The intricacies of modern farming equipment are essential for optimizing agricultural operations. A thorough comprehension of the various elements within these machines enhances their functionality and ensures efficient performance.

Identifying and analyzing the different sections of agricultural machinery enables operators to address issues proactively. This knowledge not only aids in maintenance but also empowers users to make informed decisions regarding repairs and upgrades.

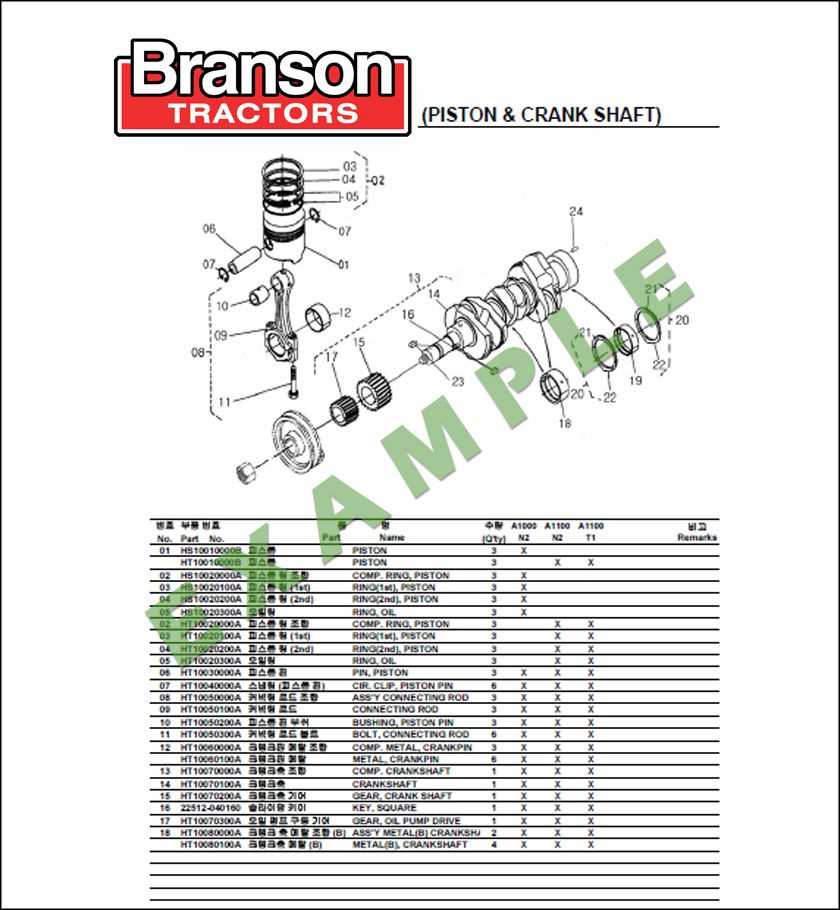

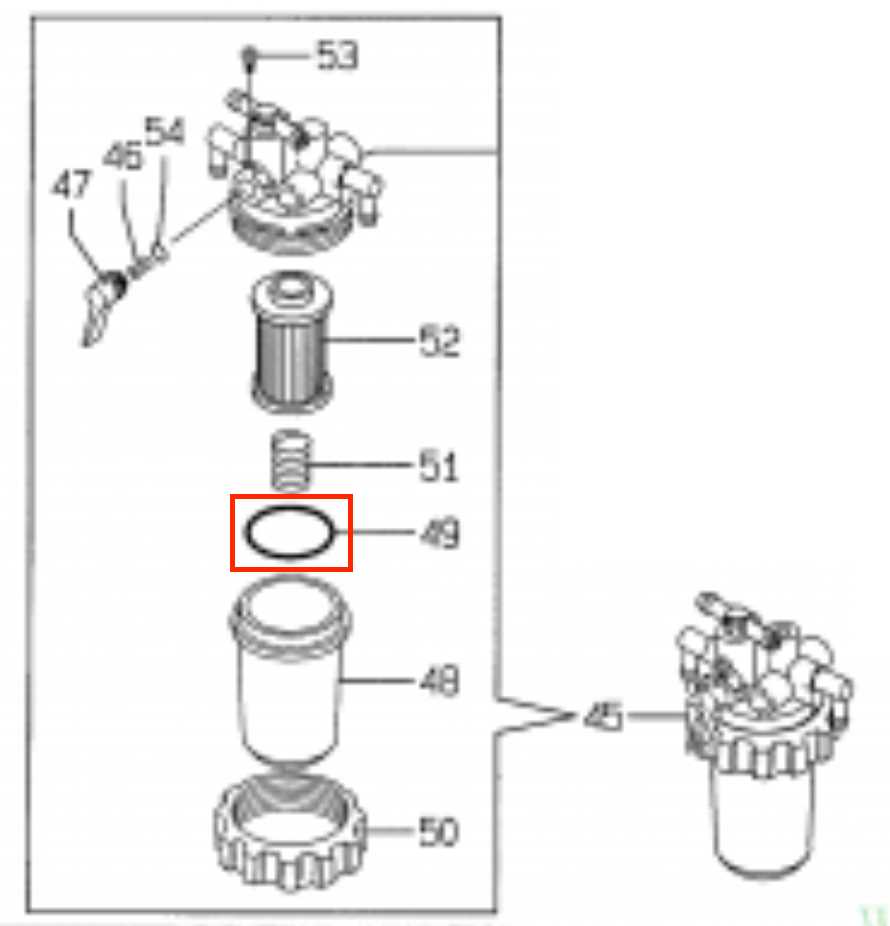

Utilizing visual representations of the machine’s components can significantly aid in this understanding. By referring to comprehensive illustrations, users can pinpoint specific areas that require attention, facilitating a smoother operational experience.

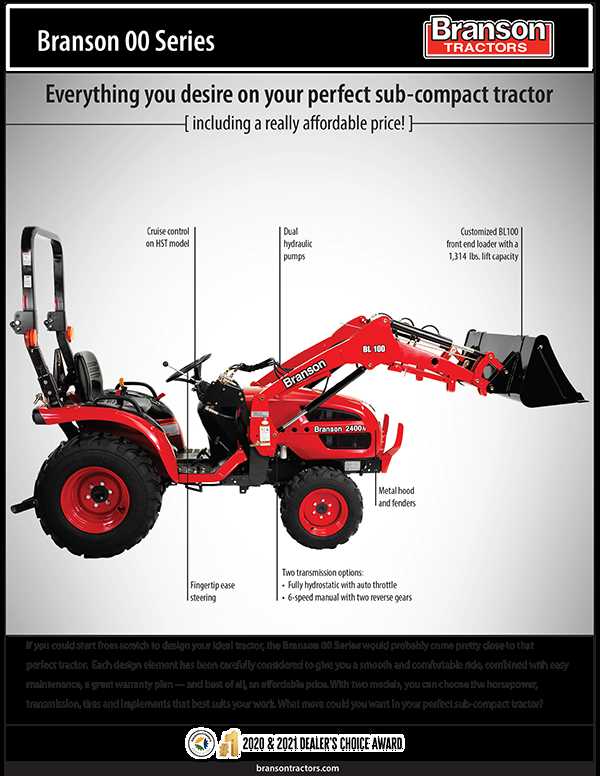

This section provides a comprehensive overview of the agricultural machinery designed for various farming tasks. These machines are known for their durability, efficiency, and user-friendly features, making them a popular choice among professionals and hobbyists alike. Understanding the components and their functions is essential for effective operation and maintenance.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit that drives the machine. | Provides the necessary power for operation. |

| Transmission | System for transferring power from the engine to the wheels. | Controls speed and torque for various tasks. |

| Chassis | Frame that supports all components. | Ensures stability and strength during use. |

| Hydraulic System | System that utilizes fluid to transfer power. | Facilitates lifting and controlling attachments. |

| Wheels | Round components that enable mobility. | Allow for movement across various terrains. |

Understanding Parts and Their Functions

Gaining insight into the components of machinery is essential for effective operation and maintenance. Each element plays a crucial role in ensuring optimal performance, contributing to the overall efficiency of the system. This section will explore various elements, their purposes, and how they interact within the machinery.

Key Components and Their Roles

Every component serves a specific function, and understanding these roles helps in troubleshooting and enhancing performance. Here are some vital elements:

- Engine: The power source, converting fuel into mechanical energy.

- Transmission: Transfers power from the engine to the wheels, enabling movement.

- Hydraulics: Facilitates lifting and controlling attachments through pressurized fluid.

- Chassis: The frame that supports the entire structure, providing stability and durability.

- Electrical System: Powers lights, ignition, and other electronic components.

Interconnection of Elements

The relationship between these components is crucial for the machinery’s functionality. Understanding how they interact can help users make informed decisions regarding maintenance and repairs. Consider the following aspects:

- Regular maintenance ensures that each component operates efficiently.

- Failures in one part can affect the overall performance.

- Upgrades or replacements can enhance productivity and extend the machinery’s lifespan.

Common Issues with Tractor Components

Machinery used in agriculture often encounters a variety of challenges that can affect its efficiency and performance. Understanding these common problems is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Some prevalent difficulties include:

- Worn Seals and Gaskets: Over time, seals may degrade, leading to leaks and loss of fluids.

- Electrical Failures: Issues with wiring or connections can result in malfunctioning systems.

- Clogged Filters: Accumulation of debris in filters can restrict airflow or fluid flow, causing operational inefficiencies.

- Corrosion: Exposure to moisture can lead to rust, compromising the integrity of various components.

- Alignment Issues: Misalignment of parts can cause increased wear and tear, leading to further complications.

Regular inspection and timely maintenance can help address these challenges effectively, ensuring smooth operation and minimizing downtime.

How to Identify Genuine Parts

Ensuring the authenticity of replacement components is crucial for optimal performance and longevity of your equipment. Genuine items not only guarantee compatibility but also maintain the reliability of your machinery. This section outlines key factors to consider when distinguishing authentic components from counterfeit alternatives.

Visual Inspection

Begin with a thorough examination of the item. Look for discrepancies in color, finish, and overall quality. Genuine components typically exhibit superior craftsmanship, while counterfeit versions may show signs of poor manufacturing.

Check for Certification

Most legitimate manufacturers provide certification or documentation with their products. This can include warranty information, serial numbers, and official branding. Always verify these details to confirm the item’s authenticity.

| Feature | Genuine Item | Counterfeit Item |

|---|---|---|

| Quality | High-quality materials | Poor craftsmanship |

| Documentation | Includes warranty and serial number | No documentation or fake papers |

| Branding | Official logos and labels | Incorrect or missing branding |

Maintenance Tips for Optimal Performance

To ensure your machinery operates at its best, regular upkeep is essential. Adopting a consistent maintenance routine can significantly enhance efficiency and prolong the lifespan of the equipment. This section provides useful strategies to help maintain optimal functionality.

Routine Inspections

Conducting regular inspections is crucial for identifying potential issues before they escalate. Check all components for signs of wear, leaks, or damage. Pay special attention to belts, fluids, and filters, as these are vital for smooth operation.

Lubrication and Cleaning

Keeping all moving parts properly lubricated reduces friction and prevents premature wear. Additionally, regular cleaning of the machinery not only improves appearance but also helps to prevent dust and debris from causing damage to internal components.

Where to Find Parts Diagrams

Locating visual references for components can greatly assist in maintenance and repairs. These resources provide essential information about individual elements and their arrangements, making the servicing process more efficient.

Online Resources

Numerous websites offer extensive collections of visual aids. Here are some recommended sources:

- Manufacturer’s official site

- Specialized parts suppliers

- Online forums and community groups

Printed Manuals

In addition to digital resources, printed manuals are valuable tools. They often include detailed visuals and can be obtained through various channels:

- Local dealerships

- Technical book retailers

- Online marketplaces

Using Diagrams for Repair Guidance

Visual representations play a crucial role in assisting individuals during maintenance tasks. These illustrations simplify complex assembly structures and provide clarity on various components, making the repair process more manageable and efficient. By offering a visual reference, users can quickly identify the necessary actions and components needed for successful restoration.

Benefits of Visual References

Utilizing these visual aids enhances understanding and reduces the likelihood of errors during repairs. They help users grasp the relationships between different elements, ensuring that every piece is accurately placed. Furthermore, visual guides can highlight specific areas that require attention, making troubleshooting more straightforward.

Best Practices for Effective Use

To maximize the effectiveness of these visual resources, it is essential to approach them methodically. First, familiarize yourself with the layout and symbols used in the illustrations. Take notes on critical steps and refer back to the visuals regularly as you progress. This practice will foster a more organized repair process, ultimately leading to better outcomes.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in understanding complex machinery. They serve as visual aids that enhance comprehension, allowing users to identify various components and their functions efficiently.

Having reliable representations is essential for effective maintenance and repair tasks. Accurate visuals help technicians pinpoint issues quickly, reducing the time needed for diagnostics. Furthermore, these resources facilitate communication among team members, ensuring everyone is on the same page regarding procedures and parts involved.

Additionally, well-crafted illustrations contribute to safety by highlighting key areas that require attention during operations. By providing a comprehensive overview, they empower users to navigate tasks with confidence and awareness, minimizing the risk of accidents or errors.

Resources for Further Assistance

When facing challenges related to equipment maintenance and functionality, it is essential to have access to reliable information and support. Various sources can provide valuable insights, troubleshooting guidance, and component information to enhance the overall experience of ownership.

Online Forums and Communities

Participating in dedicated online platforms allows users to connect with fellow enthusiasts and experts. These forums are excellent for sharing experiences, solutions, and advice.

Manufacturer Support

Reaching out to the original equipment manufacturer can yield specific guidance tailored to the equipment. They often provide manuals, troubleshooting tips, and customer support.

| Resource Type | Description | Website |

|---|---|---|

| Online Forums | Community-driven platforms for discussions and advice. | exampleforum.com |

| Manufacturer Website | Official site for support, manuals, and contact info. | examplemanufacturer.com |

| Repair Shops | Local services offering hands-on assistance and repairs. | examplerepair.com |