Valves: These control the direction, pressure, and flow of the hydraulic fluid

Troubleshooting Common Haybine Issues

Working with forage cutting equipment can present a range of challenges that operators may encounter. Recognizing these problems early can save time and resources, ensuring smooth operation during peak harvesting seasons. Understanding the typical issues that arise and knowing how to address them is essential for maintaining efficiency and productivity.

1. Poor Cutting Performance: If the machine is not cutting effectively, it may be due to dull blades or improper adjustment. Regularly inspect and sharpen the cutting edges, ensuring they are set at the correct height for optimal performance.

2. Material Jamming: Jams can occur when foreign objects enter the cutting area or if the material is too thick. Clear any debris and check for blockages regularly. Ensuring proper feed rates can also help minimize this issue.

3. Uneven Cut: An uneven cut can result from worn-out components or misalignment. Check the frame and support structures for any wear and adjust them accordingly. Ensuring that all moving parts are lubricated and functioning smoothly is crucial.

4. Vibration or Noise: Excessive vibration or unusual noise may indicate loose or damaged components. Perform a thorough inspection of all belts, pulleys, and bearings to identify any issues that need to be addressed.

5. Hydraulic Issues: If the hydraulic system is not functioning properly, it may be due to low fluid levels or leaks. Regularly check fluid levels and inspect hoses and connections for any signs of wear or damage.

By being proactive and attentive to these common problems, operators can ensure their equipment runs efficiently and effectively throughout the harvesting season.

Maintenance Tips for Extended Durability

Proper upkeep of agricultural equipment is essential for ensuring its longevity and efficient operation. Regular maintenance not only prevents unexpected breakdowns but also enhances performance, allowing machines to function at their best for years to come. Following a systematic maintenance routine can significantly extend the life of your machinery, saving you both time and resources.

Here are some essential maintenance tips to keep your equipment in top condition:

| Maintenance Task |

Frequency |

Notes |

| Inspect belts and hoses |

Monthly |

Look for signs of wear, cracking, or fraying. |

| Change oil and filters |

Every 100 hours of operation |

Use manufacturer-recommended products for best results. |

| Clean air filters |

Every 50 hours of operation |

Replace if they are excessively dirty or damaged. |

| Sharpen blades |

After every use |

Ensure clean cuts and reduce strain on the engine. |

| Check tire pressure |

Weekly |

Proper inflation improves efficiency and reduces wear. |

By adhering to these guidelines, you can maximize the operational lifespan of your equipment and minimize costly repairs. A proactive approach to maintenance will not only enhance performance but also provide peace of mind, knowing that your machinery is ready for the demands of the season.

Where to Find Replacement Parts

When it comes to maintaining agricultural machinery, sourcing the right components is essential for ensuring optimal performance and longevity. Identifying reliable suppliers and understanding the various options available can significantly impact the efficiency of your equipment.

Here are some effective ways to locate the necessary items:

- Authorized Dealers: Visiting authorized distributors is one of the most reliable ways to obtain genuine components. These suppliers often carry a comprehensive selection and provide expert advice.

- Online Retailers: Numerous e-commerce platforms specialize in machinery components. Websites like Amazon, eBay, and specialized agricultural supply stores often have a vast inventory of products suitable for your needs.

- Local Farm Supply Stores: Many local shops focus on agricultural equipment and may carry essential items or be able to order them for you. Supporting local businesses can also foster community relationships.

- Manufacturer Websites: Visiting the official website of the machinery manufacturer can lead you to available items and specifications, along with potential online purchasing options.

- Parts Recyclers: Salvage yards or recycling centers can offer affordable alternatives. While these items may be pre-owned, they can be a cost-effective solution for older models.

By exploring these avenues, you can ensure that your machinery remains functional and efficient, minimizing downtime and enhancing productivity.

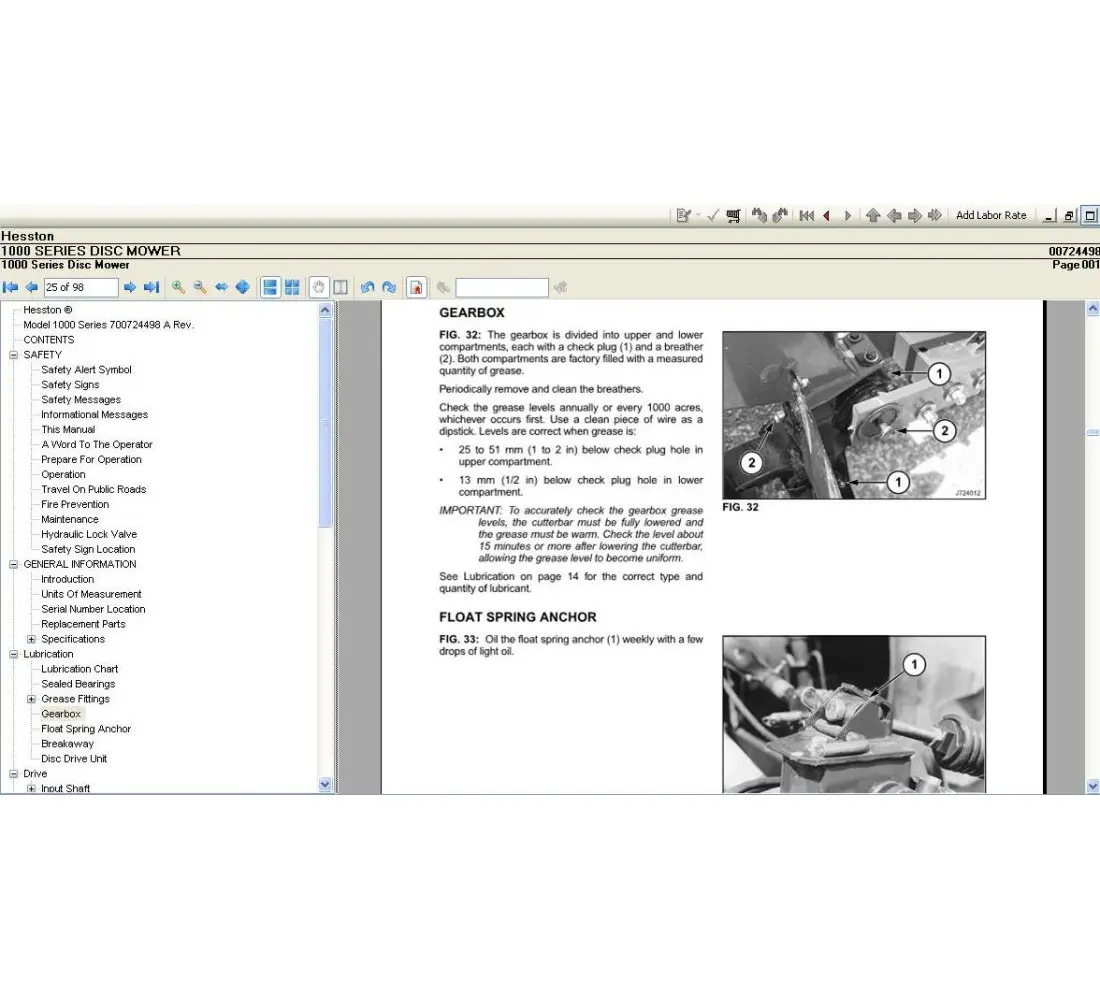

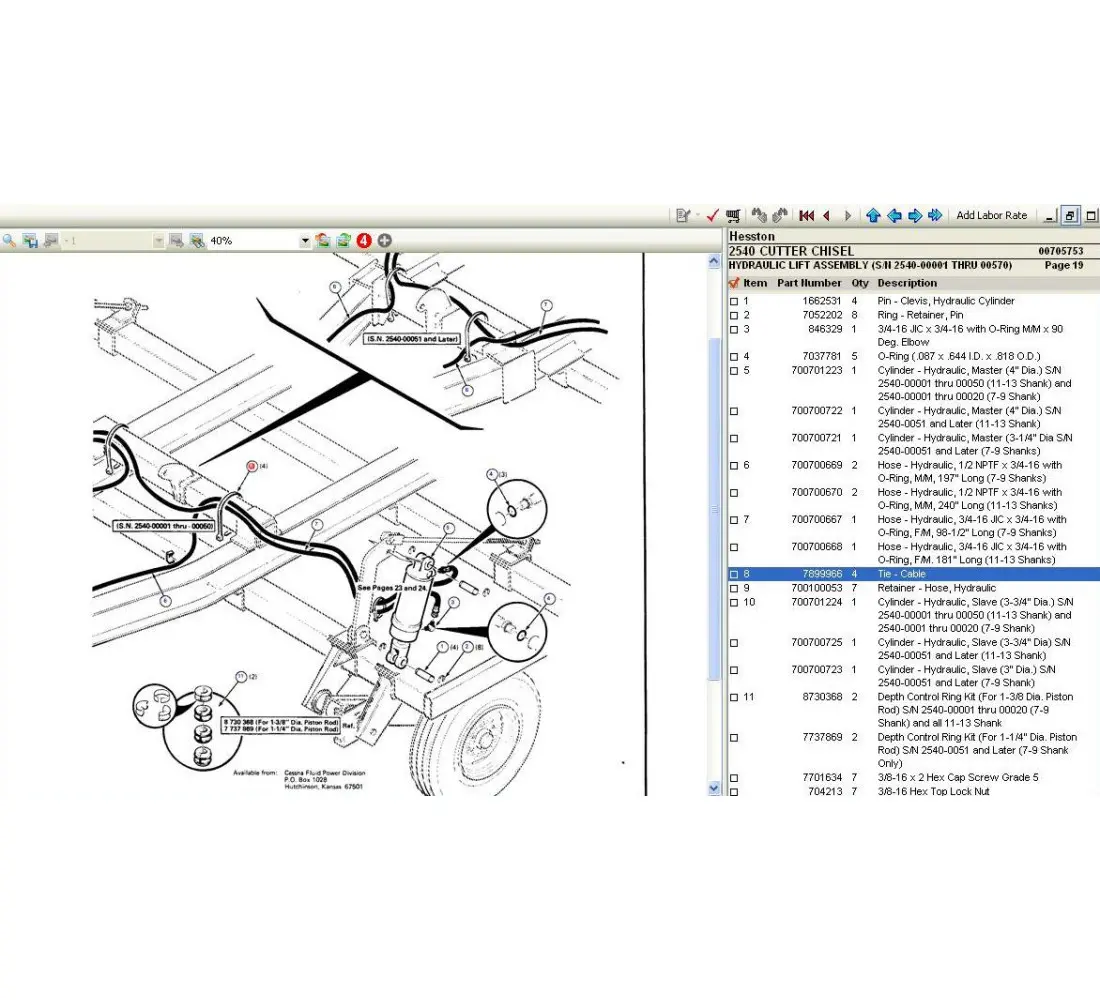

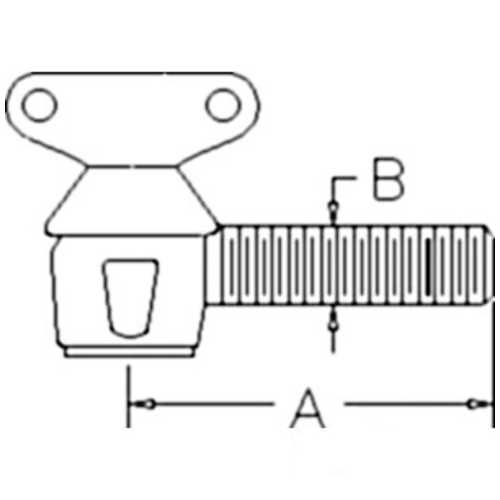

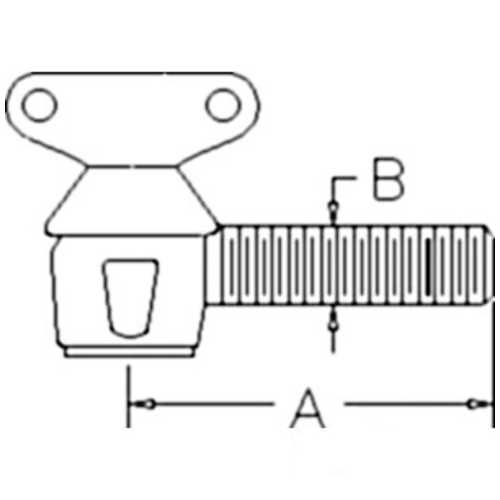

Interpreting the Hesston 1091 Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair of agricultural machinery. This guide aims to enhance your ability to navigate and comprehend such illustrations, ensuring you can identify and manage various elements with confidence.

First and foremost, familiarize yourself with the layout of the illustration. Each section is typically organized into distinct areas, which correspond to specific functions of the equipment. This organization allows for quick reference and helps pinpoint where a particular item is located within the system.

Additionally, pay attention to the labeling and numbering of the components. Each part is usually assigned a unique identifier that can be cross-referenced with a corresponding list, providing detailed information about specifications and compatibility. Being able to decipher these labels is crucial for ordering replacements or understanding the assembly process.

Finally, consider the scale of the visual representation. Knowing the proportion of the illustration relative to the actual size of the parts can aid in visualizing how they fit together. This understanding is vital when planning repairs or upgrades, as it ensures that all elements will work harmoniously within the system.