The efficient operation of farming equipment relies heavily on the intricate design and arrangement of its essential elements. Each component plays a critical role, contributing to the overall functionality and effectiveness of the machinery used in various agricultural tasks.

To enhance productivity and minimize downtime, it’s vital for operators and technicians to have a clear understanding of these elements. By delving into detailed schematics, users can identify how each part interacts and the ultimate importance of maintenance in ensuring optimal performance.

In this section, we will explore the essential features and mechanisms involved in one specific model, highlighting their roles and how they integrate within the larger system. This knowledge not only aids in troubleshooting but also in making informed decisions about repairs and upgrades.

Understanding the John Deere 435 Baler

This section explores the intricacies of a vital agricultural implement designed for effective crop management. Mastering its components enhances operational efficiency and prolongs the machine’s lifespan.

Key features include:

- Durable construction for long-term use

- Efficient baling mechanism for various materials

- Adaptability to different farming conditions

To fully appreciate this machinery, it is essential to examine:

- Operational principles and mechanics

- Maintenance best practices for longevity

- Common issues and troubleshooting techniques

By delving into these aspects, users can unlock the ultimate potential of this implement, ensuring optimal performance in the field.

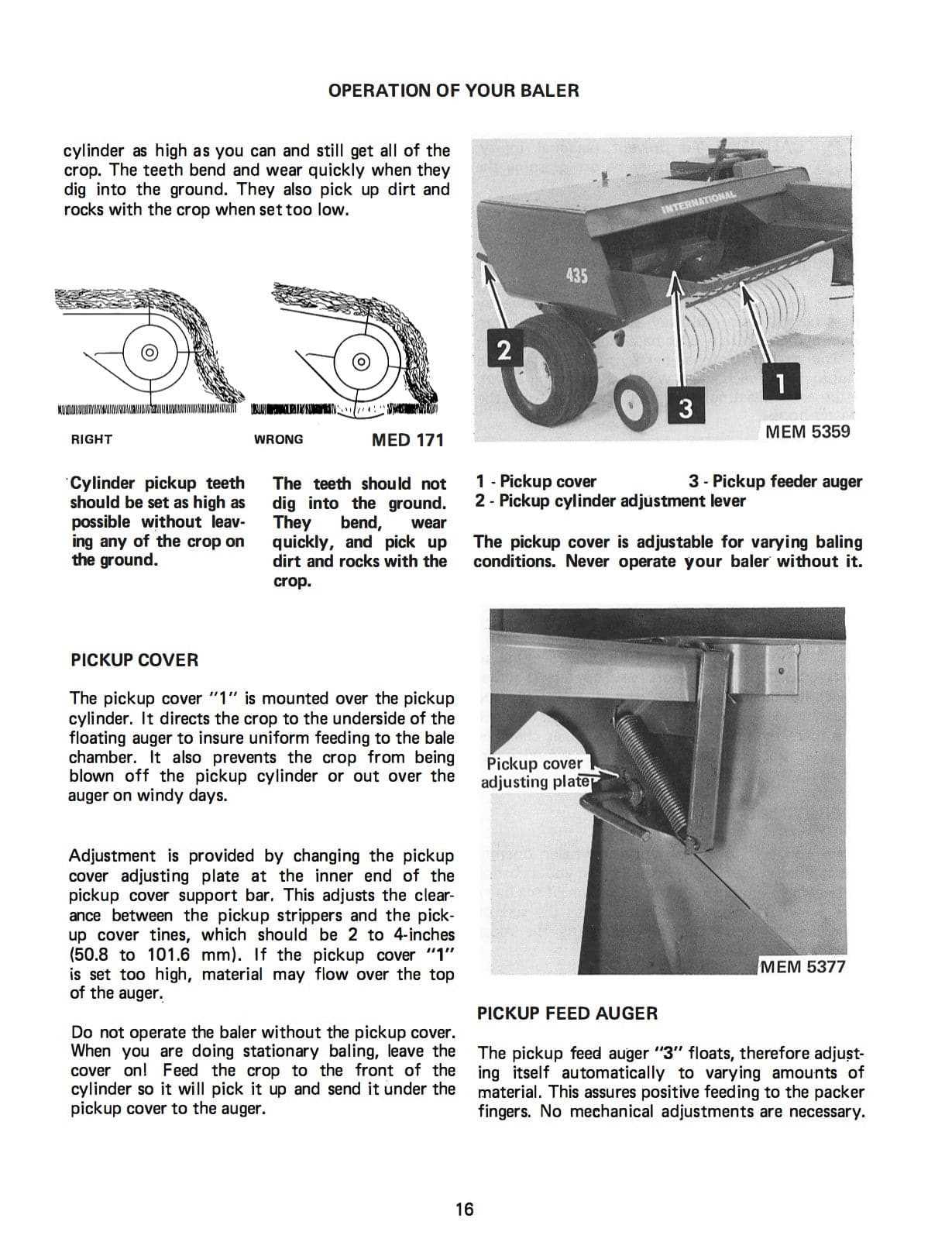

Key Components of the Baler

Understanding the essential elements of a harvesting machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring the efficiency and performance of the equipment, facilitating the smooth gathering and packaging of agricultural materials. Recognizing these parts can aid operators in troubleshooting and optimizing their machinery.

Essential Parts Overview

The following table outlines the fundamental components commonly found in these agricultural machines, along with their primary functions:

| Component | Function |

|---|---|

| Feeding System | Directs material into the chamber for compression. |

| Compression Chamber | Presses the material into compact bundles. |

| Tie Mechanism | Secures the compressed material with twine or wire. |

| Discharge System | Releases the finished bales for collection. |

| Frame | Provides structural integrity and support for all components. |

Maintenance Tips

Regular inspection and maintenance of these key components can significantly enhance the lifespan and functionality of the equipment. Operators should focus on checking for wear and tear, ensuring proper lubrication, and promptly addressing any issues to maintain optimal performance.

Importance of Maintenance for Efficiency

Regular upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Proper maintenance not only enhances the effectiveness of the equipment but also minimizes the risk of unexpected breakdowns, leading to smoother operations. By prioritizing care, operators can achieve higher productivity levels while reducing operational costs.

Enhancing Performance

Consistent maintenance routines help in identifying potential issues before they escalate. This proactive approach ensures that all components function seamlessly, thereby maximizing the output of the equipment. Regular checks and servicing can lead to improved fuel efficiency and reduced wear and tear on critical parts, ultimately translating to better yield in the field.

Cost Savings

Investing time and resources in maintenance can result in significant savings over time. By preventing major repairs and extending the lifespan of the machinery, operators can avoid costly replacements. Furthermore, well-maintained equipment is less likely to suffer from downtime, ensuring continuous operation and better financial returns.

In conclusion, the importance of regular maintenance cannot be overstated. It is an essential practice for anyone looking to maximize efficiency and ensure the durability of their agricultural equipment.

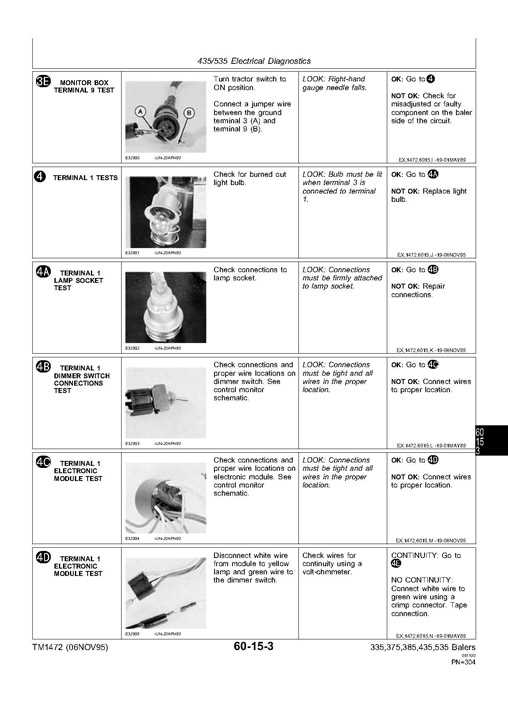

Common Issues and Troubleshooting Tips

When operating machinery designed for agricultural tasks, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems and knowing how to address them can significantly enhance productivity and reduce downtime. Below are some frequent issues and helpful solutions to keep equipment running smoothly.

Frequent Challenges

Equipment may experience a range of difficulties, from mechanical failures to operational inefficiencies. Some of the most typical concerns include:

| Issue | Description | Solution |

|---|---|---|

| Jamming | Material may become stuck, causing interruptions. | Regularly inspect and clear any blockages in the feed area. |

| Inconsistent Bale Size | Bales may vary in density and shape. | Check and adjust the tension settings to ensure uniform compression. |

| Wear and Tear | Components may show signs of damage or deterioration over time. | Perform routine maintenance and replace worn parts as necessary. |

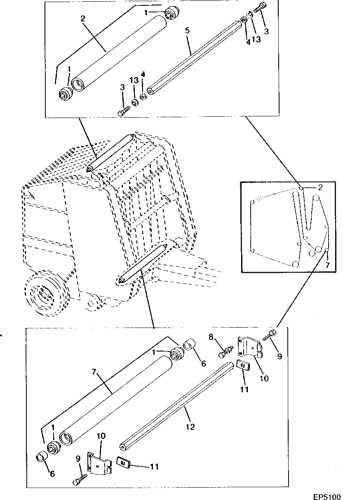

| Hydraulic Issues | Hydraulic systems can develop leaks or lose pressure. | Inspect hoses and connections for leaks and ensure proper fluid levels. |

Preventive Measures

To minimize the likelihood of encountering issues, proactive maintenance is key. Implementing a regular inspection schedule, lubricating moving parts, and ensuring proper operation techniques can significantly enhance the longevity and effectiveness of the equipment.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a straightforward task with the right approach. Many resources are available, ranging from online retailers to local suppliers, ensuring you can restore your equipment effectively.

Online Resources

The internet offers a plethora of options for sourcing machinery components. Various websites specialize in agricultural supplies, providing detailed catalogs and user-friendly search functions.

Local Suppliers

Visiting nearby agricultural stores can also yield fruitful results. Local suppliers often have the expertise to help you find the exact items you need.

| Source Type | Advantages |

|---|---|

| Online Retailers | Convenience and variety |

| Local Stores | Personalized assistance and immediate access |

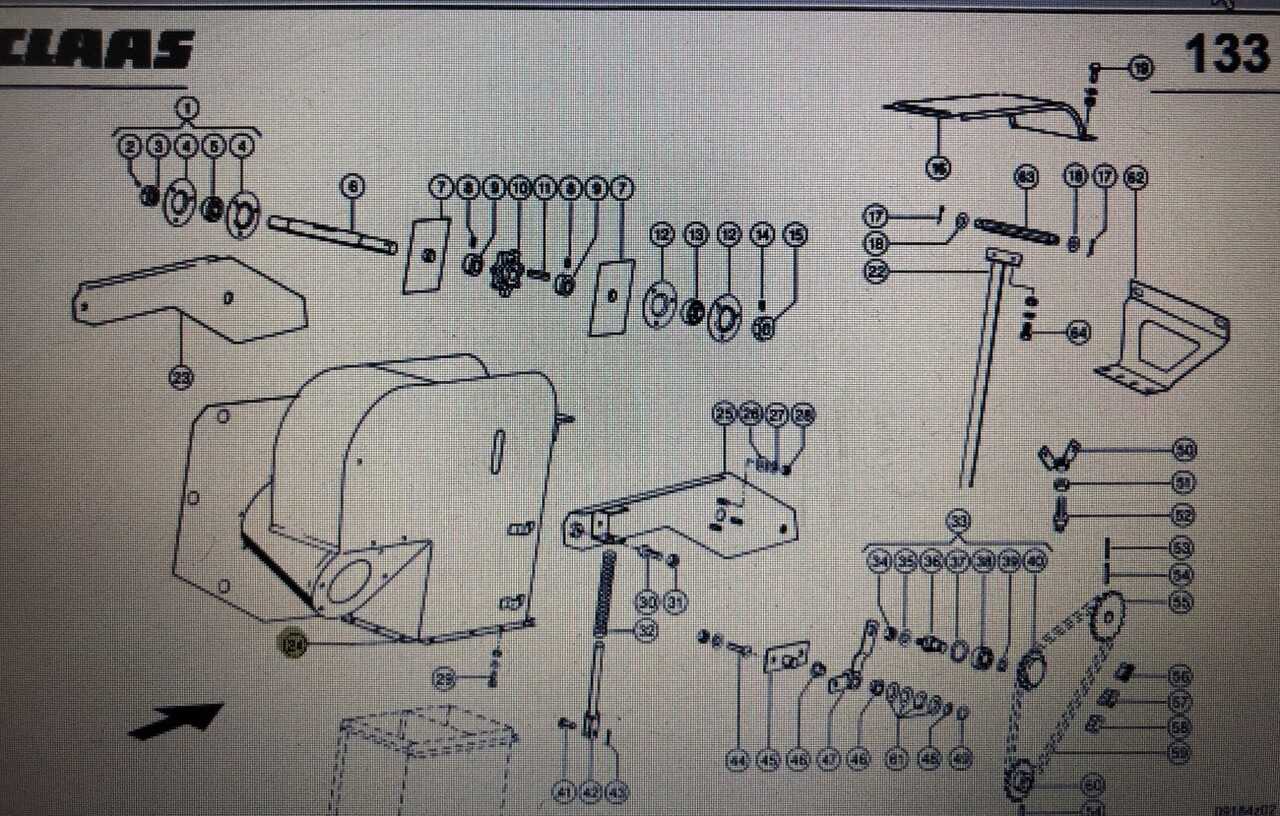

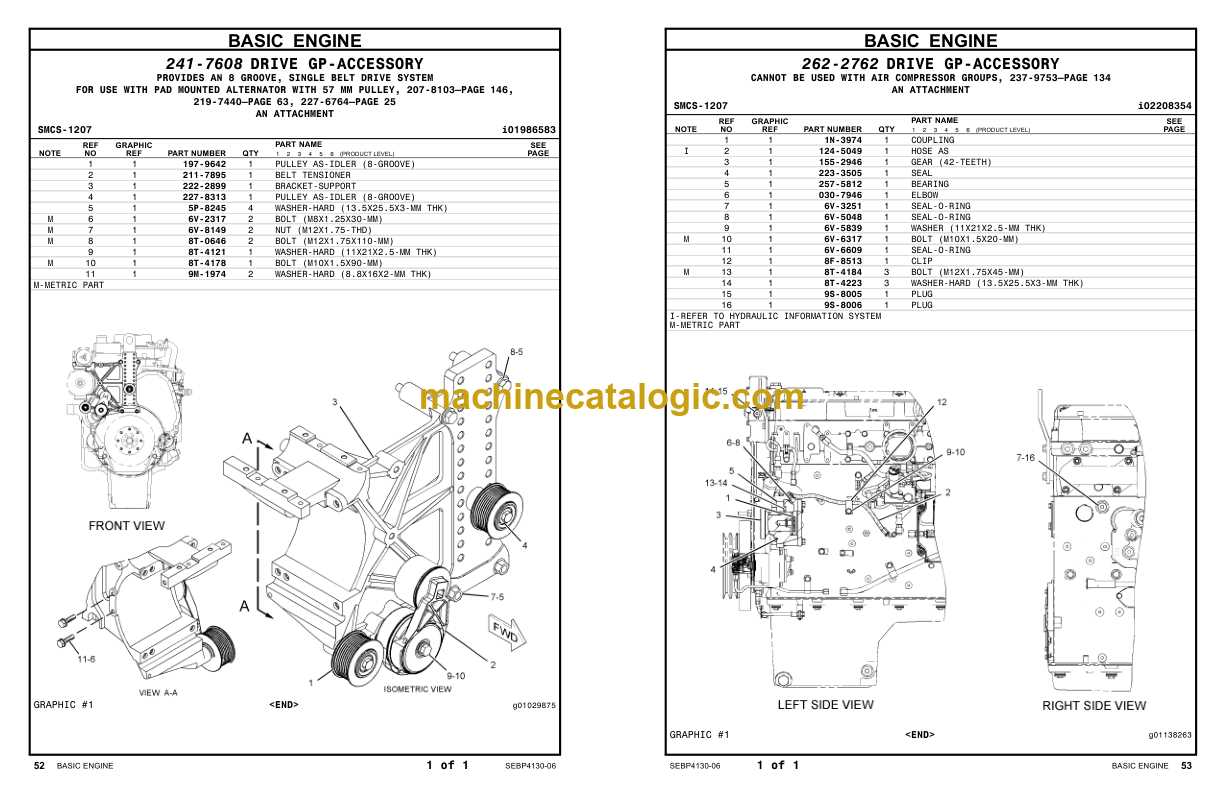

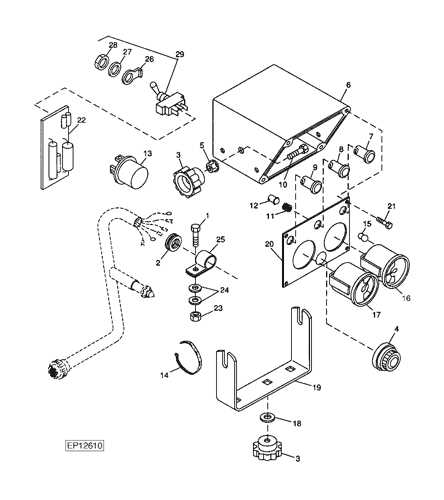

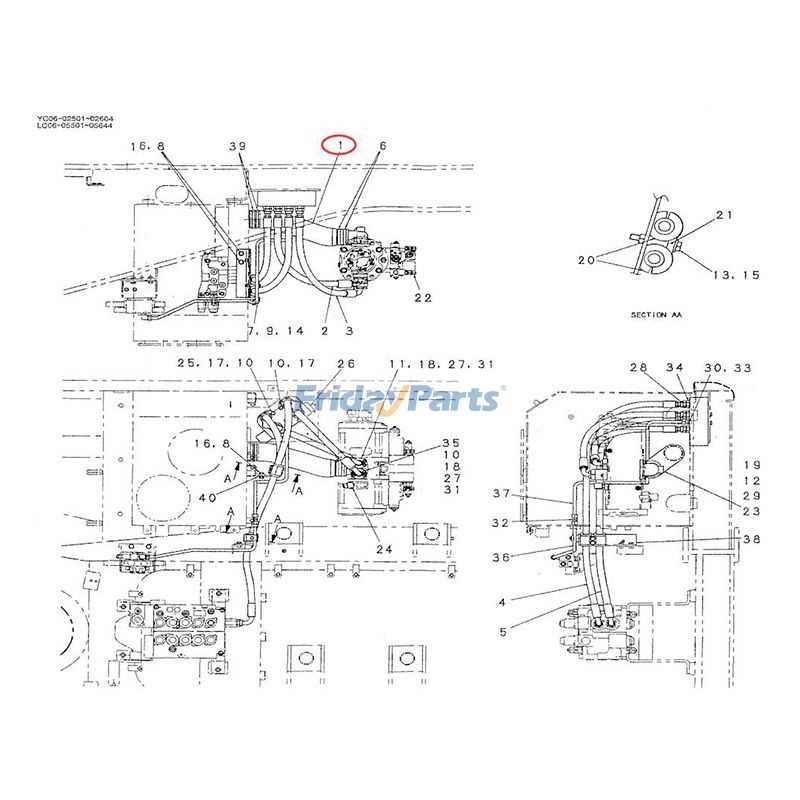

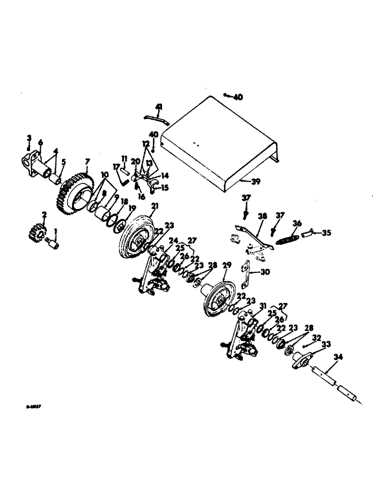

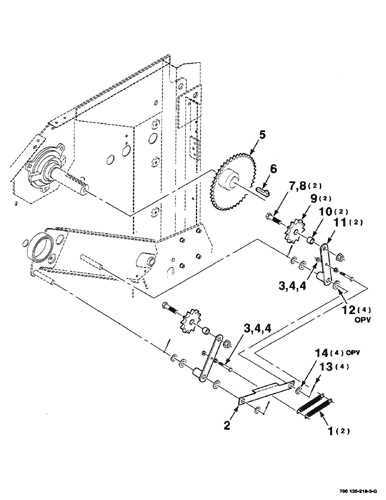

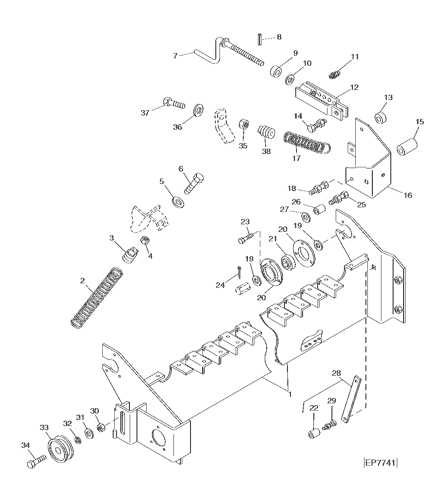

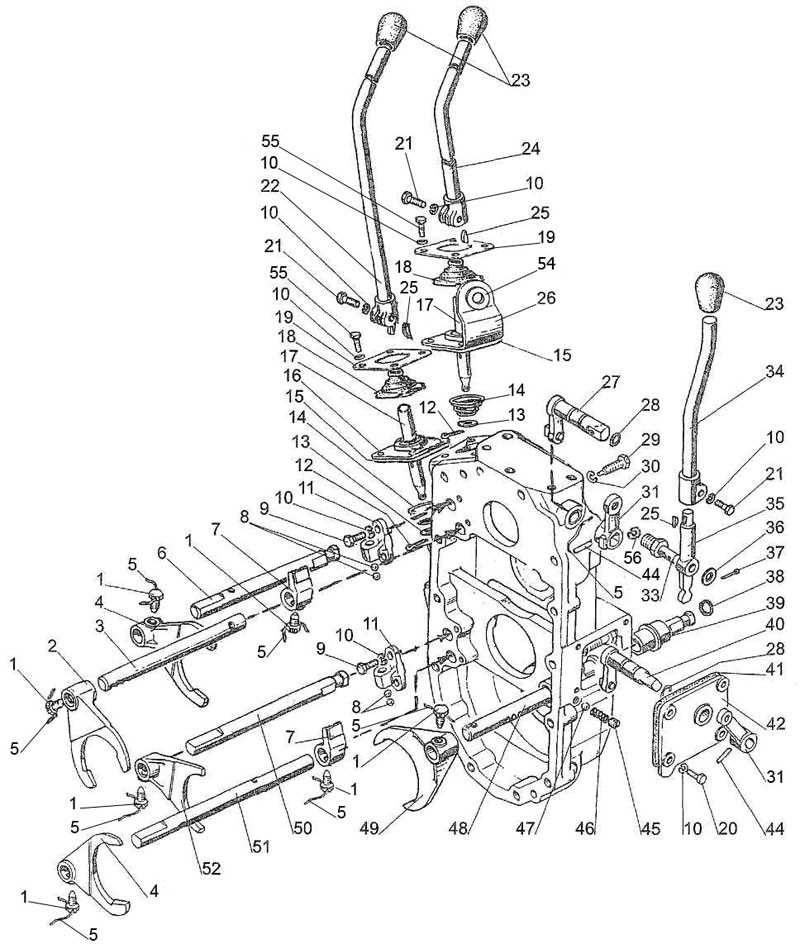

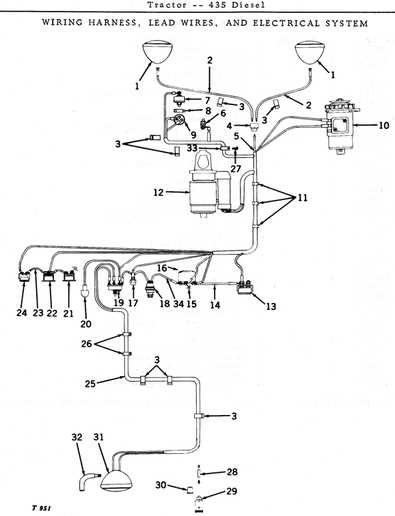

Exploring the Parts Diagram

Understanding the intricacies of machinery is essential for efficient operation and maintenance. A visual representation that outlines various components can significantly enhance one’s comprehension of how these elements work together. This section delves into the specifics of such a schematic, highlighting its importance in troubleshooting and repairs.

Component Breakdown

The illustration serves as a valuable resource, offering a detailed breakdown of individual elements. By analyzing this layout, operators can easily identify specific components, facilitating quicker access to necessary replacements or adjustments. A clear depiction fosters a deeper appreciation for the machine’s functionality, ensuring that users can optimize performance.

Maintenance Insights

Regular upkeep is crucial for longevity and efficiency. By consulting the visual guide, one can develop a routine maintenance plan tailored to the unique requirements of each segment. This proactive approach not only mitigates potential issues but also enhances overall productivity, making the machinery more reliable in the long run.

Comparative Analysis with Other Balers

This section delves into the evaluation of various agricultural machinery designed for hay and straw handling. By examining features, efficiency, and reliability, we can gain insights into how different models stack up against each other. Understanding these differences helps farmers and operators make informed decisions based on their specific needs and operational contexts.

Performance and Efficiency

When comparing these machines, performance metrics such as throughput and bale density are critical. Some models may excel in producing tighter bales, while others might offer higher speed, affecting overall productivity. It’s essential to assess how each option meets the demands of various crop types and field conditions to ensure optimal harvesting outcomes.

Maintenance and Durability

Another important aspect is maintenance requirements and the longevity of the equipment. Certain models might require more frequent servicing or have higher replacement part costs, which can impact long-term investment. Evaluating the durability of components can also shed light on expected operational lifespan, guiding users toward the most reliable choices.

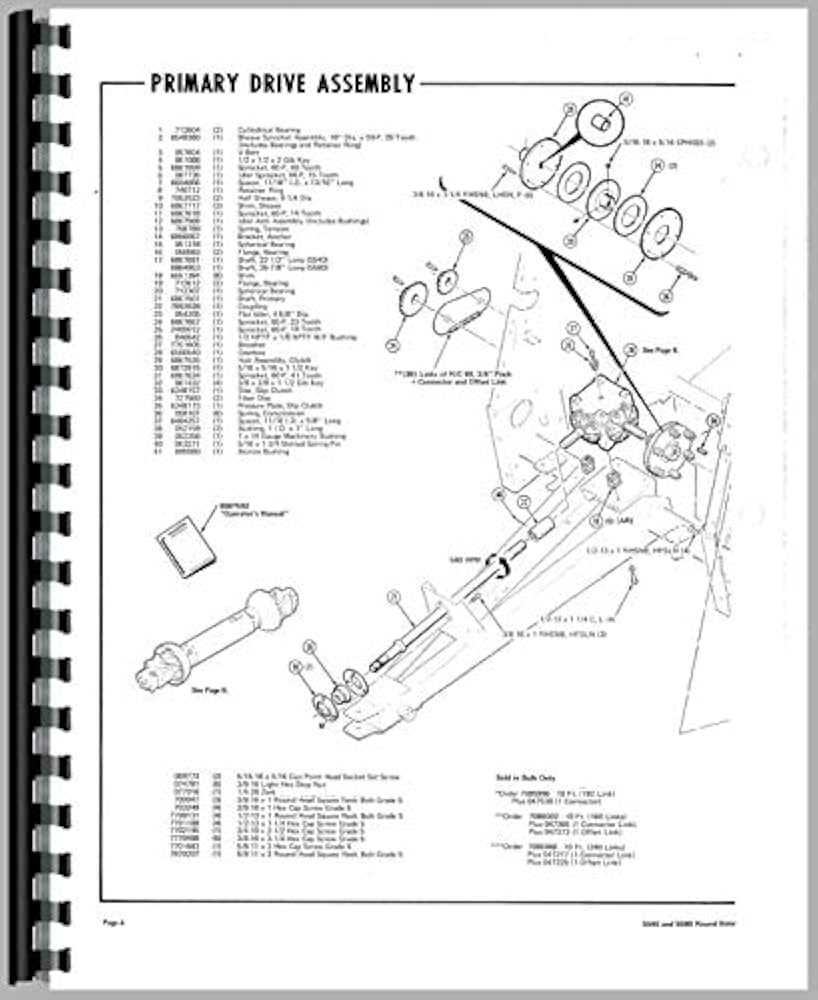

Upgrades and Modifications for Performance

Enhancing machinery efficiency through strategic improvements can lead to significant gains in productivity and reliability. Various modifications can be implemented to optimize operational capabilities, ensuring that the equipment meets the demands of modern agricultural practices. Focusing on specific components allows for tailored upgrades that can boost overall performance.

One effective approach is to upgrade the drive system. Implementing a more robust gearbox or higher-quality belts can improve power transfer and reduce slippage, leading to smoother operation. Additionally, fine-tuning the hydraulic system can enhance responsiveness and increase the speed of operation, allowing for quicker task completion.

Another area to consider is the cutting mechanism. Installing sharper blades or advanced cutting technology can result in cleaner cuts and reduce wear, extending the life of the equipment. Regular maintenance of these components, along with periodic upgrades, will ensure consistent performance during peak seasons.

Finally, integrating modern monitoring systems can provide real-time data on performance metrics. This allows for proactive adjustments and maintenance scheduling, ultimately enhancing efficiency and reducing downtime. By focusing on these areas, operators can ensure their machinery remains competitive in an evolving agricultural landscape.

User Experiences and Reviews

This section highlights the feedback and insights from users who have engaged with a specific type of agricultural equipment. Their experiences can provide valuable perspectives on performance, reliability, and overall satisfaction, which can aid potential buyers in making informed decisions.

Positive Feedback

Many users have reported excellent results when utilizing this machinery for their farming needs. Common praises include:

- Efficient operation, allowing for faster productivity.

- Robust build quality that withstands heavy use.

- Ease of maintenance, simplifying upkeep and repairs.

- Effective functionality in diverse field conditions.

Areas for Improvement

Despite the overall satisfaction, some users have pointed out certain drawbacks that could enhance their experience:

- Higher initial investment compared to similar models.

- Limited availability of certain components in local markets.

- Occasional issues with specific features that may require attention.

User reviews often emphasize the importance of understanding both the strengths and weaknesses of this equipment to ensure it aligns with individual farming operations. Engaging with the community can also provide ongoing support and insights for optimizing usage.