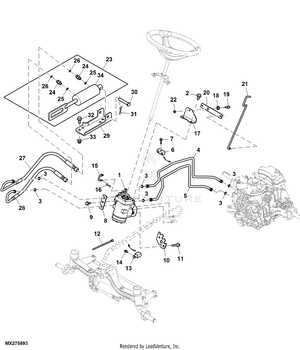

Hydraulics: Helps in power steering and other automated adjustments, improving

Maintenance Tips for Optimal Performance

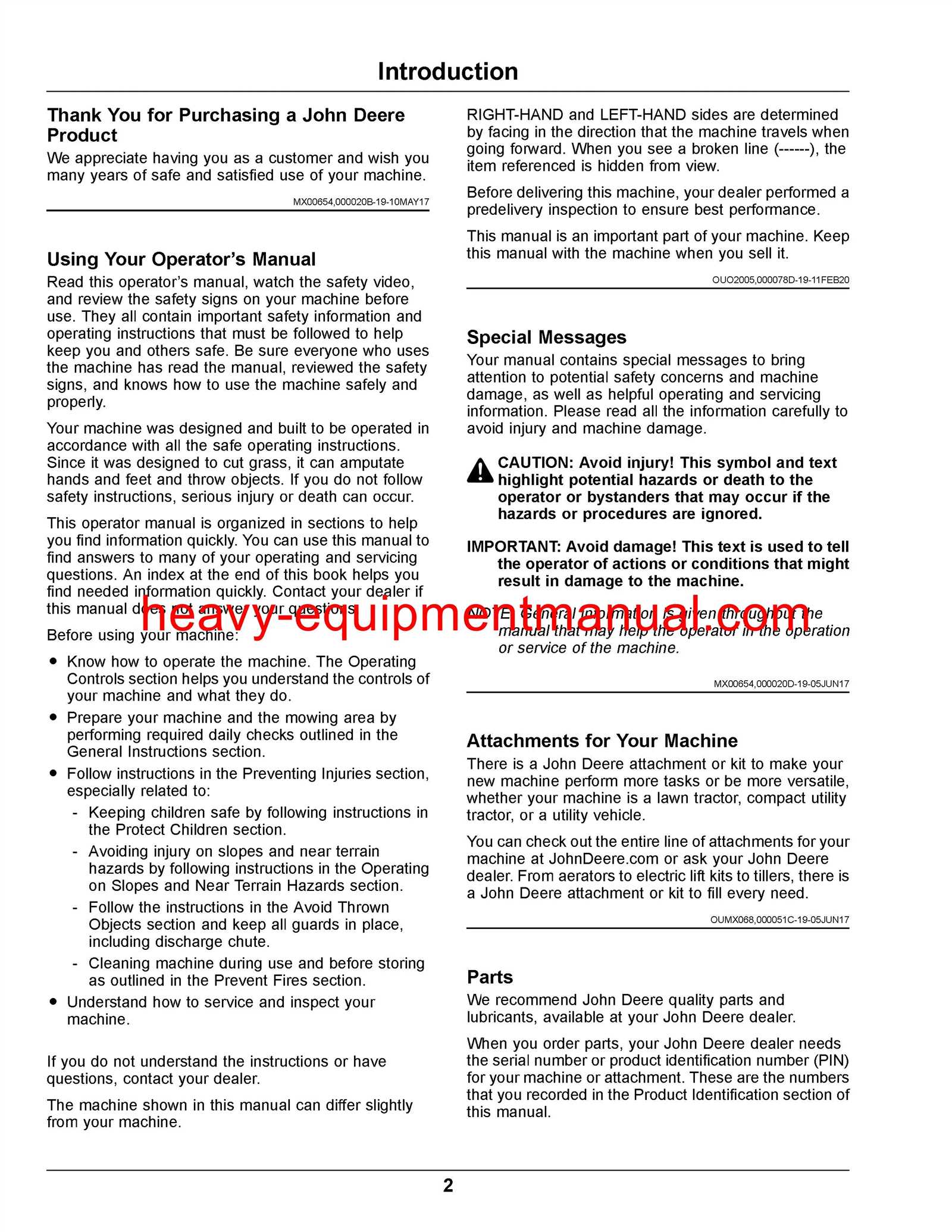

To ensure the longevity and peak functionality of your equipment, proper care and regular inspections are essential. Keeping all components clean and well-adjusted helps prevent unnecessary wear and ensures everything runs smoothly. Here, we will discuss key maintenance practices that will improve the efficiency and extend the life of your machine.

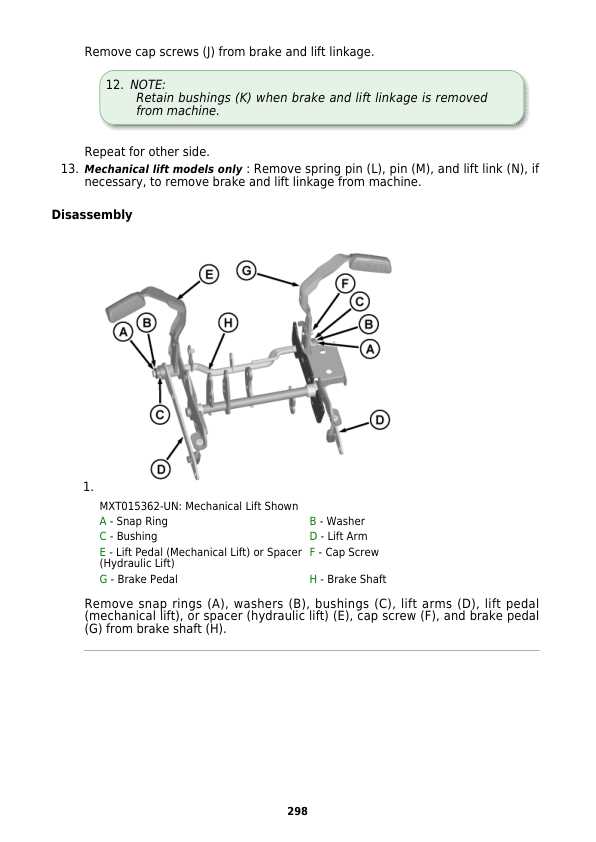

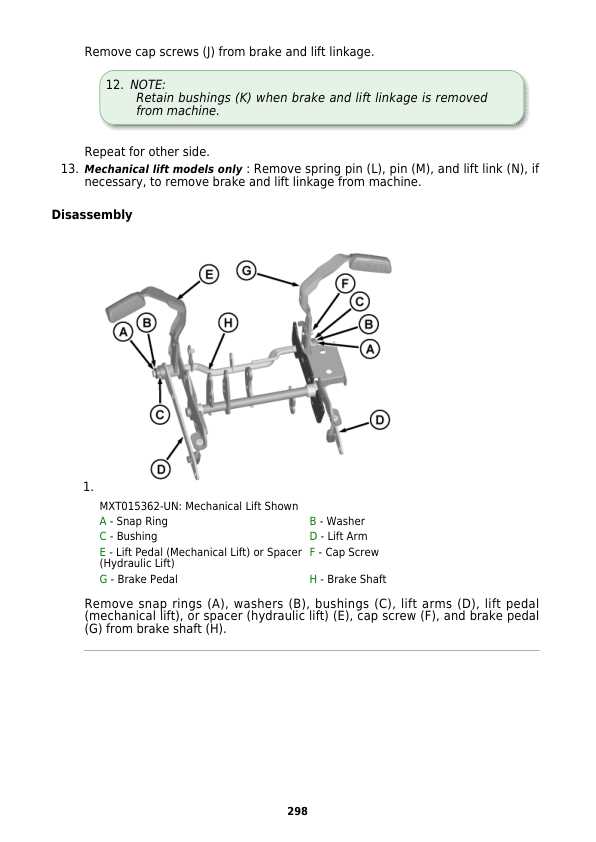

Identifying and Replacing Key Parts

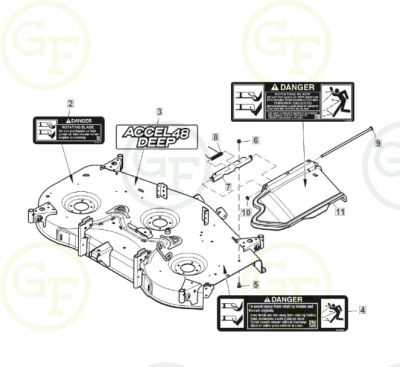

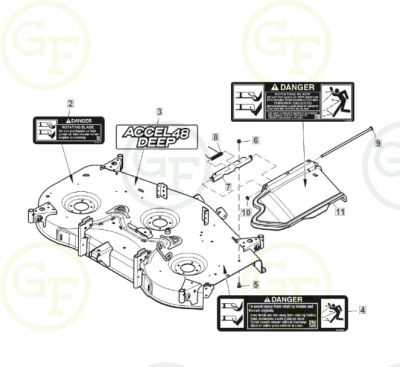

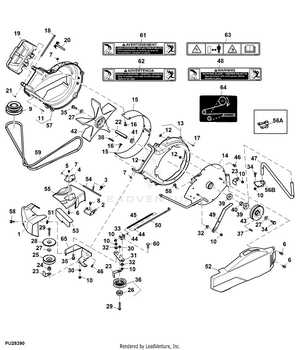

Blade and Deck Mechanism Overview

The blade and deck assembly is a crucial component in maintaining the efficiency of any mowing apparatus. This system plays a pivotal role in achieving an even cut while ensuring optimal performance during operation. Understanding its structure and functionality is essential for effective maintenance and troubleshooting.

The mechanism typically consists of several key elements, including the cutting blade, support deck, and drive components. Each part works in harmony to create a seamless mowing experience. The cutting blade is designed to slice through grass with precision, while the deck serves as the housing that stabilizes the blade and facilitates airflow, improving cutting efficiency.

Maintenance of this assembly is vital to prolonging its lifespan and ensuring peak performance. Regular inspection for wear and tear, along with timely replacement of damaged components, can prevent potential failures. Proper alignment and adjustment are also essential to guarantee uniform cutting height and to minimize the risk of scalping.

In summary, a thorough understanding of the blade and deck assembly enhances the overall functionality of mowing equipment, ensuring that it operates at its best while delivering quality results.

Electrical System and Wiring Layout

The electrical framework of a mower is essential for its optimal functioning. It comprises various components that work in harmony to provide power and ensure seamless operation. A thorough understanding of the wiring arrangement is crucial for troubleshooting and maintenance, as well as for enhancing overall performance.

Key Components of the Electrical Framework

This system includes several critical elements, such as the battery, ignition switch, and various connectors. Each component plays a vital role in facilitating energy distribution throughout the machine. Proper identification and comprehension of these parts are necessary for effective repairs and upgrades.

Wiring Configuration and Connections

The wiring layout is designed to provide clear pathways for electrical flow, ensuring safety and efficiency. Understanding how these connections are made helps prevent potential issues, such as short circuits or disconnections. Regular inspections and maintenance of the wiring can significantly extend the lifespan of the mower’s electrical system.

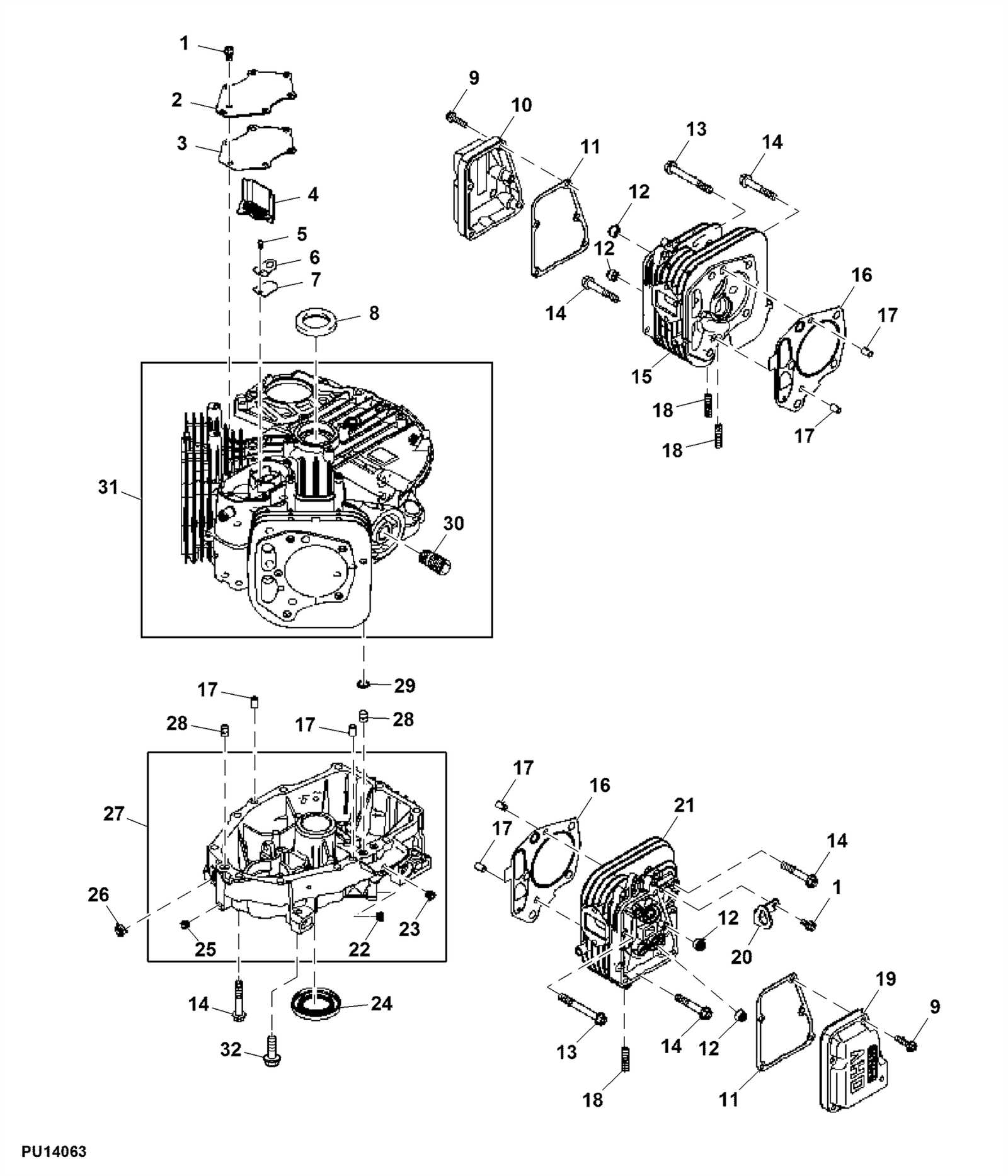

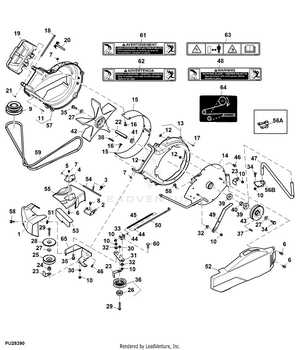

Fuel System Components and Operation

The fuel system plays a crucial role in the functionality and efficiency of internal combustion engines. Understanding its components and their interactions is essential for ensuring optimal performance and maintenance of the machinery. This system is responsible for storing, filtering, and delivering fuel to the engine, facilitating the combustion process that powers the vehicle.

Key components of the fuel system include the fuel tank, fuel pump, fuel filter, and fuel injectors. Each part has a specific function that contributes to the overall efficiency of the engine.

| Component |

Function |

| Fuel Tank |

Stores fuel until needed by the engine. |

| Fuel Pump |

Transfers fuel from the tank to the engine. |

| Fuel Filter |

Removes impurities from the fuel to prevent damage to the engine. |

| Fuel Injectors |

Atomizes and delivers fuel into the combustion chamber. |

The operation of the fuel system begins when the pump activates, drawing fuel from the tank. This fuel passes through the filter, ensuring that only clean fuel reaches the injectors. The injectors then spray the fuel into the combustion chamber, where it mixes with air and ignites, driving the engine’s pistons and providing power to the vehicle.

How to Troubleshoot Common Issues

Tackling common challenges in machinery operation requires a systematic approach. By understanding potential malfunctions and their underlying causes, operators can effectively diagnose and resolve issues, ensuring optimal performance. This section provides essential insights into identifying frequent problems and applying suitable solutions.

Identifying Symptoms

Before initiating any troubleshooting process, it’s crucial to observe and record the symptoms displayed by the equipment. Look for signs such as unusual noises, diminished power output, or erratic behavior. Documenting these indicators will aid in narrowing down the possible causes and streamline the repair process.

Common Solutions

Once the symptoms are identified, focus on potential remedies. Begin with basic checks, such as examining fluid levels and ensuring proper connections. If issues persist, refer to the manufacturer’s guidelines for further troubleshooting steps. Regular maintenance is also vital; routine inspections can prevent many issues from arising in the first place.