When it comes to maintaining lush green spaces, the efficiency of your machinery plays a crucial role. Each component of these machines is meticulously designed to enhance performance and longevity. Understanding the intricate workings of these elements allows for better upkeep and informed decision-making regarding replacements and repairs.

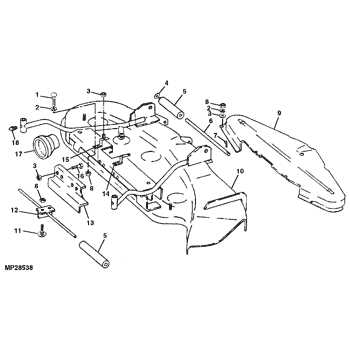

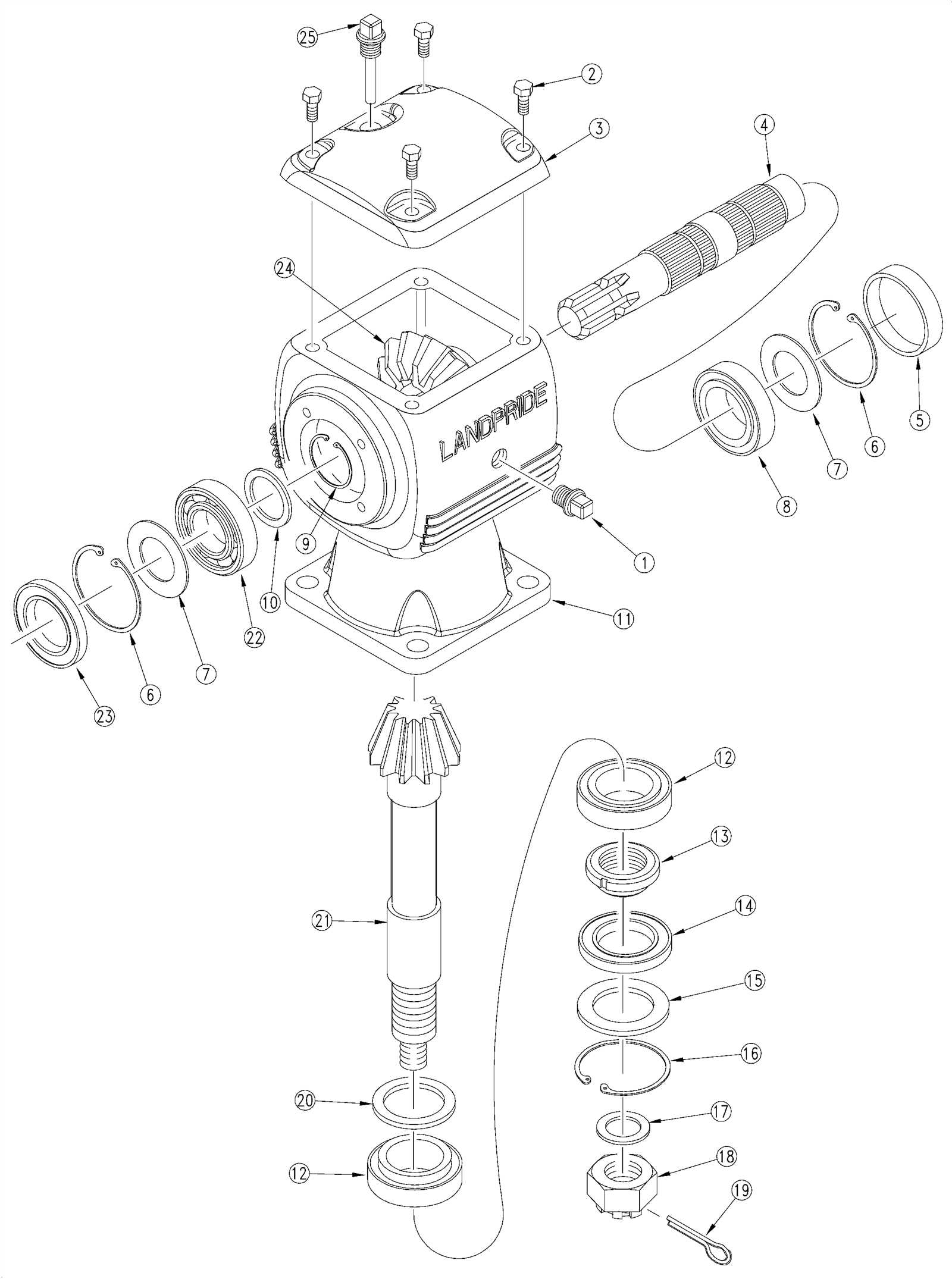

Visual aids can significantly enhance our understanding of the various elements involved. By exploring detailed schematics, operators can identify each part’s function and its relationship with the entire system. This knowledge not only simplifies maintenance tasks but also aids in troubleshooting potential issues.

Ultimately, having a comprehensive grasp of the components involved in your equipment can lead to improved performance and extended service life. Investing time in familiarizing yourself with these aspects will ensure your lawn care endeavors remain productive and efficient.

Understanding John Deere 261 Grooming Mower

Exploring the intricacies of a popular landscaping tool reveals its vital role in maintaining lush and well-groomed green spaces. This equipment is designed for precision and efficiency, ensuring that lawns and sports fields receive the best possible care. Understanding its components and functionality can greatly enhance the overall experience for users and operators.

Key Features and Benefits

- Robust construction for durability and long-term use.

- Adjustable height settings for varied terrain and grass types.

- Efficient cutting technology that promotes healthy grass growth.

- Easy maintenance procedures that prolong lifespan and performance.

Essential Components

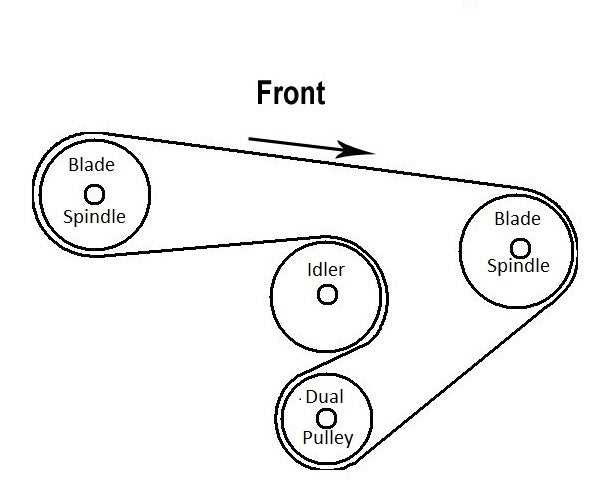

- Blades: Engineered for a clean cut and minimal grass stress.

- Deck: Provides stability and houses the cutting mechanism.

- Drive system: Ensures reliable power transfer for optimal operation.

- Handle controls: Designed for user-friendly engagement and adjustments.

Understanding these elements can significantly impact the effectiveness of lawn care practices, leading to healthier and more visually appealing landscapes.

Key Features of the 261 Model

This exceptional model is designed to deliver unparalleled performance and efficiency in various landscaping tasks. Its innovative engineering ensures that users benefit from enhanced maneuverability and precision, making it ideal for maintaining pristine outdoor spaces. With a focus on durability and ease of use, this machine stands out among its competitors.

Enhanced Performance

One of the standout characteristics is its powerful engine, which provides reliable operation even in demanding conditions. The robust cutting system ensures an even and clean finish, allowing for a professional appearance in every job. Coupled with advanced technology, it optimizes fuel efficiency, making it both cost-effective and environmentally friendly.

User-Friendly Design

The ergonomic controls and intuitive layout of this model facilitate seamless operation, reducing the learning curve for new users. Additionally, the adjustable settings cater to a variety of tasks, providing flexibility for different landscapes. Maintenance is simplified through easily accessible components, ensuring that users spend less time on upkeep and more time enjoying their outdoor spaces.

Importance of Maintenance for Mowers

Regular upkeep of lawn care equipment is essential for optimal performance and longevity. Proper maintenance not only ensures efficient operation but also minimizes the risk of breakdowns and costly repairs. By adhering to a routine service schedule, operators can significantly enhance the effectiveness of their machines while achieving a well-kept landscape.

Benefits of Regular Upkeep

- Improved Performance: Well-maintained equipment operates more smoothly, resulting in a cleaner and more precise cut.

- Extended Lifespan: Routine checks and timely repairs can prolong the life of the machinery.

- Cost Savings: Preventative care helps avoid expensive repairs and replacements.

- Safety: Regular inspections reduce the risk of accidents caused by faulty equipment.

Key Maintenance Practices

- Cleaning: Remove grass clippings and debris after each use to prevent rust and buildup.

- Sharpening Blades: Keeping blades sharp ensures efficient cutting and reduces strain on the engine.

- Oil Changes: Regular oil changes maintain engine health and efficiency.

- Inspection: Regularly check belts, hoses, and other components for wear and tear.

Common Issues and Troubleshooting Tips

Maintaining your equipment is essential for optimal performance and longevity. Over time, you may encounter various challenges that can hinder its functionality. Understanding these common issues and knowing how to address them can save you time and effort in the long run.

Typical Problems

- Engine Starting Difficulties: One of the most frequent complaints is trouble starting the engine. This can be caused by fuel issues, battery problems, or electrical faults.

- Uneven Cutting: If the cutting quality is inconsistent, it may indicate dull blades or improper height settings.

- Vibration and Noise: Excessive vibration can point to loose components or imbalanced parts, which can affect overall performance.

- Overheating: If the machine overheats, it might be due to inadequate cooling or a clogged air filter.

Troubleshooting Steps

- Check Fuel Supply: Ensure that there is sufficient fuel and that it is fresh. Old fuel can cause starting problems.

- Inspect Electrical Connections: Look for loose or corroded wires that could disrupt the power supply.

- Sharpen or Replace Blades: Regular maintenance of cutting edges ensures a clean cut and improves performance.

- Examine Air Filter: A clean air filter allows for proper airflow, preventing overheating.

- Tighten Loose Components: Regularly check bolts and screws to ensure everything is secure, reducing vibration and wear.

By identifying these common issues and applying the suggested solutions, you can maintain the efficiency of your equipment and extend its operational lifespan.

Overview of Replacement Parts Available

When it comes to maintaining your equipment, understanding the variety of components accessible for replacement is crucial. These elements ensure optimal performance and longevity, allowing you to keep your machine running smoothly. A range of options exists, catering to different needs and preferences, which can significantly enhance the efficiency of your tool.

Components such as blades, belts, and filters are essential for effective operation. Each piece serves a specific purpose, contributing to the overall functionality. Additionally, accessories and upgrades can provide enhanced capabilities, ensuring your equipment meets the demands of various tasks.

It’s advisable to explore the available selections carefully, as the right replacements can make all the difference. Quality and compatibility should be prioritized to guarantee that your equipment remains in top condition for years to come.

How to Read Parts Diagrams Effectively

Understanding visual representations of components can significantly enhance your ability to maintain and repair equipment. These illustrations serve as guides, allowing users to identify and locate individual elements quickly. Mastering the interpretation of these visuals can streamline your work process and minimize errors.

Familiarize Yourself with Symbols and Notations

Each visual representation employs specific symbols and notations. Here are steps to help you decode them:

- Identify Key Symbols: Look for a legend that explains the icons used.

- Note Color Codes: Colors may indicate different functions or types of components.

- Understand Line Types: Solid lines usually represent physical connections, while dashed lines may denote optional features.

Follow the Flow of the Diagram

Once you’re familiar with the symbols, it’s essential to understand how the components connect and interact:

- Start from the Source: Begin at the primary element to trace the workflow.

- Follow Connections: Observe how elements link to one another and note any branching paths.

- Review Annotations: Pay attention to any accompanying notes that provide additional details about each component.

By employing these techniques, you can enhance your proficiency in interpreting visual component guides, leading to more effective repairs and maintenance.

Ordering Parts for Your Mower

When it comes to maintaining your equipment, knowing how to acquire the necessary components is crucial for optimal performance. Having the right resources and information at your fingertips can save you time and ensure your machine operates efficiently.

Identifying Required Components

Start by assessing what specific items you need. Consult your user manual or any available reference guides to pinpoint the exact components required for your model. This will help you make informed decisions during the ordering process.

Finding Reliable Suppliers

Once you’ve identified the needed components, seek out trusted vendors. Online marketplaces, local retailers, and specialized shops can provide various options. Comparing prices and reviews will assist you in selecting the best supplier for your needs.

Upgrading Your John Deere Equipment

Enhancing your machinery can significantly improve performance and efficiency. By focusing on quality components and innovative technology, you can transform your equipment into a more reliable asset, ensuring it meets the demands of various tasks. This upgrade journey not only boosts productivity but also extends the lifespan of your equipment.

Choosing the Right Components

Selecting high-quality accessories is crucial for achieving optimal results. Investing in superior elements ensures better durability and functionality. Prioritize components that offer enhanced performance and compatibility with your existing machinery.

Maintenance and Care

Regular upkeep plays a vital role in the longevity of your investment. Routine inspections and timely replacements can prevent major issues down the line. Keeping your equipment well-maintained not only enhances efficiency but also maximizes its potential.

Customer Reviews and Experiences

Feedback from users provides valuable insights into the performance and reliability of equipment. Understanding customer experiences helps potential buyers make informed decisions, ensuring they choose the right tools for their needs. This section highlights various opinions and testimonials, showcasing the strengths and weaknesses as noted by real users.

Positive Feedback

- Many users appreciate the ease of use and efficiency, noting that the device operates smoothly even in challenging conditions.

- Customers often highlight the durability of components, claiming that they withstand heavy usage without significant wear.

- The quality of the finish after use is frequently praised, with many stating it surpasses their expectations.

Areas for Improvement

- Some users have reported issues with the availability of replacement components, which can lead to downtime.

- A few customers noted that the initial setup process can be complicated, requiring extra time and assistance.

- Some have suggested enhancements in design for better maneuverability in tight spaces.

Overall, reviews indicate a strong level of satisfaction, but they also offer constructive criticism that can guide future enhancements.