When it comes to maintaining the efficiency of a powerful cleaning instrument, grasping the layout and functions of its individual elements is essential. A well-organized overview of these components not only aids in troubleshooting but also enhances the overall user experience. Each segment plays a crucial role in the operation, ensuring that tasks are completed effectively and efficiently.

This section delves into the intricacies of a specific model, providing a detailed examination of its structure. Understanding how each piece interconnects allows users to appreciate the mechanics behind the equipment’s functionality. From the motor to the nozzle, every part contributes to the ultimate performance of the device.

By familiarizing yourself with these components, you can easily identify potential issues and execute necessary repairs. This knowledge empowers users to maintain their equipment, ensuring it remains in peak condition for years to come. With a comprehensive grasp of the setup, you can approach your cleaning tasks with confidence.

Understanding Ryobi Pressure Washers

Exploring the world of high-efficiency cleaning equipment reveals a remarkable range of options designed for both residential and commercial use. These machines are engineered to deliver powerful performance, making them essential tools for tackling stubborn dirt and grime in various settings.

Key Features

- Powerful motor options that cater to different cleaning needs

- Adjustable settings for varying levels of intensity

- Compact designs for easy maneuverability and storage

- Durable construction for longevity and reliability

Benefits of High-Efficiency Cleaners

- Effective removal of tough stains from surfaces like driveways and patios

- Environmentally friendly alternatives to harsh chemicals

- Saves time and effort compared to traditional cleaning methods

- Versatile attachments for a variety of tasks

Understanding the components and functionalities of these cleaning devices enhances user experience, enabling efficient and effective operation tailored to specific cleaning requirements.

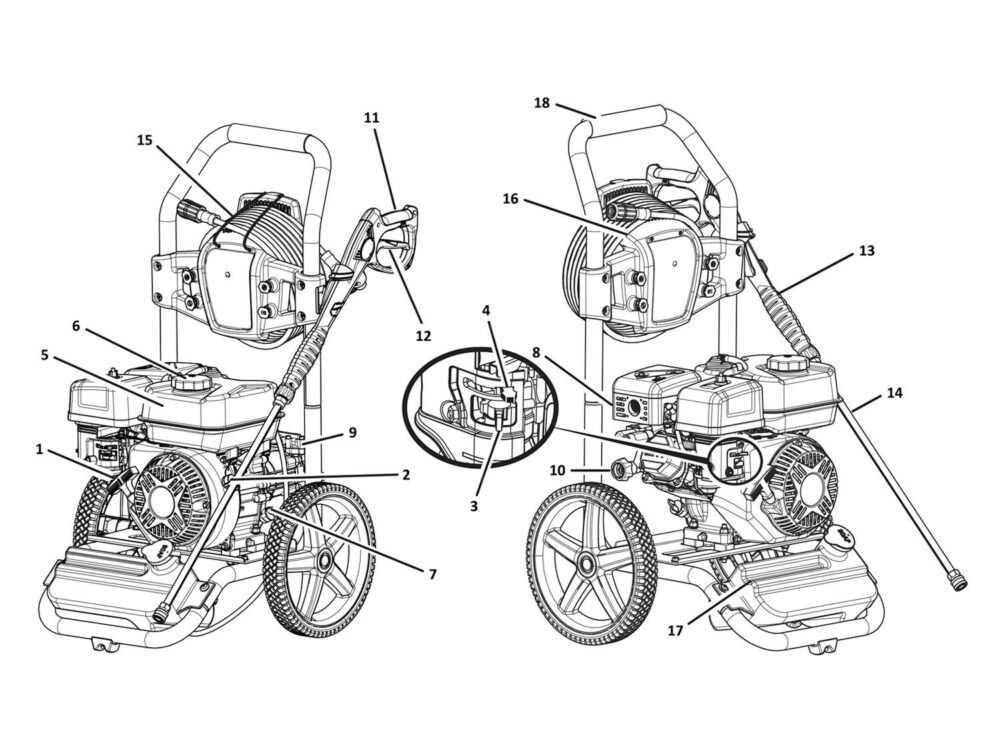

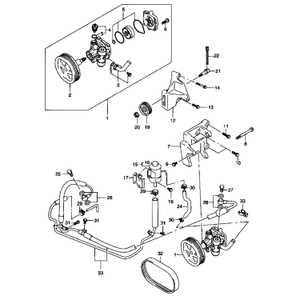

Key Components of Ryobi 2000 PSI Model

The essential elements of this high-performance cleaning device work in harmony to deliver impressive results. Understanding these key components is crucial for effective maintenance and optimal use.

Motor: The heart of the system, this component provides the necessary power to drive the entire mechanism efficiently.

Pump: This vital part converts mechanical energy into hydraulic energy, ensuring a steady flow of water under pressure.

Hose: A durable and flexible conduit that connects the device to the cleaning nozzle, allowing for the transport of pressurized water.

Nozzle: This attachment can be adjusted to vary the spray pattern, enabling users to tailor the cleaning process according to different surfaces.

Frame: The sturdy structure supports all components, enhancing portability and stability during operation.

Understanding these crucial elements allows users to maximize performance and prolong the lifespan of their equipment.

Common Issues and Solutions

When using cleaning equipment, users often encounter a range of problems that can hinder performance. These issues may stem from various sources, such as improper assembly, wear and tear, or simply neglecting routine maintenance. Below are some of the most common concerns users face, along with practical solutions to keep the equipment running smoothly.

- Low Water Pressure:

- Clogged nozzles: Inspect the nozzle for debris and clean it thoroughly.

- Damaged hose: Check the hose for leaks or blockages and replace if needed.

- Air in the system: Run the machine without a nozzle to expel air and restore pressure.

- Engine Won’t Start:

- Fuel issues: Ensure the fuel tank is filled with fresh fuel and that the fuel filter is clean.

- Dirty spark plug: Inspect the spark plug for dirt or damage and replace it if necessary.

- Choke or throttle settings: Adjust the choke and throttle to the correct positions for starting.

- Water Leaks:

- Loose connections: Tighten all hose and connector fittings to prevent leaks.

- Cracked seals or gaskets: Inspect the seals around the pump and replace any worn-out components.

- Damaged inlet valve: Check for cracks or damage in the inlet valve and replace if necessary.

- Unusual Noises:

- Blocked or worn-out pump: Check for debris or damage in the pump, and replace if needed.

- Loose parts: Tighten any loose bolts, screws, or fasteners to prevent rattling noises.

- Fuel or oil contamination: Ensure the correct type of oil and fuel is being used to avoid engine strain.

By identifying these common problems early on and applying the appropriate solutions, users can extend the lifespan of their equipment and improve overall performance. Regular maintenance and prompt attention to minor issues can save both time and money in the long run.

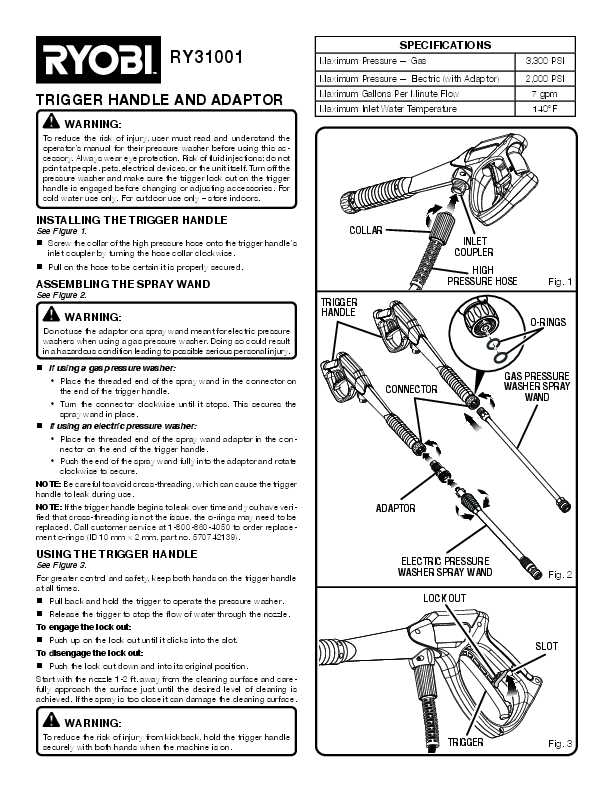

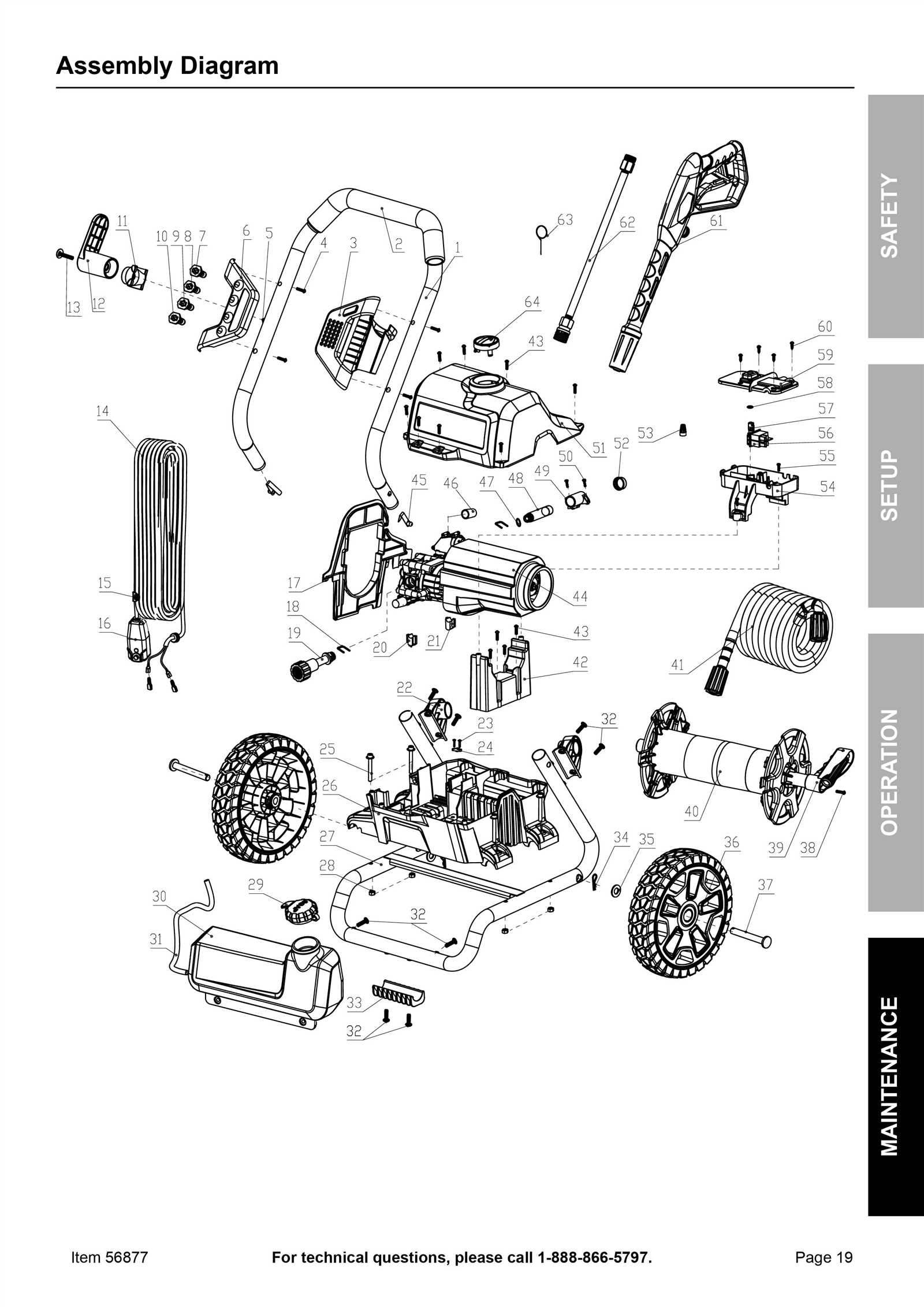

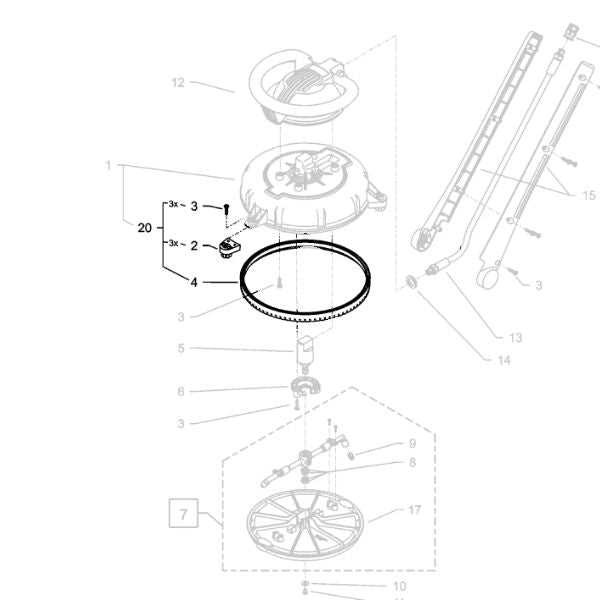

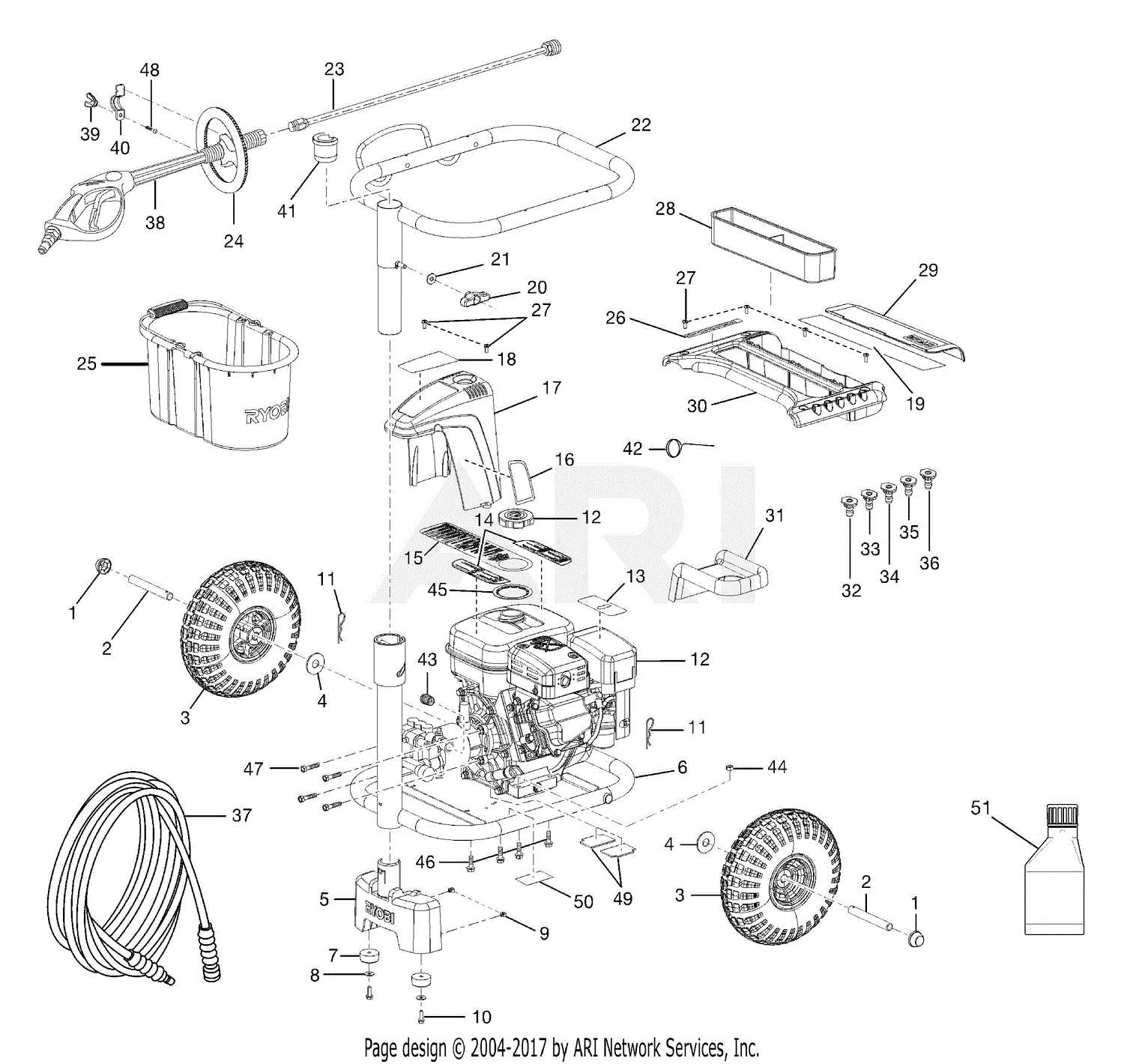

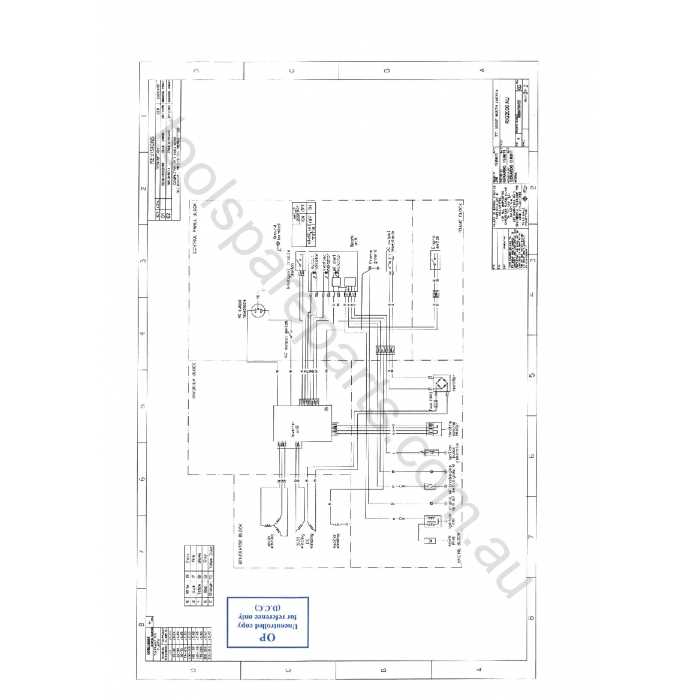

How to Read the Parts Diagram

Understanding how to interpret a technical schematic can be crucial when you need to repair or maintain your equipment. The visual guide is designed to provide a clear overview of how different components interact and fit together. Each part is typically labeled with unique identifiers, making it easier to locate and replace individual pieces when necessary.

To begin, pay close attention to the numbers or letters associated with each item in the chart. These references are often linked to a list of available components, where you can find detailed information such as part names, sizes, and other specifications. Understanding these references helps ensure you’re ordering the correct replacement items.

It’s also important to examine the overall layout, as it usually reflects the assembly process. The positioning of each piece indicates how parts connect or interact with others. Recognizing the spatial relationship between components can save you time during disassembly or reassembly.

Lastly, make sure to double-check the orientation of the parts. Some parts may be shown from a specific angle, and this detail is essential for proper installation. By following the guide carefully, you can effectively manage repairs and extend the lifespan of your equipment.

Replacement Parts Availability and Sources

When it comes to maintaining outdoor equipment, ensuring access to essential components is crucial for optimal performance. Finding suitable replacements can be a straightforward process if you know where to look and what options are available.

Local Retailers often carry a variety of components that cater to common issues. Visiting a nearby hardware store or a specialized shop can save time and provide immediate solutions. Staff members are typically knowledgeable and can assist in identifying the correct items.

Online Marketplaces present an extensive selection of options, often at competitive prices. Websites dedicated to outdoor tools or general e-commerce platforms allow you to compare prices and read reviews, making informed choices easier. Ensure that you check the specifications to confirm compatibility.

Manufacturer Websites are another reliable source for finding original components. Many brands offer online catalogs that can guide you in selecting the right replacements. Additionally, they may provide warranty information and technical support.

For those who prefer a more budget-friendly approach, aftermarket suppliers can be an excellent alternative. While these components may vary in quality, they often come at lower prices, making them appealing for those willing to do a bit of research.

Lastly, local repair shops or service centers can be invaluable. Many offer both repair services and the sale of necessary components, ensuring that you have access to professional advice and high-quality items.

Maintenance Tips for Longevity

To ensure your equipment serves you for many years, regular upkeep is essential. Routine checks and simple care practices can prevent common issues, enhance performance, and extend the life of the machine. Adopting a few maintenance habits can make all the difference in avoiding costly repairs or premature wear.

1. Clean and Inspect After Every Use: After each session, it’s vital to thoroughly clean the unit and inspect all components for wear or damage. Removing debris and buildup helps maintain smooth operation and reduces the risk of clogging or overheating. Pay close attention to the intake and exhaust areas to ensure proper airflow.

2. Check the Hose and Connections: Regularly inspect the hose for cracks, leaks, or any signs of wear. If the hose is damaged, it can decrease performance and pose safety hazards. Ensure that all connections are secure and that no parts are loose or corroded.

3. Lubricate Moving Parts: Over time, mechanical components can experience friction and wear. Apply appropriate lubricants to moving parts such as pumps, handles, and wheels. This will help prevent stiffness and ensure smooth operation.

4. Replace Worn Components: Keeping an eye on individual parts is crucial for performance. When components such as seals, filters, or nozzles begin to degrade, replace them promptly. Using worn-out or damaged parts can lead to more significant issues, such as system failure or inefficiency.

5. Store Properly: Storing your equipment in a dry, cool place away from harsh weather conditions will prevent rust, corrosion, and unnecessary stress on internal mechanisms. If possible, store it off the ground to avoid moisture exposure.

By following these simple guidelines, you can ensure your device remains reliable and efficient for years to come.

Safety Guidelines When Operating

Ensuring safety during the use of high-powered cleaning equipment is essential to prevent accidents and injuries. Adhering to specific precautions can significantly enhance your safety and that of those around you.

- Always wear appropriate protective gear, including goggles, gloves, and non-slip footwear.

- Keep children and pets at a safe distance from the operating area.

- Before use, inspect the equipment for any damages or leaks to ensure it is functioning properly.

- Read the manufacturer’s instructions thoroughly to understand proper operation and maintenance.

- Never point the nozzle at yourself or others, even when not in use.

By following these guidelines, you can create a safer environment and enjoy the ultimate efficiency of your cleaning tasks.

Upgrading Components for Better Performance

Enhancing the functionality of your cleaning equipment can significantly improve its efficiency and longevity. By focusing on upgrading specific elements, you can achieve superior results, reduce wear and tear, and ultimately elevate your cleaning experience.

Choosing Quality Upgrades

Selecting high-quality replacement components is essential. Look for durable materials and reliable brands that offer better performance compared to standard options. This investment can lead to enhanced efficiency and a noticeable difference in your cleaning tasks.

Maintenance and Compatibility

Regular maintenance is crucial when implementing upgrades. Ensure that all new parts are compatible with your existing system. Proper installation and routine checks will help you maximize the benefits of your enhancements, resulting in a more effective cleaning process.

Customer Reviews and Feedback Insights

Customer reviews play a pivotal role in helping potential buyers make informed decisions. When it comes to home improvement tools, understanding the experiences of previous users can provide valuable insights into performance, durability, and ease of use. Feedback often highlights both the strengths and weaknesses of a product, offering a balanced perspective that is difficult to get from promotional materials alone.

Positive comments frequently emphasize the tool’s reliability, efficiency, and the convenience it brings to various cleaning tasks. Many users report that the equipment is simple to set up and operate, making it ideal for both novices and seasoned professionals. The consistent performance and versatility in handling different surfaces also stand out as key advantages.

On the other hand, negative feedback often points to specific issues that could impact long-term satisfaction. Some common concerns include wear and tear of certain components over time or difficulties with certain maintenance tasks. A few users have mentioned challenges related to the power or noise level, although these aspects are typically seen as minor when balanced against the tool’s overall efficiency.

Overall, user reviews reveal that the product is generally well-received, with most customers recommending it for its combination of value, power, and ease of use. However, as with any product, it’s important to carefully consider both the positive and negative feedback to assess whether it aligns with your own needs and expectations.