In the realm of agricultural and industrial machinery, a comprehensive understanding of individual elements is crucial for effective maintenance and repair. Each piece plays a significant role in ensuring optimal functionality and longevity of the equipment. By familiarizing oneself with the various components, operators can enhance performance and troubleshoot issues more effectively.

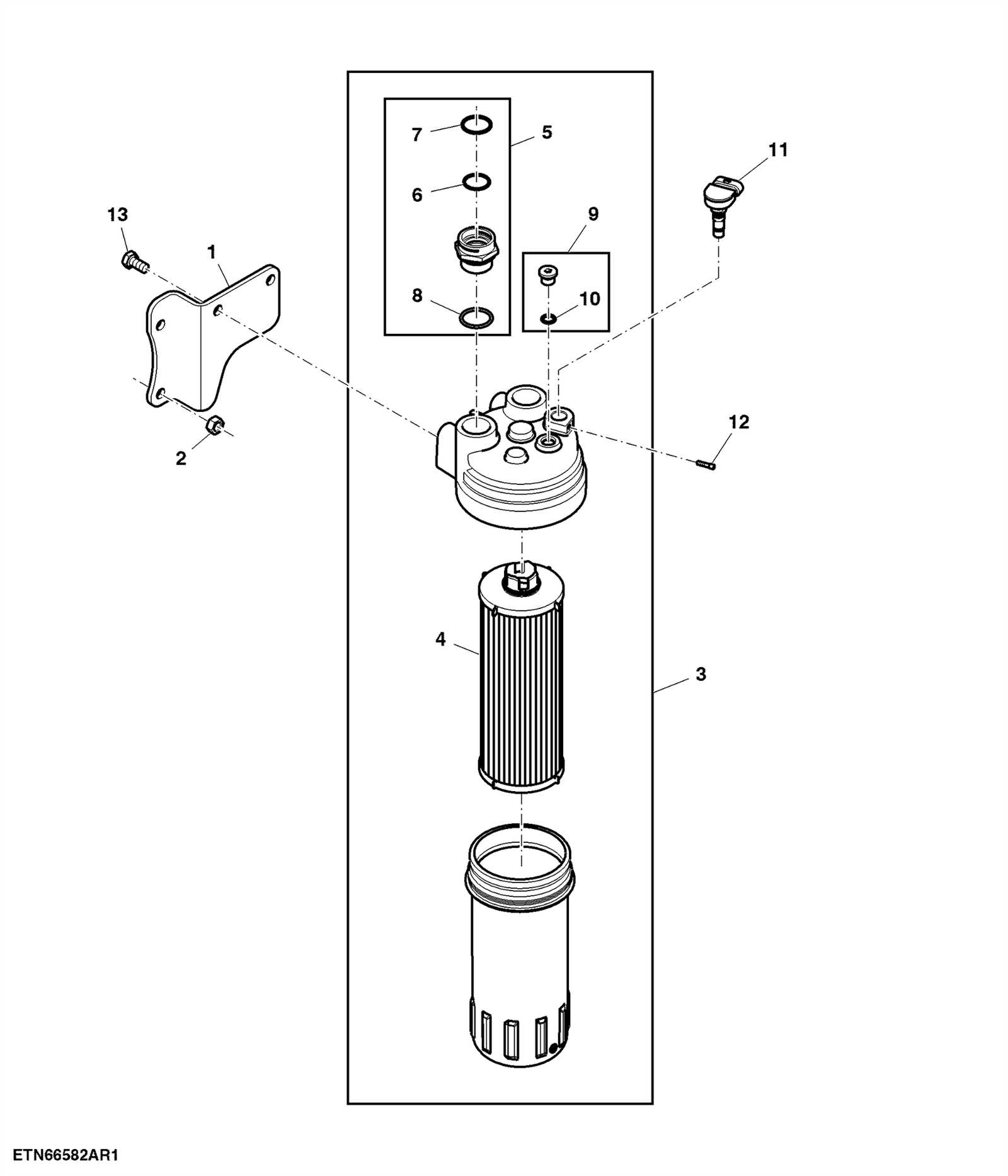

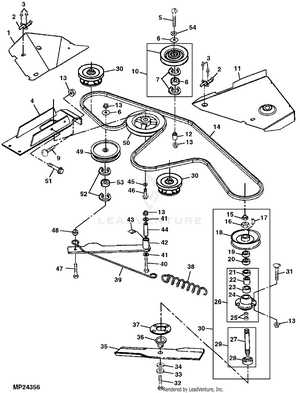

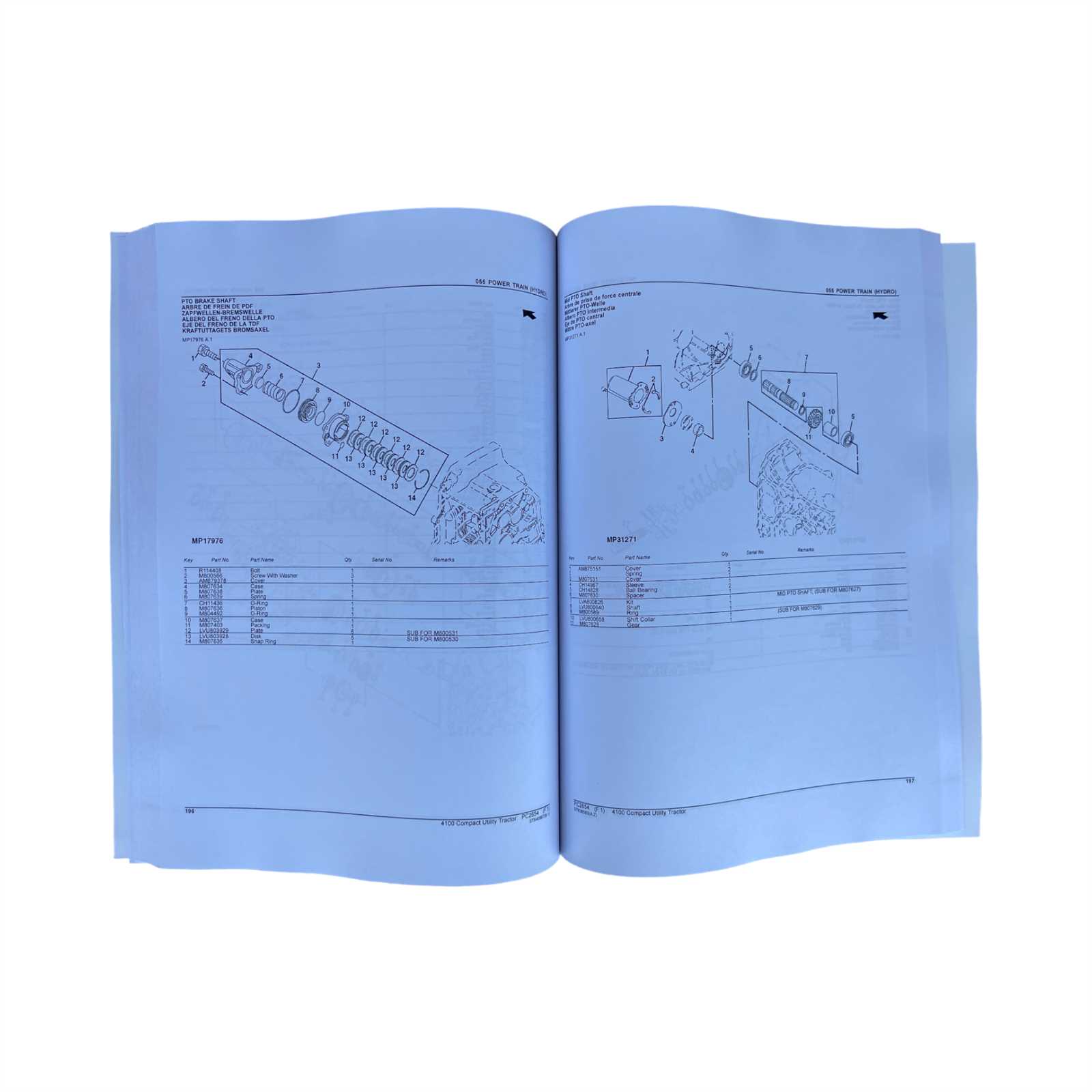

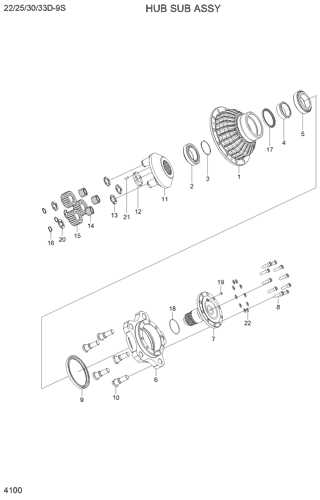

Visual representations of the intricate network of parts can greatly aid in the identification and management of these essential elements. Such illustrations serve not only as valuable references but also as educational tools, allowing users to gain insight into the relationships and functions of different sections. This knowledge empowers operators to undertake repairs confidently and make informed decisions regarding replacements.

Furthermore, a detailed exploration of the structure of these machines fosters a deeper appreciation for the engineering behind them. Recognizing how each component interconnects contributes to a broader understanding of overall machinery operation. Ultimately, this knowledge facilitates better care and enhances the lifespan of these vital tools in various sectors.

Understanding the John Deere 4100

This section aims to explore the intricacies of a compact utility vehicle known for its efficiency and versatility in various agricultural and landscaping tasks. By examining its components and functionality, users can appreciate the robust engineering that supports optimal performance.

| Feature | Description |

|---|---|

| Engine | A powerful unit designed for durability and efficiency. |

| Transmission | Offers smooth shifting for enhanced control and productivity. |

| Hydraulics | Facilitates various attachments and implements for diverse tasks. |

| Cab Design | Ergonomically crafted for operator comfort and visibility. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. These illustrations provide clarity on how individual elements fit together, facilitating effective repairs and replacements. By offering a detailed view, they enhance the overall efficiency of maintenance tasks and contribute to the longevity of equipment.

Benefits of Visual Guides

- Improved Understanding: Clear images help users grasp the relationships between various components.

- Efficient Repairs: Quick identification of parts allows for faster troubleshooting and resolution of issues.

- Enhanced Accuracy: Precise locations of components reduce the risk of errors during assembly or disassembly.

Practical Applications

- Maintenance teams utilize these visuals for routine check-ups, ensuring all elements are in optimal condition.

- Technicians reference them during repairs to avoid overlooking critical parts.

- Users can identify replacement needs quickly, minimizing downtime.

In summary, these illustrations serve as an essential resource for both novice and experienced users, promoting a deeper understanding and more effective management of machinery.

Common Issues with the 4100

Many operators encounter various challenges when working with this compact utility vehicle. Understanding these common problems can enhance maintenance practices and extend the machine’s lifespan. Identifying symptoms early allows for timely interventions, ensuring optimal performance and reliability.

Hydraulic System Problems

One frequent issue involves the hydraulic system, which can lead to diminished lifting capabilities or slow response times. Operators may notice leaks around the hydraulic lines or a drop in fluid levels, indicating the need for inspection and potential replacement of seals or hoses. Regular maintenance checks can prevent these issues from escalating.

Engine Performance Issues

Another area of concern is engine performance. Symptoms such as hard starting, stalling, or uneven power output can arise from several factors, including fuel system blockages or air filter restrictions. Ensuring clean fuel and routinely replacing filters can significantly mitigate these risks and promote smoother operation.

Where to Find Replacement Parts

Finding the right components for your equipment can enhance performance and extend its lifespan. Various sources offer a range of options for sourcing these necessary items, from online retailers to local suppliers. Understanding where to look can make the replacement process more efficient and cost-effective.

Online Retailers

The internet is a treasure trove of resources for acquiring needed components. Numerous websites specialize in machinery supplies, providing detailed descriptions and user reviews. Shopping online allows for easy comparison of prices and availability, ensuring you find the best deal.

Local Dealerships and Stores

Visiting a nearby dealership or hardware store can be advantageous for immediate needs. Local establishments often have knowledgeable staff who can assist in identifying the right items. Additionally, purchasing locally supports the community and can sometimes lead to discounts or promotions.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide crucial information, enabling users to identify components and their arrangements within machinery. Familiarity with these illustrations enhances efficiency and accuracy in troubleshooting.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent different elements.

- Identify Sections: Many illustrations are divided into segments, each focusing on a particular area of the machinery.

- Refer to the Legend: Most visuals include a legend that explains the symbols and numbering system used.

- Use an Exploded View: This perspective helps visualize how parts fit together, making it easier to understand their relationships.

By following these guidelines, you can confidently navigate technical illustrations, ensuring you have the ultimate understanding for successful repairs.

Essential Maintenance Tips for Longevity

Regular upkeep is crucial for ensuring the durability and efficiency of your machinery. Implementing a few fundamental practices can significantly extend the life of your equipment, enhance performance, and prevent costly repairs. Here are key tips to maintain optimal function.

Routine Inspections

- Check fluid levels regularly to avoid overheating and mechanical failure.

- Inspect belts and hoses for wear and tear, replacing them as needed.

- Examine tires for proper inflation and tread depth to ensure safety and efficiency.

Proper Cleaning

- Remove dirt and debris after each use to prevent buildup that can cause damage.

- Use appropriate cleaners for specific components to avoid corrosion.

- Clean air filters regularly to maintain optimal airflow and engine performance.

By adhering to these maintenance practices, you can safeguard your machinery against premature wear and ensure it operates at peak efficiency for years to come.

Compatibility with Other John Deere Models

This section explores the interchangeability of components across various machinery within the same brand, focusing on similarities that can enhance maintenance and repair processes.

- Many models share similar structural designs, allowing for cross-utilization of components.

- Specific features, such as hydraulic systems and engine parts, often align with other units.

- Identifying compatible models can lead to cost-effective repairs and upgrades.

Below are some models that showcase compatibility:

- Model A

- Model B

- Model C

Understanding these relationships can ultimately simplify the search for replacement components and improve overall operational efficiency.

Expert Recommendations for Quality Parts

When it comes to maintaining and enhancing the performance of machinery, selecting superior components is essential. Quality replacements not only ensure longevity but also optimize functionality, allowing equipment to operate at its best. This guide highlights key considerations and suggestions for sourcing reliable components to achieve optimal results.

Research Reputable Suppliers

Start by identifying trusted vendors known for their high standards. Look for suppliers who offer a solid warranty and have a proven track record in the industry. Reading reviews and testimonials can provide valuable insights into the reliability and performance of their offerings. Always prioritize brands that have established a reputation for excellence.

Evaluate Material and Design

Pay close attention to the materials used in the construction of the components. Durable, high-quality materials often lead to enhanced performance and reduced wear over time. Additionally, consider the design aspects; components that are engineered with precision will typically integrate better with existing systems, reducing the likelihood of issues. Investing in quality now can prevent costly repairs in the future.