also reduces physical strain, allowing operators to focus on their tasks more effectively.

Benefits of Enhanced Integration

The streamlined integration provided by this system leads to improved operational efficiency. With the capability to swiftly switch between various implements, users can adapt to changing tasks on the field without unnecessary delays. Moreover, the design promotes durability, ensuring that the components withstand the rigors of regular use while maintaining optimal performance.

In summary, this advanced coupling mechanism is essential for modern agricultural practices, offering ease of use and reliability for users seeking to enhance their operational workflows.

Overview of Auto Connect Technology

This innovative system revolutionizes the way implements are attached to tractors, enhancing efficiency and user experience. The design minimizes manual effort and streamlines the process, making it accessible for operators of all skill levels. The result is a seamless integration of machinery, allowing for quick changes and optimized workflow.

Key Features

The following are essential characteristics of this cutting-edge attachment mechanism:

| Feature | Description |

|---|---|

| Quick Attach | Enables fast and effortless coupling of tools without the need for extensive physical labor. |

| Safety Mechanisms | Includes built-in safeguards to prevent accidental disconnection during operation. |

| User-Friendly Design | Engineered for ease of use, allowing operators to focus on productivity. |

Benefits of the System

This system not only enhances operational efficiency but also significantly reduces downtime. Operators can swiftly transition between tasks, leading to increased productivity and improved workflow. Additionally, the intuitive design ensures that even those with minimal experience can operate the machinery effectively, promoting a more inclusive working environment.

Key Components of the 60D Model

The efficiency and functionality of this agricultural attachment are rooted in its well-designed elements. Understanding these key features can enhance performance and maintenance practices, ultimately contributing to a smoother operation in the field.

Structural Framework

The frame serves as the backbone of the implement, providing stability and support during usage. Constructed from durable materials, it ensures resilience against the rigors of agricultural tasks, allowing for reliable performance in various conditions.

Operational Mechanisms

Another critical aspect involves the mechanical systems that facilitate movement and attachment. These include hydraulic components, which enable smooth transitions and adjustments. The use of advanced engineering in these mechanisms enhances the adaptability and efficiency of the implement, making it easier to tackle diverse farming activities.

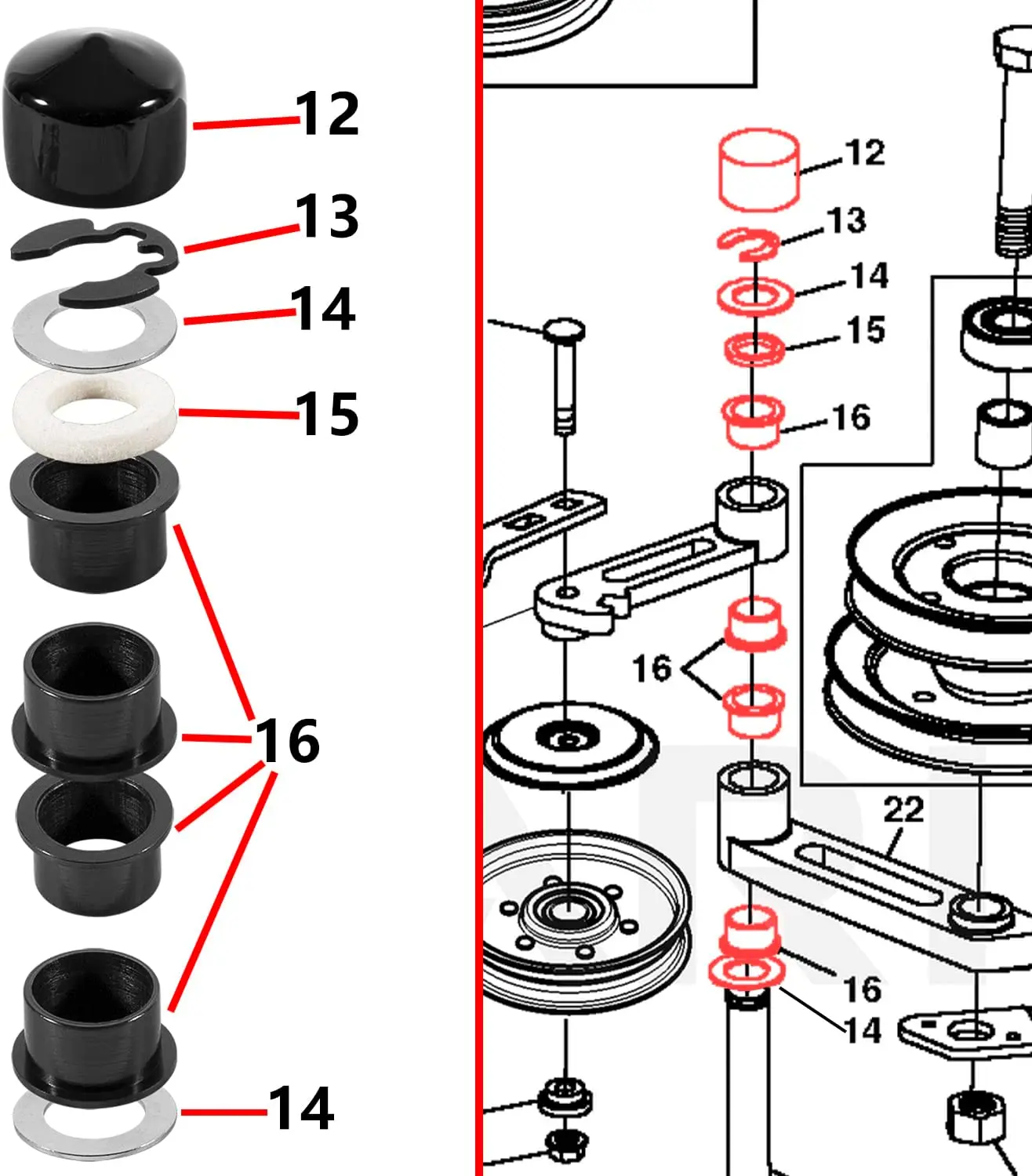

How to Read Parts Diagrams

Understanding schematic illustrations is essential for effective maintenance and repair. These visual guides provide a detailed overview of various components, allowing users to identify and locate specific elements easily. By familiarizing yourself with the structure and symbols used in these representations, you can streamline your troubleshooting and assembly processes.

1. Familiarize Yourself with Symbols: Each illustration uses standardized symbols to represent different components. Take time to learn what these symbols mean, as this knowledge will greatly enhance your comprehension of the visual materials.

2. Study the Layout: The arrangement of elements in a schematic often reflects their physical relationships. Observe how components are grouped or connected to understand their function within the overall system.

3. Reference the Legend: Many illustrations include a legend or key that explains the symbols and numbers used. Always refer to this section for clarification, as it can provide crucial information about specific parts.

4. Trace Connections: Follow the lines or arrows that indicate connections between components. This will help you visualize how different parts interact and assist in identifying potential issues.

5. Take Notes: As you analyze the illustration, jot down important details or questions that arise. This practice can aid in retaining information and assist during actual repair or maintenance tasks.

Maintenance Tips for 60D Parts

Proper upkeep of equipment components is essential for ensuring optimal performance and longevity. By adhering to a few key practices, operators can enhance efficiency and minimize the risk of breakdowns.

- Regular Inspection: Frequently check for wear and tear. Look for any signs of damage or unusual wear on various elements.

- Lubrication: Ensure that all moving parts are adequately lubricated. This helps reduce friction and prevent premature wear.

- Cleaning: Keep components clean from dirt and debris. Regularly remove any buildup that could hinder operation.

- Tightening Fasteners: Periodically check that all bolts and screws are securely fastened to prevent loosening during use.

- Storage: When not in use, store equipment in a dry and sheltered area to protect it from the elements.

Implementing these maintenance strategies will lead to better performance and extend the lifespan of the equipment. Regular attention to detail is key to achieving reliable results in the field.

Common Issues and Solutions

This section addresses frequent challenges encountered with a specific equipment attachment system. Understanding these common issues and their respective solutions can enhance operational efficiency and prolong the lifespan of your machinery.

Frequent Problems

- Inconsistent attachment alignment

- Difficulty in engaging or disengaging the implement

- Wear and tear on connecting components

- Fluid leakage from hydraulic connections

Recommended Solutions

- Check and adjust the alignment to ensure proper fit.

- Inspect locking mechanisms and lubricate moving parts to facilitate easier operation.

- Regularly examine wear points and replace any worn components promptly.

- Inspect hydraulic hoses and fittings for damage; replace as needed to prevent leaks.

Where to Buy Replacement Parts

Finding high-quality components for your equipment is essential for maintaining optimal performance. There are several reliable sources where you can acquire the necessary items to keep your machinery running smoothly. Whether you are looking for original equipment or aftermarket alternatives, knowing where to shop can save you time and ensure you get the right fit.

Authorized Dealers

One of the most dependable options is to visit authorized dealers. These establishments often stock genuine components, guaranteeing compatibility and quality. They typically have knowledgeable staff who can assist with your inquiries and help you find what you need quickly.

Online Retailers

The internet offers a vast array of online retailers specializing in equipment components. Websites dedicated to agricultural and industrial supplies often feature extensive catalogs, allowing you to compare prices and availability from the comfort of your home. Look for customer reviews to ensure you are purchasing from a reputable source.

Local Repair Shops can also be a valuable resource, as many have access to various suppliers and can often order specific items for you. Networking with fellow equipment owners may provide additional recommendations for reliable sources.

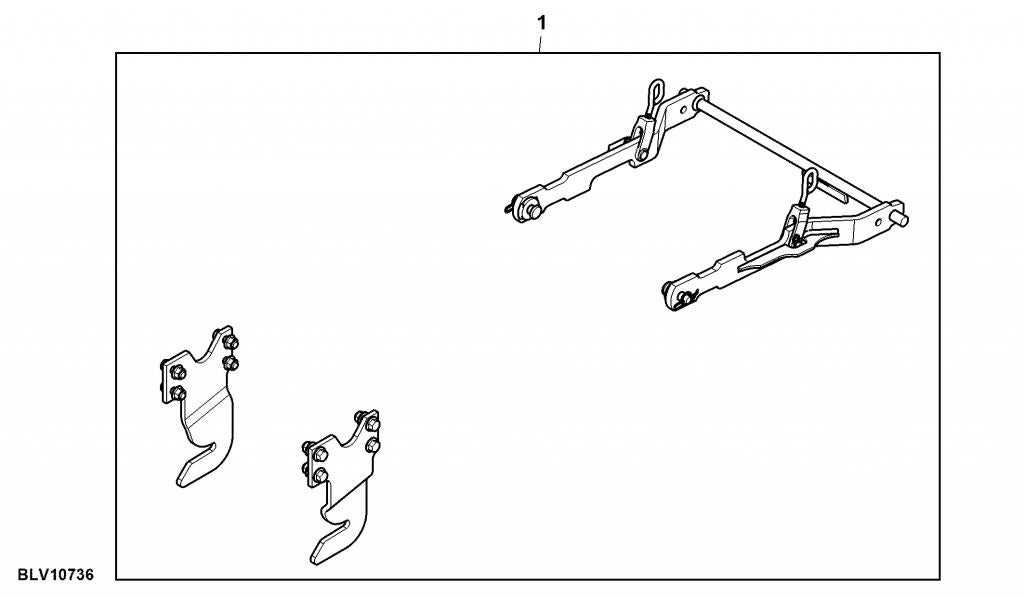

Installation Process for 60D Attachments

This section outlines the procedure for effectively installing attachments designed for specific models of agricultural machinery. Proper installation ensures optimal performance and longevity of both the equipment and the attachments. Following these steps will help maintain functionality and safety during operation.

Preparation Steps

- Ensure the machine is on a flat, stable surface.

- Gather all necessary tools and components for installation.

- Read the instruction manual thoroughly to familiarize yourself with the parts and procedure.

Installation Procedure

- Position the attachment near the mounting area of the machine.

- Align the attachment with the designated mounting points.

- Secure the attachment using the appropriate bolts and fasteners.

- Tighten all connections to the manufacturer’s specifications.

- Perform a visual inspection to ensure everything is properly aligned and secured.

Following this installation guide will facilitate a smooth process, ensuring that attachments are mounted securely for optimal usage.

Benefits of Using Auto Connect Systems

Implementing modern attachment systems in agricultural machinery streamlines the process of hooking up implements, providing numerous advantages for operators. These advancements not only enhance efficiency but also contribute to a more user-friendly experience in various farming tasks.

Increased Efficiency

One of the primary benefits of advanced attachment systems is the significant reduction in time required to switch between tools. Operators can quickly and easily engage or disengage implements without the need for extensive manual labor or adjustments. This efficiency allows for more productive workdays and minimizes downtime during crucial farming activities.

Improved Safety and Convenience

Modern systems are designed with safety in mind, reducing the risks associated with manual attachment processes. The intuitive design enables users to operate machinery with less physical strain, decreasing the likelihood of accidents. Furthermore, the convenience of seamless connections enhances the overall user experience, making it easier for individuals of all skill levels to manage their equipment effectively.