Exploring the intricacies of machinery components is essential for anyone involved in maintenance and repair. Knowledge of how different elements interact can enhance efficiency and prolong the lifespan of the equipment.

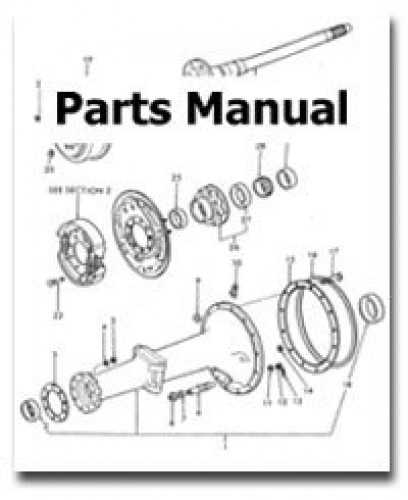

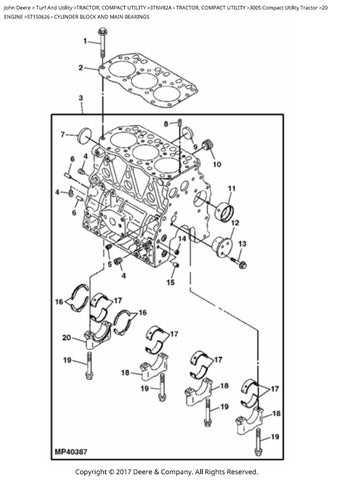

In this section, we will examine the specific layout of essential elements, providing a comprehensive visual representation. This allows users to easily identify and access crucial parts, facilitating effective troubleshooting and maintenance.

Detailed insights into each segment will empower users to make informed decisions, ensuring their machinery operates at peak performance. By delving into these schematics, we can uncover the ultimate connection between functionality and upkeep.

Understanding John Deere 1070 Components

Familiarity with the various elements of agricultural machinery is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring efficiency and longevity. By exploring the structure and function of these individual parts, operators can enhance their understanding of the equipment and address any issues that may arise during operation.

Key Elements of Agricultural Machinery

Every piece of equipment is composed of numerous parts that contribute to its overall functionality. From the engine and transmission to hydraulic systems and control mechanisms, each section must work harmoniously. Recognizing the interconnections between these elements can aid in troubleshooting and repairs.

Maintenance and Performance Optimization

Regular upkeep of machinery components is vital for maintaining peak performance. Understanding how each part operates allows users to implement effective maintenance practices. Proactive care not only extends the life of the equipment but also improves its reliability and productivity in the field. Identifying potential wear and tear early on can prevent more significant issues down the line.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They serve as essential tools for maintenance and repair, enabling users to identify specific elements and their functions efficiently. Such illustrations simplify the intricate relationships between various units, making troubleshooting more accessible.

Clarity is one of the primary advantages of these visual guides. By providing a clear view of individual components, users can quickly locate issues and address them with precision. This not only saves time but also reduces the risk of errors during repairs.

Additionally, these representations foster better communication among technicians and operators. When discussing repairs or modifications, referring to a visual aid helps ensure everyone is on the same page, minimizing misunderstandings. This shared language enhances teamwork and improves overall efficiency in maintenance tasks.

Moreover, visual references contribute to a deeper understanding of machinery operations. By studying the layout of components, users can gain insights into how different parts interact, leading to improved performance and longevity of equipment.

In conclusion, these visual aids are invaluable for effective maintenance and repair processes. They enhance clarity, communication, and understanding, ultimately contributing to more reliable and efficient machinery operation.

Common Issues with John Deere 1070

Various mechanical and operational challenges can arise with agricultural machinery, affecting efficiency and productivity. Understanding these prevalent concerns can help users effectively maintain their equipment and avoid costly downtime.

Hydraulic System Failures

A frequent issue involves the hydraulic system, which may experience leaks or pressure loss. Regular inspections and prompt repairs are crucial to ensuring optimal functionality.

Electrical Malfunctions

Another common problem pertains to electrical components, including wiring and fuses. Symptoms such as erratic behavior or complete system shutdowns often indicate underlying electrical faults. Addressing these issues swiftly can prevent more severe complications.

Where to Find Replacement Parts

Locating components for your machinery can be essential for maintaining performance and efficiency. There are several reliable sources available for acquiring these necessary items, ensuring you can keep your equipment in optimal working condition.

Online Retailers

The internet provides a vast array of options for purchasing components. Consider the following:

- Specialized websites focused on agricultural machinery

- General e-commerce platforms with a wide selection

- Manufacturer’s official online stores

Local Dealers and Stores

Your local dealerships and hardware stores can also be valuable resources. They often carry a variety of items and can assist in finding specific needs:

- Authorized dealerships for expert advice

- Independent retailers with a selection of aftermarket options

- Salvage yards for used components at lower prices

Tools Needed for Maintenance

Regular upkeep of equipment is essential to ensure optimal performance and longevity. Having the right tools on hand can significantly ease the maintenance process, allowing for efficient repairs and adjustments. Below is a list of essential tools commonly required for effective servicing.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are crucial for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for securing and removing screws in various components.

- Pliers: These tools assist in gripping, bending, and cutting wires and other materials.

- Oil Filter Wrench: This specialized tool is essential for removing and replacing oil filters during routine oil changes.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Grease Gun: Used for applying grease to moving parts, helping to reduce friction and wear.

Having these tools readily available not only streamlines the maintenance process but also promotes a safe working environment. Regular inspections and timely repairs will enhance the overall functionality and durability of your machinery.

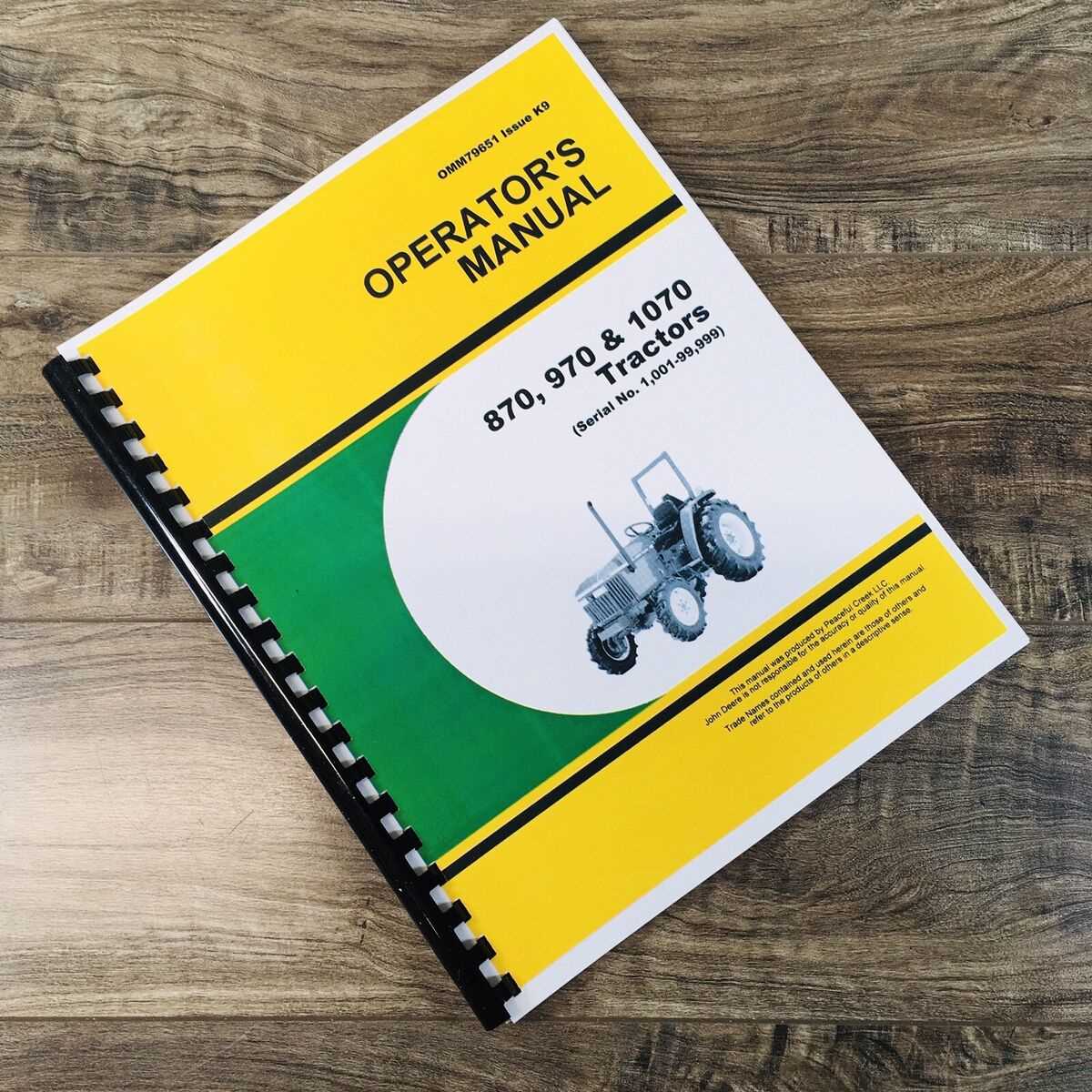

Tips for Efficient Repairs

When it comes to performing maintenance on machinery, efficiency is key. A well-organized approach not only saves time but also reduces the risk of errors. By following a few strategic steps, you can streamline your repair process and ensure that your equipment operates smoothly.

| Tip | Description |

|---|---|

| Preparation | Gather all necessary tools and materials before starting the repair. This minimizes interruptions and keeps the workflow steady. |

| Documentation | Keep a manual or service guide on hand. This can provide valuable insights into specific procedures and troubleshooting techniques. |

| Labeling | Label all components and fasteners as you disassemble parts. This helps in quick reassembly and ensures nothing is overlooked. |

| Checklists | Create a checklist for the repair process. This can help track progress and ensure that all steps are completed efficiently. |

| Cleanliness | Maintain a clean workspace. Removing debris and clutter can prevent accidents and make it easier to locate tools and parts. |

Upgrading Your John Deere 1070

Enhancing your agricultural machine can lead to improved efficiency and performance. Whether you’re looking to boost power or increase functionality, there are several avenues to explore.

- Consider upgrading the engine for better horsepower.

- Install advanced technology for precision farming.

- Enhance the suspension system for improved stability.

Before making any modifications, evaluate your specific needs and how they align with your goals. Research compatible accessories to ensure optimal integration.

- Identify the areas most in need of improvement.

- Research available upgrades tailored for your model.

- Consult with professionals if necessary.

Ultimately, well-planned upgrades can significantly extend the lifespan of your equipment and enhance productivity on the field.

Customer Reviews and Feedback

Feedback from users plays a crucial role in understanding the quality and performance of machinery components. It offers insights into the experiences of fellow operators, highlighting both the strengths and areas for improvement. This section collates valuable opinions that can assist potential buyers in making informed decisions.

Positive Experiences

Many customers have expressed satisfaction with the reliability and durability of their equipment. Users frequently commend the efficient operation and the ease of maintenance, noting that the components function seamlessly, reducing downtime significantly. One user remarked, “The reliability has made my daily tasks much smoother, and I couldn’t be happier with my choice.” Such testimonials underscore the importance of quality in machinery.

Areas for Improvement

While the majority of reviews are favorable, some users have pointed out challenges they faced. Issues such as difficulty in sourcing specific components or unclear installation instructions have been noted. Another reviewer mentioned, “I had a hard time finding the right parts, which was frustrating at times.” These comments indicate opportunities for manufacturers to enhance customer support and resources.