Maintaining outdoor machinery can often seem daunting, especially when it comes to identifying the various elements that contribute to its functionality. A comprehensive guide to the intricate components of your mower can greatly simplify the repair and upkeep process. By familiarizing yourself with these essential pieces, you empower yourself to tackle maintenance tasks with confidence.

In the realm of garden machinery, having a clear visual representation of the different segments can be invaluable. This not only aids in understanding how everything fits together but also highlights the importance of each component in the overall performance of the machine. Grasping this knowledge can lead to more informed decisions regarding repairs and replacements.

As you delve deeper into the specifics, recognizing the roles of various items will enhance your ability to troubleshoot issues effectively. Whether you’re replacing a worn-out element or upgrading a feature, a detailed overview of the machinery’s layout provides a solid foundation for any project. Knowledge of these integral parts ensures your equipment operates smoothly and efficiently for years to come.

Understanding John Deere LA110 Parts

Familiarizing oneself with the components of a lawn care machine is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring that the equipment operates smoothly, allowing users to achieve the best results in their gardening tasks.

Here are some key categories of components to consider:

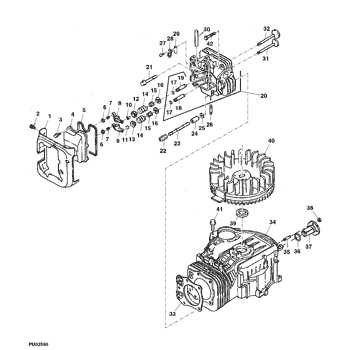

- Engine Elements: The heart of the machine, where power is generated.

- Transmission System: Responsible for transferring power from the engine to the wheels.

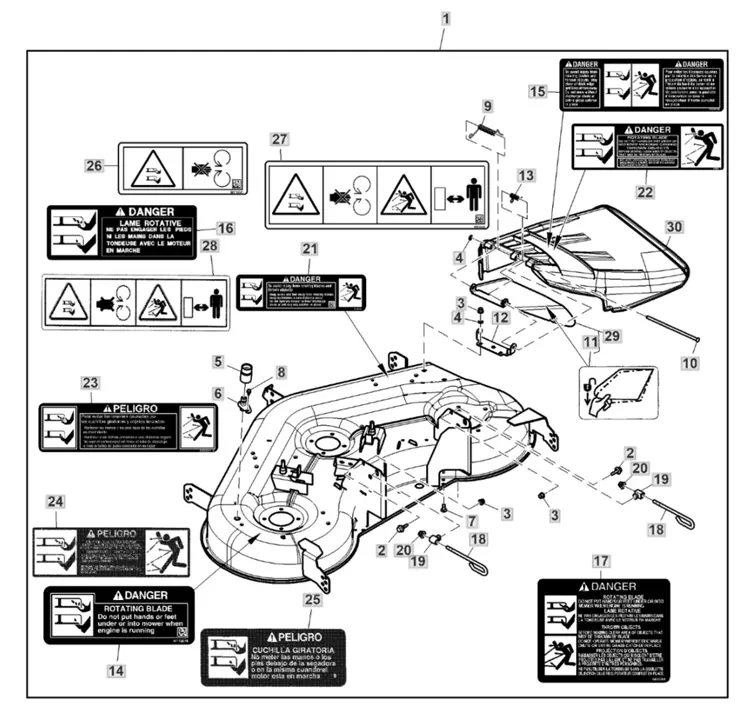

- Cutting Mechanism: Essential for achieving a clean and even cut on grass.

- Chassis and Frame: Provides structural integrity and support for all other components.

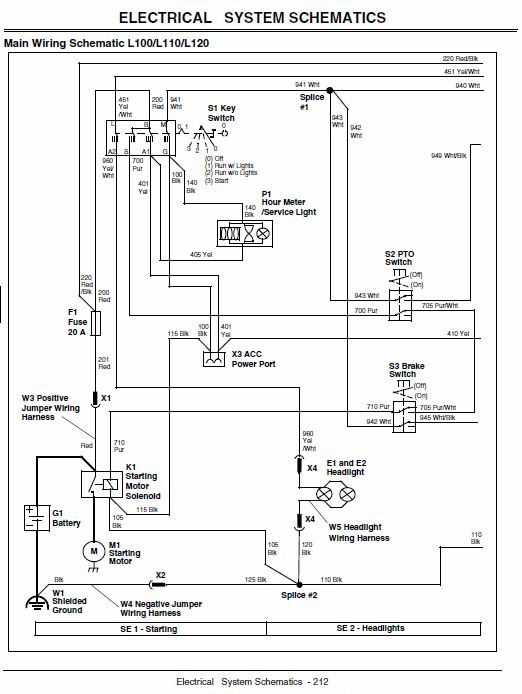

- Electrical System: Powers the ignition and other essential features.

Understanding these categories can help in identifying issues, performing repairs, or upgrading specific components. Knowledge of the machine’s construction will also enhance the user’s ability to maintain it properly.

Regular maintenance of these crucial elements ensures longevity and efficiency, allowing users to enjoy a well-maintained lawn throughout the seasons.

Key Components of the LA110 Model

The model’s design includes several essential elements that contribute to its overall functionality and efficiency. Each component plays a crucial role in ensuring optimal performance, making it a reliable choice for various landscaping tasks.

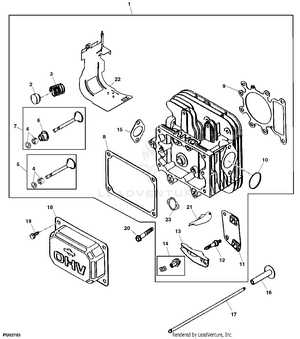

One of the primary features is the engine, which provides the necessary power to tackle demanding jobs. This robust unit is complemented by a well-engineered transmission system, allowing for smooth operation across different terrains.

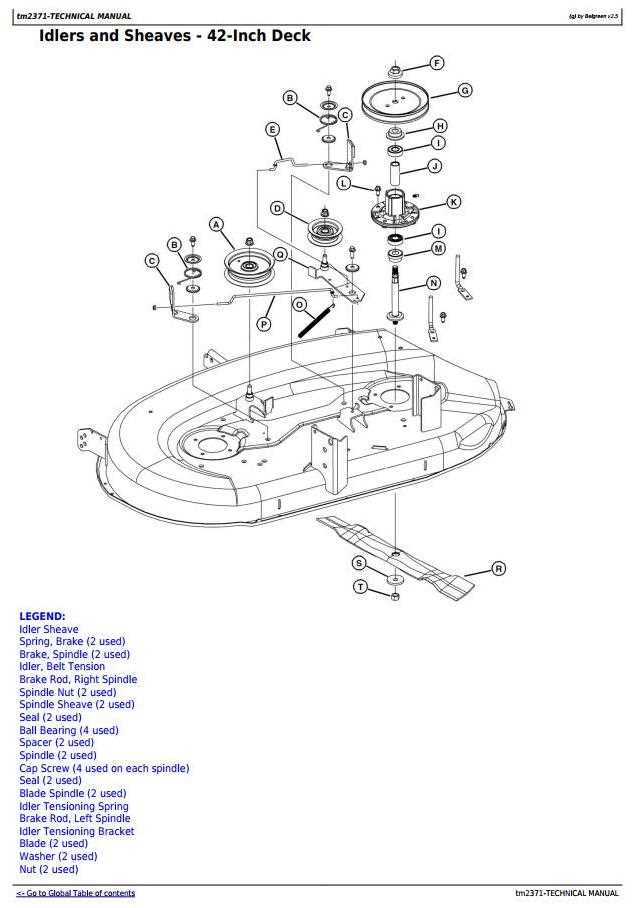

The cutting deck is another vital aspect, designed for precision and ease of use. Its sharp blades and adjustable height settings enable users to achieve a clean finish on lawns and gardens. Additionally, the chassis provides stability and durability, supporting the machine during operation.

Moreover, the steering system is crafted for user comfort and control, making navigation effortless. Safety features are also integrated, ensuring a secure experience while operating the equipment.

In summary, the intricate assembly of these components is what makes this model a dependable partner for outdoor maintenance, delivering both efficiency and effectiveness in every task.

Benefits of Using Original Parts

Utilizing authentic components in machinery enhances performance, reliability, and longevity. These specialized elements are designed to fit seamlessly, ensuring optimal functionality and safety. Investing in original pieces not only supports the equipment’s efficiency but also provides peace of mind regarding maintenance and repair.

| Advantage | Description |

|---|---|

| Quality Assurance | Original components are manufactured to meet strict standards, ensuring durability and superior performance. |

| Perfect Fit | These elements are engineered specifically for the machinery, minimizing the risk of compatibility issues. |

| Warranty Protection | Using genuine components often helps maintain the warranty of the equipment, protecting your investment. |

| Safety | Authentic parts reduce the likelihood of malfunctions, promoting a safer operating environment. |

| Enhanced Resale Value | Machines maintained with original components typically have a higher resale value due to their reliability. |

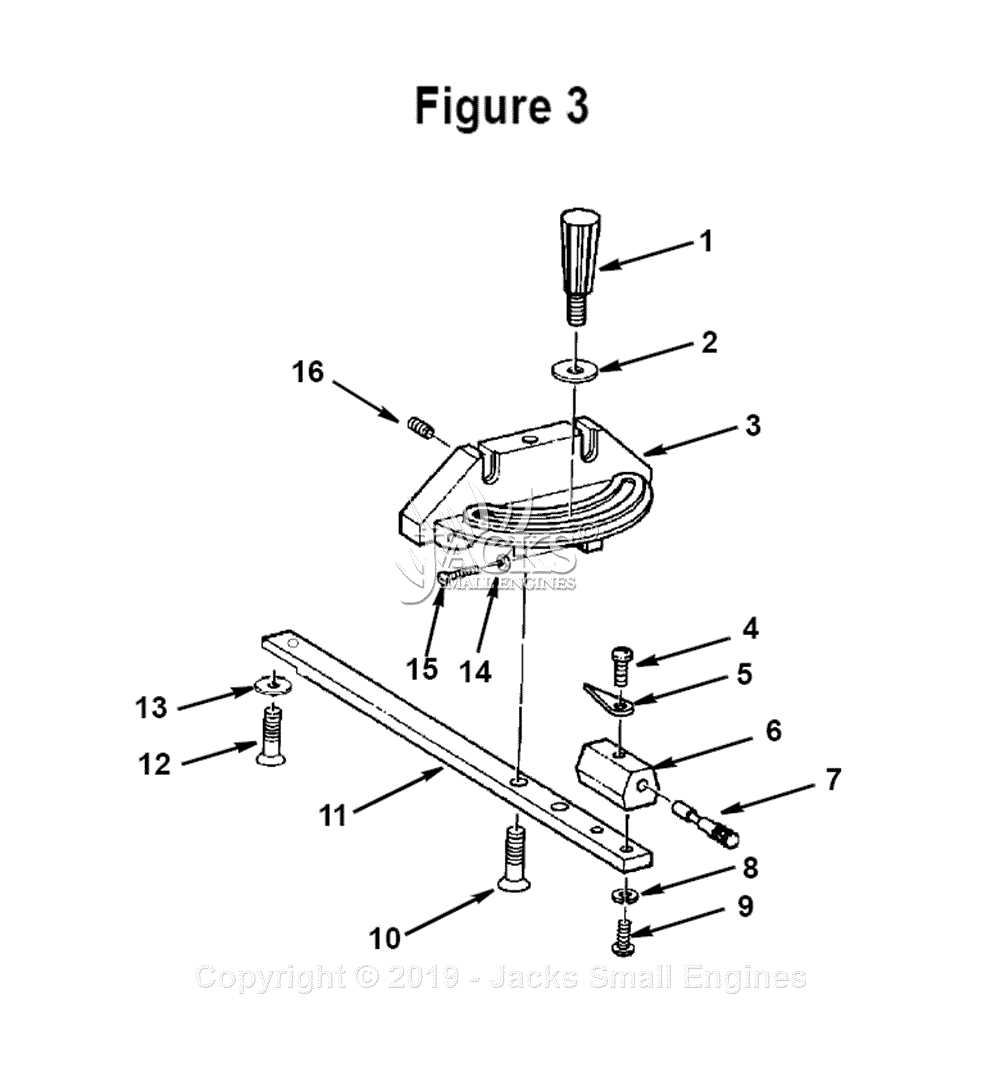

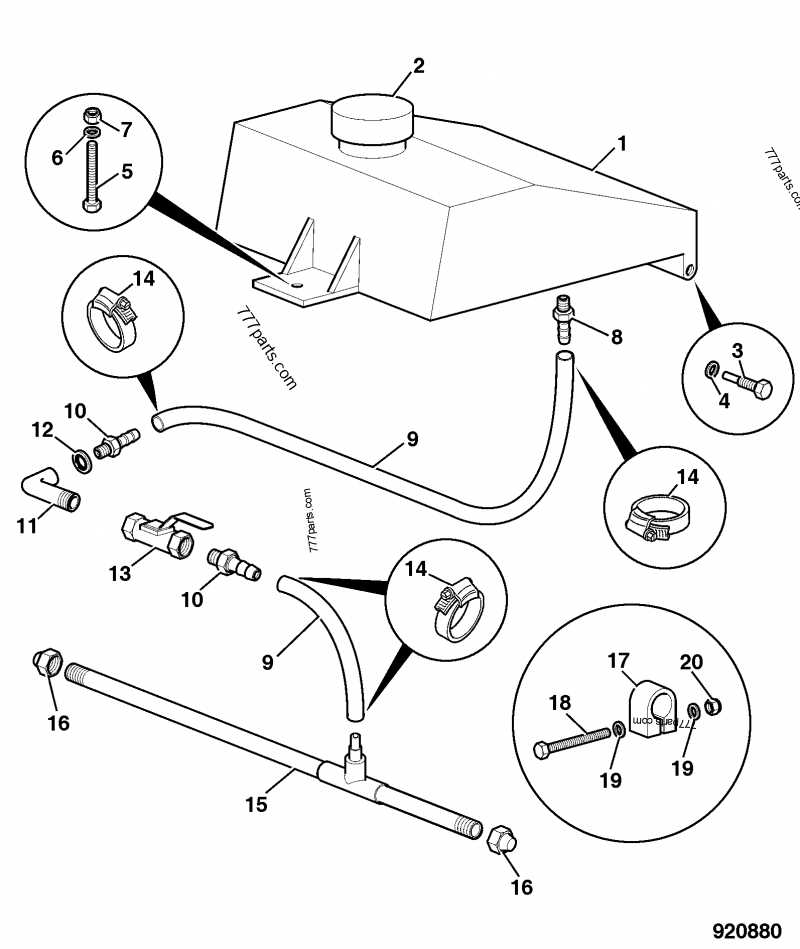

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visuals provide a comprehensive breakdown of components, allowing users to identify, source, and replace items as needed. A clear grasp of these representations enhances overall efficiency and reduces downtime.

Key Elements to Identify

Familiarize yourself with the primary features of the visual guide. Each segment usually includes numbers or codes corresponding to specific components, along with a reference list for easy identification.

Decoding the Legend

The accompanying legend is essential for interpreting the symbols and notations used. Each symbol often represents a particular function or type of part, making it easier to understand the assembly and its requirements.

| Symbol | Meaning |

|---|---|

| A | Fastener |

| B | Component |

| C | Connector |

Common Issues with LA110 Lawn Tractors

Lawn tractors can encounter a range of challenges that affect their performance and reliability. Understanding these common issues can help users maintain their equipment effectively and prolong its lifespan.

Engine Problems

One frequent concern involves the engine, which may exhibit difficulty starting or stalling during operation. Such issues can arise from various factors, including fuel quality, spark plug condition, or air filter blockages.

Cutting Deck Malfunctions

Another common problem pertains to the cutting deck, which may not engage properly or produce uneven grass cuts. This can result from dull blades, belt wear, or debris accumulation.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Poor fuel, spark plug issues | Check fuel quality, replace spark plugs |

| Uneven cutting | Dull blades, debris | Sharpen blades, clean deck |

Finding Replacement Parts Online

Locating the necessary components for machinery can be a daunting task, but the internet offers numerous resources to simplify this process. With just a few clicks, you can access various platforms that provide detailed catalogs and specifications, ensuring you find exactly what you need.

Where to Search

- Manufacturer’s Website

- Online Retailers

- Specialty Parts Suppliers

- Forums and Community Groups

Tips for Successful Searches

- Use specific terms related to the component.

- Check for compatibility with your equipment.

- Read customer reviews for quality assurance.

- Compare prices across different platforms.

Maintenance Tips for LA110 Owners

Proper upkeep is essential for maximizing the longevity and performance of your lawn equipment. Regular attention to specific components can prevent costly repairs and enhance overall efficiency.

1. Check Oil Levels: Regularly inspect and change the engine oil to ensure smooth operation. Clean oil contributes to the optimal functioning of internal parts.

2. Clean Air Filters: Keep air filters free from debris to maintain airflow and engine performance. A clean filter allows the engine to breathe efficiently.

3. Inspect Belts and Cables: Regularly examine belts and cables for wear or damage. Prompt replacements can prevent further issues and ensure reliable operation.

4. Sharpen Blades: Dull blades can damage grass and reduce cutting efficiency. Sharpen them periodically for a clean cut and healthier lawn.

5. Check Tire Pressure: Maintaining the correct tire pressure ensures optimal traction and maneuverability. Regularly inspect and adjust as needed.

6. Store Properly: When not in use, store equipment in a dry place to prevent rust and degradation. Covering it can protect against dust and moisture.

By adhering to these maintenance practices, owners can ensure their equipment remains in top condition for years to come.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining machinery, choosing the right components is crucial for optimal performance and longevity. Two main categories often come into play: original equipment manufacturer options and those produced by third-party vendors. Each type has its own set of advantages and disadvantages, making the decision a significant one for users.

Original options are typically crafted by the same company that produced the original machinery, ensuring compatibility and adherence to specific quality standards. On the other hand, alternative offerings can provide a more cost-effective solution, with varying levels of quality and compatibility.

- Quality Assurance: Original components generally come with a guarantee of quality, as they must meet strict manufacturing criteria.

- Cost: Third-party options often present a more budget-friendly alternative, though prices can vary widely based on the manufacturer.

- Availability: Aftermarket vendors may offer a wider selection, allowing users to find parts that are harder to locate through original sources.

- Warranty Considerations: Using original components often helps maintain warranties on the machinery, while third-party options may void such guarantees.

Ultimately, the choice between original and alternative components hinges on individual priorities, including budget, quality requirements, and the specific needs of the machinery in question.

Resources for Troubleshooting Issues

When facing challenges with machinery, having access to the right resources is crucial for effective resolution. Various tools and guides can assist in identifying problems and implementing solutions efficiently. Utilizing these materials can ultimately enhance performance and prolong the life of the equipment.

Online Forums: Engaging with communities online provides valuable insights from experienced users. These platforms often feature discussions that can help pinpoint common issues and solutions.

Manufacturer Manuals: Consulting official manuals offers detailed information about maintenance and troubleshooting. These documents typically include diagrams and step-by-step instructions for repairs.

YouTube Tutorials: Visual learners may find video tutorials particularly helpful. These resources demonstrate repair processes, allowing users to follow along and grasp complex tasks more easily.

Local Repair Shops: Seeking advice from professionals can provide tailored guidance. Local experts often have practical experience and can offer solutions based on firsthand knowledge.

Technical Support: Contacting customer service can yield specific assistance related to the equipment. Support teams are equipped to address unique concerns and may offer insights not found in manuals.