When it comes to modern farming, the efficiency of machinery plays a crucial role in maximizing productivity. Each piece of equipment consists of numerous elements that work together seamlessly to ensure optimal performance. Understanding these components is essential for maintenance, troubleshooting, and enhancing overall functionality.

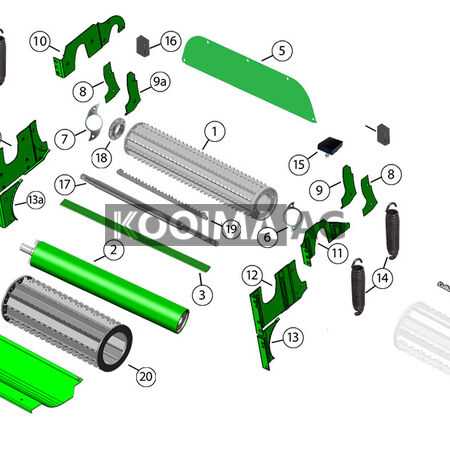

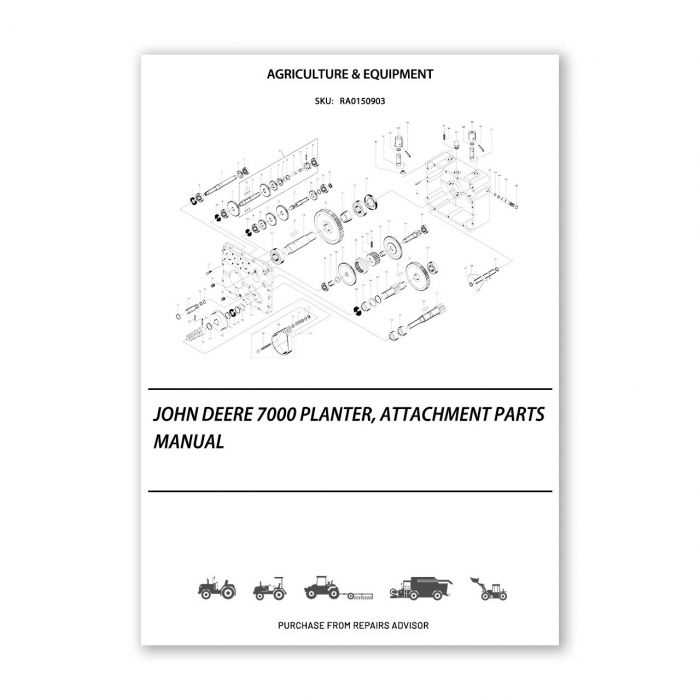

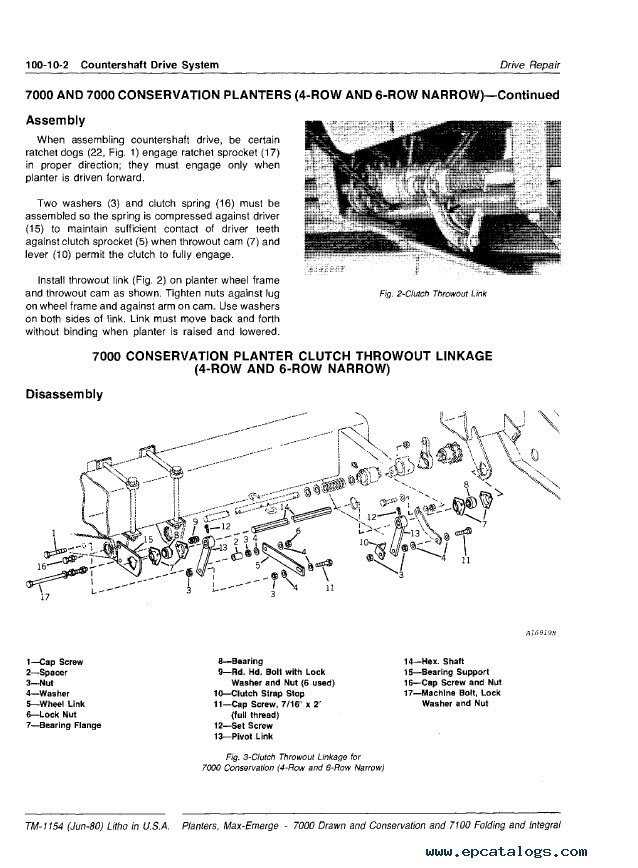

Detailed schematics serve as invaluable resources for operators and technicians alike. They provide clear visual representations of each component, making it easier to identify, replace, or repair parts as needed. With a thorough grasp of these illustrations, one can navigate the intricacies of their equipment with confidence.

Moreover, exploring the connections and relationships between different elements not only aids in practical applications but also deepens the appreciation for the engineering that goes into creating reliable machinery. This knowledge empowers users to make informed decisions that can lead to improved efficiency and longevity of their agricultural tools.

Understanding John Deere 7000 Parts

Comprehending the components of agricultural machinery is essential for effective maintenance and operation. Each element plays a crucial role in ensuring the overall functionality and efficiency of the equipment. A thorough understanding of these elements enables operators to make informed decisions regarding repairs and replacements, ultimately enhancing productivity.

Key Components and Their Functions

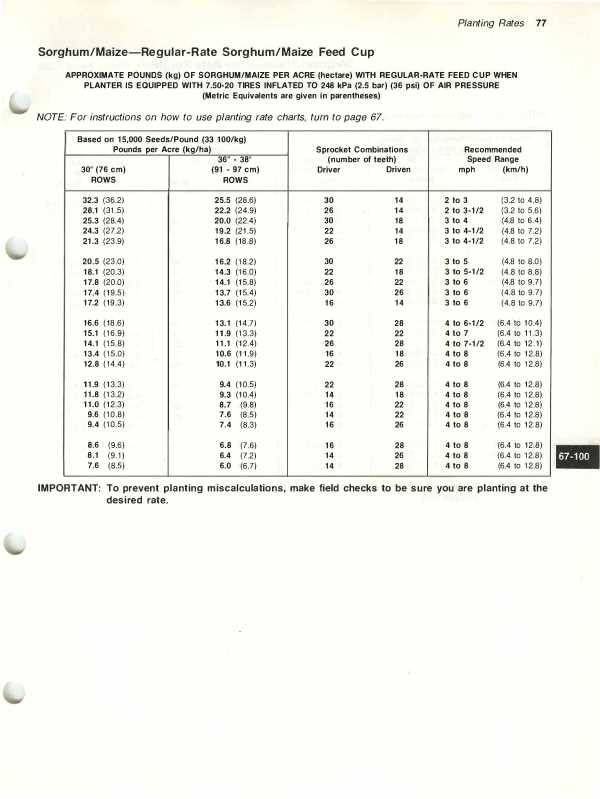

Recognizing the main elements is vital for troubleshooting and upkeep. These include the transmission system, which facilitates power transfer, and the hydraulic components, responsible for various movements and adjustments. Additionally, the seed metering system ensures precise planting, while the frame provides the structural integrity necessary for stability during operation.

Maintenance and Replacement Insights

Regular inspection and timely replacement of worn-out components are crucial for sustaining performance. Operators should familiarize themselves with the signs of wear and damage, as early detection can prevent more significant issues. Access to comprehensive information on these elements will empower users to maintain their machinery effectively and prolong its lifespan.

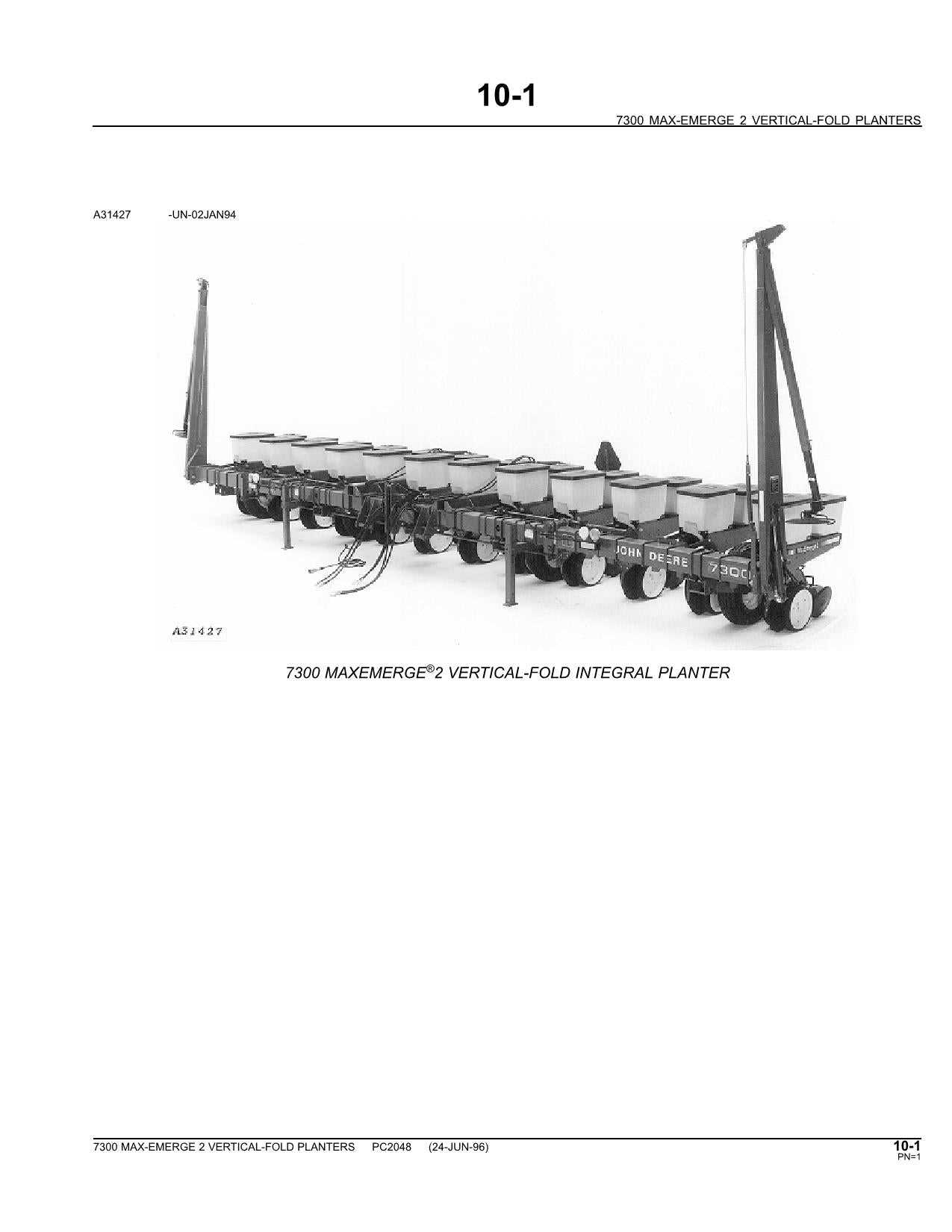

Overview of John Deere 7000 Series

The series represents a significant advancement in agricultural machinery, designed to enhance efficiency and productivity on the field. This lineup is known for its durability, precision, and innovative features that cater to the needs of modern farming.

Key Features

- Robust construction ensuring longevity in demanding environments.

- Advanced planting technology for improved seed placement.

- Adjustable settings for various soil types and crop requirements.

- User-friendly controls and instrumentation for ease of operation.

Benefits for Farmers

- Increased yield potential through accurate planting.

- Reduced labor costs with efficient machinery operation.

- Enhanced soil health with minimal disturbance techniques.

- Compatibility with a range of attachments for versatile use.

Key Components of the 7000 Model

The effectiveness of this agricultural equipment is largely determined by its essential elements. Understanding these components helps operators maximize performance and ensure efficient operation. Each part plays a specific role in the overall functionality, contributing to the machine’s reliability and effectiveness in the field.

Main Functional Elements

- Transmission System: Facilitates power transfer from the engine to the wheels, allowing for smooth operation across various terrains.

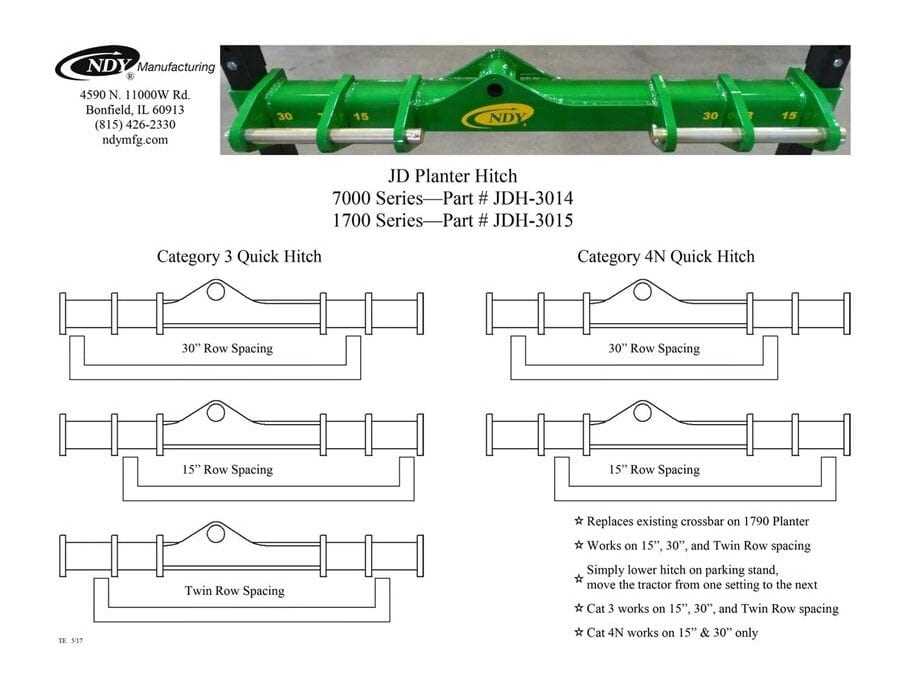

- Hitch Mechanism: Connects the implement to the tractor, ensuring stability and control during use.

- Engine: The heart of the machinery, providing the necessary power for all operations.

- Steering Assembly: Enables precise control and maneuverability, crucial for navigating tight spaces.

Supportive Components

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

- Electrical System: Powers lights, sensors, and other electronic components for enhanced functionality.

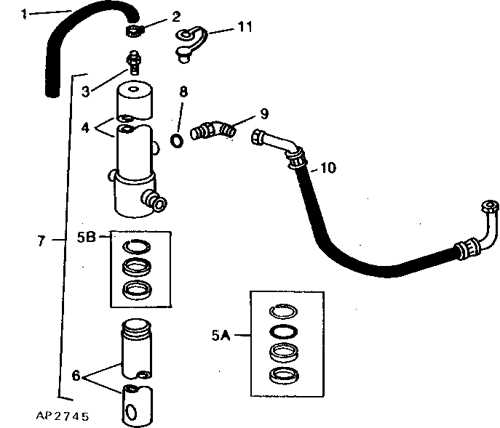

- Hydraulic System: Facilitates lifting and lowering of attachments, improving versatility and efficiency.

- Chassis: Provides structural integrity, supporting the weight of all components while withstanding field conditions.

How to Read Parts Diagrams

Understanding the visual representation of components is crucial for effective maintenance and repair. These illustrations serve as a valuable tool for identifying individual elements, their functions, and how they fit together. By mastering this skill, users can efficiently navigate through the assembly, leading to quicker troubleshooting and replacement processes.

Key Elements to Identify

When examining these illustrations, it’s important to familiarize yourself with various aspects. Here are some essential elements to look for:

| Element | Description |

|---|---|

| Numbers | Often assigned to each component, aiding in reference to a list of parts. |

| Lines | Indicate how parts connect or relate to each other. |

| Labels | Provide names or specifications for each element, clarifying their roles. |

Steps to Interpret Effectively

To effectively decode these visuals, follow these steps:

- Start by identifying the overall layout and orientation.

- Locate the reference numbers and match them with the accompanying list.

- Trace the connections to understand how each piece interacts within the system.

- Take note of any special markings that indicate unique functions or requirements.

Common Issues with John Deere 7000

When operating agricultural machinery, users often encounter a variety of challenges that can hinder efficiency and productivity. Understanding these common issues can help in preventive maintenance and timely repairs.

Mechanical Failures

- Wear and tear on components leading to breakdowns.

- Alignment problems causing uneven performance.

- Hydraulic leaks affecting operation.

Electrical Problems

- Faulty wiring leading to power issues.

- Sensor malfunctions impacting functionality.

- Battery failures resulting in starting difficulties.

Finding Replacement Parts Efficiently

Locating suitable components for your machinery can often seem daunting. However, with a structured approach, you can simplify the process and ensure you acquire the necessary items quickly and effectively. Understanding how to navigate resources and identify specific elements is key to minimizing downtime and maintaining optimal performance.

Begin by categorizing your requirements. Knowing whether you need mechanical, electrical, or hydraulic elements will streamline your search. Utilize online platforms, manuals, and dealer networks to gather information on available options.

| Category | Resources | Tips |

|---|---|---|

| Mechanical | Online retailers, local distributors | Check reviews for reliability |

| Electrical | Manufacturer’s website, technical forums | Consult guides for compatibility |

| Hydraulic | Specialty suppliers, repair shops | Inquire about warranties |

Lastly, don’t hesitate to seek advice from professionals or fellow operators. Sharing experiences and recommendations can lead to valuable insights, making your search for the right components not only efficient but also effective.

Maintenance Tips for Optimal Performance

Ensuring that agricultural equipment operates at its best requires regular upkeep and attention. By following a few essential maintenance practices, you can enhance the longevity and efficiency of your machinery, leading to better productivity in the field.

- Regular Inspections: Frequently check all components for wear and tear. Look for signs of damage, rust, or loose parts.

- Lubrication: Keep all moving parts properly lubricated to reduce friction and prevent premature wear. Use the recommended oils and greases for optimal results.

- Filter Replacement: Change air, fuel, and hydraulic filters as needed to ensure clean operation. Clogged filters can lead to decreased performance.

- Calibrate Settings: Regularly check and adjust settings according to manufacturer guidelines. Proper calibration ensures that your equipment operates efficiently.

- Cleanliness: Maintain a clean environment for your equipment. Regularly wash off dirt and debris to prevent buildup that can cause issues over time.

- Storage: Store machinery in a dry, sheltered area to protect it from the elements. Use covers when possible to further shield it from moisture and dust.

By adhering to these maintenance tips, you can achieve optimal performance and extend the life of your agricultural equipment, ensuring that it remains reliable when you need it most.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the performance and longevity of machinery. These components are specifically designed to fit and function seamlessly with the equipment, ensuring optimal operation and reducing the risk of malfunctions.

One of the primary benefits of employing these components is their superior quality and reliability. Manufactured to the highest standards, they undergo rigorous testing to guarantee durability and performance under various conditions. This reliability translates into decreased downtime and maintenance costs, allowing users to focus on productivity.

Another significant advantage is the assurance of compatibility. OEM components are crafted to meet precise specifications, ensuring a perfect match with existing systems. This compatibility not only simplifies installation but also minimizes the likelihood of further issues arising from improper fittings or mismatched parts.

Moreover, investing in original components can lead to enhanced resale value. Equipment maintained with high-quality, manufacturer-recommended parts typically retains its value better, appealing to potential buyers who prioritize reliability and performance. In the long run, this can be a strategic financial decision for any operator.

Finally, choosing OEM components supports the manufacturer’s commitment to quality and innovation. By using these original items, operators contribute to a cycle of improvement and sustainability within the industry, promoting advancements that benefit all users.

Resources for Parts and Support

Accessing the right resources for machinery components and assistance is crucial for optimal performance and longevity. Here are various avenues to explore for acquiring necessary items and support services.

Online Resources

- Manufacturer Websites: Official platforms often provide catalogs and guides.

- Online Marketplaces: Platforms like eBay and Amazon feature listings from various sellers.

- Specialized Forums: Community discussions can offer insights and recommendations.

Local Support

- Authorized Dealers: Local representatives can offer genuine components and expert advice.

- Repair Shops: Experienced technicians can assist with both parts and repairs.

- Trade Shows: Industry events allow for direct connections with suppliers and networking.