A comprehensive exploration of agricultural equipment reveals the intricate systems that enable efficient land cultivation. Within this context, grasping the configuration and functionality of various implements is essential for optimal performance in the field. The mechanics involved not only enhance productivity but also contribute to the longevity of the machinery.

To effectively maintain and operate these tools, it is crucial to have a clear representation of their individual elements. By examining the layout of components, operators can better understand how each part interacts within the larger system. This knowledge is invaluable for troubleshooting issues and conducting repairs, ensuring that the equipment remains in peak condition.

Furthermore, a detailed look at the structure of these implements can illuminate best practices for usage and maintenance. This insight empowers users to make informed decisions, ultimately leading to improved outcomes in agricultural operations. The ability to visualize and comprehend the relationships between parts plays a pivotal role in fostering efficiency and effectiveness in farming activities.

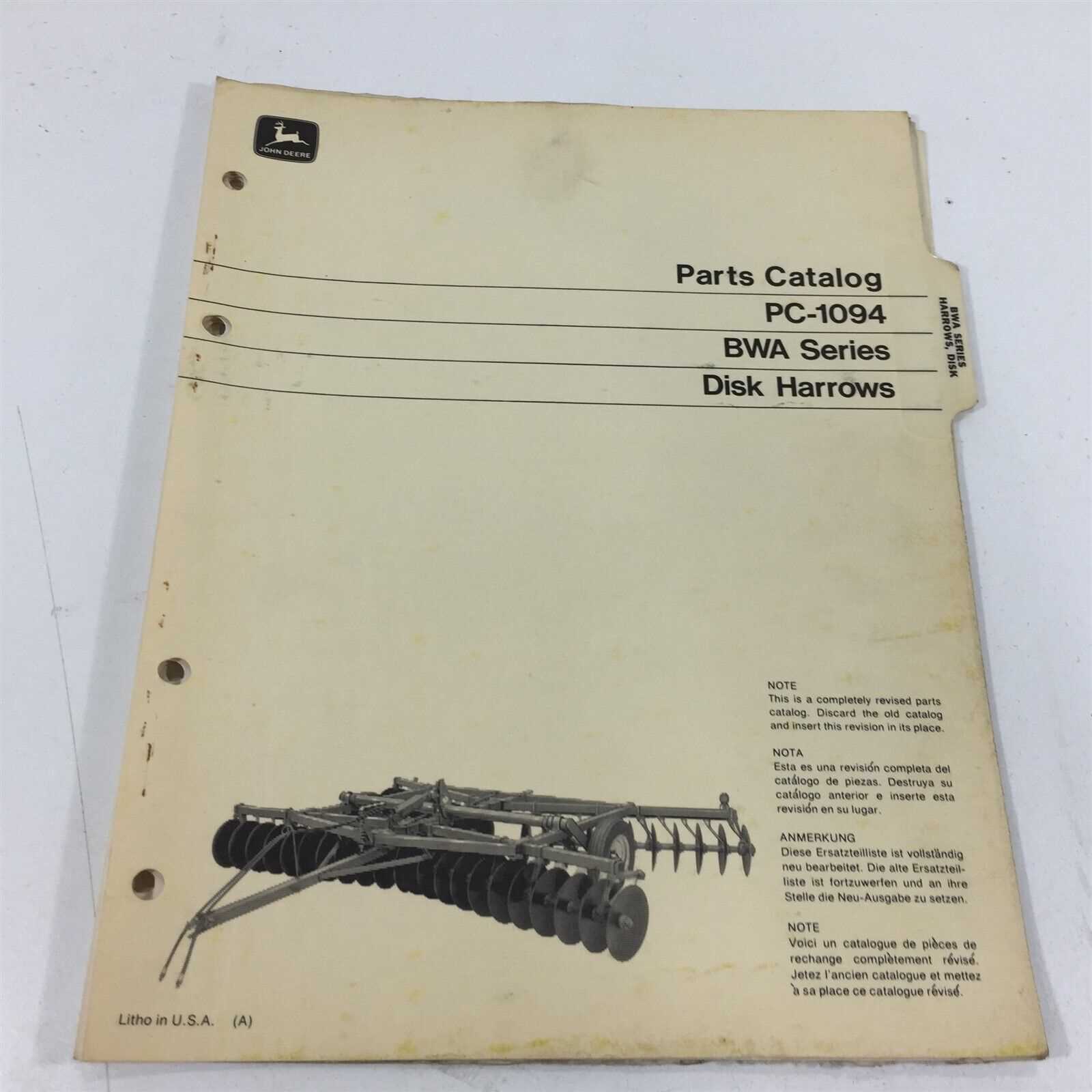

Understanding John Deere BW Disc Components

Grasping the intricacies of the implements used in agricultural practices is essential for maximizing efficiency and performance. Various elements work together to create a cohesive unit that facilitates soil preparation and cultivation. By examining these components, one can appreciate their roles and interactions within the larger system.

Each section of the equipment serves a specific function, contributing to the overall effectiveness of the machinery. The arrangement and design of these components are carefully considered to ensure optimal performance. Knowing how each piece operates not only enhances the user’s experience but also aids in maintenance and troubleshooting.

In addition, familiarity with the assembly allows for informed decision-making regarding repairs and upgrades. Understanding the interplay between different elements can lead to better management practices and improved outcomes in the field. Overall, a comprehensive grasp of these implements supports successful agricultural endeavors.

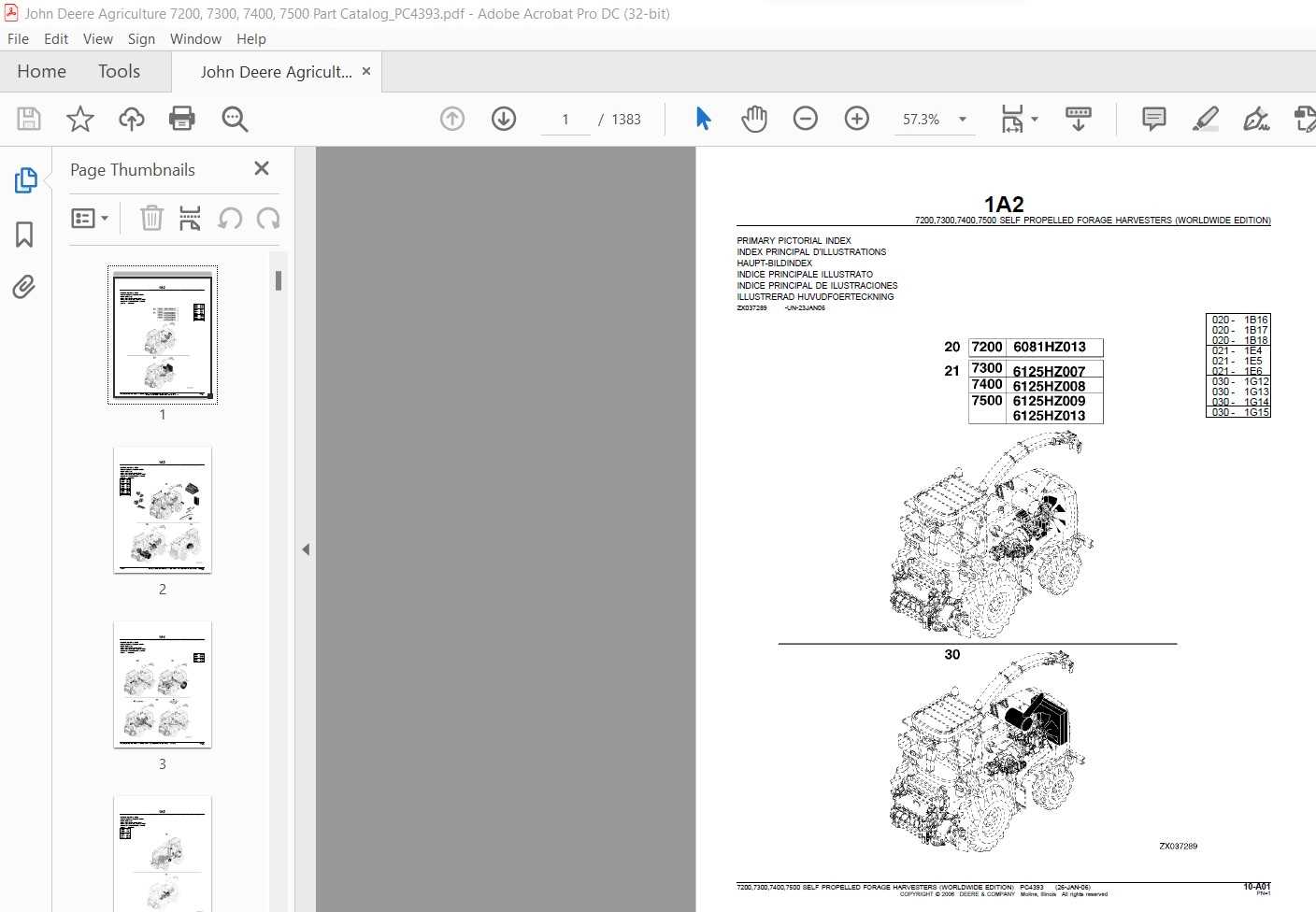

Importance of Accurate Parts Diagrams

Precision in technical illustrations is essential for ensuring the efficient functioning of machinery. When users have access to well-crafted visual guides, they can easily identify components, understand their roles, and perform maintenance tasks with confidence. This clarity reduces the likelihood of errors during repairs and enhances overall equipment longevity.

Facilitating Maintenance and Repairs

Having clear and detailed visual references allows operators to conduct maintenance effectively. When individuals can quickly locate and understand the configuration of various elements, they can streamline the repair process. This not only saves time but also minimizes the risk of damage to other parts during handling.

Enhancing Training and Safety

Accurate technical illustrations play a crucial role in training new personnel. When trainees can refer to precise images, they develop a better understanding of equipment functions and safety protocols. This familiarity fosters a safer working environment, as individuals are less likely to make mistakes that could lead to accidents.

In conclusion, reliable visual guides are invaluable for maintaining operational efficiency and safety. The benefits of clarity in machinery illustrations cannot be overstated, making them an essential tool for any equipment user.

Common Issues with BW Disc Parts

When operating agricultural machinery, users often encounter various complications that can hinder performance and efficiency. Recognizing these challenges is crucial for maintaining optimal functionality and prolonging the lifespan of the equipment. Below are some frequently observed problems associated with specific components.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Over time, components may experience degradation due to regular use. | Regular inspections and timely replacements can mitigate this issue. |

| Misalignment | Components may become misaligned, leading to uneven operation. | Adjustments and realignment can restore proper functionality. |

| Rust and Corrosion | Exposure to moisture can cause rusting and deterioration of metal parts. | Applying protective coatings and storing equipment in dry conditions can help. |

| Hydraulic Issues | Leaks or failures in hydraulic systems can impair operation. | Regular maintenance and timely repairs of hydraulic lines and fittings are essential. |

| Improper Lubrication | Lack of lubrication can lead to increased friction and component failure. | Establish a routine lubrication schedule to ensure smooth operation. |

Step-by-Step Assembly Instructions

When it comes to putting together your agricultural equipment, following a structured approach is essential for achieving optimal performance. This section provides a clear guide to assembling the various components effectively, ensuring that each piece fits seamlessly into the whole. By adhering to these detailed steps, you can enhance both the functionality and longevity of your machinery.

Gathering Tools and Components

Before you begin the assembly process, ensure that you have all necessary tools and components at hand. Check that each item is free from damage and corresponds to the specifications required for assembly. Common tools needed may include wrenches, screwdrivers, and pliers. Organizing these items beforehand can save time and streamline the process.

Step-by-Step Assembly Process

1. Start by laying out all components in a designated workspace to maintain order. This will help you visualize the assembly and identify each part’s placement.

2. Follow the instruction manual closely, ensuring that you attach each component in the correct sequence. Pay attention to alignment and fit, as improper assembly can lead to functionality issues.

3. Secure each piece using the appropriate fasteners, making sure they are tightened but not overdone, which could cause damage.

4. Once fully assembled, conduct a thorough inspection to confirm that all parts are correctly positioned and secured before using the equipment.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your agricultural machinery requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also reduces the likelihood of unexpected breakdowns, leading to more productive operations. This section outlines essential practices that can help achieve optimal functionality.

Routine Inspections

Conducting regular inspections is critical for identifying wear and tear before it escalates into significant issues. Focus on key components, checking for signs of damage or misalignment. Keeping a maintenance log can help track inspections and repairs over time.

Lubrication and Cleaning

Proper lubrication reduces friction, preventing parts from wearing down prematurely. Ensure that all moving elements are adequately lubricated according to the manufacturer’s guidelines. Additionally, regular cleaning helps eliminate debris that could impair performance and lead to malfunctions.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for obvious wear or damage. |

| Lubrication | Monthly | Follow manufacturer’s recommendations. |

| Cleaning | After Use | Remove dirt and debris to prevent build-up. |

| Component Replacement | As Needed | Replace worn components immediately. |

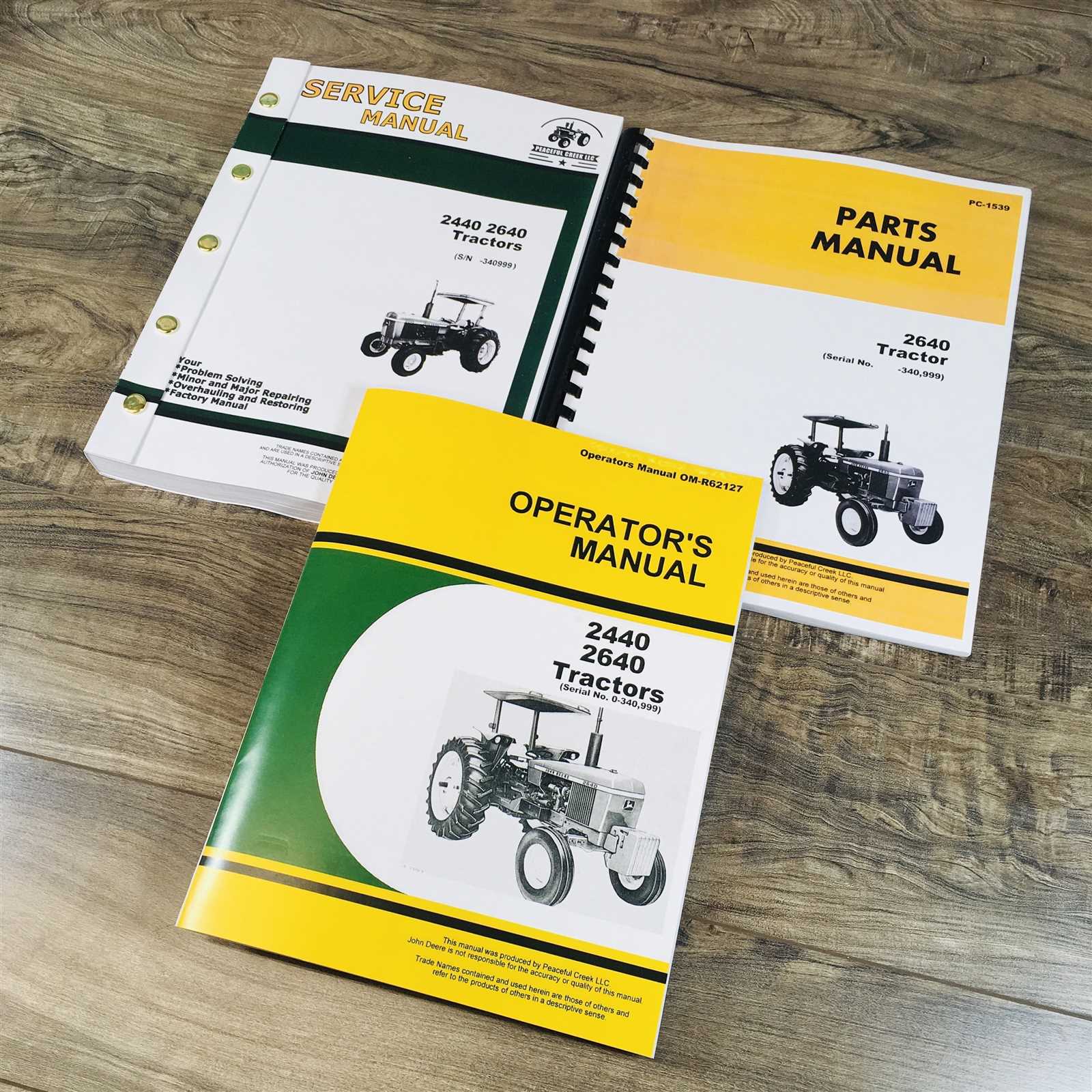

Where to Find Replacement Parts

Locating suitable components for your agricultural equipment is essential for maintaining efficiency and performance. Various sources offer a range of options, from authorized dealers to online retailers. Understanding where to look can save time and ensure you acquire high-quality replacements.

Authorized dealerships often provide genuine items, ensuring compatibility and reliability. Visiting these establishments can also grant access to expert advice and additional services. Additionally, many manufacturers maintain online catalogs, allowing you to browse their inventory conveniently.

For those seeking competitive pricing, third-party suppliers and e-commerce platforms can be excellent alternatives. These vendors typically offer a variety of aftermarket solutions that can fit your requirements without compromising on quality. It’s crucial to check customer reviews and ratings to ensure the credibility of these sources.

Local agricultural supply stores might also stock essential components. Establishing a relationship with your local provider can lead to personalized service and valuable recommendations tailored to your needs.

Finally, online forums and community groups can be rich resources for information on where to find specific items. Engaging with fellow equipment owners may lead to discovering lesser-known suppliers or helpful insights about alternative options.

Comparing Models: BW Disc Variants

This section explores the various models within the BW lineup, highlighting their unique features and specifications. Each variant is designed to meet specific agricultural needs, offering different benefits to users. Understanding these differences can aid in selecting the most suitable option for individual farming practices.

| Model | Working Width | Weight | Number of Blades | Depth Adjustment |

|---|---|---|---|---|

| Variant A | 12 ft | 3,200 lbs | 24 | Manual |

| Variant B | 14 ft | 3,600 lbs | 28 | Hydraulic |

| Variant C | 16 ft | 4,000 lbs | 32 | Manual |

| Variant D | 18 ft | 4,500 lbs | 36 | Hydraulic |

When comparing these models, consider the specific requirements of your land and the type of cultivation you intend to perform. Each model offers a different combination of size, weight, and adjustability, making it essential to evaluate which features align best with your agricultural goals.

User Experiences and Troubleshooting

This section delves into the shared experiences of users, highlighting common challenges and solutions encountered during operation. Insights from various operators reveal that familiarity with equipment can significantly enhance performance and longevity.

Common Issues: Users frequently report issues such as uneven wear and tear, difficulties in calibration, and unexpected mechanical failures. Understanding these problems is crucial for effective maintenance.

Troubleshooting Tips: Many operators recommend regular inspections to identify potential wear spots before they escalate into serious malfunctions. Checking alignment and ensuring proper lubrication are essential steps that can prevent many common issues.

Community Feedback: Engaging with fellow users through forums and support groups has proven invaluable. Sharing experiences not only fosters a sense of community but also provides practical solutions based on real-world use.

Conclusion: By leveraging user insights and implementing proactive maintenance strategies, operators can enhance the reliability and efficiency of their equipment, ultimately leading to improved outcomes in their agricultural tasks.

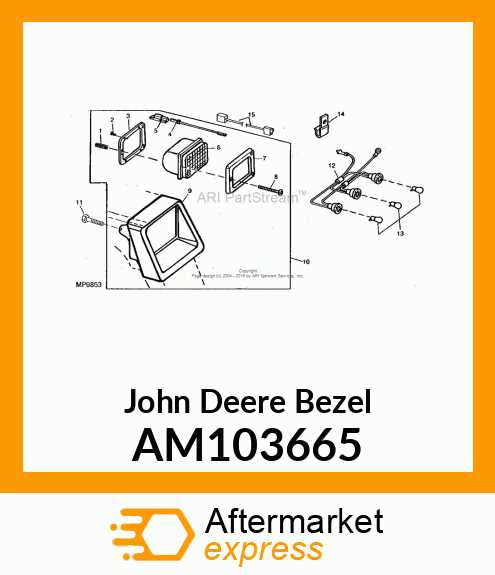

Benefits of Using Genuine John Deere Parts

Utilizing authentic components for your equipment ensures optimal performance, longevity, and reliability. These original items are specifically designed to work seamlessly with your machinery, enhancing its efficiency and maintaining its value over time. Choosing genuine products can save you from frequent repairs and unexpected breakdowns, ultimately reducing operational costs.

Quality Assurance

Original components undergo rigorous testing and quality control to meet the highest industry standards. This commitment to excellence guarantees that each item performs as expected, reducing the likelihood of malfunction.

Compatibility and Performance

Authentic components are engineered to fit perfectly within your machinery, ensuring smooth operation and optimal functionality. This compatibility minimizes wear and tear, contributing to the overall health of your equipment.

| Benefit | Description |

|---|---|

| Reliability | Reduces the risk of equipment failure and downtime. |

| Longevity | Extends the lifespan of your machinery through superior materials. |

| Warranty Protection | Maintains warranty validity, safeguarding your investment. |

| Resale Value | Increases resale value by ensuring the machine is in top condition. |