In the realm of agricultural equipment, comprehending the intricate assembly of various machinery is essential for effective maintenance and repair. Each component plays a pivotal role in ensuring optimal functionality, and a thorough understanding of these elements can significantly enhance operational efficiency.

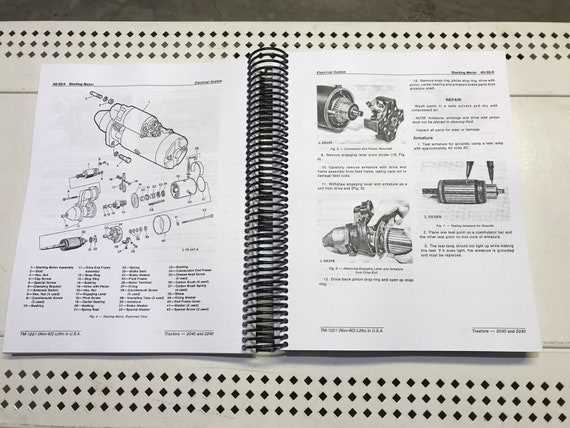

When exploring the arrangement of individual parts, visual aids become invaluable. These representations provide clarity, allowing users to identify specific sections and their relationships within the overall system. Such insights not only facilitate troubleshooting but also empower operators to perform routine inspections and replacements with confidence.

Additionally, knowledge of component interactions fosters a deeper appreciation of machinery performance. By recognizing how each piece contributes to the larger mechanism, users can make informed decisions regarding upgrades and modifications. This holistic understanding ultimately leads to improved productivity and longevity of equipment.

Understanding the John Deere 2040

This section aims to explore the intricacies of a specific agricultural machine, highlighting its key components and functionality. By breaking down its features, users can gain insights into how it operates and how to maintain it effectively.

Key Features

The machine is renowned for its reliability and efficiency in farming tasks. Its robust design allows it to handle various attachments, making it versatile for different agricultural needs. Operators appreciate its ease of use, coupled with powerful performance.

Maintenance and Care

| Component | Function |

|---|---|

| Engine | Drives the machine and powers various functions. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulics | Facilitates movement of implements and attachments. |

| Electrical System | Controls ignition, lighting, and various electronic components. |

Key Components of the 2040 Model

The machinery in question features a range of essential elements that contribute to its efficiency and functionality. Understanding these components is crucial for optimal operation and maintenance. Each part plays a significant role in ensuring the overall performance and reliability of the equipment, making it important for users to familiarize themselves with their functions.

Engine and Transmission

The power unit is at the heart of the equipment, providing the necessary energy for operation. Coupled with a robust transmission system, it ensures seamless power transfer to the wheels, allowing for smooth movement across various terrains. Regular maintenance of these elements is vital to prevent breakdowns and ensure longevity.

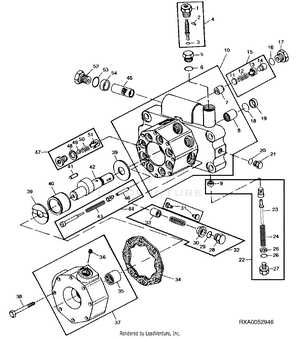

Hydraulic System

The hydraulic assembly is integral for various functionalities, including lifting and tilting implements. This system relies on fluid dynamics to generate the force needed for different tasks. Understanding its components, such as pumps and cylinders, can help users troubleshoot issues and maintain effective operation.

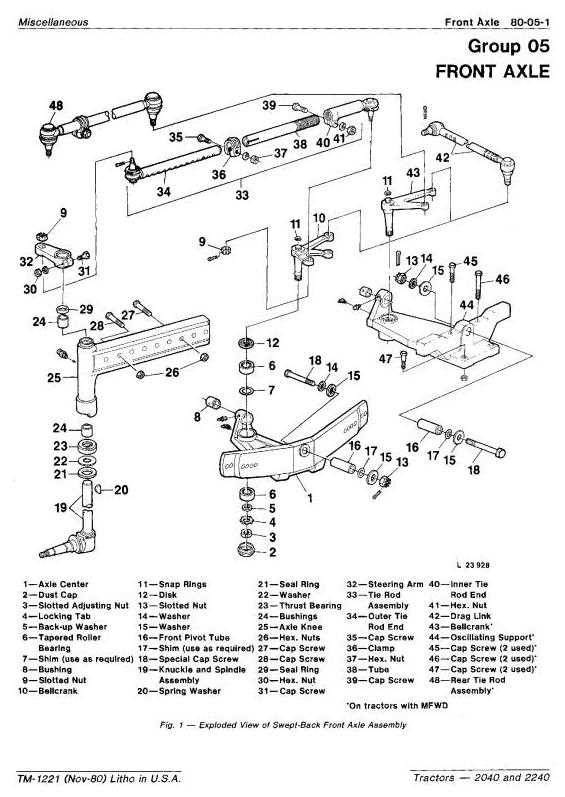

Parts Identification for Maintenance

Effective upkeep of machinery requires a clear understanding of its components. Identifying the various elements is crucial for ensuring smooth operation and longevity. This section focuses on how to recognize and locate different segments, facilitating timely maintenance and repairs.

Key Components Overview

Understanding the primary components helps in diagnosing issues and planning maintenance tasks. Familiarity with each part’s function allows for more efficient troubleshooting and ensures that every element is functioning as intended.

Identification Table

| Component | Description | Common Issues |

|---|---|---|

| Engine | Power unit that drives the machine | Overheating, loss of power |

| Transmission | System that transmits power to wheels | Slipping gears, fluid leaks |

| Hydraulics | System used for lifting and moving | Weak pressure, leaks |

| Electrical System | Wiring and components for operation | Starting issues, blown fuses |

Where to Find Parts Diagrams

Understanding where to access detailed schematics is essential when looking to repair or maintain various types of machinery. Reliable sources for these visual guides not only help identify specific components but also simplify the process of ordering replacements or performing upgrades. Knowing the right places to search can save time and effort, ensuring that the correct resources are at your disposal.

Online Platforms for Schematics

Numerous online platforms specialize in providing comprehensive illustrations for a variety of equipment. These platforms often offer intuitive search tools, allowing users to browse by model number or machine type. Many also feature downloadable PDFs, making it easy to view and print the information needed. Some of the most popular sources even offer forums or community support, where users can discuss details and troubleshooting tips related to specific schematics.

Manufacturer Websites

Many manufacturers host extensive libraries of schematics on their official websites. These sites often require creating an account, but they provide access to the most up-to-date and accurate resources. With features like model-specific searches and interactive diagrams, official sites can be one of the best resources for anyone looking to maintain or repair equipment effectively. Additionally, these websites may offer additional resources, such as maintenance guides, manuals, and support contact information.

Common Issues with John Deere 2040

These rugged agricultural machines, despite their durable construction, can encounter a range of common technical concerns as they age. Understanding frequent maintenance needs helps operators keep these machines running smoothly, avoiding costly downtime. Below, we explore some of the most typical areas where malfunctions may arise, offering insights into what to look for and how to address these recurring issues effectively.

Engine Performance Problems

One of the primary areas of concern relates to the motor’s reliability, which may exhibit symptoms such as stalling, overheating, or reduced power. Often, these issues stem from blocked filters, fuel line obstructions, or irregular ignition settings. Regular inspection and replacement of filters, along with proper fuel system maintenance, can significantly enhance the machine’s operational efficiency.

Hydraulic System Leaks

Fluid leaks in the hydraulic mechanisms are another frequent problem area, potentially leading to reduced lifting power and decreased machine performance. These leaks can often be traced back to worn seals or damaged hoses within the system. Routine examination of all hydraulic components, accompanied by timely repairs, can minimize the risk of leaks and ensure t

How to Use Parts Diagrams Effectively

Understanding technical illustrations is essential for proper equipment maintenance and efficient problem-solving. These visual tools can help you identify each component and understand its role within a larger system, making it easier to replace or repair specific elements as needed.

Step-by-Step Navigation

- Start by locating the relevant illustration based on the area of the equipment you need to address. Many visual guides are organized by systems, such as engine components, electrical connections, or hydraulic systems.

- Identify each element within the illustration using the provided labels or numbers. Cross-reference these identifiers with the accompanying list or index to gain a full understanding of each part’s function and specifications.

- Double-check that you’re referencing the correct diagram. For certain models, multiple versions of the same system may exist, so ensure that you’re viewing the appropriate one for your particular setup.

Tips for Effective Use

- Keep a notepad handy fo

Benefits of Accurate Parts Replacement

Replacing components with precision is crucial for maintaining the efficiency and longevity of machinery. When the correct items are selected, it ensures optimal performance and reduces the likelihood of future issues.

Enhanced Performance

Utilizing the right components leads to:

- Improved operational efficiency

- Better fuel economy

- Increased reliability during use

Cost Efficiency

Investing in accurate replacements can save money in the long run through:

- Minimized repair costs

- Extended lifespan of equipment

- Reduction in downtime

Ordering Parts for the 2040

When it comes to keeping your equipment running smoothly, having the right components on hand is essential. Finding replacement items that fit your machinery perfectly can make all the difference in maintaining optimal performance and preventing future issues. This section will guide you through the process of acquiring the necessary items to ensure reliable operation of your machinery.

Component Category Description Suggested Maintenance Interval Engine Elements Includes filters, belts, and spark plugs crucial for smooth engine function. Every 250 hours Hydraulic System Seals, hoses, and pumps designed to sustain fluid power operations. Every 500 hours Electrical Components Contains batteries, fuses, and wiring for reliable electric performance. Annually Transmission Units Clutches, gears