Understanding how different elements of machinery work together is key to ensuring smooth and efficient operation. In this section, we will dive into the various mechanical parts that make up one of the most popular models in its class. By exploring each component, you will gain a better grasp of their roles and how they contribute to the overall functionality of the equipment.

Knowing the key features and mechanisms behind each element is not just beneficial for maintenance; it also empowers you to identify potential issues before they escalate. From the engine to smaller intricate details, this guide will walk you through everything you need to keep the equipment in optimal working condition.

Essential Components of the John Deere S240

Understanding the main elements of this high-performance machine is crucial for ensuring its longevity and efficiency. Each component works together to provide a smooth and reliable operation. Below, we explore the key elements that make up its core structure, ensuring a balanced and effective performance.

- Engine System: The powerful engine is designed to deliver consistent performance, driving the machine’s operations efficiently across various terrains.

- Transmission: A robust transmission system enables smooth transitions between speeds, allowing the operator to maintain control in different mowing conditions.

- Mowing Deck: This wide cutting deck ensures even and precise grass trimming, while its adjustable height settings offer versatility for different lawn types.

- Steering Mechanism: An ergonomic steering system provides easy maneuverability, making it simpler to navigate tight spaces

Understanding the Drive Belt System

The drive belt system plays a critical role in the smooth operation of various mechanical components within the machine. This system ensures that power is transferred efficiently from the engine to other essential parts, allowing the equipment to function effectively. Regular maintenance and proper understanding of how the belts work can help avoid unexpected issues and ensure long-term reliability.

Key Components of the System

The drive belt system consists of several key elements, including pulleys, tensioners, and the belt itself. These components work in unison to transmit power to areas like the cutting deck and other mechanical sections. Ensuring the belt is properly tensioned and free of wear is vital for smooth operation. Tensioners keep the belt tight, while pulleys guide its movement.

Signs of Wear and Replacement Indicators

Over time, the belt can show signs of deterioration, such as cracks, fraying, or

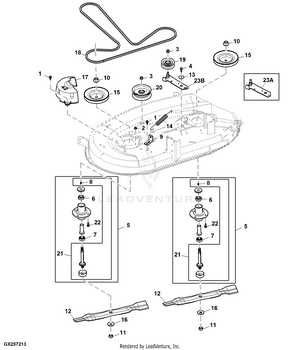

Key Features of the Mower Deck

The mower deck is a critical component of any lawn maintenance machine, designed to ensure an even and clean cut across various terrains. Its construction and functional elements determine the overall performance and longevity of the cutting system. Let’s take a closer look at what makes this deck stand out and contribute to efficient grass cutting.

Durable Construction

- Reinforced steel deck for long-lasting durability

- Weather-resistant coating to prevent rust and wear

- High-strength spindles that provide stability during operation

Efficient Cutting System

- Multiple blades for superior grass clipping

- Adjustable cutting height to suit different grass lengths

- Optimized airflow to enhance mulching capabilities

- Blades: The cutting element responsible for trimming the grass evenly. Regular sharpening and maintenance are necessary to ensure a clean cut.

- Spindle: The central rotating component that drives the blades. This piece ensures smooth operation by allowing the blades to spin at the required speed.

- Bearings: These support the spindle and reduce friction, ensuring the rotation remains smooth over time.

- Housing: A protective casing that shields the spindle and bearings from dirt and debris, prolonging their lifespan

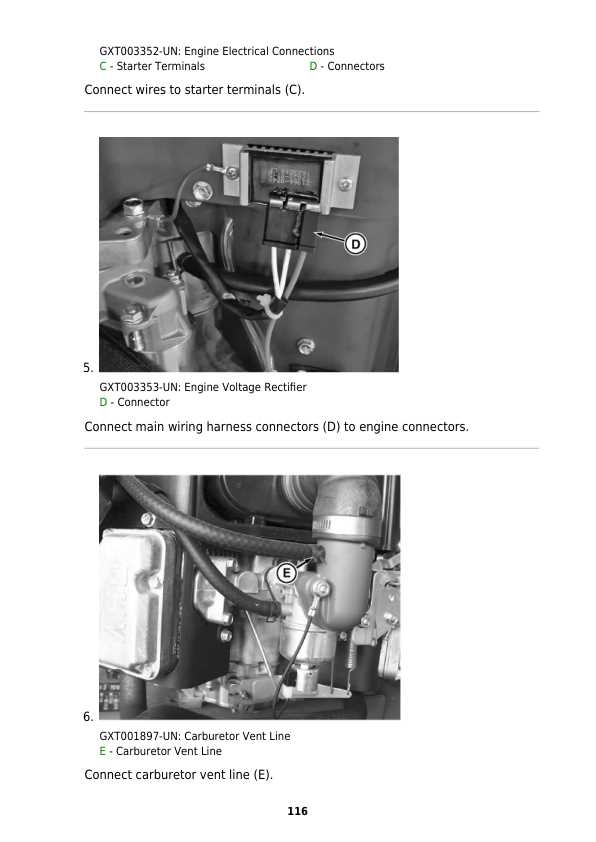

Fuel System and Carburetor Breakdown

The fuel system is a crucial component in ensuring optimal performance and efficiency of any small engine. Understanding its intricacies, particularly the carburetor, is essential for effective maintenance and troubleshooting. This section delves into the various elements of the fuel system, focusing on their functions and how they work together to deliver the right air-fuel mixture for combustion.

Key Components of the Fuel System

The fuel system comprises several vital parts, including the fuel tank, fuel lines, fuel pump, and carburetor. Each component plays a specific role in the overall functionality. The fuel tank stores the gasoline, while the fuel lines transport it to the pump. The fuel pump then sends the fuel to the carburetor, where it is mixed with air before entering the engine. Regular inspection and maintenance of these components can prevent issues such as leaks, blockages, and inefficient fuel delivery.

Understanding the Carburetor

The carburetor is a mechanical device that mixes air with fuel in the correct proportions. It features various parts, including the float chamber, jets, and throttle valve. The float chamber maintains a consistent fuel level, while the jets regulate fuel flow based on engine demands. The throttle valve controls airflow, which directly impacts engine speed and power output. Proper calibration and cleaning of the carburetor are essential for optimal engine performance and to avoid common problems such as stalling or difficulty starting.

Transmission and Clutch System Components

The transmission and clutch system plays a vital role in the efficient operation of lawn and garden machinery. This system is responsible for transferring power from the engine to the wheels, allowing for smooth acceleration and deceleration. Understanding the components involved in this system is essential for effective maintenance and troubleshooting.

Key components of the transmission and clutch system include:

- Transmission: This device alters the speed and torque delivered to the wheels, enabling the machine to adapt to different working conditions.

- Clutch: The clutch engages and disengages the engine from the transmission, allowing the operator to control the power flow during operation.

- Drive Belt: This belt connects the engine to the transmission, transmitting power effectively while accommodating movement and vibrations.

- Shift Linkage: This mechanism facilitates the smooth shifting between gears, ensuring proper alignment and engagement.

- Torque Converter: In some systems, this component multiplies the engine torque, providing enhanced power during acceleration.

Regular inspection and maintenance of these components are crucial for ensuring optimal performance. Replacing worn or damaged parts can prevent further complications and extend the life of the machinery.

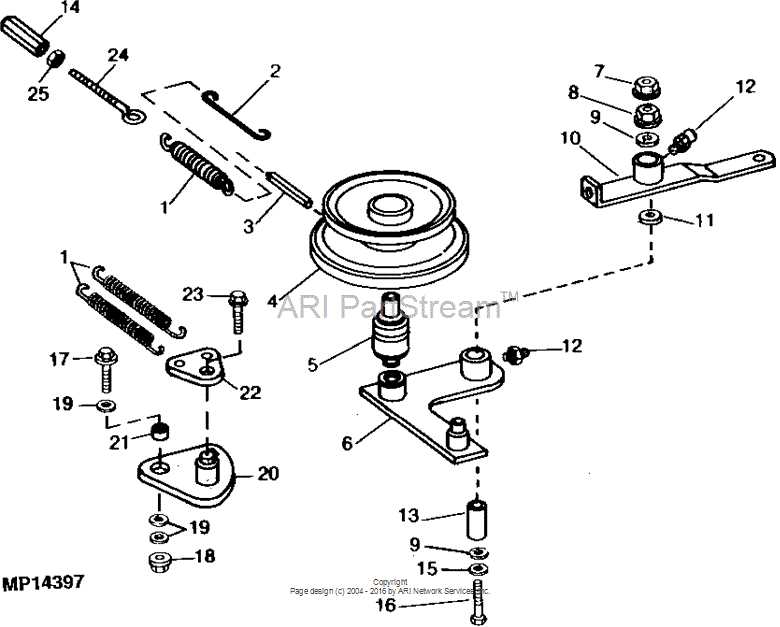

Maintenance Guide for Steering Assembly

The steering assembly is a vital component that ensures smooth maneuverability and control of your machine. Regular maintenance is essential for optimal performance and longevity of the steering system. This guide provides key insights and steps to effectively maintain the steering assembly, ensuring reliable operation.

Regular Inspection

Routine checks can prevent major issues. Follow these steps for effective inspection:

- Examine the steering linkage for any signs of wear or damage.

- Check the fluid levels in the steering system to ensure they are adequate.

- Look for any leaks around the seals and joints.

- Inspect the steering wheel for any looseness or play.

Lubrication

Proper lubrication is crucial for the smooth operation of the steering assembly. Consider the following tips:

- Apply grease to all moving parts of the steering mechanism.

- Use a high-quality lubricant recommended by the manufacturer.

- Ensure that all pivot points are adequately lubricated to prevent friction.

By following these maintenance practices, you can enhance the durability and functionality of your steering assembly, ensuring a safer and more efficient operating experience.

Cooling and Air Filtration Parts

Effective temperature regulation and clean air intake are essential for optimal engine performance. This section explores the critical components that contribute to maintaining proper cooling and filtration systems, ensuring efficient operation and longevity of the machinery.

The cooling system comprises several key elements designed to dissipate heat generated during operation. A well-functioning radiator plays a vital role in this process, utilizing coolant to absorb heat and transfer it away from the engine. Additionally, hoses and thermostats are crucial for regulating coolant flow, helping to prevent overheating.

Equally important is the air filtration system, which safeguards the engine from harmful contaminants. This system typically includes an air filter that traps dust and debris before they can enter the engine. Regular maintenance and timely replacement of the filter are essential for ensuring optimal airflow and preventing performance issues.

In summary, understanding the cooling and air filtration components is vital for maintaining the efficiency and reliability of your equipment. Regular inspections and proactive maintenance will help avoid potential problems and ensure smooth operation in various conditions.

Battery and Electrical System Overview

The electrical system is a critical component that powers key functions, including ignition, lighting, and accessory systems. The battery serves as the primary power source, delivering energy to various parts of the machinery, while the alternator ensures continuous charging during operation. Together, these elements maintain optimal functionality and ensure smooth performance.

Below is a breakdown of the main components involved in the electrical system:

Component Function Battery Provides the initial power needed to start the engine and run electrical systems. Alternator Recharges the battery and powers electrical components while the engine is running. Starter Motor Engages to start the engine by drawing power from the battery. Blade and Spindle Assembly Explained

The blade and spindle assembly is a key component in ensuring optimal cutting performance and longevity of the mowing equipment. This system combines various moving parts, working together to deliver precise and efficient cutting action. Understanding how these components interact can help maintain your equipment and improve its performance.

Main Components of the Assembly