In the realm of agricultural machinery, comprehending the intricate layout of individual elements is crucial for efficient operation and maintenance. Each segment plays a vital role in the overall functionality, influencing performance and longevity. Familiarity with these components can greatly enhance a user’s ability to troubleshoot and optimize their equipment.

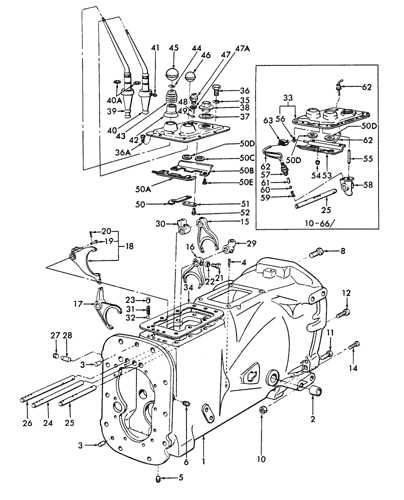

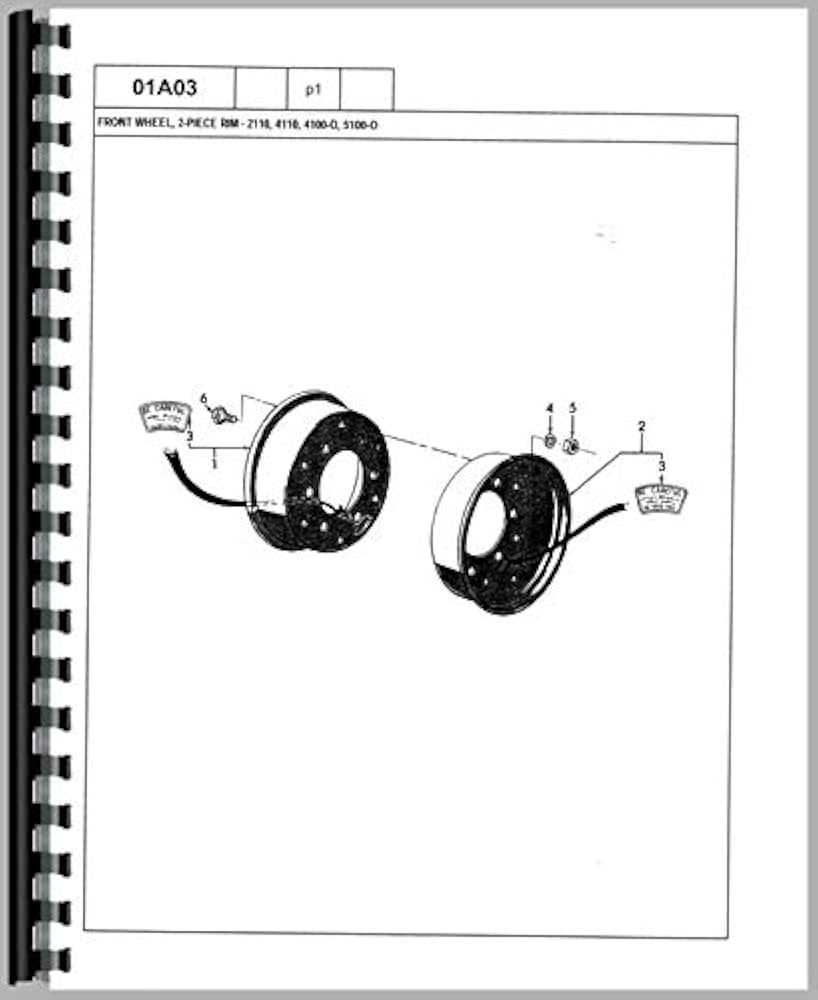

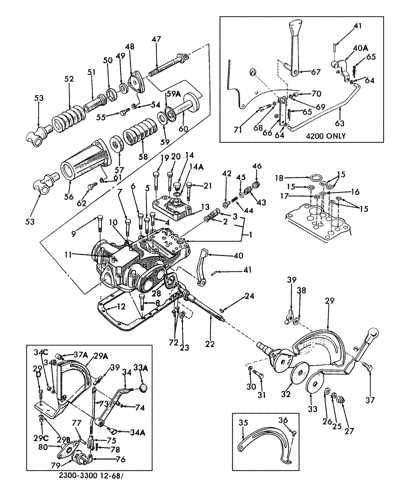

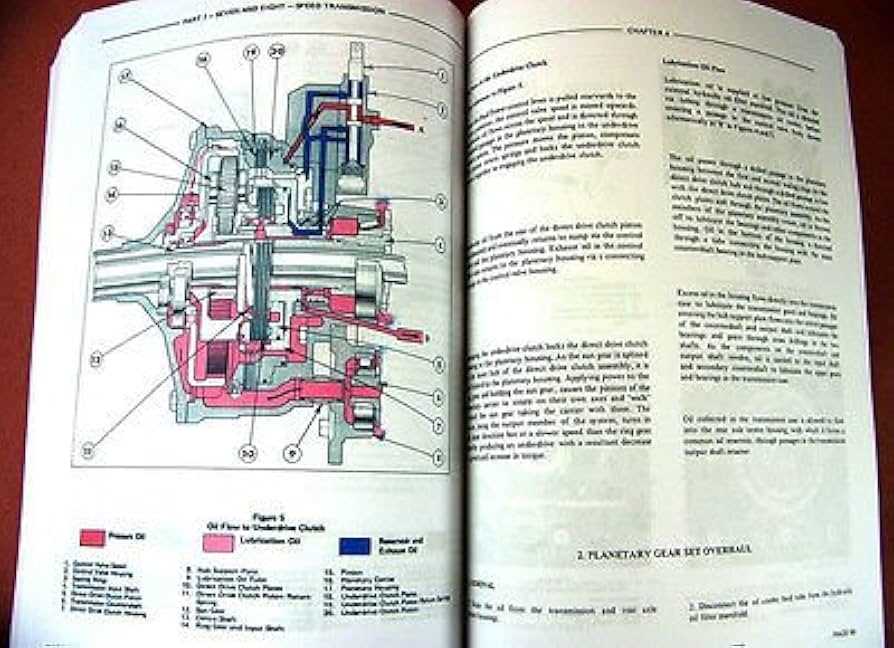

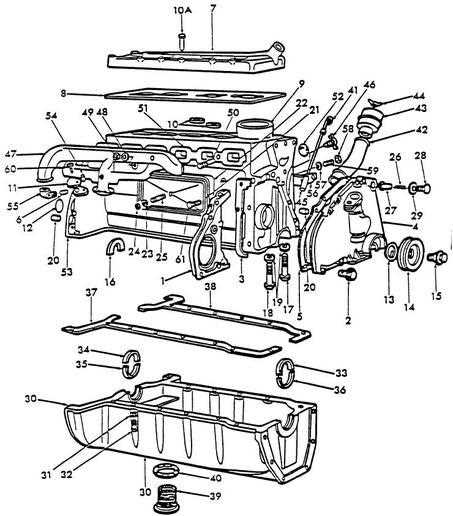

Visual representations of machinery components serve as essential tools for both novice and experienced operators. They provide clarity and facilitate a deeper understanding of how various pieces interact within the larger assembly. This knowledge empowers users to identify issues quickly and ensure that every part functions harmoniously.

Moreover, having access to detailed illustrations can significantly streamline repair and replacement processes. Whether for routine upkeep or unexpected breakdowns, recognizing the specific arrangement and connections of parts enables more efficient interventions. Ultimately, this proficiency not only minimizes downtime but also contributes to the sustained productivity of agricultural operations.

Understanding the Ford 3000 Model

This section explores a popular agricultural machine known for its reliability and efficiency in farming tasks. Its design incorporates various components that work harmoniously, making it a favorite among operators. Understanding these features is essential for optimal performance and maintenance.

Key Features

The machine is equipped with an array of innovative technologies that enhance its functionality. Here are some of the standout characteristics:

| Feature | Description |

|---|---|

| Engine Power | Robust engine providing ample horsepower for various tasks. |

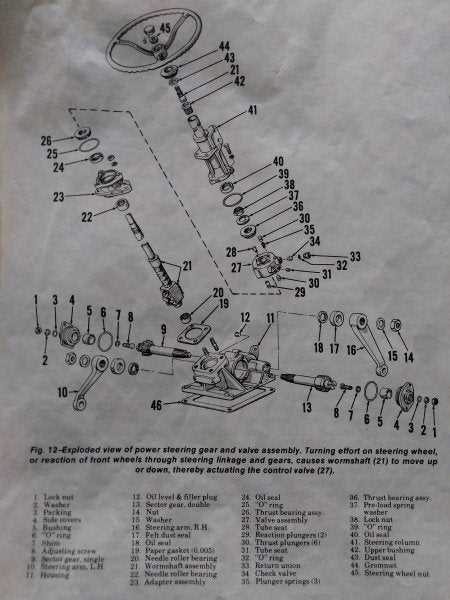

| Hydraulic System | Advanced hydraulics that ensure smooth operation and control. |

| Transmission | Efficient transmission allowing for easy gear shifting and maneuverability. |

Maintenance Considerations

Key Features of the Ford 3000

This section explores the essential characteristics that define a classic agricultural machine, focusing on its robust design and versatility. These attributes contribute to its popularity among farmers and operators worldwide, making it a reliable choice for various tasks.

Durability and Reliability

The machine is known for its solid construction, which allows it to withstand challenging working conditions. Key aspects include:

- Sturdy frame for enhanced stability

- High-quality materials that resist wear and tear

- Consistent performance across different environments

Versatile Functionality

This equipment is adaptable to a wide range of applications, making it an excellent investment for any agricultural operation. Notable features include:

- Ability to handle various implements, such as plows and harrows

- Efficient fuel consumption, maximizing productivity

- Compact size, facilitating maneuverability in tight spaces

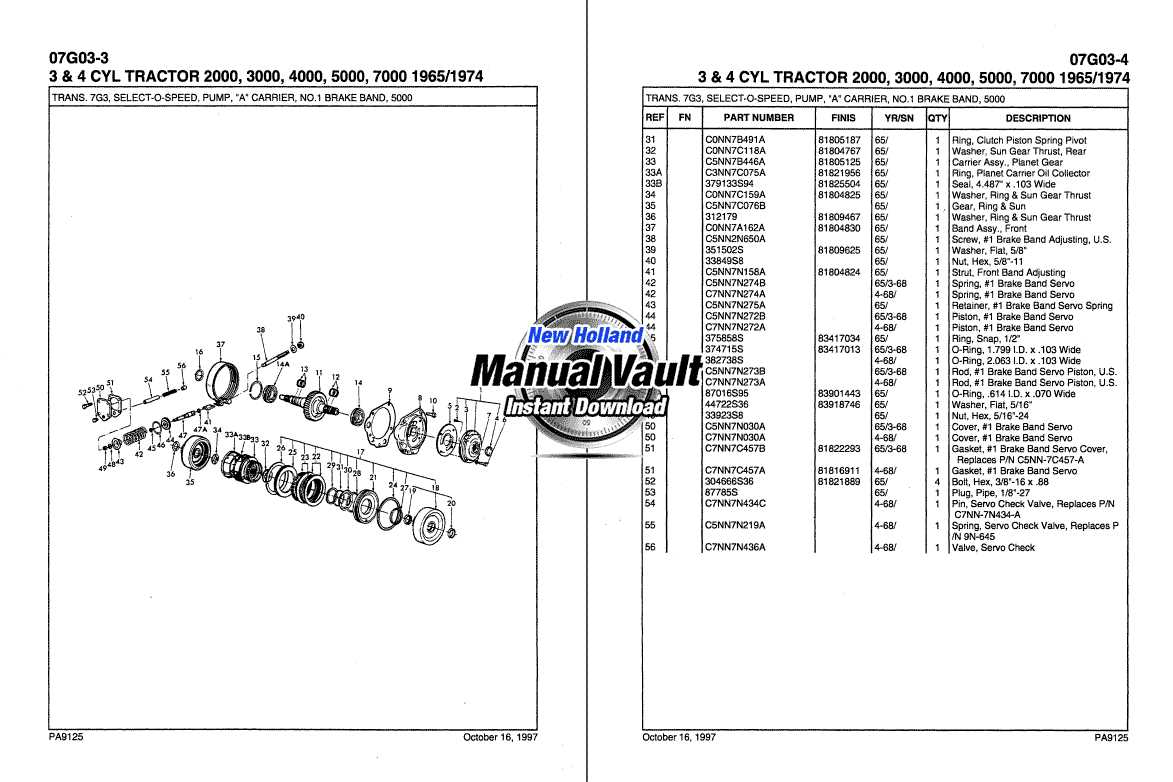

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that enhance clarity, allowing users to identify and address issues efficiently. These illustrations facilitate the proper assembly and disassembly of equipment, ultimately leading to improved functionality.

Enhanced Maintenance

Visual aids significantly streamline the maintenance process by providing a clear reference point. Technicians can quickly locate specific elements, reducing the time spent on repairs and ensuring that every component is correctly addressed.

Informed Decision-Making

With accurate visual references, users can make informed decisions regarding replacements and upgrades. Understanding how parts interact fosters better choices in sourcing replacements and optimizing performance, ensuring longevity and reliability of the machinery.

Common Repairs for Ford 3000

Maintenance of agricultural machinery is essential for optimal performance and longevity. Several typical issues arise that require attention, and understanding these can help owners keep their equipment running smoothly. Below are some frequent repairs encountered with these models.

| Repair Type | Description | Common Symptoms |

|---|---|---|

| Hydraulic System Issues | Leakage or failure in hydraulic functions often requires seals or pump replacement. | Slow or unresponsive hydraulics, visible leaks. |

| Electrical Problems | Wiring or battery faults can lead to starting issues or electrical failures. | Dim lights, failure to start, erratic gauge readings. |

| Engine Performance | Regular servicing may be needed, including oil changes, filter replacements, and adjustments. | Poor fuel efficiency, rough idling, excessive smoke. |

| Transmission Repairs | Shifting problems often stem from worn gears or low fluid levels. | Slipping gears, grinding noises, difficulty in shifting. |

| Cooling System Maintenance | Overheating can be prevented by flushing the radiator and replacing hoses. | High temperature gauge readings, coolant leaks. |

Where to Find Parts Diagrams

Locating detailed illustrations of components for machinery can significantly simplify repair and maintenance tasks. These resources offer visual guidance, making it easier to identify specific pieces and their relationships within the system. Here are some effective methods to obtain such references.

Online Resources

- Manufacturer Websites: Many producers provide comprehensive catalogs featuring diagrams for their products.

- Online Marketplaces: Platforms dedicated to equipment sales often include visual aids in their listings.

- Forums and Community Groups: Enthusiast communities frequently share valuable resources, including diagrams and manuals.

Print Materials

- Service Manuals: Often available for purchase, these books include detailed breakdowns of machinery components.

- Library Resources: Local libraries may have reference materials or access to databases that include technical drawings.

- Workshops and Classes: Engaging in hands-on training can also provide access to illustrative materials.

Essential Components for Maintenance

Proper upkeep of machinery requires a keen understanding of its vital elements. Each component plays a crucial role in ensuring smooth operation and longevity, necessitating regular checks and timely replacements. By focusing on these key parts, operators can prevent unexpected breakdowns and enhance overall efficiency.

Critical Parts for Regular Checks

Routine inspections should prioritize specific elements that directly impact functionality. Regular monitoring can identify wear and tear, allowing for proactive maintenance actions.

| Component | Function | Maintenance Tips |

|---|---|---|

| Engine | Drives the overall machinery | Check oil levels regularly and replace filters as needed |

| Transmission | Transfers power from the engine | Inspect for leaks and ensure fluid levels are adequate |

| Hydraulic System | Facilitates lifting and moving | Monitor fluid levels and check for signs of wear |

Replacement Parts to Consider

When wear becomes evident, certain components often require replacement to maintain optimal performance. Ensuring the right parts are on hand can minimize downtime.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Belts | Cracking or fraying | Every 1-2 years |

| Batteries | Difficulty starting machinery | Every 3-5 years |

| Filters | Reduced performance | Every 100 hours of operation |

Tips for Using Diagrams Effectively

Utilizing visual representations can greatly enhance your understanding and efficiency when working on machinery. These illustrations serve as valuable guides, helping you navigate complex assemblies and components with ease. To maximize their utility, consider the following strategies.

Understand the Layout

Before diving into the details, take a moment to familiarize yourself with the overall structure of the illustration. Identify key sections and how they relate to one another. This foundational understanding will provide context as you explore individual elements, making it easier to follow instructions.

Cross-Reference with Documentation

Always keep relevant manuals or specifications nearby when consulting visual aids. Cross-referencing these resources ensures accuracy and can clarify any ambiguities in the illustrations. Additionally, it helps reinforce your knowledge, allowing for a more comprehensive grasp of the system.

By implementing these techniques, you can significantly improve your proficiency in interpreting and utilizing visual guides, ultimately leading to more effective maintenance and repairs.

Choosing Quality Replacement Parts

When it comes to maintaining machinery, selecting high-quality components is essential for ensuring longevity and optimal performance. The right replacements can significantly impact efficiency and reduce the need for frequent repairs.

- Research reputable manufacturers known for their durability and reliability.

- Consider compatibility with your specific model to avoid installation issues.

- Look for warranties that reflect confidence in the product’s quality.

- Read customer reviews and seek recommendations from experienced users.

Ultimately, investing time in choosing superior components will save both time and money in the long run, enhancing overall operational success.