When it comes to maintaining small engines, a clear understanding of their individual elements is crucial for optimal performance. This knowledge empowers users to troubleshoot issues effectively and ensure long-lasting operation. In this guide, we will explore various components that contribute to the efficiency of a specific engine model.

Familiarizing yourself with the intricate layout of these mechanisms not only aids in maintenance but also enhances your overall mechanical insight. By dissecting the functionality of each part, enthusiasts and professionals alike can delve deeper into repair and enhancement strategies.

Ultimately, having access to a comprehensive visual reference can streamline your maintenance tasks and inspire confidence in your repair abilities. As we examine the specific sections of this engine, you will gain the tools needed to address common challenges and elevate your understanding.

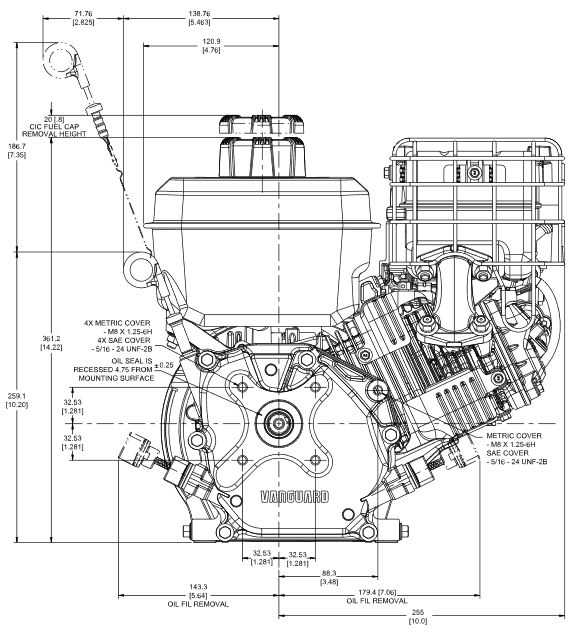

Understanding Vanguard Engine Components

Engines are complex machines made up of various elements that work together to provide power and efficiency. A clear comprehension of these components is crucial for maintenance and troubleshooting. Each piece plays a specific role, contributing to the overall functionality and performance of the engine.

Key Components include the cylinder block, which houses the cylinders and provides structural support. The crankshaft converts linear motion into rotational force, essential for driving the output. The camshaft controls the opening and closing of the intake and exhaust valves, regulating airflow and fuel mixture.

Additionally, the fuel system is vital, delivering the necessary fuel to the combustion chamber. The ignition system generates the spark that ignites the fuel-air mixture, initiating combustion. Understanding how these elements interact can significantly enhance one’s ability to manage engine performance and longevity.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any machinery. By implementing consistent care practices, users can prevent unexpected failures and enhance overall performance. This proactive approach not only safeguards investments but also ensures reliability in operation.

Key Benefits of Maintenance

- Reduces the risk of major breakdowns.

- Enhances efficiency and performance.

- Increases safety for operators.

- Minimizes repair costs over time.

Best Practices for Effective Maintenance

- Conduct regular inspections to identify wear and tear.

- Follow manufacturer guidelines for servicing.

- Replace worn components promptly.

- Keep machinery clean to prevent buildup.

Key Features of 35 HP Engines

The 35 horsepower engines are designed to deliver reliable performance across various applications, making them a popular choice for both commercial and residential use. These power sources are characterized by their robust construction, efficient operation, and versatility, catering to a wide range of equipment and machinery needs.

Performance and Efficiency

One of the standout attributes of 35 HP engines is their ability to provide consistent power while maintaining fuel efficiency. This balance enables users to maximize productivity without incurring high operational costs. The engineering behind these engines ensures that they can handle demanding tasks while minimizing environmental impact.

Durability and Maintenance

Constructed with high-quality materials, these engines are built to withstand rigorous use over extended periods. Their design allows for easy maintenance, which helps in prolonging lifespan and ensuring optimal performance. Regular upkeep is simplified, making it convenient for operators to keep the machinery in top condition.

| Feature | Description |

|---|---|

| Power Output | Delivers 35 HP, suitable for various applications |

| Fuel Efficiency | Optimized to reduce fuel consumption while maximizing output |

| Durability | Constructed with robust materials for long-lasting use |

| Ease of Maintenance | Designed for straightforward service and upkeep |

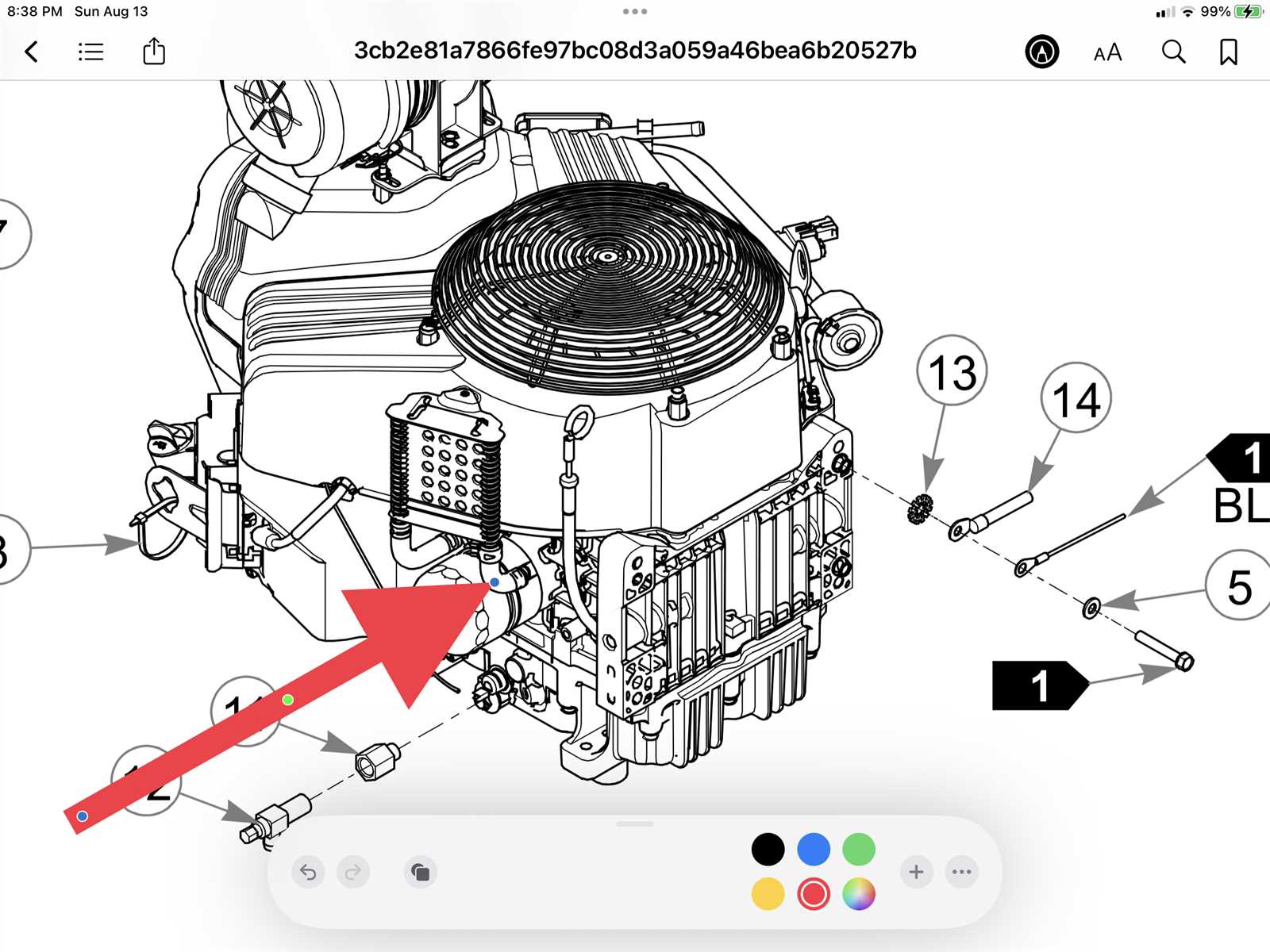

How to Read Parts Diagrams

Understanding technical illustrations is essential for maintenance and repair tasks. These visuals offer a clear representation of components and their relationships, allowing users to identify and locate specific items within a machine.

Key Elements to Focus On

When examining these illustrations, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Each component is usually accompanied by a label indicating its name or part number. |

| Connections | Arrows or lines often illustrate how different components are linked or interact with one another. |

| Legend | A key or legend can help interpret symbols or colors used throughout the illustration. |

Tips for Effective Reading

Take your time to familiarize yourself with the layout. Cross-reference with manuals for clarification, and always note the scale, as it can impact your understanding of the relationships between components.

Common Issues with Vanguard Engines

Small engines are essential for various applications, and they can encounter several typical challenges over time. Understanding these common problems can help in maintaining performance and ensuring longevity. Here are some frequent issues that users may face.

Engine Starting Difficulties

One of the most frustrating issues is trouble starting the engine. Several factors can contribute to this problem:

- Faulty spark plugs

- Clogged fuel filter

- Weak battery or poor electrical connections

- Dirty carburetor

Performance Issues

Inconsistent performance can arise from various underlying problems:

- Overheating due to insufficient cooling

- Fuel system contamination

- Worn or damaged internal components

- Improper oil levels or quality

Addressing these common challenges promptly can lead to better reliability and efficiency in engine operation.

Identifying Parts for Replacement

When maintaining machinery, recognizing components that require attention is crucial for optimal performance. Each element plays a vital role in the overall functionality, and understanding how they interact can help in making informed decisions about upkeep and repairs. A systematic approach to identifying which pieces need replacement can save time and resources.

Start by consulting the equipment manual, which often includes detailed illustrations or lists of essential elements. This resource serves as a foundation for understanding the configuration and specific characteristics of each component. Observing wear and tear visually or through operational inefficiencies can also indicate which items may need to be replaced.

It’s beneficial to familiarize yourself with common indicators of failure. For instance, unusual noises, leaks, or diminished performance may signal that specific elements are no longer functioning optimally. Regular inspections and maintenance schedules can further aid in pinpointing these issues before they escalate, ensuring the longevity and reliability of your equipment.

Additionally, consider keeping a log of any discrepancies or malfunctions. This documentation can provide valuable insights over time, allowing for a more comprehensive understanding of recurring issues. Being proactive in identifying and addressing these elements will ultimately contribute to the smooth operation of your machinery.

Where to Find Replacement Parts

Finding suitable components for machinery can be crucial for maintaining performance and longevity. Whether you’re a professional or a hobbyist, knowing where to source these elements can save time and ensure reliability in your equipment.

Here are some effective options to explore:

| Source | Description |

|---|---|

| Manufacturer’s Website | Often the best place to find original components, ensuring compatibility and quality. |

| Local Dealerships | Authorized sellers can provide genuine items and may offer expert advice on selection. |

| Online Retailers | Websites specializing in machinery components can offer a wide variety of options at competitive prices. |

| Second-Hand Markets | Used components can be found through local classifieds or online platforms, often at a reduced cost. |

Tools Needed for Engine Repairs

Effective engine maintenance and repair require a selection of essential instruments to ensure tasks are completed efficiently and accurately. Having the right tools on hand not only facilitates the process but also enhances safety and reduces the likelihood of errors.

Here is a list of fundamental tools you will need:

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening bolts.

- Screwdrivers: A set of flathead and Phillips screwdrivers will cover most fasteners.

- Torque Wrench: Essential for applying the correct amount of force to bolts, ensuring proper assembly.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating components.

- Jack and Stands: Necessary for safely lifting the engine or vehicle to access the underside.

- Oil Drain Pan: Used for collecting fluids during maintenance procedures.

- Multimeter: Helpful for diagnosing electrical issues within the engine.

- Shop Manual: Provides specific information and guidelines for repairs and adjustments.

By gathering these essential tools, you will be well-prepared to tackle various repair tasks, ensuring both efficiency and effectiveness in your work.