In the realm of winter maintenance, the functionality of snow clearing machines relies heavily on a multitude of critical elements. Grasping the intricate interplay of these components not only enhances operational efficiency but also extends the lifespan of the equipment. This section delves into the essential features that contribute to the overall performance of these vital tools.

Whether you are a seasoned operator or a newcomer to winter maintenance, having a comprehensive grasp of the various mechanisms involved is paramount. From the key attachments that facilitate movement to the intricate systems that ensure seamless operation, understanding each part’s role is essential for effective snow management. This knowledge empowers users to troubleshoot issues and optimize performance.

Furthermore, familiarizing oneself with the layout and interconnections of these components can greatly simplify maintenance tasks. By recognizing how each element fits into the larger system, operators can make informed decisions about repairs and upgrades. This insight ultimately leads to a more reliable and efficient snow management process, ensuring that winter challenges are met with confidence and preparedness.

Sno-way Plow Overview

This section provides a comprehensive look at a renowned snow-clearing device that is widely utilized in various environments. Designed for efficiency and durability, this equipment plays a crucial role in managing winter conditions and ensuring safe travel. Understanding its components and functionality can greatly enhance its performance and longevity.

The mechanisms employed in this apparatus are engineered to optimize snow removal, making it a favorite among professionals and homeowners alike. With a robust structure and user-friendly features, it caters to a wide range of applications, from residential driveways to expansive commercial properties.

| Feature | Description |

|---|---|

| Material | Constructed from high-quality steel for enhanced strength and durability. |

| Design | Ergonomic design facilitates ease of use and maneuverability. |

| Adjustability | Offers multiple angle settings for effective snow management. |

| Compatibility | Designed to fit a variety of vehicles, ensuring versatility. |

| Maintenance | Requires minimal upkeep to ensure optimal performance over time. |

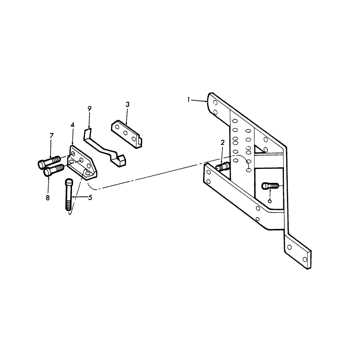

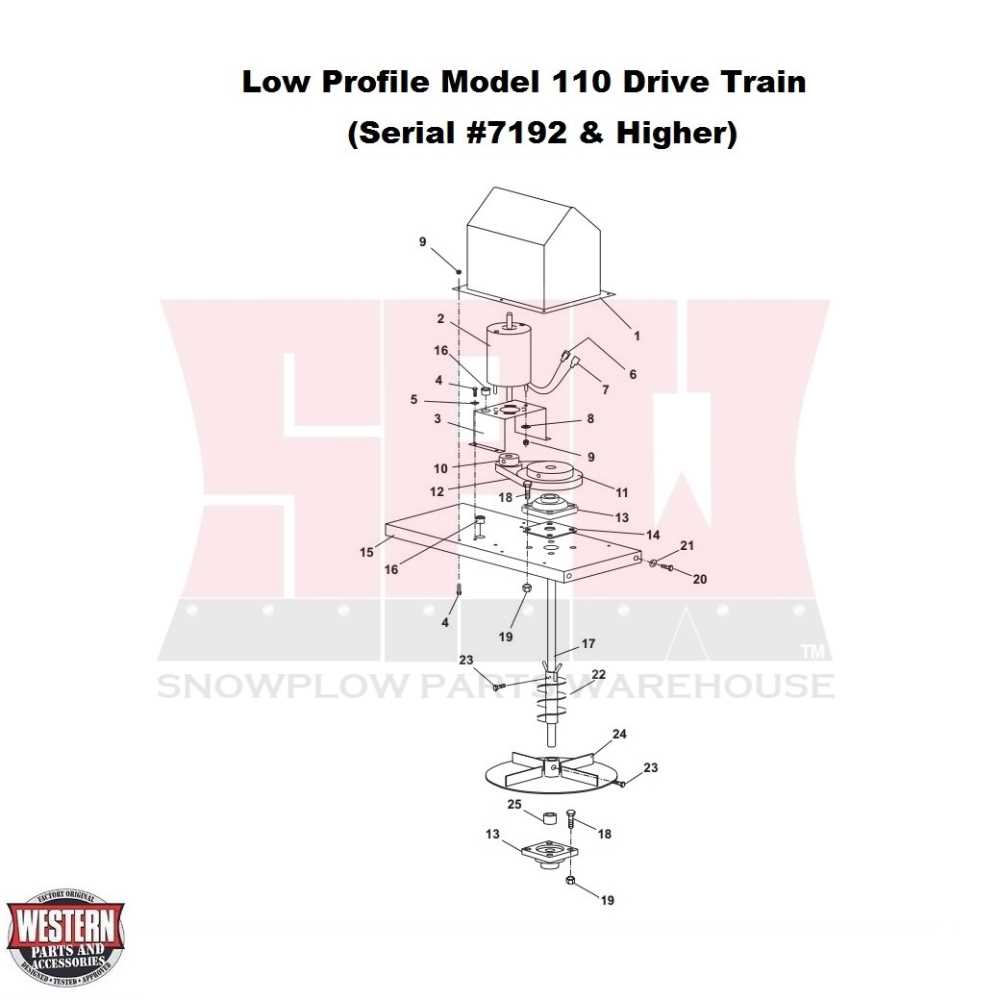

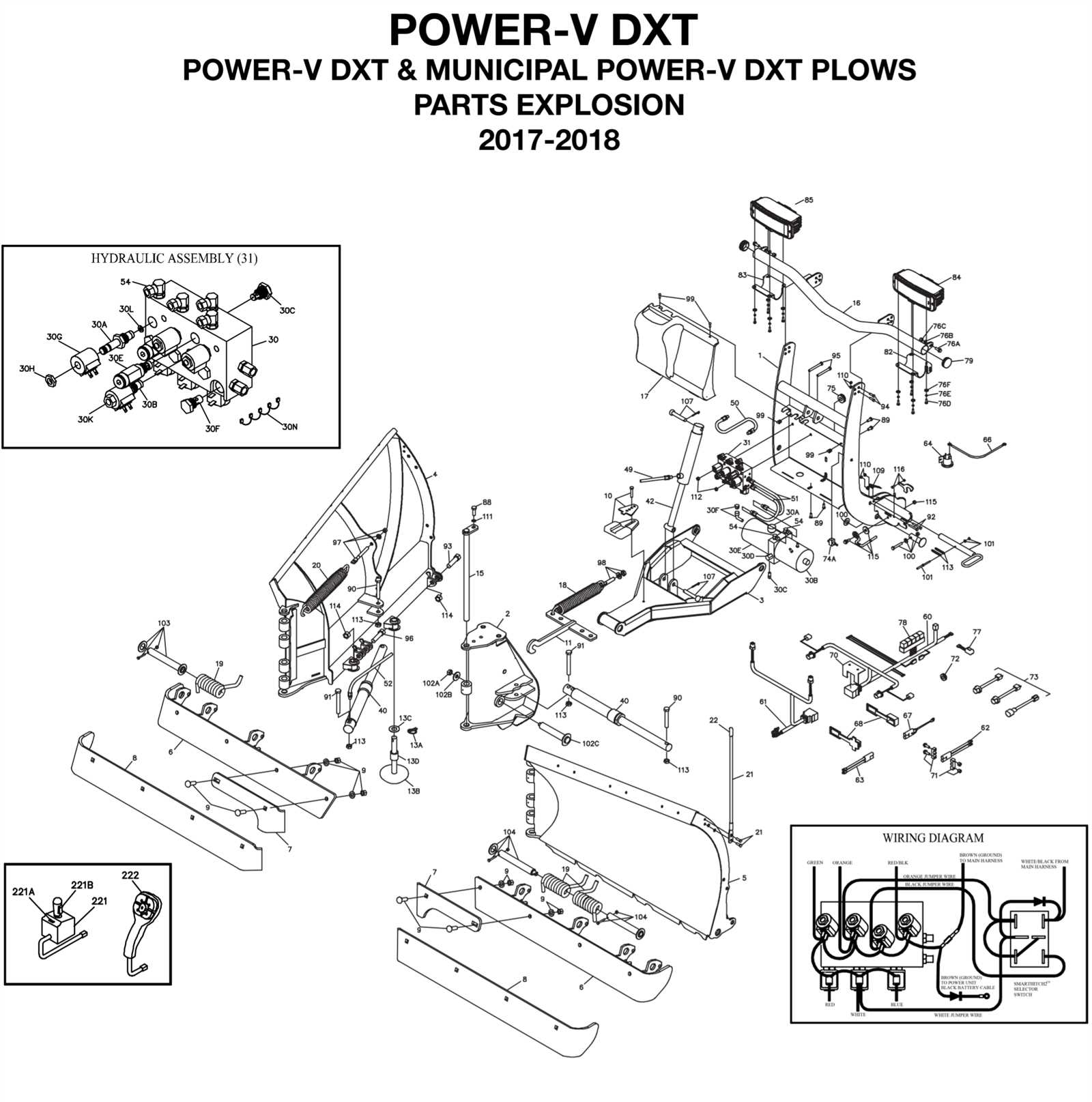

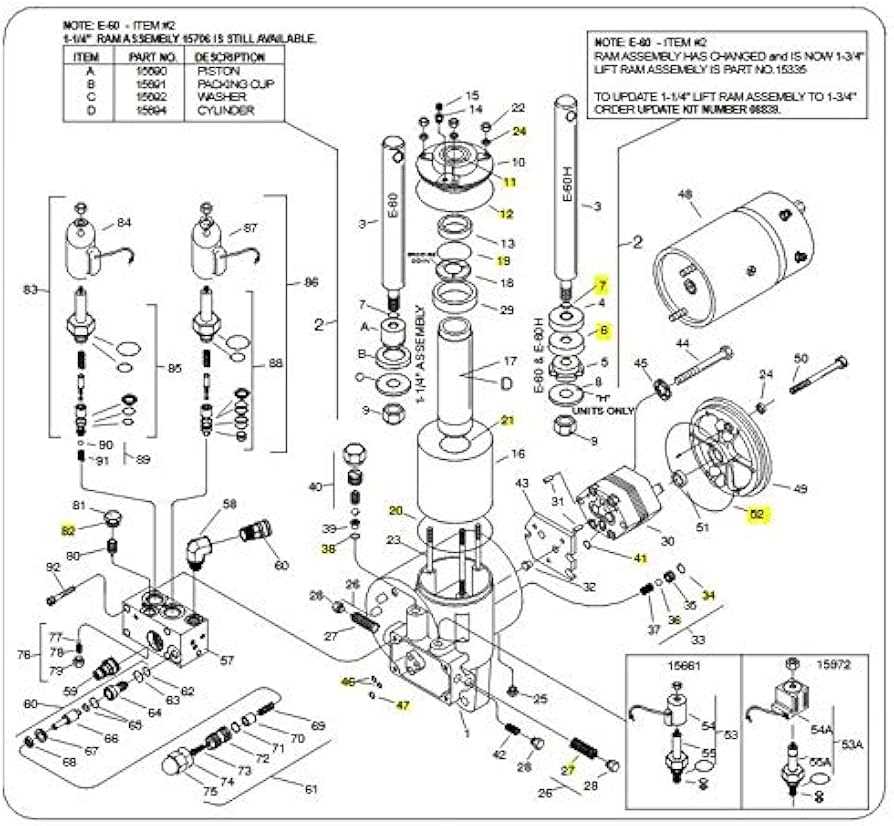

Understanding Plow Components

In the world of snow removal equipment, familiarity with the essential elements is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the system. Grasping the purpose and interrelation of these elements can greatly enhance both performance and durability.

| Component | Description | Function |

|---|---|---|

| Blade | The primary surface for clearing snow. | Directs and moves snow away from the area. |

| Mounting Frame | The structure that attaches the equipment to the vehicle. | Ensures stability and alignment during operation. |

| Lift Mechanism | A system for raising and lowering the blade. | Allows for adjusting the height for different surfaces. |

| Angle Adjustment | A feature that enables changing the direction of the blade. | Facilitates optimal snow movement based on conditions. |

| Control System | The interface for operating various functions. | Provides user control over adjustments and settings. |

By understanding these components, operators can ensure efficient and effective snow management, ultimately leading to enhanced safety and accessibility during winter conditions.

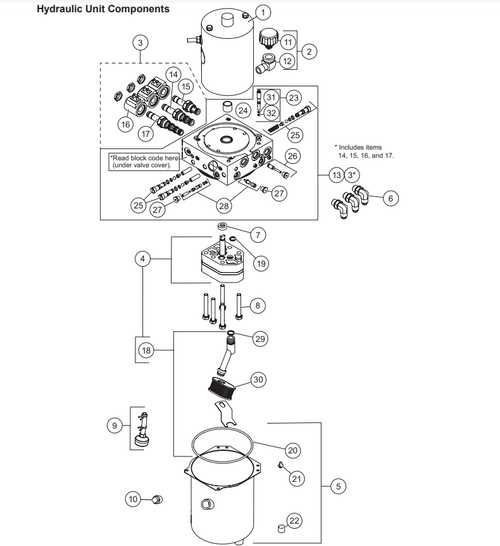

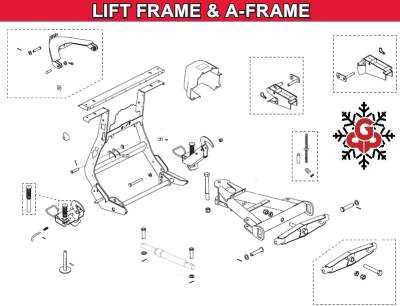

Importance of a Parts Diagram

A visual representation of components is essential for anyone involved in maintenance and repair tasks. Such illustrations serve as a crucial reference, helping users identify specific elements and their functions within a larger system. This clarity not only facilitates efficient troubleshooting but also ensures that all necessary components are accounted for during servicing.

Understanding Component Relationships

By depicting how various elements interact, these visuals allow users to grasp the overall structure and workflow of the mechanism. Recognizing the connections between different pieces can prevent missteps and enhance the accuracy of repairs.

Streamlining the Repair Process

Having a clear reference can significantly reduce downtime. Technicians can quickly locate the required components, leading to faster assembly or disassembly. This efficiency is particularly beneficial during peak seasons when time is of the essence.

Guiding Replacement Decisions

When a component fails, the visual guide aids in determining what needs to be replaced. This not only helps in ordering the correct items but also encourages users to consider compatibility and quality, ensuring longevity and reliability in the repairs.

Enhancing User Confidence

Familiarity with the visual representation empowers users, making them more confident in their ability to manage repairs. As they become adept at navigating the information, their skill set grows, leading to better outcomes and reduced reliance on external assistance.

How to Read the Diagram

Understanding the visual representation of components is crucial for efficient assembly and maintenance. This section aims to guide you through the essential elements, enabling you to interpret the layout with ease.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point for various elements. |

| Arrow | Shows the direction of movement or flow. |

| Rectangle | Represents a component or unit in the system. |

| Dashed Line | Denotes an optional or secondary pathway. |

Familiarizing yourself with these symbols will empower you to navigate the representation effectively, leading to better decision-making during your projects.

Common Sno-way Plow Issues

When operating snow removal equipment, users may encounter a variety of challenges that can affect performance and efficiency. Understanding these common concerns is essential for effective troubleshooting and maintenance.

1. Hydraulic Problems: One of the most frequent issues involves the hydraulic system, where leaks or low fluid levels can lead to reduced functionality. Regular checks and timely fluid replacement are crucial.

2. Electrical Failures: Electrical components may fail due to wear or corrosion, causing operational issues. Inspecting wiring and connections can help identify potential problems.

3. Blade Wear: Over time, the cutting edge may wear down, reducing effectiveness. Regular sharpening or replacement ensures optimal performance.

4. Attachment Misalignment: Improper alignment can cause uneven wear and inefficient operation. Ensuring correct attachment and adjustment can mitigate this issue.

5. Control Malfunctions: Issues with control mechanisms can hinder the responsiveness of the system. Checking the controller and associated connections can help resolve these concerns.

Being aware of these common issues enables operators to address them proactively, ensuring smoother operations during snow removal tasks.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan of your equipment. By implementing a few simple practices, you can ensure optimal performance and prevent premature wear and tear. Consistency in maintenance not only enhances efficiency but also saves on costly repairs in the long run.

Routine Inspections

- Check for wear on all components.

- Look for any signs of rust or corrosion.

- Ensure all connections are tight and secure.

Proper Cleaning

- Remove debris after each use.

- Wash with mild soap and water regularly.

- Dry thoroughly to prevent moisture buildup.

By following these guidelines, you can significantly enhance the durability and effectiveness of your equipment, ensuring it serves you well for years to come.

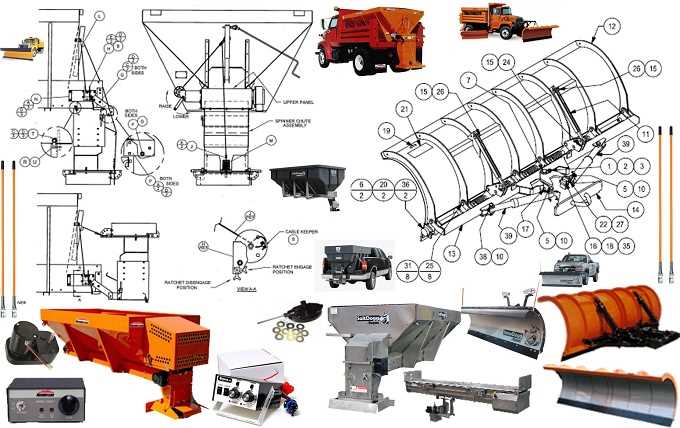

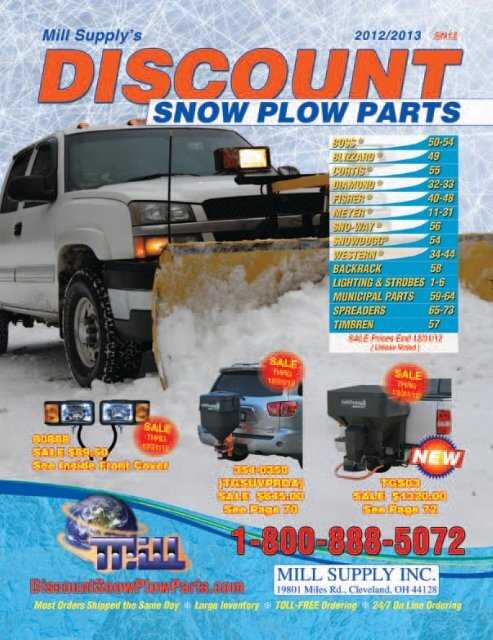

Finding Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance. Identifying the necessary elements can often feel overwhelming, but with the right approach, you can streamline the process and ensure longevity in your machinery.

Researching Options

Start by exploring various resources, including manufacturer websites and online forums. These platforms often provide valuable insights and user experiences that can guide your search for the best replacements.

Consulting Experts

Reaching out to professionals or local suppliers can offer additional assistance. Their expertise may help you uncover the most suitable alternatives and ensure compatibility with your machinery.

Upgrading Your Sno-way Plow

Enhancing your snow-clearing equipment can significantly improve its efficiency and longevity. By focusing on various components, you can elevate performance and tackle winter conditions with greater ease. This guide explores effective strategies to modernize your gear, ensuring optimal results during the cold season.

Assessing Your Current Setup

Begin by evaluating the existing configuration. Identify areas that may require enhancement, such as functionality or durability. Consider factors like the type of terrain you often face and the frequency of use, which will guide your upgrade decisions.

Selecting Quality Components

When choosing new elements, prioritize high-quality options that offer superior resilience. Look for innovations in technology that can streamline operations and reduce maintenance efforts. Investing in premium materials will provide long-term benefits and improve overall performance.