In the realm of climate control systems, grasping the intricacies of their internal configurations is essential for optimal maintenance and repair. A thorough comprehension of how various elements interact within these units enhances both functionality and efficiency. This knowledge empowers technicians and enthusiasts alike to troubleshoot issues effectively, ensuring a prolonged lifespan for the equipment.

Each system comprises a multitude of interconnected components, each serving a specific role in the overall operation. From heating elements to cooling coils, understanding the arrangement and relationship of these individual units is crucial. A detailed overview allows users to visualize how air flows through the mechanism, optimizing performance and reducing energy consumption.

By familiarizing oneself with the layout of these essential components, one can significantly improve the diagnostic process. Recognizing potential problem areas and understanding how to access and replace parts can lead to swift solutions, minimizing downtime and enhancing user satisfaction. Thus, an insightful exploration of the structure not only aids in repairs but also fosters a deeper appreciation for the technology behind climate control.

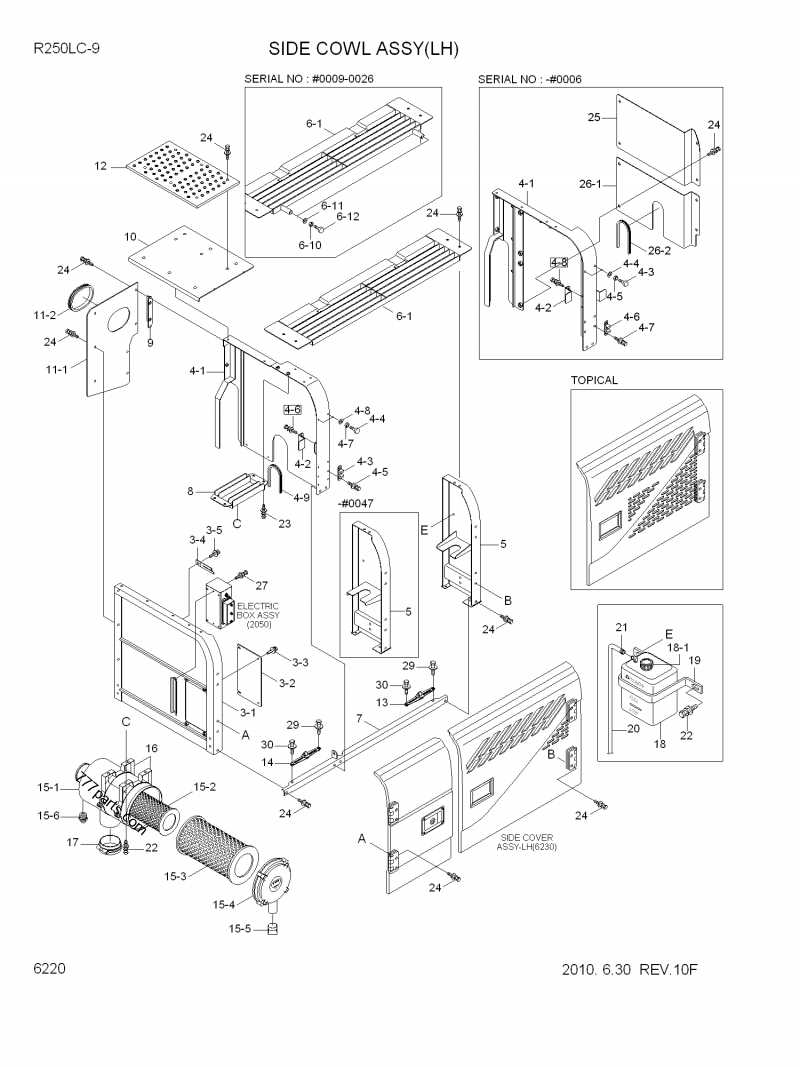

Understanding Ptac Parts Diagrams

Grasping the layout and components of a particular system is essential for effective maintenance and troubleshooting. This section aims to provide clarity on the visual representations that illustrate the various elements and their relationships within the unit. By familiarizing oneself with these schematics, users can enhance their understanding and streamline repair processes.

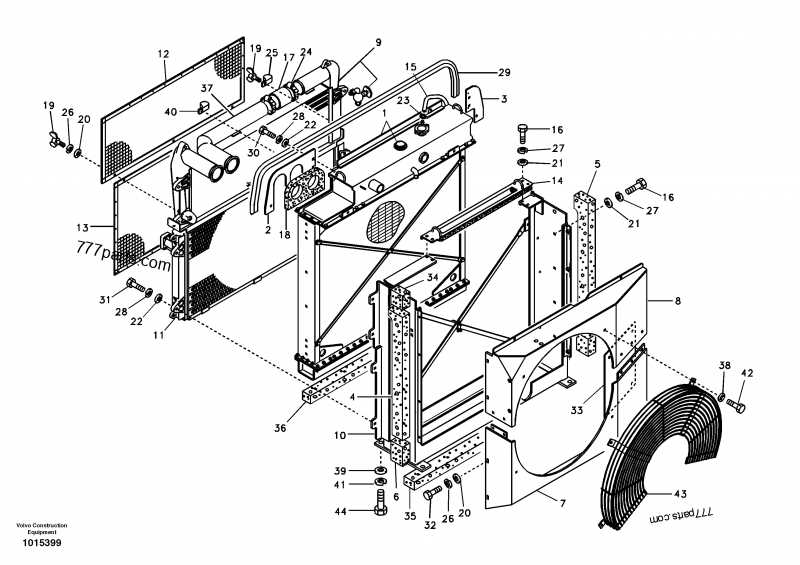

Key Components

The visual representations typically highlight critical components, such as electrical connections, mechanical parts, and functional units. Recognizing these elements allows for quicker identification of potential issues and facilitates informed decision-making during repairs or upgrades.

Interconnectivity and Functionality

Understanding how individual elements interact within the overall system is crucial. These visuals often depict the flow of energy and signals, providing insights into operational efficiency. A clear comprehension of this interconnectedness empowers users to optimize performance and enhance longevity through targeted interventions.

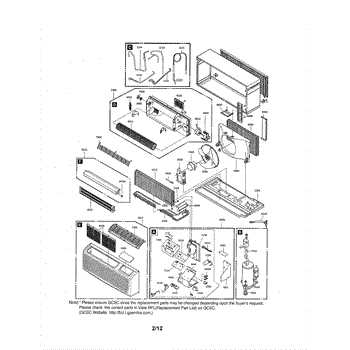

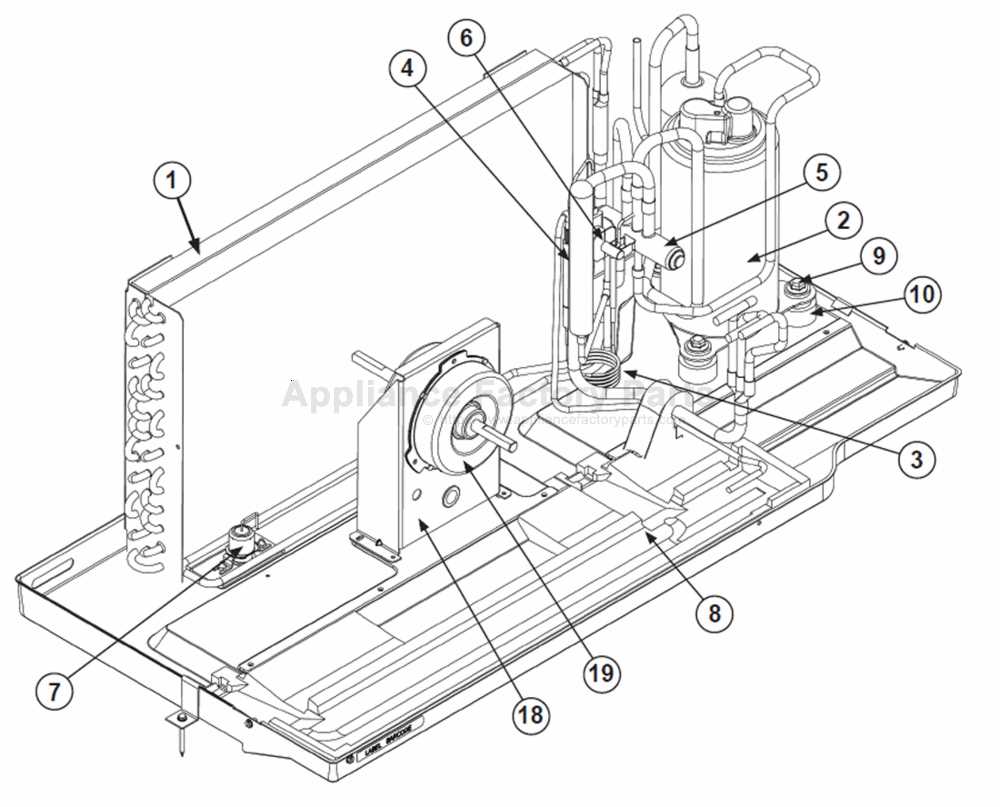

Key Components of Ptac Units

Understanding the essential elements of these heating and cooling systems is crucial for effective maintenance and operation. Each component plays a specific role, contributing to the overall functionality and efficiency of the unit.

Essential Elements

- Compressor: Responsible for circulating refrigerant and maintaining temperature.

- Evaporator Coil: Facilitates heat exchange, allowing the system to cool or heat the air.

- Condenser Coil: Releases absorbed heat into the outside environment.

- Fan: Distributes air throughout the space, ensuring even temperature control.

- Thermostat: Monitors and regulates the desired indoor temperature.

Additional Features

- Filter: Cleans the air by trapping dust and allergens.

- Drain Pan: Collects condensation, preventing water damage.

- Control Panel: Provides user interface for adjusting settings.

- Electrical Components: Enable operation and control of the system.

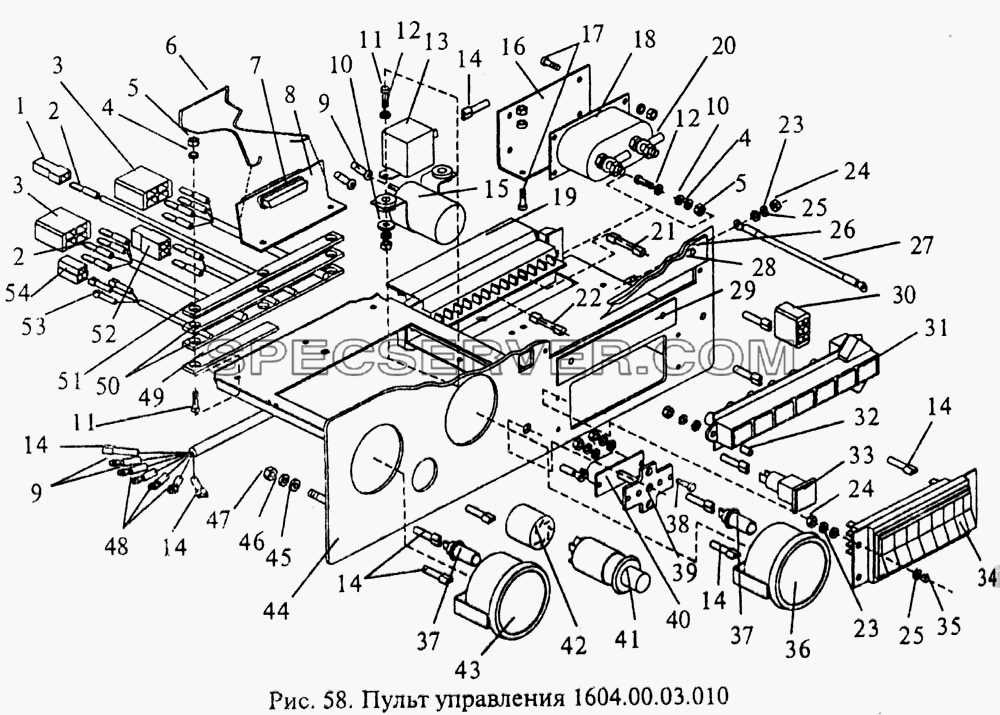

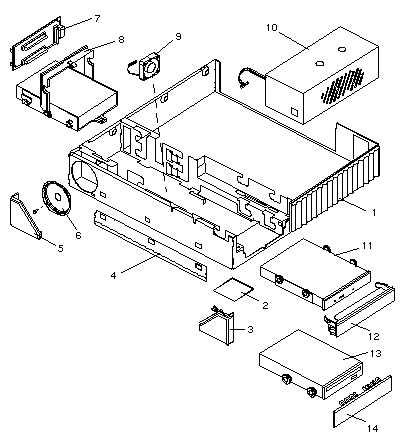

How to Read a Ptac Diagram

Understanding a schematic representation is essential for effective maintenance and troubleshooting. This visual guide simplifies complex information, allowing users to identify components and their relationships quickly. Familiarizing yourself with the symbols and layout will enhance your ability to interpret the information accurately.

Familiarize Yourself with Symbols

Every illustration utilizes specific icons to represent various elements. Pay attention to these symbols, as they are standardized across many designs. Each icon corresponds to a particular component, such as switches, connectors, or mechanical parts. Knowing these symbols will enable you to navigate the representation with confidence.

Understanding Connections and Flow

After recognizing the symbols, focus on the connections depicted. Lines and arrows indicate how components interact with each other. Understanding the flow of energy or data between elements is crucial for diagnosing issues and making repairs. Take note of how each part links to others, as this will provide insight into the overall system operation.

Common Issues Identified in Diagrams

In technical representations, various challenges can arise that hinder accurate interpretation and usability. These concerns can affect maintenance, troubleshooting, and overall understanding of the system components. Identifying and addressing these issues is crucial for effective communication and functionality.

Frequent Errors in Representations

Several common pitfalls can be observed in these visual aids. Mislabeling, missing elements, and unclear connections often lead to confusion among users. These inaccuracies can result in significant delays during repairs or installations, highlighting the importance of clarity and precision.

| Issue | Description | Impact |

|---|---|---|

| Mislabeling | Incorrect identification of components. | Leads to improper handling and repairs. |

| Missing Elements | Omission of crucial parts from the visual representation. | Results in incomplete understanding of the system. |

| Unclear Connections | Poorly defined links between components. | Causes difficulty in tracking flow and functionality. |

Recommendations for Improvement

To enhance the effectiveness of these visual tools, it is essential to ensure accuracy in labeling, include all necessary components, and clearly define connections. Regular updates and reviews can prevent outdated information and improve the reliability of these resources.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in any technical field. When components are illustrated with clarity, it enhances the ability of users to comprehend complex systems and facilitates more efficient troubleshooting and maintenance.

Clear visuals serve as essential tools that guide users in the assembly, disassembly, and repair processes. They reduce the likelihood of errors, which can lead to costly mistakes or equipment failure. When each element is depicted accurately, it not only streamlines operations but also fosters confidence in handling intricate machinery.

Moreover, accurate illustrations promote safety by ensuring that individuals can identify potential hazards and operate equipment correctly. This is especially vital in environments where misinterpretation can lead to dangerous situations. Ultimately, investing time in creating and utilizing precise visuals enhances overall efficiency and safety in various applications.

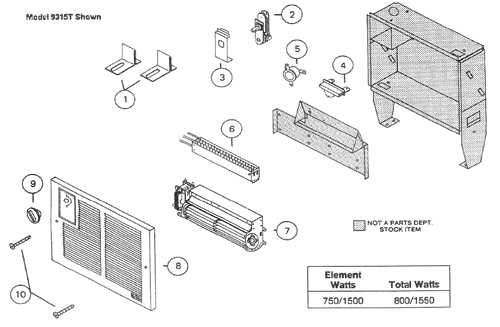

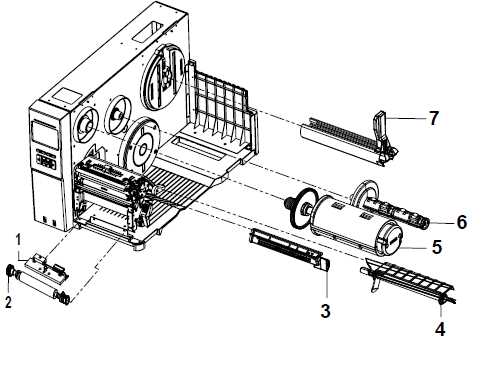

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for the assembly process, ensuring that each component is correctly fitted together for optimal performance. Following these systematic instructions will help streamline the entire procedure, making it accessible for both beginners and experienced individuals.

Preparation

Before starting the assembly, gather all necessary components and tools. Ensuring that you have everything at hand will prevent interruptions during the process. Lay out each piece in a clear workspace to facilitate easy access.

Assembly Steps

| Step | Description |

|---|---|

| 1 | Begin by aligning the base structure on a flat surface. Ensure that all mounting points are accessible. |

| 2 | Attach the side panels to the base using screws, making sure each connection is secure. |

| 3 | Install the central unit, ensuring that it is correctly positioned for optimal airflow. |

| 4 | Connect the electrical components, following the manufacturer’s guidelines to avoid any malfunctions. |

| 5 | Finally, perform a thorough inspection to verify that all parts are properly assembled and secured. |

Maintenance Tips for Ptac Systems

Regular upkeep of heating and cooling units is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also minimizes energy costs and extends the lifespan of the equipment. Here are some effective strategies to maintain these systems.

Regular Cleaning

One of the most important aspects of maintenance is keeping the unit clean. Dust and debris can obstruct airflow and reduce efficiency.

- Clean or replace filters every 1-3 months, depending on usage.

- Dust the exterior and surrounding areas to prevent dirt accumulation.

- Check and clean the evaporator and condenser coils at least once a year.

Seasonal Inspections

Conducting seasonal checks can help identify potential issues before they escalate. It’s advisable to schedule inspections at the beginning of each heating and cooling season.

- Inspect electrical connections and tighten any loose components.

- Test the thermostat to ensure accurate temperature readings.

- Examine drainage systems for blockages and clean as necessary.

Implementing these maintenance tips will help maintain efficiency and ensure reliable operation throughout the year.

Tools Required for Repairs

When tackling maintenance tasks, having the right instruments on hand is crucial for achieving successful outcomes. A well-equipped toolkit not only simplifies the process but also enhances efficiency, allowing for swift troubleshooting and effective resolutions. Understanding the essential tools can significantly impact the ease and quality of your repair work.

Key instruments typically include screwdrivers in various sizes, pliers for gripping and bending, and wrenches for fastening or loosening. Additionally, a multimeter is invaluable for electrical assessments, while utility knives can assist in precise cutting tasks. Safety gear, such as gloves and goggles, should also be prioritized to ensure personal protection during repairs.

Investing in quality tools is advisable, as they not only last longer but also perform better. Whether you’re a novice or an experienced individual, having the proper equipment tailored to specific tasks will undoubtedly lead to more effective maintenance and repair endeavors.

When to Consult a Professional

In various situations, the expertise of a specialist is crucial for ensuring safety and efficiency. While some tasks can be tackled independently, recognizing the right moments to seek help can save time, resources, and potential hazards. This section highlights key instances when professional intervention is advisable.

| Scenario | Reason for Professional Help |

|---|---|

| Complex Repairs | Specialized knowledge is required to address intricate issues that may arise. |

| Safety Concerns | When there are risks of injury or damage, a trained expert should handle the situation. |

| Lack of Experience | Inadequate familiarity with the task can lead to mistakes that may escalate the problem. |

| Regulatory Compliance | Professionals ensure that all work meets local codes and regulations. |

| Time Constraints | When time is limited, hiring an expert can expedite the process significantly. |

Consulting a trained individual not only enhances the quality of work but also provides peace of mind, knowing that the task is in capable hands.