In the realm of outdoor equipment, having a thorough grasp of the various elements that contribute to a machine’s performance is essential. Whether you are a seasoned operator or a newcomer, knowing how these components work together can enhance your efficiency and prolong the lifespan of your investment.

Within this guide, we will delve into the intricate layout of a specific mower model, highlighting key sections and functionalities. By breaking down the assembly into easily digestible parts, you will gain insights into maintenance, troubleshooting, and potential upgrades that can elevate your mowing experience.

Furthermore, understanding the relationship between each segment is crucial for effective repair and upkeep. This exploration aims to equip you with the knowledge needed to navigate the complexities of your equipment confidently, ensuring it operates at its best for years to come.

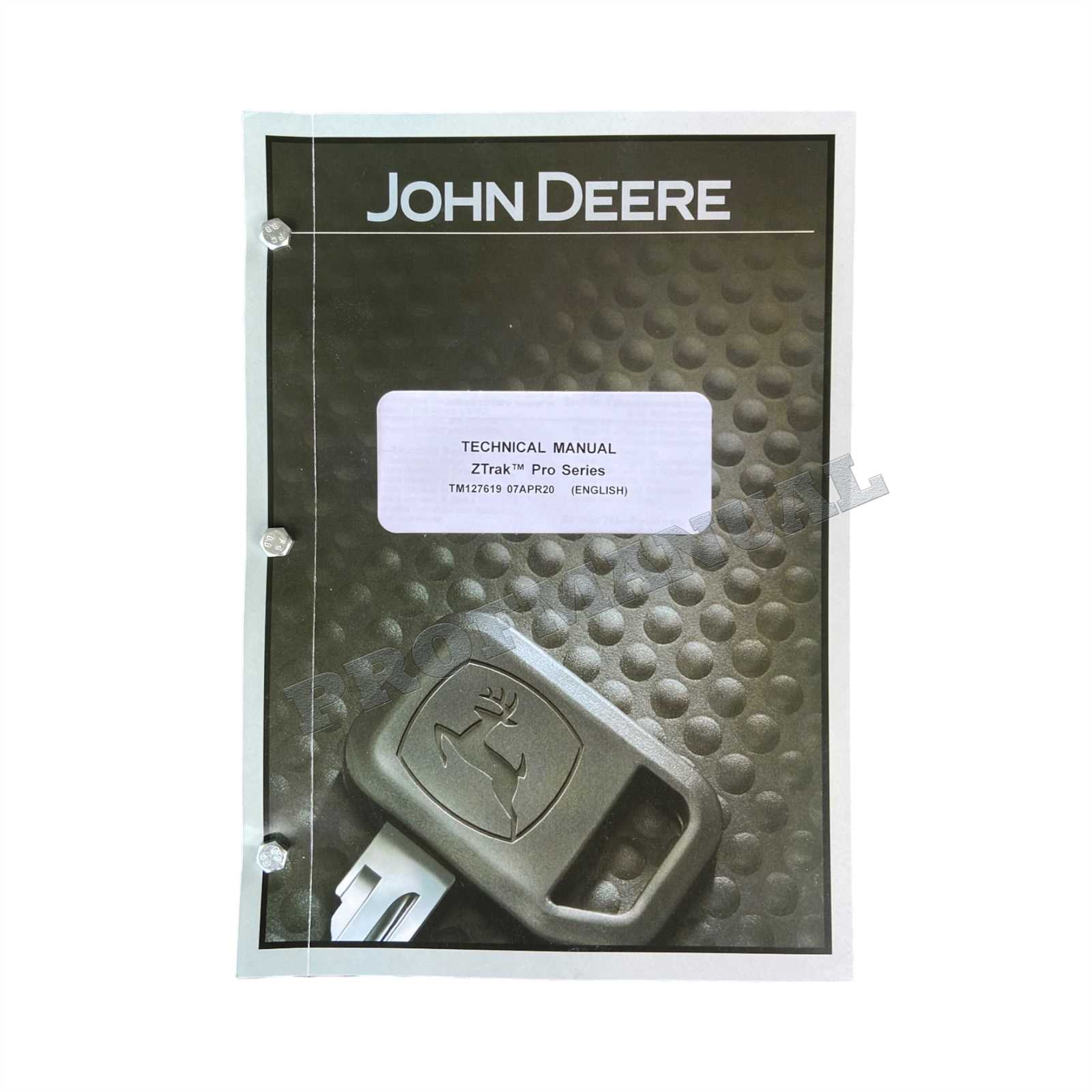

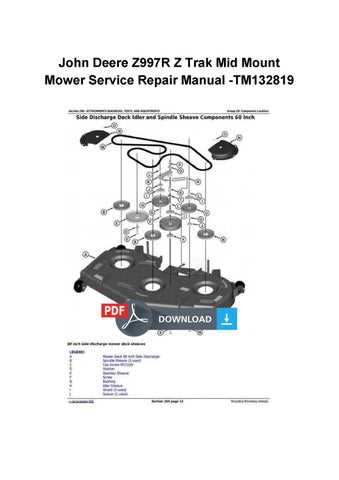

Overview of John Deere Z997R

This section provides a comprehensive look at a premium model in the realm of commercial mowing equipment. Designed for efficiency and performance, this machine caters to the needs of professional landscapers and large property owners alike. Its robust engineering ensures reliability in various challenging environments, making it a top choice for those who demand excellence in lawn care.

The model features advanced technology that enhances maneuverability and user experience. Operators benefit from a well-designed control system that allows for precision handling, making it easy to navigate tight spaces and intricate landscapes. Additionally, the innovative cutting deck is engineered to deliver a clean and consistent cut, ensuring that lawns maintain a pristine appearance.

Moreover, the powertrain offers impressive performance, allowing users to tackle even the toughest grass with ease. The machine is built to last, incorporating high-quality materials and components that withstand daily wear and tear. Maintenance is straightforward, contributing to reduced downtime and increased productivity for users.

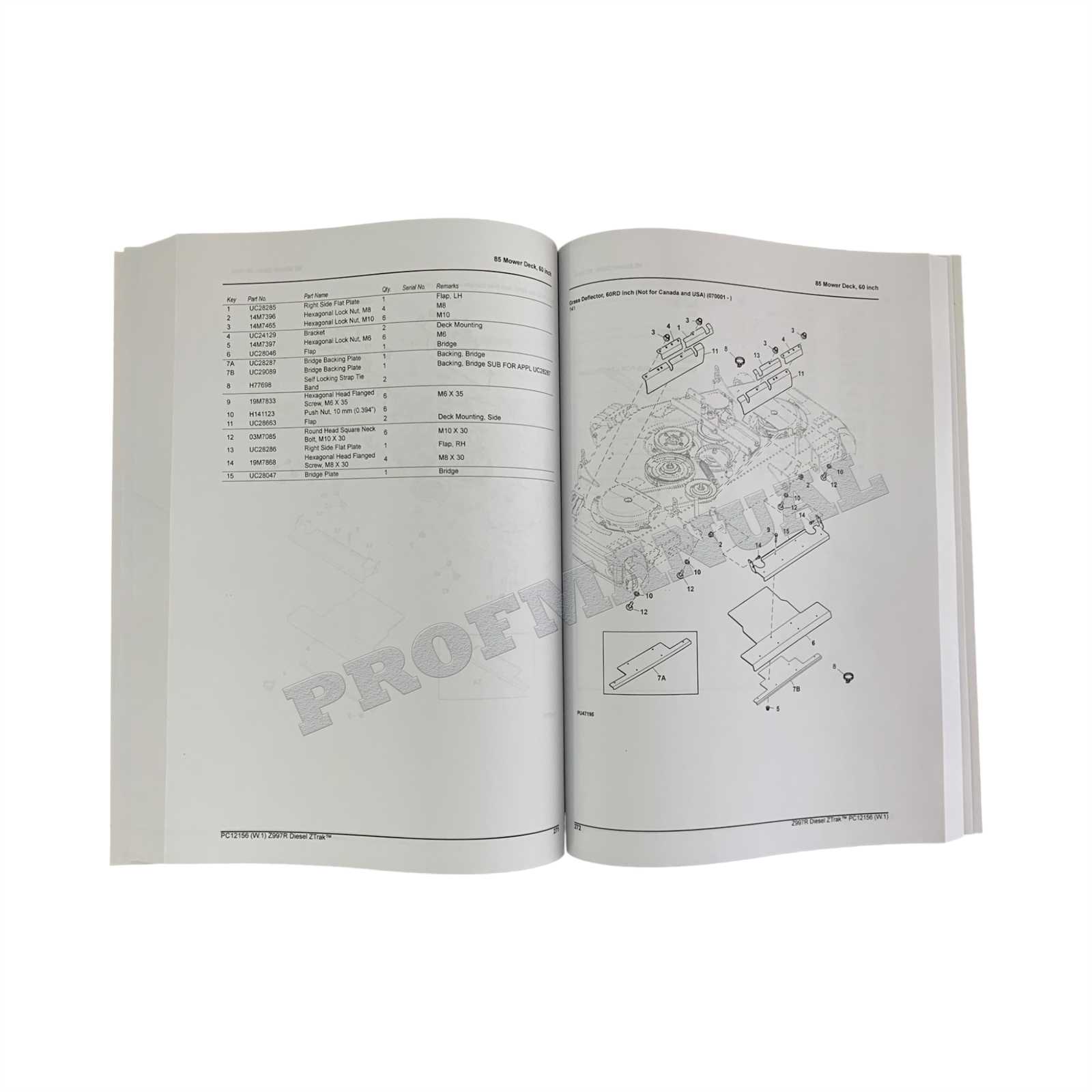

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components play a crucial role in this process, providing clarity and aiding in the identification of individual elements within complex systems.

These illustrations offer several advantages:

- Enhanced Clarity: Detailed visuals simplify the understanding of how different components interact.

- Efficient Troubleshooting: Quickly pinpointing issues becomes more manageable with clear depictions of parts.

- Improved Communication: Technicians and operators can discuss specific elements with greater precision.

- Streamlined Ordering: Identifying the correct components for replacement is easier when visuals are available.

Moreover, utilizing these graphical aids ensures that repairs are conducted accurately, reducing the likelihood of errors that could lead to further complications.

In summary, employing visual representations is indispensable for anyone involved in machinery upkeep, fostering both efficiency and effectiveness in the maintenance process.

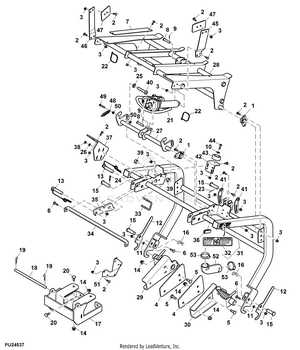

Key Components of Z997R Mower

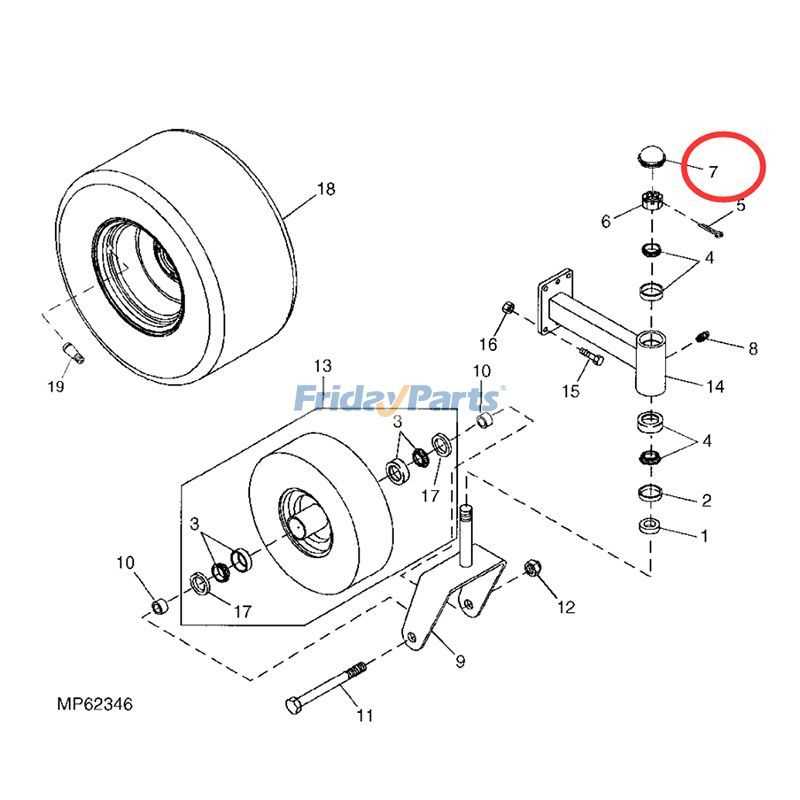

The efficiency and performance of a commercial mowing machine rely heavily on its essential components. Understanding these parts is crucial for proper maintenance and operation, ensuring longevity and optimal functionality.

- Engine: The powerhouse of the mower, responsible for delivering the necessary torque and horsepower for efficient cutting.

- Cutting Deck: This component houses the blades and is designed to provide an even cut, enhancing the overall aesthetic of the lawn.

- Transmission: A vital element that transfers power from the engine to the wheels, allowing for smooth movement and maneuverability.

- Wheels: Equipped with durable treads, they provide traction and stability on various terrains.

- Control System: The interface for the operator, facilitating adjustments to speed, cutting height, and direction.

- Blade Assembly: Comprising sharp blades that rotate to achieve a precise cut, essential for maintaining healthy grass.

Each of these components plays a significant role in the overall performance of the mower. Regular inspection and maintenance can prevent breakdowns and enhance the machine’s capabilities.

Understanding Maintenance Needs

Proper upkeep is essential for ensuring the longevity and efficiency of any machinery. Recognizing the specific requirements for maintenance helps prevent unexpected breakdowns and costly repairs. By adhering to a systematic approach, operators can maximize performance and enhance the overall lifespan of their equipment.

To effectively manage maintenance, consider the following aspects:

- Regular Inspections: Conduct routine checks to identify wear and tear before it leads to significant issues.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and prevent overheating.

- Cleaning: Keep components free of dirt and debris to maintain optimal functionality.

- Replacement Schedule: Follow a timeline for replacing worn-out parts to avoid operational disruptions.

Implementing a comprehensive maintenance plan not only enhances reliability but also contributes to safer operating conditions. By prioritizing these practices, users can achieve better performance and reduce downtime.

Identifying Common Replacement Parts

When it comes to maintaining equipment, recognizing frequently needed components is essential for ensuring optimal performance. Understanding these elements can help streamline repairs and minimize downtime. Below are some key categories and items often required for effective upkeep.

1. Engine Components

- Air Filters: Vital for maintaining air quality and performance.

- Oil Filters: Crucial for keeping the engine lubricated and free of contaminants.

- Fuel Filters: Essential for preventing debris from damaging the fuel system.

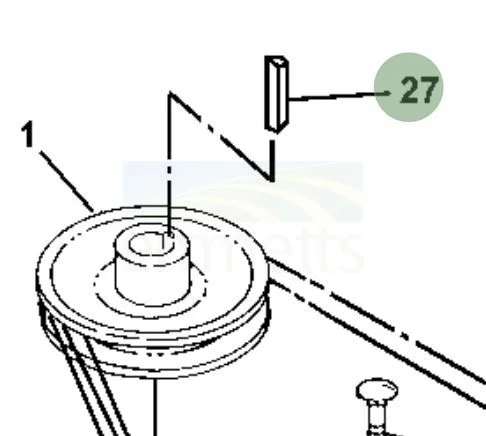

2. Cutting System Elements

- Blades: Central to achieving a clean cut; periodic replacement is necessary.

- Spindle Assemblies: Important for maintaining blade rotation and efficiency.

- Belts: These components ensure power transmission to the cutting deck.

By focusing on these commonly used items, operators can enhance equipment reliability and performance while reducing the likelihood of unexpected failures.

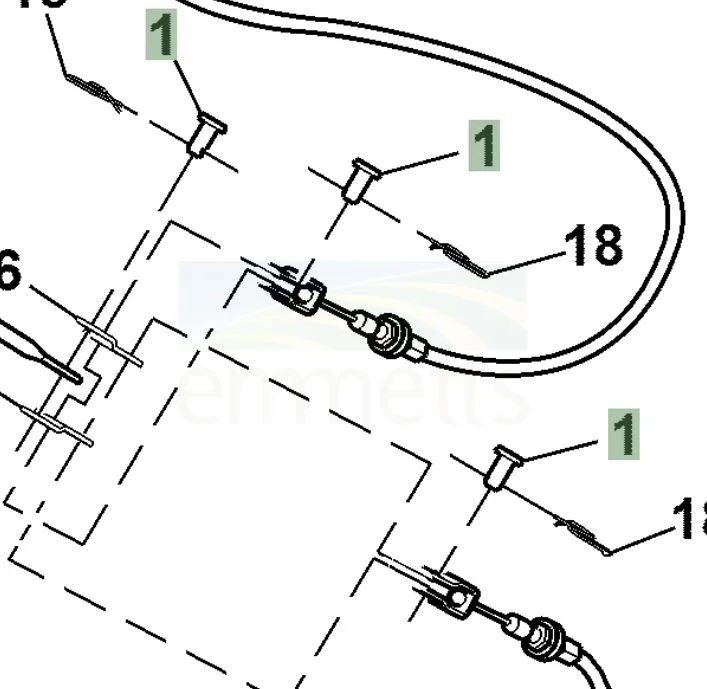

Using Diagrams for Troubleshooting

Visual aids play a crucial role in diagnosing issues within complex machinery. By providing a clear representation of components and their relationships, these illustrations facilitate a deeper understanding of systems, making it easier to identify potential faults. When faced with malfunctions, referring to these visual guides can streamline the troubleshooting process, saving both time and effort.

When examining a malfunctioning unit, a well-structured visual reference allows users to pinpoint areas of concern quickly. It serves as a roadmap, guiding individuals through the intricate assembly of parts. This not only aids in locating the source of the problem but also enhances the overall comprehension of how each element interacts within the system.

Moreover, utilizing such resources fosters a more systematic approach to repairs. By following the outlined sequences and connections, users can systematically eliminate potential issues. This organized method reduces the likelihood of overlooking critical elements that may contribute to the malfunction, ultimately leading to a more effective resolution.

In addition, visual representations can aid in communicating problems to others, whether to colleagues or support teams. Clear illustrations enhance the ability to convey specific issues, making it easier for others to provide guidance or assistance. This collaborative aspect can be invaluable, especially in more complex situations where expert insight is beneficial.

In summary, leveraging visual resources significantly enhances the troubleshooting experience. By offering clarity and structure, these tools empower users to tackle problems efficiently, ensuring that machinery operates smoothly and reliably.

Where to Find Genuine Parts

Finding authentic components for your machinery is essential for optimal performance and longevity. Here are some reliable sources to consider:

- Authorized Dealers: Visit local authorized retailers for genuine offerings and expert advice.

- Manufacturer Websites: Browse the official websites for direct purchasing options and detailed catalogs.

- Online Marketplaces: Utilize trusted e-commerce platforms that specialize in machinery equipment.

- Specialty Shops: Seek out stores dedicated to equipment maintenance, which often carry a range of original products.

Ensuring the authenticity of the components is crucial to maintain the efficiency and durability of your machinery.

Benefits of OEM vs Aftermarket Parts

When it comes to maintenance and repair, the choice between original equipment manufacturer (OEM) components and alternative options can significantly impact performance and longevity. Understanding the advantages of each type can help ensure that machinery remains efficient and reliable over time.

Quality and Compatibility

OEM components are designed specifically for particular models, ensuring perfect compatibility and adherence to manufacturer standards. This tailored approach often results in superior durability and functionality. In contrast, aftermarket alternatives may vary in quality, and while some can match or even exceed OEM specifications, others might fall short, leading to potential issues in performance.

Cost Considerations

While OEM components often come with a higher price tag, they typically provide peace of mind in terms of reliability and warranty coverage. Aftermarket options can be more budget-friendly, allowing for savings in the short term. However, it’s crucial to weigh these savings against possible long-term costs associated with decreased performance or increased wear on the machinery.

In conclusion, the decision between OEM and aftermarket options should be made based on individual needs, considering factors such as quality, compatibility, and overall cost-effectiveness.