The intricate world of agricultural equipment encompasses a vast array of mechanisms designed to enhance productivity on the farm. These machines, pivotal for various tasks, consist of numerous elements that work in harmony to ensure optimal performance. A comprehensive grasp of these components is essential for maintenance and efficient operation.

In exploring the layout of these essential tools, one can uncover the underlying structure that supports their functionality. Each section plays a critical role, and recognizing how they interconnect can lead to more effective troubleshooting and repairs. With this knowledge, operators can maximize their machinery’s potential and minimize downtime.

Furthermore, delving into the specifics of these assemblies reveals the ultimate importance of each piece. Understanding the purpose and interaction of various parts not only enhances operational efficiency but also contributes to the longevity of the equipment. This article aims to shed light on these aspects, offering insights that empower users in their daily agricultural practices.

Kuhn GMD 700 Overview

This section provides a comprehensive insight into a specific type of agricultural equipment designed for efficient mowing operations. The implement is engineered to optimize performance in various field conditions, making it a valuable asset for modern farming practices. Its innovative features enhance productivity and ensure reliability during use.

Key Features

The machinery is equipped with advanced cutting technology, allowing for precise and clean cuts. Its robust construction ensures durability, even under demanding circumstances. Additionally, the design incorporates user-friendly elements, facilitating ease of operation and maintenance.

Applications

This equipment is ideal for a range of agricultural tasks, particularly in grassland management and forage production. Its versatility makes it suitable for both small and large-scale operations, contributing significantly to efficient land use and crop yield improvement.

Key Components of the GMD 700

This section delves into the essential elements that constitute a highly efficient agricultural implement designed for optimal performance. Understanding these components is crucial for maintaining functionality and enhancing productivity in the field. Each part plays a vital role in ensuring seamless operation and durability, contributing to overall effectiveness.

Main Elements

The following table outlines the primary components and their respective functions, highlighting their importance in the overall system.

| Component | Function |

|---|---|

| Drive System | Provides power to the entire mechanism, ensuring efficient operation. |

| Cutter Bar | Facilitates precise cutting of grass or crops, promoting clean harvesting. |

| Hitch Assembly | Connects the implement to the tractor, allowing for stable towing and maneuverability. |

| Driveline | Transmits power from the tractor to the working components, enabling movement. |

| Gearbox | Adjusts the speed and torque delivered to the cutter bar, optimizing cutting efficiency. |

Additional Features

In addition to the main elements, other features such as safety mechanisms and adjustable settings enhance the overall functionality and adaptability of the equipment, making it suitable for various agricultural tasks. Proper understanding and maintenance of these components can lead to increased lifespan and operational success.

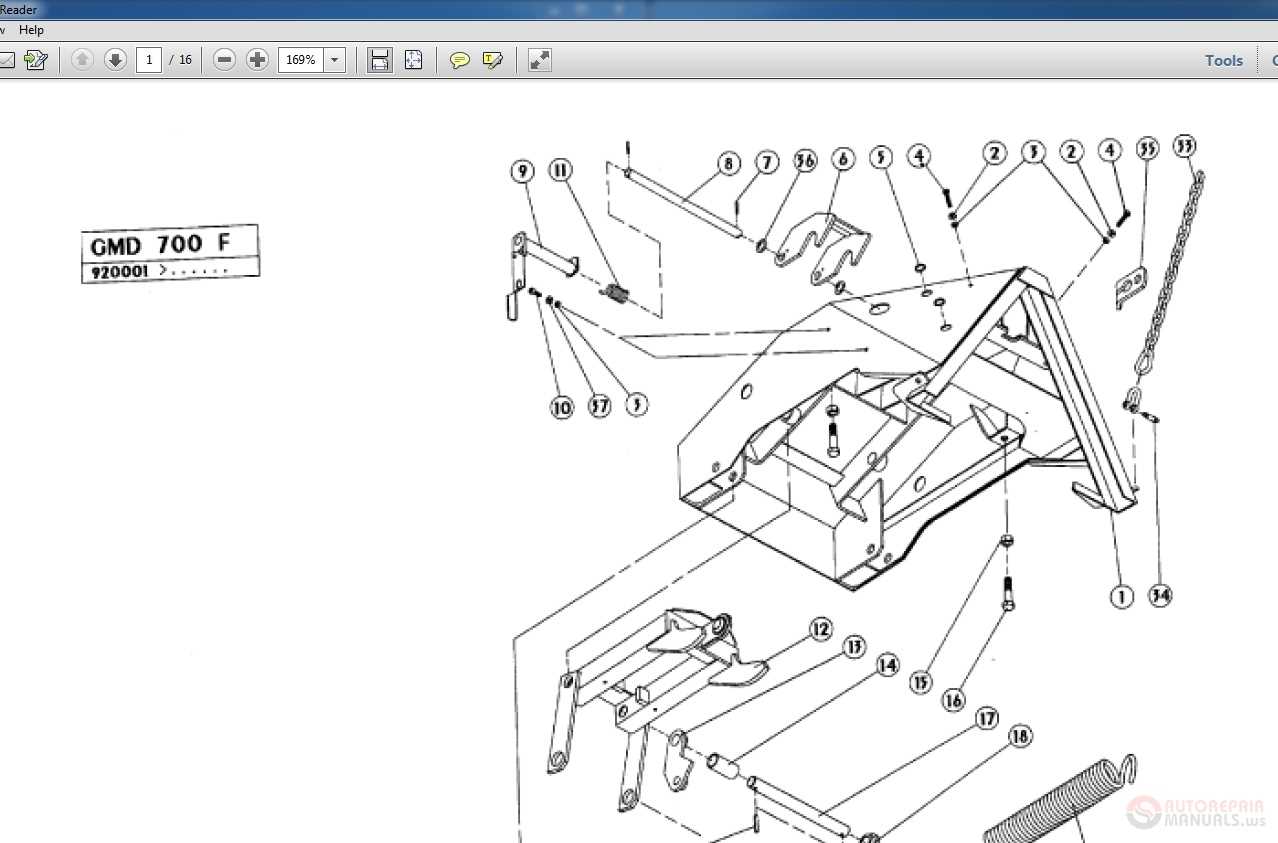

Understanding the Parts Diagram

The visual representation of components is essential for comprehending the functionality and maintenance of machinery. This illustration serves as a guide, offering insight into the various elements that work together to ensure optimal performance. By familiarizing oneself with this schematic, users can more effectively diagnose issues and facilitate repairs.

Key Elements of the Visual Representation

The graphic typically includes several vital features:

- Labels: Each component is clearly marked, making it easier to identify specific parts.

- Connections: Lines and arrows indicate how different elements interact with one another.

- Exploded Views: These sections provide a three-dimensional perspective, showcasing how parts fit together.

Benefits of Understanding the Schematic

Grasping the layout offers numerous advantages:

- Improved maintenance efficiency through quick identification of necessary components.

- Enhanced troubleshooting capabilities, allowing for swift resolution of issues.

- Increased confidence in conducting repairs and modifications.

Ultimately, a solid understanding of this visual guide empowers users to maximize the longevity and functionality of their equipment.

Importance of Accurate Maintenance

Maintaining agricultural machinery is essential for optimal performance and longevity. Proper upkeep ensures that equipment operates efficiently, reducing the risk of breakdowns and enhancing productivity. Understanding the significance of meticulous care can lead to improved outcomes in farming operations.

Benefits of Regular Servicing

- Enhanced Performance: Regular checks and maintenance help keep machinery running at peak efficiency, allowing for consistent and reliable operation.

- Cost Savings: Preventive care can identify potential issues before they escalate, saving on costly repairs and replacements.

- Increased Lifespan: Equipment that receives proper attention tends to have a longer lifespan, maximizing the return on investment.

- Safety Assurance: Well-maintained machines are less likely to malfunction, ensuring the safety of operators and workers in the field.

Key Maintenance Practices

- Routine Inspections: Conduct regular assessments to identify wear and tear or other issues.

- Lubrication: Keep moving parts well-lubricated to prevent friction and extend their service life.

- Replacement of Worn Components: Promptly replace parts that show signs of damage to maintain optimal functionality.

- Cleaning: Regularly clean machinery to prevent dirt and debris buildup, which can lead to inefficiency.

Common Issues and Solutions

In agricultural machinery, various challenges can arise during operation and maintenance. Understanding these common problems and their potential solutions is essential for ensuring optimal performance and longevity. This section highlights frequent issues encountered with such equipment and provides practical remedies to keep operations running smoothly.

| Issue | Description | Solution |

|---|---|---|

| Uneven Cutting | Inconsistent height and quality of cut across the working width. | Check and adjust the cutting height settings, ensuring all blades are sharp and aligned. |

| Frequent Clogs | Material buildup causing stoppages during operation. | Regularly clear debris and ensure proper feed rate; consider adjusting the operating speed. |

| Vibration Issues | Excessive shaking leading to wear and tear on components. | Inspect for loose bolts or damaged parts; balance the machine if necessary. |

| Poor Performance | Reduced efficiency and effectiveness during operation. | Conduct a thorough inspection of the machine, checking for worn belts and filters; perform necessary replacements. |

| Hydraulic Leaks | Fluid leaks causing loss of pressure and functionality. | Identify the source of the leak, replace damaged hoses or seals, and ensure connections are tight. |

Upgrading and Replacing Parts

Enhancing and substituting components of agricultural machinery is essential for maintaining optimal performance and longevity. Regularly assessing the condition of various elements can lead to improved efficiency and productivity in the field.

When considering upgrades, it’s vital to research compatible alternatives that offer better durability or functionality. Advanced materials and innovative designs can significantly enhance operational capabilities, making it worthwhile to explore these options.

Replacement of worn or damaged components should be conducted promptly to avoid further issues. Identifying specific weaknesses allows for targeted interventions, ensuring that the machinery operates smoothly and reliably.

Ultimately, investing in quality upgrades and timely replacements not only boosts performance but also prolongs the lifespan of the equipment, providing better returns in the long run.

Where to Find Replacement Parts

Locating suitable components for agricultural equipment is essential for maintaining performance and longevity. There are several reliable sources to explore for obtaining these necessary items, ensuring optimal operation of your machinery.

| Source | Description |

|---|---|

| Authorized Dealers | These vendors offer genuine components and often provide expert advice. |

| Online Retailers | Websites specializing in agricultural machinery frequently stock a wide range of items. |

| Local Distributors | Regional suppliers can have immediate availability and local support. |

| Salvage Yards | Used components can be a cost-effective solution, often available in good condition. |

| Manufacturer’s Website | The official site may offer direct sales or guidance on where to purchase. |

Tips for Effective Troubleshooting

Effective troubleshooting is essential for maintaining the functionality of machinery and ensuring optimal performance. A systematic approach can help identify issues quickly and accurately, minimizing downtime and repair costs.

Here are some strategies to enhance your troubleshooting skills:

- Understand the System: Familiarize yourself with the equipment’s design and components. Knowledge of how everything works together is crucial for pinpointing problems.

- Gather Information: Collect data on the symptoms and any error messages. Documenting these details can provide valuable insights during the diagnostic process.

- Follow a Logical Sequence: Develop a step-by-step method to isolate the problem. Start with the most obvious issues before moving to more complex ones.

Consider these additional tips:

- Utilize Manuals: Reference user manuals or technical documentation for guidance on specific components and troubleshooting protocols.

- Perform Routine Checks: Regular maintenance can prevent many issues. Inspect components regularly to catch problems before they escalate.

- Seek Expert Advice: Don’t hesitate to consult with experienced technicians or forums when facing challenging issues.

By implementing these techniques, you can improve your troubleshooting efficiency and ensure your equipment operates smoothly.