When it comes to maintaining expansive green spaces, having a reliable machine can make all the difference. This discussion focuses on the intricate details of a specific model that has gained popularity among landscaping professionals and enthusiasts alike. By exploring the inner workings of this equipment, users can better understand how each segment contributes to its overall functionality.

Within the realm of outdoor machinery, every element plays a crucial role in ensuring optimal performance. From the cutting mechanism to the drive system, grasping the relationship between these components is essential for effective maintenance and troubleshooting. This knowledge not only enhances the user experience but also prolongs the lifespan of the machine.

As we delve deeper into the various sections, we will uncover the ultimate guide to recognizing and replacing essential elements when necessary. Whether you’re a seasoned operator or a newcomer, understanding these components will empower you to achieve the best results in your lawn care endeavors.

Overview of John Deere 757 ZTrak

This section provides a comprehensive examination of a particular model of commercial mower, known for its efficiency and performance in landscaping tasks. Users can expect a robust design and features tailored for optimal functionality, ensuring reliable operation across various terrains.

Key Features

The model boasts a powerful engine, allowing for swift cutting and enhanced maneuverability. Durability is a hallmark, with components designed to withstand rigorous use. Additionally, the intuitive control system provides ease of handling, making it suitable for both professionals and enthusiasts alike.

Maintenance Considerations

Regular upkeep is crucial for maintaining peak performance. Routine checks on the engine and cutting deck can prolong the lifespan and ensure smooth operation. Access to replacement components is vital for efficient repairs and adjustments, contributing to overall reliability.

Key Features of the 757 ZTrak

This machine boasts a range of exceptional characteristics that enhance its performance and usability. Designed for efficiency and durability, it stands out in the realm of outdoor equipment.

One notable aspect is its powerful engine, which delivers impressive torque and speed, making tasks easier and quicker. The advanced cutting system ensures a clean, precise finish, ideal for maintaining manicured lawns.

Additionally, the ergonomic controls provide comfort during operation, allowing users to navigate various terrains effortlessly. The robust construction offers longevity, making it a reliable choice for both residential and commercial applications.

Ultimately, these features combine to create a versatile tool that meets the needs of any landscape enthusiast or professional.

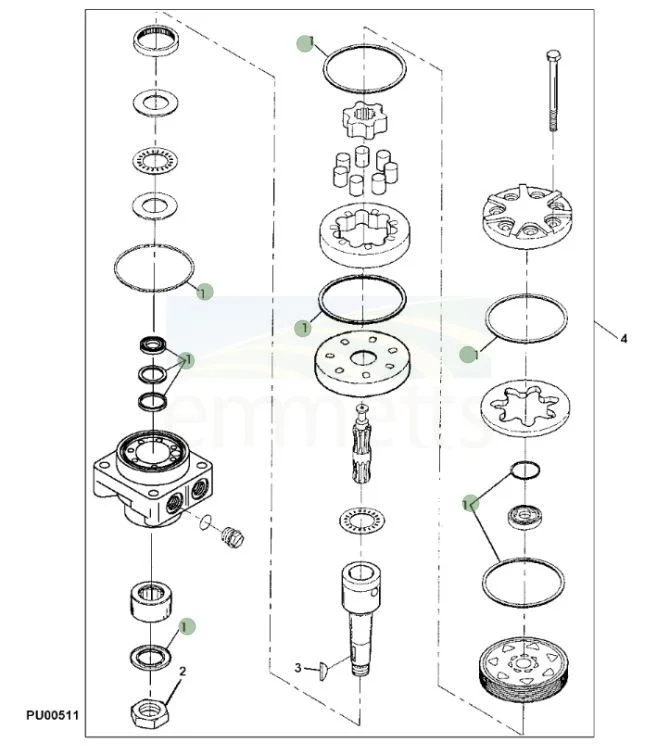

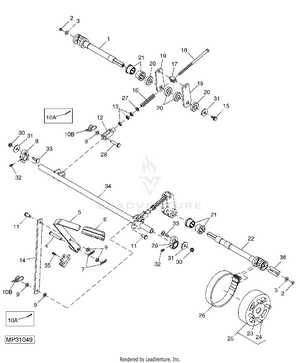

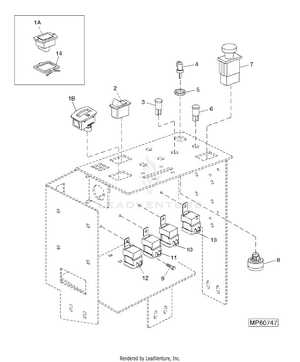

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a visual representation of its components. These illustrations serve as essential tools for maintenance and repair, ensuring that users can efficiently identify and address issues.

Here are several key benefits of utilizing such visual aids:

- Enhances comprehension of assembly and disassembly processes.

- Facilitates accurate ordering of necessary components.

- Simplifies troubleshooting by clearly showing connections and layouts.

- Reduces the risk of errors during repairs, leading to improved efficiency.

Ultimately, leveraging these visual references is crucial for anyone seeking to maintain machinery effectively.

Common Maintenance for ZTrak Models

Regular upkeep is essential for ensuring the longevity and performance of your lawn care equipment. Implementing a consistent maintenance routine can help prevent breakdowns and enhance efficiency, ultimately leading to a better mowing experience.

Key Maintenance Tasks

- Check and change the oil regularly.

- Inspect and replace air filters as needed.

- Sharpen or replace mower blades frequently.

- Examine belts and cables for wear and tear.

- Keep tires properly inflated and check for damage.

Seasonal Considerations

- At the beginning of the season, perform a comprehensive inspection.

- Before winter storage, clean and service the equipment thoroughly.

- Ensure all fluids are topped off and protected against freezing.

Identifying Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process when you know where to look and how to approach it. Understanding the structure and functionality of each element allows for efficient identification and replacement. By familiarizing yourself with the common features and specifications, you can streamline your maintenance tasks significantly.

Utilize Resources: Various online resources provide comprehensive catalogs and detailed visuals, helping you locate specific items quickly. These tools can simplify the search, offering insights into compatibility and functionality.

Consult Manuals: Operating manuals often contain valuable information, including illustrations and descriptions that clarify the roles of different elements. Reviewing these documents can enhance your understanding and assist in identifying the necessary replacements.

Join Online Communities: Engaging with fellow users through forums and social media can be incredibly beneficial. Members often share experiences, tips, and recommendations that can lead you directly to the components you need.

Keep a Maintenance Log: Documenting your maintenance activities can help you track what components require attention and when. This proactive approach ensures that you are always prepared for future repairs, making it easier to find replacements as needed.

Understanding the Parts Diagram Layout

Comprehending the arrangement of components is essential for effective maintenance and repair of machinery. A well-structured layout provides clear visual references, allowing operators to quickly identify and locate individual elements. This understanding is crucial for troubleshooting and ensuring optimal performance.

Key Features of the Layout

- Identification Labels: Each section is typically marked with labels that denote specific parts, facilitating easier recognition.

- Groupings: Related components are often clustered together, which helps in understanding their functional relationships.

- Numbering System: A systematic numbering approach assists in tracking each part’s location and ordering replacements if necessary.

Benefits of Familiarity with the Layout

- Enhances efficiency in repairs and replacements.

- Reduces downtime by streamlining the identification process.

- Improves overall understanding of machine functionality.

Being familiar with the layout not only aids in maintenance but also empowers operators to perform tasks with confidence and precision.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. High-quality replacements are designed to meet the original specifications, providing reliability and durability that aftermarket options often lack.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These retailers are recognized by manufacturers and often carry a wide range of genuine items. Visiting an authorized dealership not only guarantees quality but also provides access to expert advice and support tailored to your specific needs.

Online Marketplaces

The internet offers various platforms where you can find original replacements. Reputable online marketplaces often feature sections dedicated to equipment accessories, ensuring that you can browse through legitimate options. Always verify the seller’s reputation and look for customer reviews to ensure you are purchasing authentic merchandise.

Tips: Check for warranties, return policies, and certifications that confirm authenticity when shopping online or in-store.

Troubleshooting Common Issues

Maintaining optimal performance of your mowing equipment is crucial for effective operation. While these machines are designed for durability, issues may arise that can hinder functionality. Identifying and resolving these problems promptly can save time and prevent further damage.

Here are some common issues and their possible solutions:

- Engine Won’t Start

- Check the fuel level and ensure it’s fresh.

- Inspect the battery for proper charge and connections.

- Examine the ignition system, including spark plugs.

- Uneven Cutting

- Inspect the blades for sharpness and proper alignment.

- Check tire pressure to ensure balanced height.

- Ensure the deck is level and clean of debris.

- Excessive Vibration

- Look for loose bolts or components that may require tightening.

- Examine the blades for damage or bending.

- Check for worn-out bearings or spindles.

- Hydraulic Issues

- Check hydraulic fluid levels and leaks in hoses.

- Inspect filters for clogs or contamination.

- Ensure all connections are secure and operational.

By addressing these common challenges, operators can enhance the longevity and efficiency of their equipment. Regular maintenance and timely troubleshooting are key to sustaining peak performance.

Benefits of Using Original Components

Utilizing authentic parts ensures optimal performance and longevity of your equipment. These components are specifically designed to fit seamlessly, enhancing reliability and reducing the risk of malfunctions.

Quality Assurance

Original components undergo rigorous testing, guaranteeing high standards of quality and durability. This leads to better overall functionality and peace of mind for the user.

Compatibility

Using genuine parts ensures perfect compatibility with existing systems, minimizing potential issues during installation and operation.

| Benefit | Description |

|---|---|

| Performance | Ensures optimal operation and efficiency. |

| Durability | Designed to withstand wear and tear over time. |

| Support | Access to expert assistance and guidance. |