The efficiency of agricultural machinery is heavily reliant on its various components working in harmony. A thorough comprehension of these elements is essential for effective maintenance and operation. By analyzing the layout and relationships among different sections, users can enhance performance and longevity.

Exploring the intricacies of these machines allows operators to identify potential issues early, ensuring timely interventions. Recognizing the arrangement and function of each component fosters a more profound appreciation for the overall system, contributing to improved productivity.

Furthermore, having access to detailed illustrations of these assemblies enables better planning and execution of repairs or upgrades. Such resources empower users to approach challenges with confidence, ensuring optimal functionality and reducing downtime in agricultural activities.

This section aims to provide a comprehensive look into the essential elements that make up a specific agricultural machine. Understanding these components is crucial for maintenance and efficient operation, enabling users to identify issues and perform necessary repairs effectively.

Key Elements of the Machine

The core components of this agricultural machine include:

- Engine: The powerhouse that drives the entire unit.

- Transmission: Responsible for transferring power from the engine to the wheels.

- Hydraulic System: Facilitates the operation of various implements and attachments.

- Chassis: The framework that supports all other components.

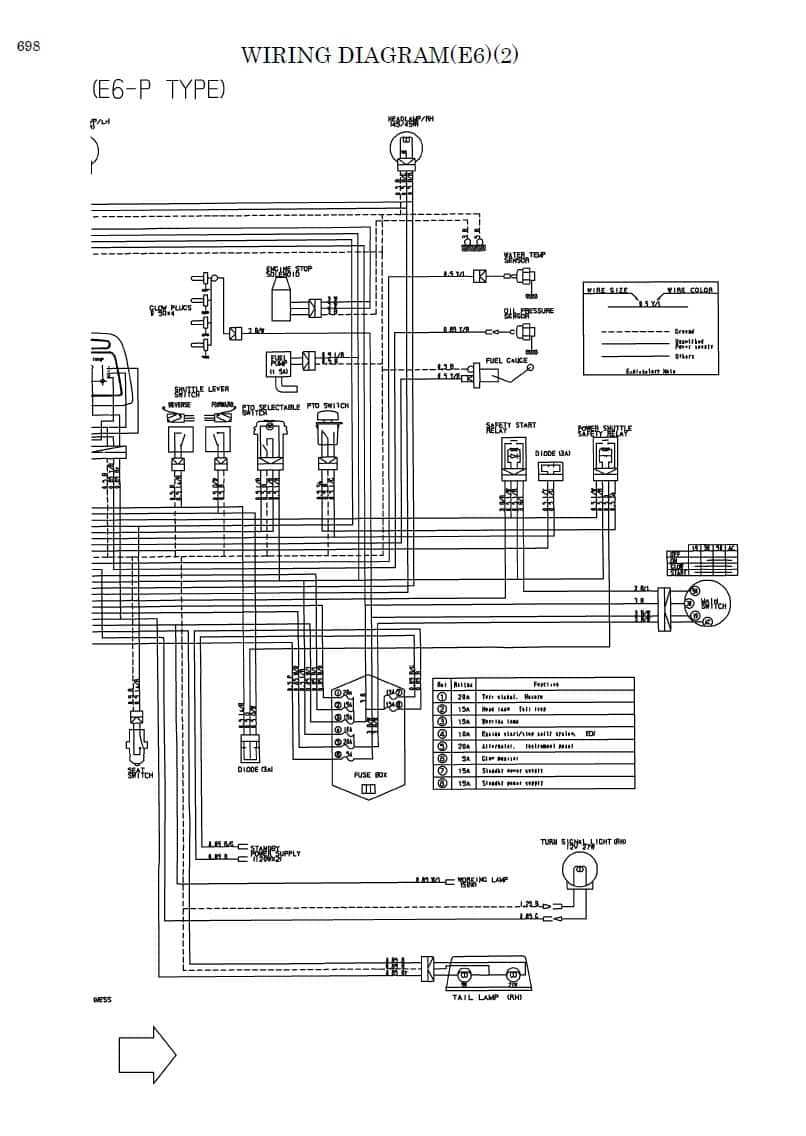

- Electrical System: Powers the machine’s lighting and control systems.

Importance of Regular Maintenance

Routine inspections and maintenance of these elements are vital to ensure the longevity and performance of the machine. Neglecting any of these components can lead to reduced efficiency and costly repairs.

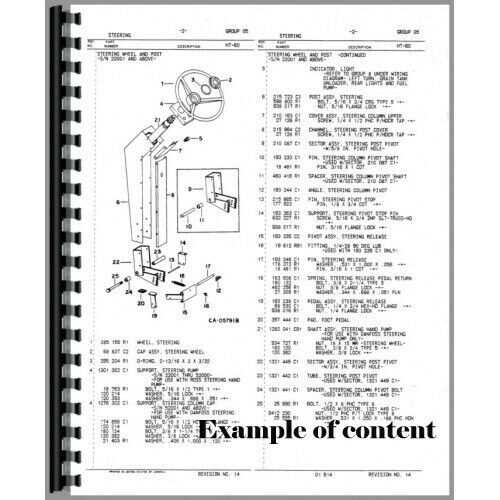

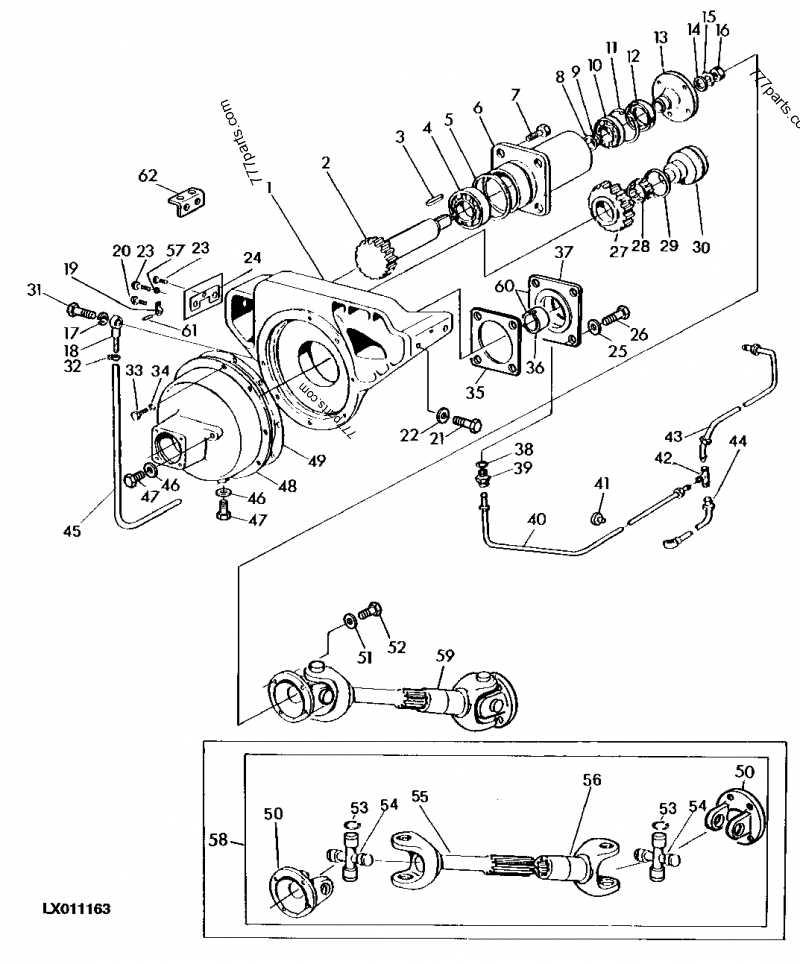

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair tasks. These illustrations serve as essential guides, enabling users to identify various elements and their interconnections accurately. By utilizing clear and detailed schematics, operators can ensure the proper functioning of machinery and enhance overall efficiency.

Moreover, these visuals help in minimizing errors during assembly or disassembly processes. When individuals rely on accurate representations, they are less likely to misplace or incorrectly install components. This accuracy not only saves time but also reduces the likelihood of costly mistakes that can arise from misunderstandings or misinterpretations.

Furthermore, such illustrations facilitate communication between technicians and manufacturers, ensuring that everyone is on the same page regarding specifications and requirements. In essence, well-crafted visual guides are indispensable tools that contribute significantly to the longevity and reliability of machinery.

Common Issues in Tractor Maintenance

Regular maintenance of agricultural machinery is crucial for optimal performance and longevity. Over time, these machines can face various operational challenges that require timely attention to avoid downtime and costly repairs.

1. Mechanical Wear and Tear

- Components such as belts, bearings, and hydraulic seals experience wear due to continuous use.

- Regular inspection and replacement of worn-out parts are essential to prevent breakdowns.

- Using high-quality replacement parts can extend the lifespan of critical components.

2. Electrical System Problems

- Issues with the electrical system can lead to starting problems or erratic operation.

- Common electrical issues include faulty wiring, corroded connectors, or malfunctioning sensors.

- Periodic checks and cleaning of electrical connections can mitigate these issues.

By addressing these common maintenance issues proactively, farmers and agricultural workers can ensure their equipment operates efficiently, minimizing downtime during critical periods of use.

Key Features of Zetor Models

The models from this renowned manufacturer are celebrated for their robust construction and versatile functionality. Designed to meet a wide range of agricultural needs, these machines offer exceptional performance and reliability across various tasks.

Power and Efficiency

One of the standout characteristics of these machines is their powerful engines, which provide impressive torque and fuel efficiency. The well-engineered powertrains ensure that users can tackle demanding jobs with ease, making them suitable for both small and large-scale operations.

User-Friendly Design

Another notable feature is the ergonomic design of the operator’s area. With intuitive controls and comfortable seating, these vehicles allow for prolonged use without fatigue. Additionally, maintenance is simplified, enabling quick access to essential components, ensuring optimal performance over time.

Understanding Hydraulic Systems in Tractors

Hydraulic systems play a crucial role in the functionality of various machinery, facilitating the efficient transfer of power and control. These systems utilize fluid under pressure to operate different components, allowing for enhanced performance in tasks that require significant force and precision. A thorough understanding of these mechanisms is essential for optimizing operations and ensuring the longevity of equipment.

Components of Hydraulic Systems often include pumps, cylinders, and valves, each serving a specific function in the overall operation. The pump is responsible for generating the hydraulic fluid’s pressure, while the cylinders convert this pressure into linear motion. Valves regulate the flow of fluid, directing it to the appropriate components as needed.

Maintenance of hydraulic systems is vital for avoiding potential issues that can lead to reduced efficiency or equipment failure. Regular checks on fluid levels, seals, and connections can prevent leaks and ensure optimal performance. Understanding the intricacies of these systems empowers operators to make informed decisions regarding repairs and enhancements.

Essential Tools for Parts Replacement

When it comes to maintaining and upgrading machinery, having the right equipment at hand is crucial. The appropriate tools not only ensure efficiency but also enhance safety during the process. This section outlines the key instruments necessary for effectively carrying out replacements.

Basic Hand Tools

Basic hand tools are fundamental for any maintenance task. These instruments are versatile and can be used for a variety of functions, from loosening screws to tightening bolts. Some essential hand tools include:

| Tool | Purpose |

|---|---|

| Wrench | Used for gripping and turning nuts and bolts. |

| Screwdriver | Essential for inserting and removing screws. |

| Pliers | Useful for gripping and bending various components. |

| Hammer | Ideal for driving nails or adjusting parts. |

Power Tools

In addition to hand tools, power tools can significantly speed up the replacement process. These tools are designed for heavy-duty tasks, making them invaluable in more demanding maintenance scenarios. Common power tools include:

| Tool | Purpose |

|---|---|

| Impact Wrench | Provides high torque output for loosening tight fasteners. |

| Drill | Used for creating holes or driving screws quickly. |

| Angle Grinder | Ideal for cutting and grinding metal parts. |

Where to Find Genuine Zetor Parts

Locating authentic components for your agricultural machinery can significantly impact its performance and longevity. Whether you are conducting maintenance or repairs, accessing reliable sources is essential for ensuring that you obtain the correct items.

Here are some effective avenues to explore:

- Authorized Dealers: Official distributors often carry a comprehensive selection of genuine components. They are knowledgeable about the specific requirements of your equipment.

- Online Retailers: Various e-commerce platforms specialize in agricultural supplies. Ensure they are reputable and provide a warranty on their products.

- Manufacturer’s Website: Visiting the official website can provide direct access to the latest inventory, special offers, and contact information for assistance.

- Local Workshops: Mechanics with experience in agricultural equipment may have connections to trusted suppliers or may carry genuine items themselves.

Prioritizing authentic components not only enhances the reliability of your machinery but also contributes to its efficiency and overall effectiveness in the field.

Tips for Effective Parts Identification

Identifying components accurately is essential for maintaining machinery and ensuring optimal performance. Whether you’re working on repairs or replacements, having a clear understanding of each element can significantly streamline the process.

- Consult the Manual: Always refer to the user guide or maintenance manual to get detailed information about various components.

- Use Visual Aids: Diagrams, images, and illustrations can help you visualize parts and their placements within the system.

- Organize Components: Sort elements by type or function to simplify identification and avoid confusion during assembly.

- Keep a Reference List: Maintain a list of common components, including their names and specifications, for quick access.

- Seek Expert Advice: Don’t hesitate to ask experienced technicians or online forums for assistance if you’re uncertain about specific items.

Utilizing these strategies can enhance your ability to recognize components accurately, thereby improving your overall maintenance efficiency.

Maintaining Your Zetor Tractor Efficiently

Effective upkeep of your agricultural machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and productivity in your daily operations. By adopting a proactive approach, you can address minor issues before they escalate into major problems, thereby saving time and resources.

Regular Inspection and Cleaning

Conducting frequent inspections is vital for identifying wear and tear in various components. Keep all parts clean and free of debris to ensure smooth operation. Regularly checking fluid levels, filters, and belts can help you catch potential issues early on, allowing for timely repairs.

Routine Lubrication and Adjustments

Proper lubrication of moving parts minimizes friction and wear, contributing to the overall efficiency of your machinery. Ensure that all joints and bearings are adequately greased according to the manufacturer’s recommendations. Additionally, making necessary adjustments to alignments and tensions can significantly improve performance.