The intricate world of machinery maintenance often requires a deep dive into the various elements that make up a specific model. For enthusiasts and professionals alike, grasping the configuration and functionality of each component is essential for effective upkeep and repair. This knowledge not only enhances the longevity of the equipment but also optimizes its performance in demanding tasks.

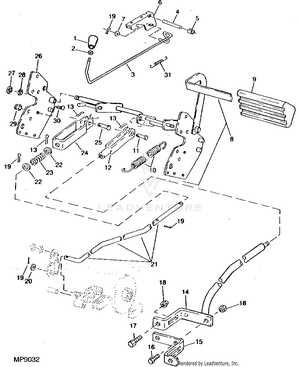

By exploring the schematic representation of a particular machine, users can better identify and understand the relationships between different parts. This exploration reveals how each section interacts within the larger framework, allowing for informed decision-making during repairs and modifications. Such insights can lead to improved efficiency and reduced downtime, critical factors in both personal and commercial settings.

In this guide, we will delve into the detailed layout of one such machinery model, focusing on the specific components that play a pivotal role in its operation. With clarity and precision, we aim to equip readers with the necessary knowledge to navigate through the complexities of machinery maintenance. The visual representation serves as a valuable tool, providing a clear understanding of how to approach repairs and replacements effectively.

Understanding the John Deere 175 Hydro

This section delves into the intricacies of a particular model known for its efficiency and versatility. Designed for various tasks, it offers unique features that enhance usability and performance. Familiarizing oneself with its components and functionality can significantly improve maintenance and operation.

Key characteristics that define this model include:

- Robust construction ensuring durability and longevity.

- Efficient transmission system for smooth operation.

- Intuitive controls designed for user-friendly navigation.

- Adaptability for different attachments and accessories.

Understanding the various elements involved is crucial for effective management. The following areas are essential:

- Powertrain components, which play a vital role in overall performance.

- Steering and braking systems that ensure precision and safety.

- Electrical systems that power essential functions.

- Hydraulic mechanisms that enhance operational capabilities.

In summary, a comprehensive grasp of these elements contributes to better handling and upkeep of the equipment, ensuring optimal functionality for all intended applications.

Key Features of the 175 Hydro

This section highlights the significant attributes that define the efficiency and functionality of the model. With a blend of advanced engineering and user-friendly design, it stands out in its category, making tasks easier and more efficient for users.

Performance and Efficiency

- Powerful engine offering reliable performance for various tasks.

- Hydraulic system designed for smooth operation and enhanced control.

- Optimized fuel consumption, ensuring longer run times and reduced operational costs.

Comfort and Usability

- Ergonomically designed seat for increased comfort during extended use.

- User-friendly controls, allowing for easy navigation and adjustments.

- Compact design that enhances maneuverability in tight spaces.

Common Issues and Solutions

In any machinery, certain challenges may arise during operation, leading to performance issues or mechanical failures. Understanding these common problems and their solutions can help in maintaining optimal functionality and prolonging the equipment’s lifespan.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive heat can lead to engine failure and reduced efficiency. | Check coolant levels and ensure proper airflow around the engine. Replace any damaged hoses. |

| Poor Maneuverability | Difficulty in steering or controlling movement may indicate hydraulic issues. | Inspect hydraulic fluid levels and connections. Replace any worn seals or hoses. |

| Uneven Cutting | Inconsistent performance can result in an unkempt appearance. | Adjust blade height and ensure blades are sharp and balanced. |

| Electrical Failures | Malfunctions in electrical components can cause start-up issues or equipment failure. | Check battery connections, fuses, and wiring for signs of damage or corrosion. |

| Fuel System Problems | Issues with fuel delivery can hinder performance and efficiency. | Inspect fuel filters and lines for clogs. Replace filters as necessary. |

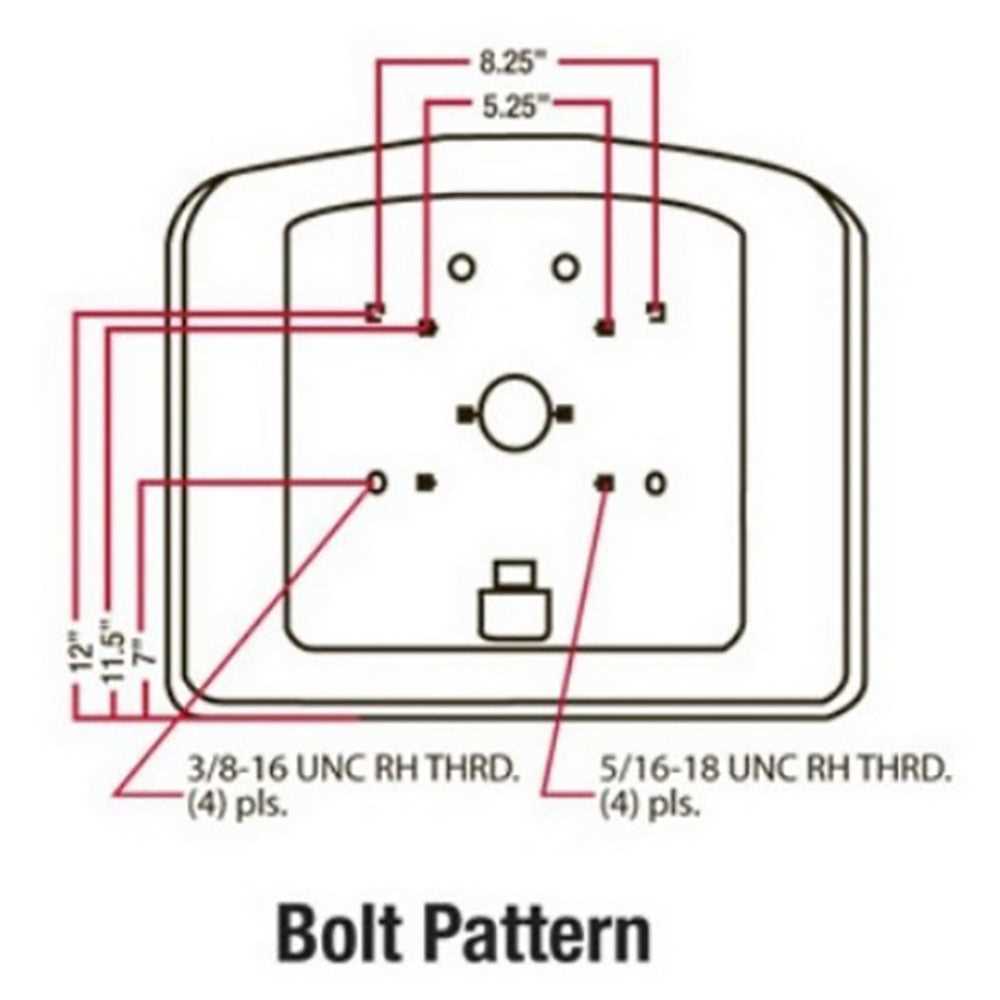

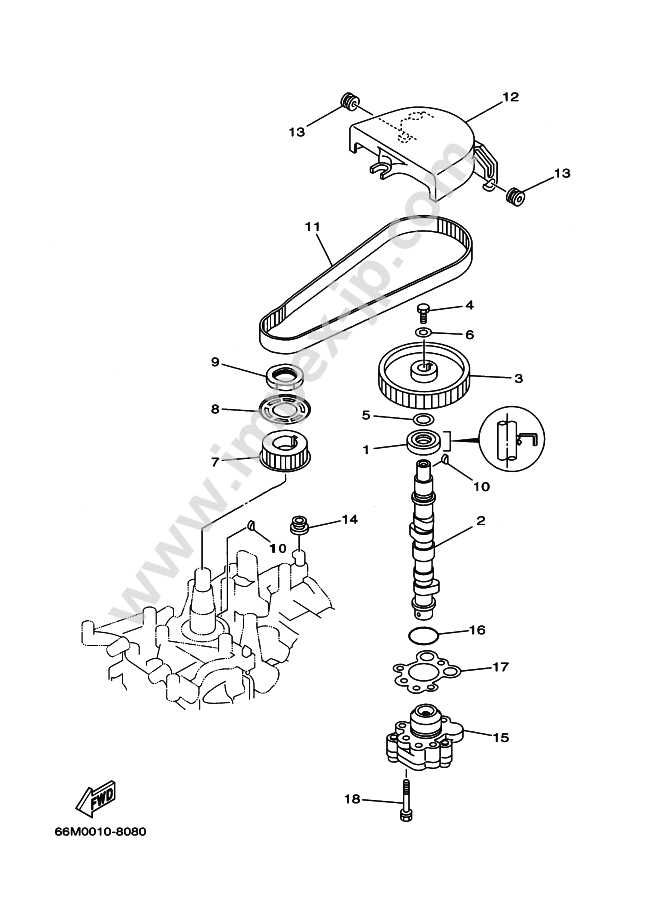

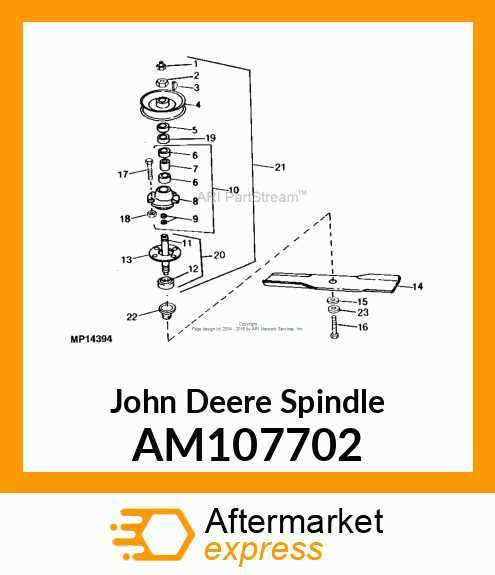

Importance of Parts Diagrams

Visual representations of components are essential tools for anyone involved in maintenance and repair. They provide clarity and understanding, allowing users to identify and locate necessary elements quickly. These illustrations serve not only as guides but also as educational resources, ensuring that individuals can work efficiently and accurately.

Benefits of Visual Guides

- Enhances comprehension of complex systems

- Facilitates quicker troubleshooting and repairs

- Assists in ordering the correct replacements

- Improves overall workflow and efficiency

Applications in Various Fields

- Agriculture: Helps farmers maintain and repair machinery effectively.

- Automotive: Assists mechanics in understanding vehicle systems.

- Manufacturing: Supports assembly line workers in assembling parts correctly.

In summary, these illustrations are invaluable for ensuring proper functionality and longevity of equipment across different industries.

Where to Find Replacement Parts

Locating components for your machinery can often feel daunting, but there are numerous avenues to explore. Whether you need original equipment or high-quality alternatives, the right resources can simplify your search and ensure your equipment remains operational.

Online Marketplaces

One of the most convenient options is to browse various online platforms. Websites specializing in equipment and tools offer a wide range of components, often at competitive prices. Look for trusted sellers who provide detailed descriptions and images to help you make informed decisions. Customer reviews can also guide you in selecting reliable options.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair establishments can be beneficial as well. These locations frequently stock essential components and can assist you in finding the exact match for your needs. Additionally, knowledgeable staff members can provide valuable insights and advice, helping you choose the best solutions for your equipment.

In summary, whether you opt for digital platforms or local establishments, being proactive in your search will greatly enhance your chances of finding the right components.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment ensures optimal performance and longevity. This guide outlines essential procedures to maintain functionality and prevent unexpected breakdowns. By following these steps, you can enhance the efficiency of your machine and prolong its lifespan.

Routine Checks

Begin with frequent inspections of key components. Check fluid levels, including oil, coolant, and hydraulic fluids. Ensure filters are clean and free from debris. Look for any signs of wear or damage on belts, hoses, and tires. Regularly examining these parts can help you catch potential issues early.

Seasonal Maintenance

Perform a comprehensive service at the start and end of each operational season. Change the oil and replace filters to maintain engine health. Sharpen or replace blades as necessary. Additionally, clean the machine thoroughly, removing dirt and debris that can hinder performance. This proactive approach will keep your equipment running smoothly throughout its usage period.

Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be a rewarding experience, offering both a sense of accomplishment and potential cost savings. However, it requires a clear understanding of the components involved, as well as the right approach to ensure safety and efficiency. Below are some valuable suggestions to enhance your repair efforts.

Understand the Basics

Before diving into any maintenance tasks, familiarize yourself with the fundamental elements of the equipment. Reviewing user manuals and online resources can provide essential insights. Additionally, knowing how various components interact will aid in troubleshooting and identifying issues.

Gather the Right Tools

Having the proper tools at your disposal is crucial for successful repairs. Invest in a reliable toolkit, including wrenches, screwdrivers, and diagnostic devices. Make sure your tools are well-maintained and organized to streamline the repair process. Always prioritize safety by using protective gear and ensuring the equipment is powered down before starting any work.

Comparing Models in the Series

In the world of agricultural machinery, it is essential to evaluate the various options available within a particular line of equipment. Each model offers distinct features and capabilities tailored to meet specific operational needs. Understanding these differences can help users make informed decisions when selecting the right machine for their tasks.

Key Features and Specifications

The following table summarizes the main characteristics of different models in this series, allowing for an easy comparison of their specifications:

| Model | Engine Power (HP) | Cutting Width (inches) | Transmission Type | Weight (lbs) |

|---|---|---|---|---|

| Model A | 20 | 42 | Automatic | 350 |

| Model B | 25 | 48 | Manual | 400 |

| Model C | 30 | 54 | Automatic | 450 |

Choosing the Right Fit

Selecting the most suitable machine requires careful consideration of factors such as power, cutting width, and ease of operation. Users should assess their specific requirements and compare the models based on their unique features. By doing so, they can ensure optimal performance and efficiency in their agricultural tasks.

Resources for Further Information

Exploring additional resources can greatly enhance your understanding of maintenance and repair for various machinery. Numerous platforms offer valuable insights, technical specifications, and community support to assist you in your endeavors.

- Official Manufacturer Websites: These sites often provide manuals, service guides, and troubleshooting tips directly related to their equipment.

- Online Forums: Communities of enthusiasts and professionals share their experiences and solutions, making these forums a rich source of practical knowledge.

- Repair Guides: Many websites and publications specialize in repair tutorials and step-by-step instructions that can simplify complex tasks.

- Parts Retailers: Online retailers frequently offer exploded views and detailed descriptions of components, which can be useful when identifying specific items.

Utilizing these resources can help you navigate repairs more effectively and deepen your understanding of the machinery you are working with.