In the world of heavy machinery, comprehending the layout of various components is essential for efficient maintenance and repair. An organized representation of each element allows operators and technicians to visualize how parts interact and function together. This knowledge is crucial for troubleshooting issues and ensuring the longevity of equipment.

Accurate illustrations serve as valuable references for anyone involved in the upkeep of machinery. By providing detailed insights into the arrangement of elements, these visuals help users identify specific components quickly. Familiarity with the configuration promotes a more efficient workflow, reducing downtime and enhancing productivity.

Moreover, an in-depth understanding of component positioning not only aids in repairs but also empowers users to perform regular maintenance tasks. This proactive approach minimizes the risk of unexpected failures and contributes to the overall reliability of the equipment. Engaging with these representations encourages a deeper appreciation of machinery mechanics.

This section aims to provide a comprehensive overview of the various elements that make up agricultural machinery, emphasizing their functionality and interrelation. Understanding these components is crucial for effective maintenance and repair, ensuring optimal performance in field operations.

1. Overview of Essential Elements

Every piece of farming equipment consists of numerous vital elements, each playing a significant role in the overall operation. Recognizing these components allows for better troubleshooting and upkeep.

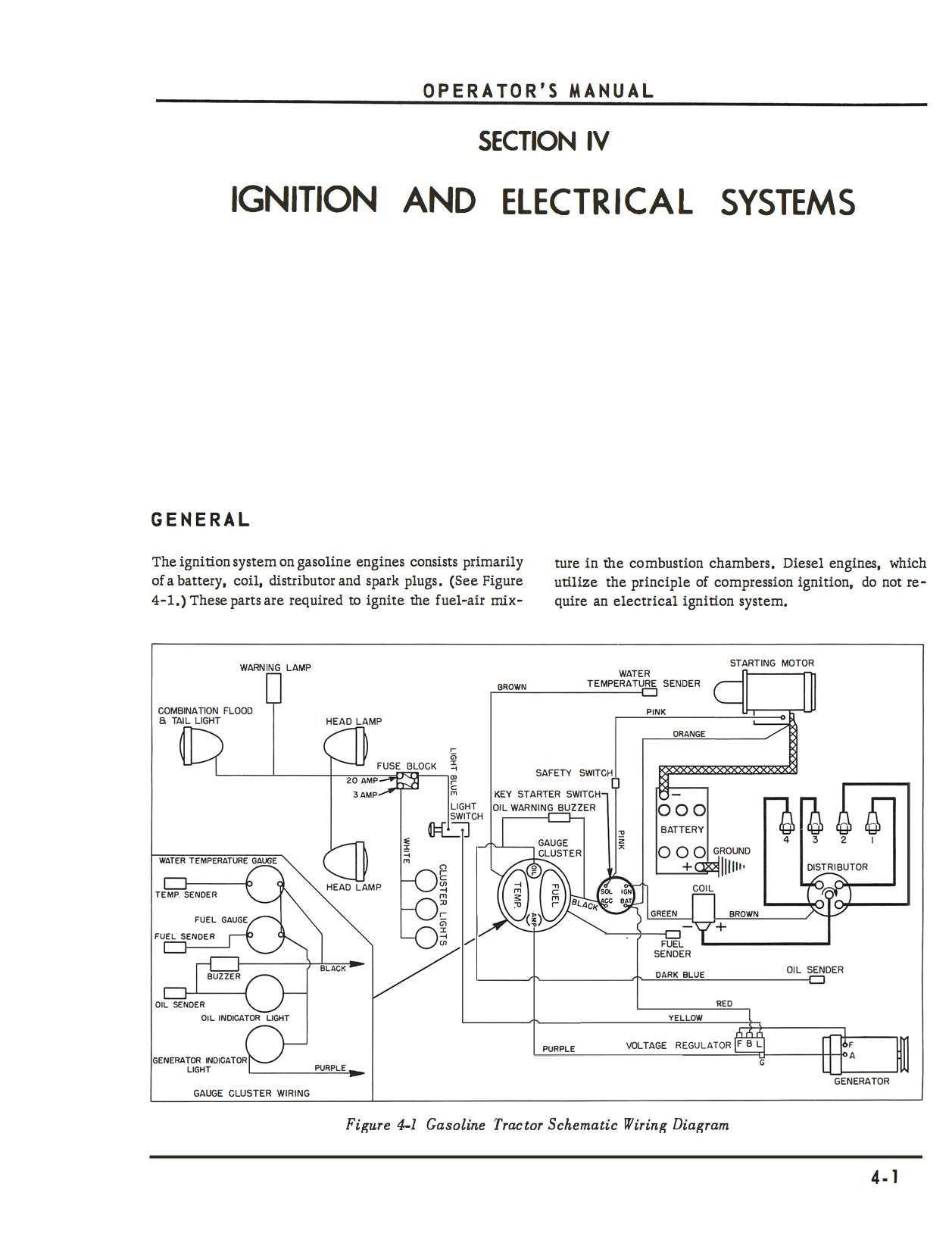

2. Engine and Power Transmission

The engine serves as the heart of the machinery, converting fuel into mechanical energy. Coupled with the power transmission system, it facilitates movement and power distribution across the equipment.

3. Hydraulic System Basics

The hydraulic system operates various attachments and implements, enhancing the versatility of the equipment. Understanding its components, such as pumps and cylinders, is essential for efficient functionality.

4. Chassis and Frame Structure

The chassis provides the structural integrity necessary for supporting all other elements. A well-designed frame ensures stability and durability, impacting overall performance.

5. Steering and Control Mechanisms

Effective steering and control systems are vital for maneuvering in diverse terrain. Familiarity with these components improves operational precision and safety.

6. Maintenance and Repair Practices

Regular maintenance and timely repairs are essential for prolonging the life of machinery. Knowledge of component-specific care techniques contributes to sustained performance.

7. Troubleshooting Common Issues

Identifying and addressing common problems can prevent major breakdowns. A systematic approach to troubleshooting can significantly enhance operational efficiency.

8. Resources for Further Learning

Numerous resources are available for those seeking to deepen their understanding of machinery components. Manuals, online forums, and workshops offer valuable insights into effective management practices.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy |

| Power Transmission | Distributes power to wheels and attachments |

| Hydraulic System | Operates implements and attachments |

| Chassis | Supports all components and provides stability |

| Steering System | Facilitates movement and control |

Essential Parts of Oliver Tractors

This section discusses the key components crucial for the optimal functioning of agricultural machines, highlighting their roles and significance in ensuring efficiency and reliability. Understanding these elements is essential for effective maintenance and operation, contributing to the longevity and performance of the equipment.

Various elements contribute to the effective operation of these machines. Each plays a specific role in the overall functionality, and knowing their details can help operators perform necessary upkeep.

| Component | Description | Function |

|---|---|---|

| Engine | The power source of the equipment. | Drives the machinery and provides necessary energy for operation. |

| Transmission | System that transfers power from the engine to the wheels. | Controls the speed and torque, enabling movement. |

| Hydraulics | Fluid power system that operates various attachments. | Facilitates lifting, steering, and other functions requiring force. |

| Chassis | The frame that supports all other components. | Provides stability and structure for the overall machine. |

| Wheels | Round components that allow movement across terrain. | Support the weight and enable mobility on various surfaces. |

Common Issues with Tractor Parts

Maintenance of agricultural machinery is crucial for ensuring optimal performance and longevity. Various challenges can arise during usage, often leading to reduced efficiency and potential breakdowns. Understanding these common complications can help in timely intervention and enhance the operational lifespan of the equipment.

Frequent Mechanical Failures

Mechanical failures often stem from wear and tear over time. Components such as gears and belts may exhibit signs of fatigue, resulting in operational inefficiencies. Regular inspections can help identify these issues early, minimizing the risk of severe damage and costly repairs.

Improper Installation and Alignment

Incorrect installation or misalignment of components can lead to significant performance issues. It is essential to follow the manufacturer’s guidelines during assembly and ensure all parts are properly aligned to avoid unnecessary stress on the machinery. Regular maintenance and checks can prevent these problems from escalating, ensuring smooth operation.

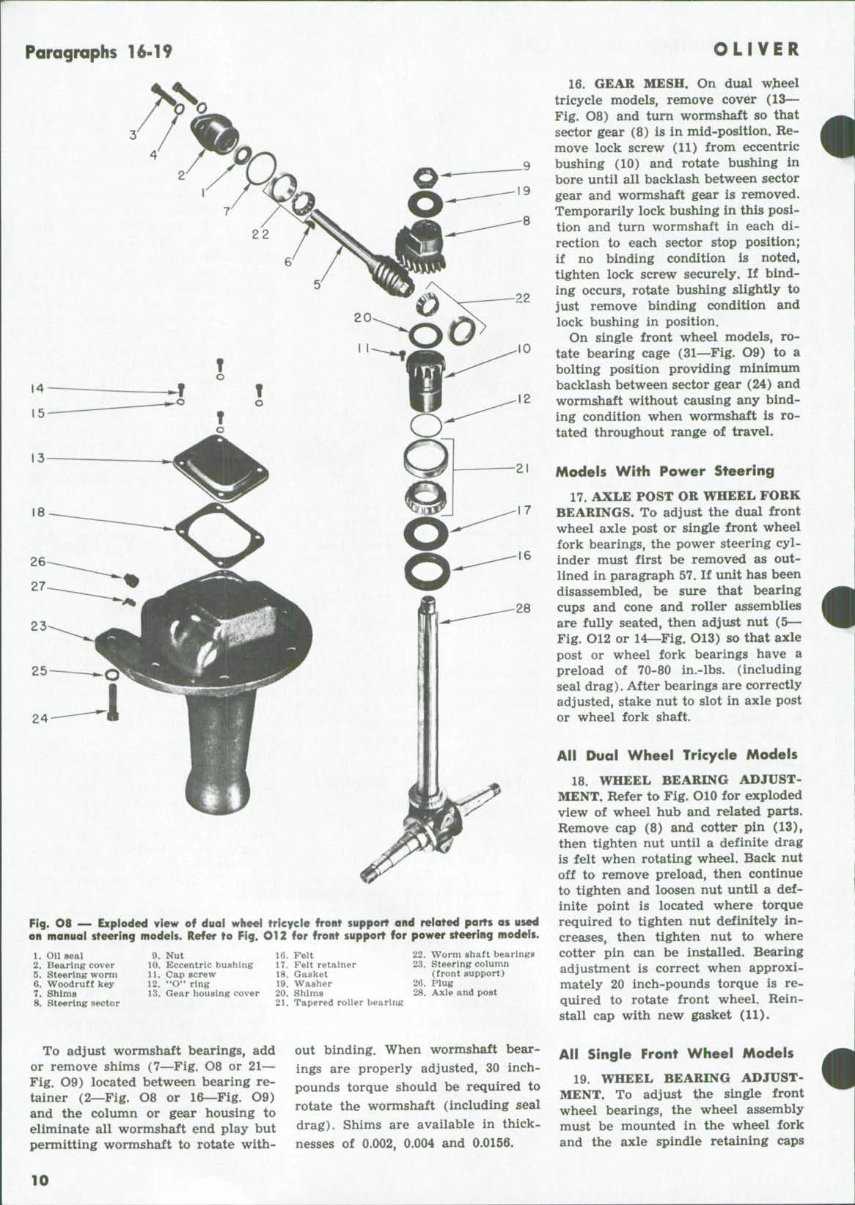

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. This guide aims to enhance your ability to interpret these illustrations, ensuring you can identify each item and its function within a system.

Identifying Key Symbols

Every illustration contains specific symbols that denote various elements. Familiarizing yourself with these signs is crucial, as they provide valuable information regarding the components’ roles and connections.

Locating Reference Numbers

Typically, illustrations include reference numbers that correspond to a list of items. These numbers facilitate the identification of components, allowing for accurate ordering and replacement. Understanding how to navigate this reference system is vital for efficient repairs.

| Symbol | Description |

|---|---|

| ▲ | Indicates assembly points |

| ▼ | Denotes disassembly points |

| ◆ | Represents optional components |

| ● | Shows standard parts |

Maintenance Tips for Oliver Tractors

Proper upkeep is essential for ensuring the longevity and optimal performance of agricultural machinery. Regular care and attention can prevent unexpected breakdowns and costly repairs, leading to more efficient operations in the field.

Routine Inspections

Conducting frequent assessments of the equipment is crucial. Check fluid levels, examine belts and hoses for wear, and ensure that all components are securely fastened. Addressing minor issues promptly can avert more significant problems later on.

Scheduled Servicing

Establish a servicing schedule based on usage and manufacturer’s recommendations. Regular oil changes, filter replacements, and other routine maintenance tasks contribute to smooth operation and extend the lifespan of the machinery.

Finding Replacement Parts Efficiently

Locating suitable components for machinery can often be a daunting task. However, with the right strategies and resources, this process can become significantly more manageable. Understanding the available options and where to find them is crucial for ensuring the longevity and functionality of your equipment.

Utilizing Online Resources

One of the most effective methods for finding necessary components is to leverage online platforms. Numerous websites specialize in providing detailed catalogs and diagrams, allowing users to search by model or part number. Here are some tips for efficient online searches:

- Use specific keywords related to the equipment type.

- Check for reputable retailers or manufacturers’ websites.

- Look for user forums or communities for shared experiences and recommendations.

Visiting Local Dealers and Shops

In addition to online searches, visiting local dealers can offer personalized assistance. Many establishments have knowledgeable staff who can help identify the required components and provide insights into availability. Consider the following when visiting local shops:

- Bring along any existing components for reference.

- Ask about special orders if the item is not in stock.

- Inquire about any warranties or return policies on purchased items.

Upgrades for Enhanced Performance

Improving the functionality of agricultural machinery can significantly boost efficiency and productivity. Implementing specific enhancements not only optimizes performance but also extends the lifespan of the equipment. Various modifications can be considered to achieve these goals.

Engine Enhancements

One of the primary areas for improvement is the power unit. Upgrading components such as the fuel system, air intake, and exhaust can lead to better combustion efficiency and increased horsepower. Investing in a high-performance fuel filter and a premium air cleaner can make a noticeable difference in the machine’s overall output.

Hydraulic System Improvements

Another crucial area for enhancement is the hydraulic system. Revising hydraulic fluid quality and optimizing hose sizes can improve the responsiveness of attachments. Additionally, incorporating advanced hydraulic filters can help maintain cleaner fluid circulation, further enhancing operational efficiency.

Repair Techniques for Common Failures

Understanding and addressing frequent malfunctions is essential for maintaining optimal performance. This section outlines various methods and strategies that can be applied to resolve typical issues encountered in machinery. Proper diagnosis and implementation of these techniques can prolong the lifespan of equipment and enhance its efficiency.

Preventative Measures

Regular inspections and maintenance are crucial in preventing breakdowns. Keeping components clean and well-lubricated reduces wear and tear, thereby minimizing the risk of failures. Establishing a routine check-up schedule allows for early detection of potential problems, enabling timely repairs before they escalate.

Effective Troubleshooting Approaches

When encountering a malfunction, a systematic troubleshooting approach can help identify the root cause. Start by examining the symptoms and ruling out simple issues, such as loose connections or insufficient fuel supply. Utilizing diagnostic tools can aid in pinpointing specific problems, facilitating efficient and targeted repairs.

Resources for Oliver Tractor Owners

For individuals who own classic farming machinery, having access to reliable information and tools is essential for effective maintenance and restoration. Numerous resources exist to assist enthusiasts in finding the right solutions for their equipment needs, ranging from manuals to online forums. These valuable assets can enhance the ownership experience and ensure that the machinery remains in optimal condition.

Online Communities and Forums

Engaging with fellow enthusiasts through online communities can provide invaluable support and knowledge sharing. Various forums are dedicated to discussions about machinery maintenance, troubleshooting, and restoration techniques. Participants often share their experiences, offer advice, and provide recommendations on reliable suppliers for essential components.

Instructional Guides and Manuals

Accessing detailed instructional guides and manuals is crucial for effective equipment management. These documents typically include step-by-step procedures for repairs, maintenance schedules, and safety protocols. Many manuals can be found in digital format, making it easy for owners to download and reference them at any time.