Exploring the intricate structure of the human form can be both fascinating and essential for various fields, from medicine to art. A comprehensive visual representation can greatly enhance our comprehension of how different elements are interconnected within the organism. This knowledge not only supports educational endeavors but also informs practical applications in health and science.

In this section, we will delve into the various segments that compose the human figure, highlighting their functions and relationships. By providing a clear and informative visual aid, we aim to facilitate a deeper understanding of the complexities that make up our physical selves. Such insights are invaluable for students, professionals, and anyone interested in the marvels of human biology.

Through detailed illustrations, readers will gain clarity on the various regions, enabling them to appreciate the harmonious integration of form and function. Whether for academic study or personal interest, a well-structured visual resource serves as a powerful tool for enhancing knowledge and fostering curiosity about the human anatomy.

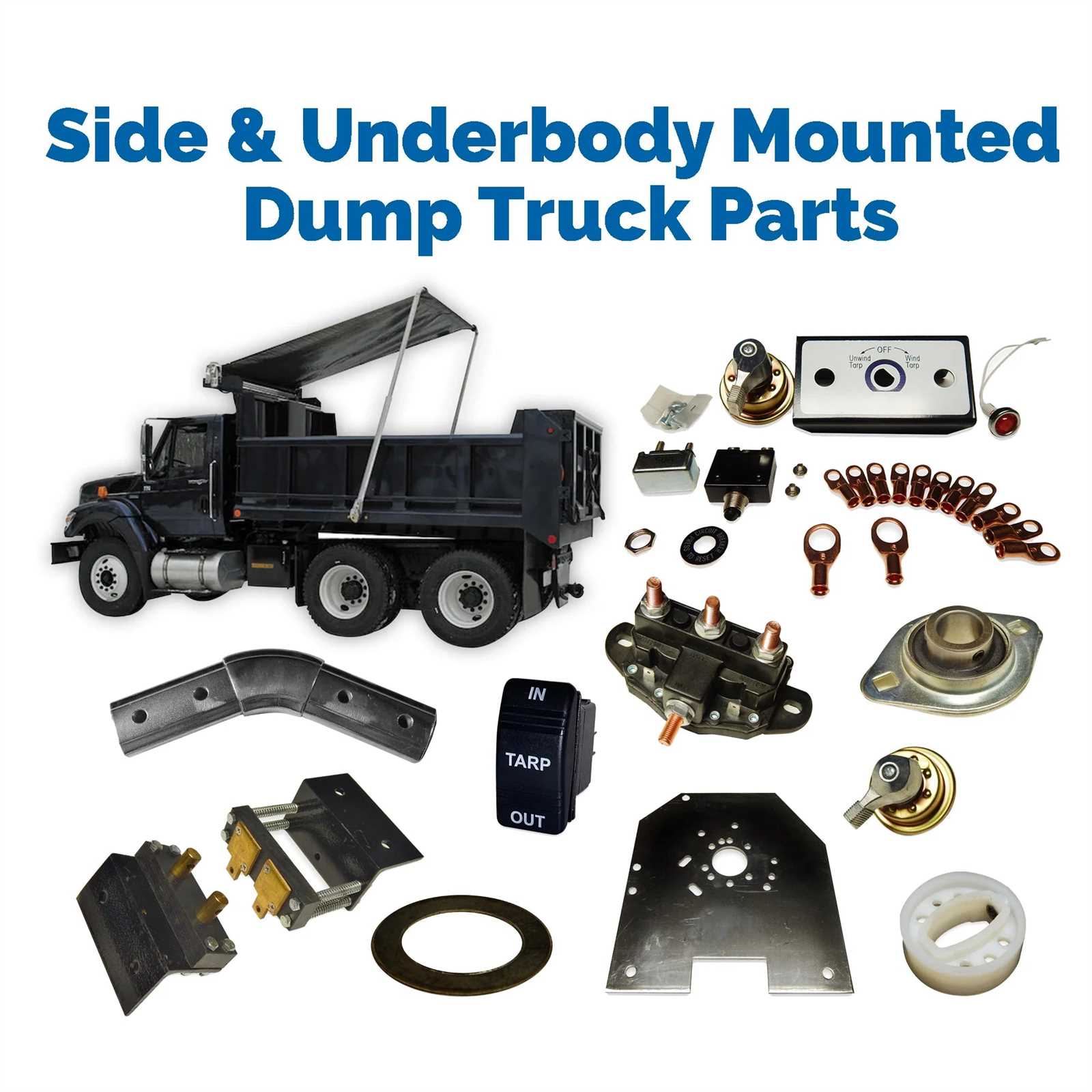

Understanding Dump Body Parts

This section aims to explore the essential components involved in the operation of specialized vehicles used for transporting materials. A comprehensive understanding of these elements is crucial for both maintenance and effective usage.

Key Components

- Chassis: The foundational framework providing structural integrity.

- Hydraulic System: Responsible for lifting and tilting the cargo area.

- Bed: The area designed to hold and transport various materials.

- Controls: Interfaces for operating the vehicle and managing loads.

Importance of Each Element

- The chassis ensures durability and support for heavy loads.

- A reliable hydraulic system enhances operational efficiency.

- The bed design maximizes load capacity and ease of unloading.

- Effective controls improve user experience and safety.

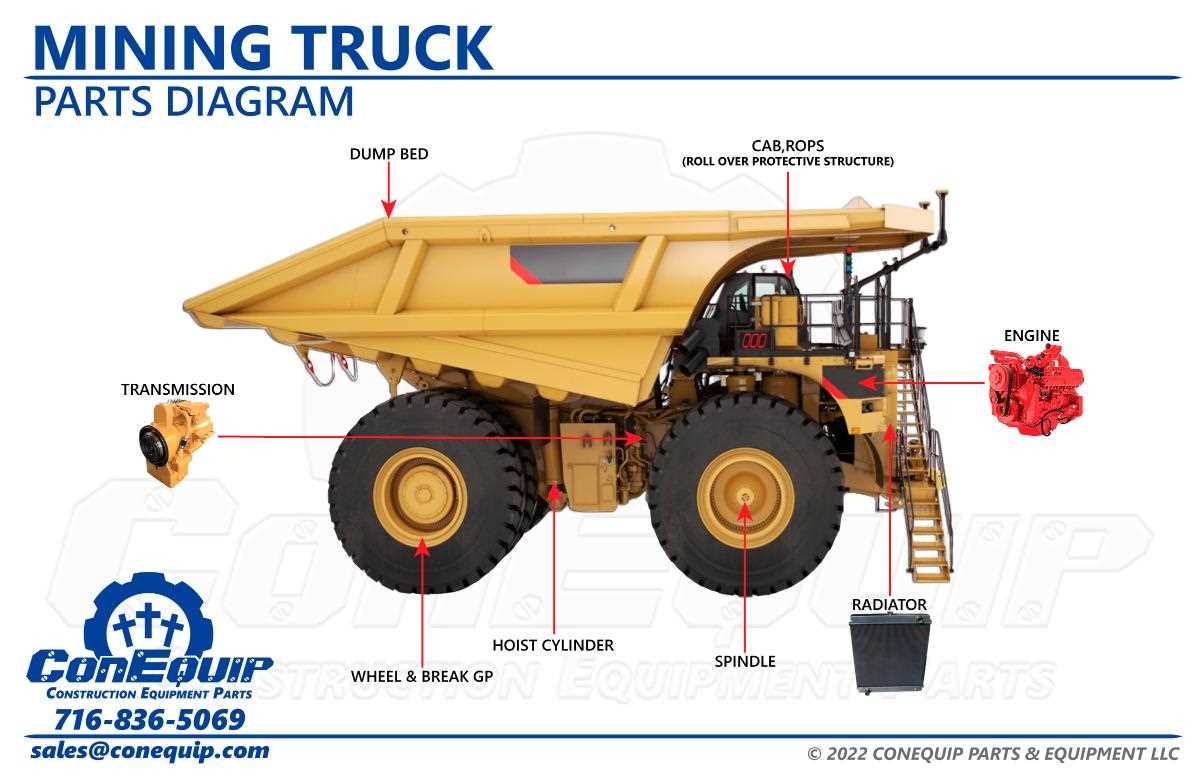

Key Components of Dump Bodies

The efficient transportation and unloading of materials rely heavily on the specific elements that make up these robust structures. Understanding the main features is crucial for optimizing performance and ensuring durability during operation. Each component plays a vital role in the overall functionality and reliability of the vehicle designed for material handling.

Structural Integrity

The framework of these vehicles is designed to withstand heavy loads and resist wear over time. Strong materials, such as high-strength steel or aluminum, are often used to enhance durability while minimizing weight. This balance is essential for maximizing payload capacity and ensuring the longevity of the structure under challenging conditions.

Lifting Mechanism

The unloading process is facilitated by a sophisticated lifting mechanism that enables the efficient release of contents. Hydraulic systems are commonly employed, providing the necessary force to elevate the container smoothly. This functionality not only improves productivity but also enhances safety by reducing manual handling risks during unloading.

Types of Dump Body Configurations

This section explores various configurations that optimize cargo handling and transportation efficiency. Each layout serves specific purposes, enhancing functionality and adaptability for different materials and environments.

Common Configurations

- Standard Configuration: Ideal for general hauling, offering versatility across multiple applications.

- Side Discharge: Allows for unloading materials from the side, perfect for construction sites.

- End Dump: Facilitates quick unloading by tipping the rear, commonly used for aggregates.

- Live Floor: Features a conveyor system, enabling smooth unloading of bulk materials.

Specialized Options

- Roll-Off: Designed for easy loading and unloading of containers, often seen in waste management.

- Tri-Axle: Enhances stability and weight distribution, ideal for heavy loads.

- Low-Profile: Offers a lower height for easier access to tight spaces or loading docks.

Materials Used in Construction

The selection of materials is crucial in any building endeavor, influencing both the structural integrity and aesthetic appeal of the final product. Various elements come into play, each contributing unique properties that cater to specific requirements in the construction process.

Commonly employed substances include concrete, steel, wood, and glass, each offering distinct advantages. Concrete provides strength and durability, while steel adds resilience and flexibility. Wood is favored for its natural appearance and workability, whereas glass enhances light penetration and visual openness.

Additionally, advancements in technology have introduced innovative materials such as composites and sustainable options, promoting eco-friendly practices in the industry. Understanding the characteristics and applications of these materials allows architects and builders to make informed decisions, ultimately shaping the success of their projects.

Hydraulic Systems Explained

Hydraulic systems utilize fluid power to perform various tasks, offering remarkable efficiency and control. By harnessing the force of liquids, these systems are able to transmit energy and facilitate movement in diverse applications, from industrial machinery to everyday vehicles.

The fundamental components of a hydraulic system work together to generate, control, and transfer force. Understanding how each element contributes to the overall function is crucial for optimizing performance and ensuring safety.

| Component | Function |

|---|---|

| Hydraulic Fluid | Transmits power and lubricates components. |

| Pump | Generates flow and pressure to move the fluid. |

| Actuator | Converts hydraulic energy into mechanical motion. |

| Reservoir | Holds the hydraulic fluid and maintains system pressure. |

| Valves | Control the flow and direction of the fluid. |

By delving into the mechanics of these components, one can appreciate the ultimate versatility and power of hydraulic systems in modern technology.

Maintenance Tips for Dump Bodies

Proper upkeep of heavy equipment is essential for optimal performance and longevity. Regular maintenance not only enhances functionality but also ensures safety and reliability during operations.

Regular Inspections

- Conduct visual checks for any signs of wear or damage.

- Inspect hydraulic systems for leaks and ensure all connections are secure.

- Examine the bed for cracks or corrosion that may compromise strength.

Cleaning and Lubrication

- Wash the surface regularly to remove dirt, debris, and corrosive substances.

- Apply appropriate lubricants to moving parts to minimize friction.

- Ensure drain holes are clear to prevent water accumulation.

Safety Features in Dump Trucks

Ensuring the well-being of operators and pedestrians is paramount in the transportation industry. Vehicles designed for heavy loads incorporate various mechanisms and technologies aimed at minimizing risks and enhancing operational safety. These features play a crucial role in preventing accidents and protecting everyone involved in the process.

Stability and Load Management

Stability is vital for vehicles that carry substantial weights. Advanced load distribution systems help maintain balance, preventing tipping during unloading or while navigating uneven terrain. Additionally, automated monitoring systems provide real-time feedback to operators, alerting them to any potential overload situations.

Visibility and Communication

Enhanced visibility features, such as larger mirrors and integrated cameras, significantly improve awareness of surroundings. These tools assist operators in detecting obstacles and ensuring a safe environment. Moreover, communication systems facilitate interaction between drivers and ground crew, further reducing the likelihood of mishaps.

Common Issues and Troubleshooting

This section addresses frequent challenges encountered during the handling and organization of anatomical representations. Understanding these issues can significantly enhance efficiency and accuracy in various applications.

Misalignment often occurs when components are not properly arranged, leading to confusion and misinterpretation. Ensure that all elements are aligned according to established guidelines.

Inconsistent Labeling can create misunderstandings. It’s crucial to maintain uniformity in terminology and annotations for clarity and precision.

Data Overload may hinder the analysis process. Prioritize essential information and eliminate unnecessary details to facilitate easier comprehension.

Software Compatibility issues may arise if the tools used are outdated. Regularly update your software to ensure seamless functionality and access to the latest features.

By being aware of these common pitfalls, one can troubleshoot effectively and enhance overall workflow.

Innovations in Dump Body Design

The evolution of construction equipment has led to remarkable advancements in the design and functionality of transportation systems used for bulk materials. These innovations focus on improving efficiency, safety, and ease of use, ultimately enhancing performance in various applications.

| Innovation | Description |

|---|---|

| Lightweight Materials | Utilization of advanced composites and alloys to reduce weight while maintaining strength. |

| Hydraulic Enhancements | Improved hydraulic systems for faster lifting and lowering, increasing productivity. |

| Smart Technology | Integration of IoT devices for real-time monitoring and data collection, enhancing operational efficiency. |

| Customizable Features | Modular designs that allow for tailored configurations to suit specific tasks and materials. |

| Safety Innovations | Advanced safety features such as stability monitoring systems to prevent tipping and accidents. |