When it comes to maintaining your outdoor machinery, a comprehensive understanding of its key elements is vital. Familiarizing yourself with the intricate layout and functionality of various parts ensures efficient operation and longevity of your equipment. This knowledge not only enhances performance but also simplifies troubleshooting and repairs.

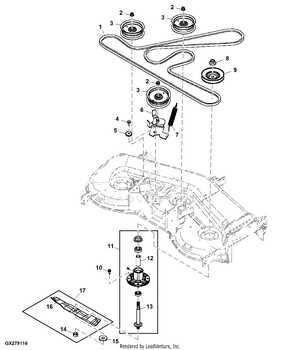

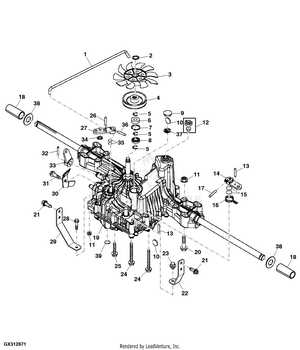

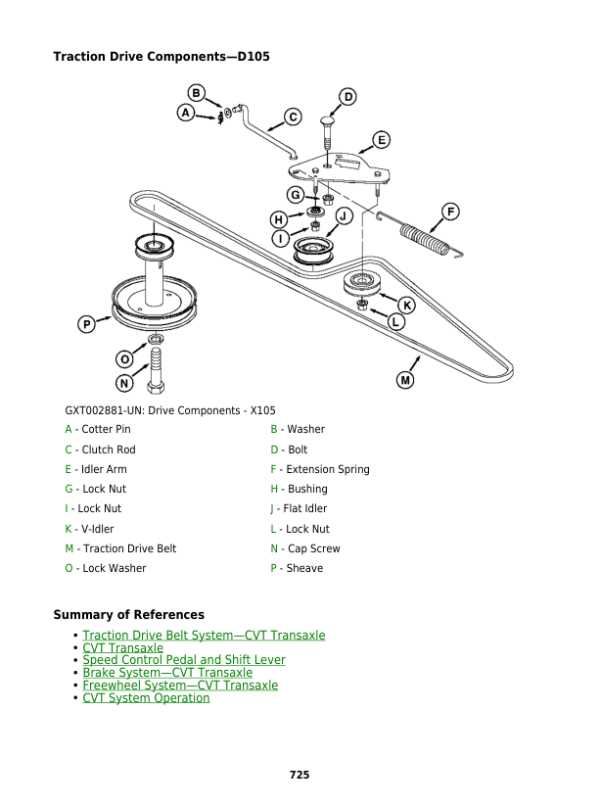

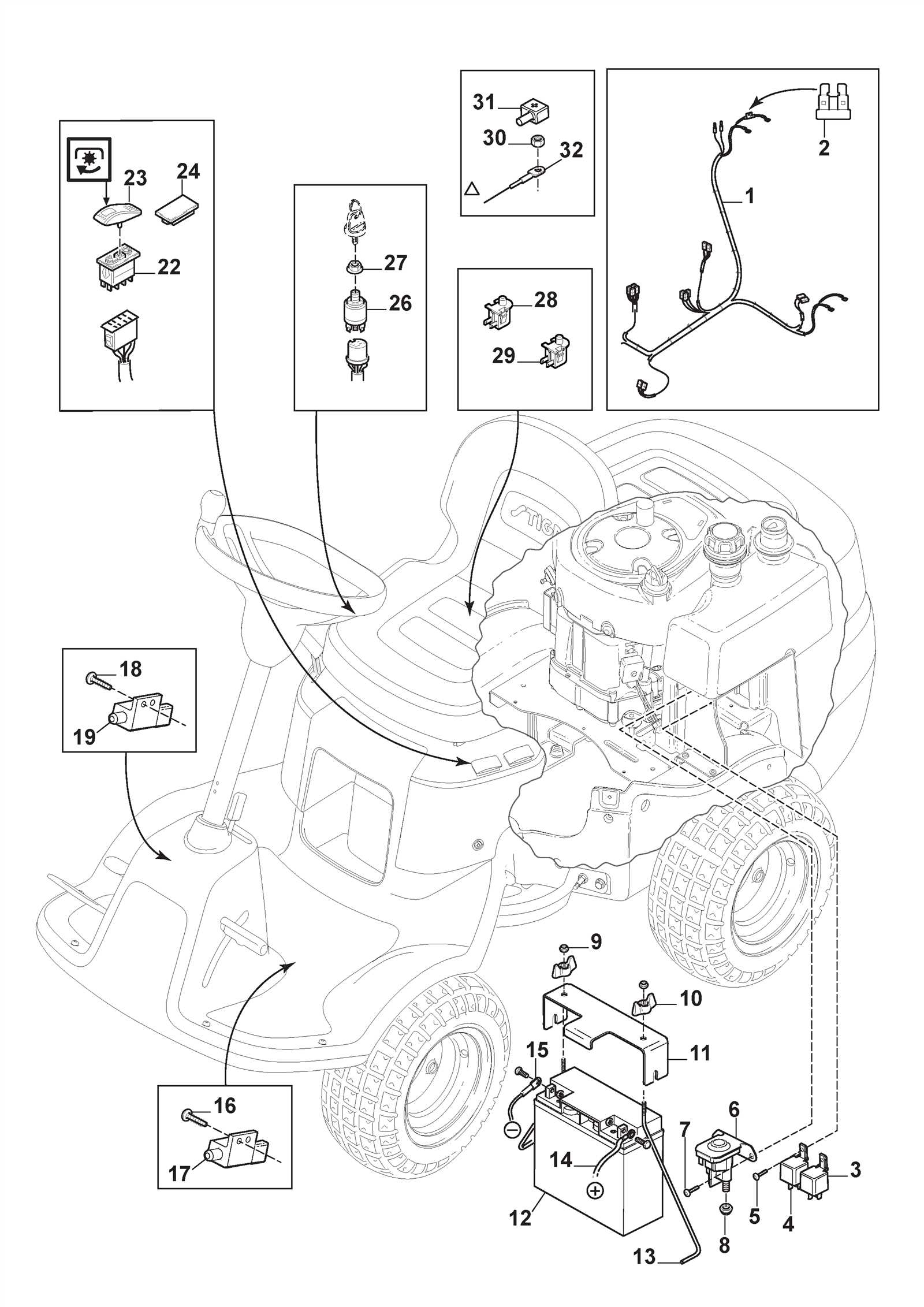

Visualizing the Assembly can significantly aid in identifying specific elements and their relationships within the overall structure. By examining the arrangement of components, users can pinpoint potential issues more effectively and address them with confidence. Furthermore, having access to clear illustrations makes the learning process more intuitive.

Whether you are a seasoned operator or a newcomer, gaining insights into the mechanics behind your mower can transform your maintenance approach. This exploration allows for a deeper appreciation of engineering and craftsmanship involved in outdoor machinery, ultimately leading to more informed decisions regarding upkeep and repairs.

Understanding John Deere D170 Components

When maintaining a complex machine, recognizing its various elements is crucial for effective operation and repair. Each component plays a vital role in ensuring the overall functionality and performance of the equipment.

- Engine: The powerhouse that drives all operations.

- Transmission: Responsible for power transfer and speed regulation.

- Chassis: The structural framework that supports all other parts.

- Electrical System: Powers lights, ignition, and essential electronics.

- Cooling System: Prevents overheating to maintain optimal performance.

By grasping the significance of these components, operators can better manage upkeep and troubleshoot issues, ultimately enhancing the longevity and efficiency of their machinery.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repair processes. Accurate illustrations not only streamline the identification of each element but also enhance the efficiency of assembly and disassembly procedures.

When working on machinery, the significance of well-crafted visuals cannot be overstated. Here are several reasons why they are essential:

- Efficiency: Clear images facilitate quicker identification of necessary components, reducing downtime during repairs.

- Accuracy: Detailed representations minimize the risk of errors, ensuring that the correct items are selected for replacement or repair.

- Training: They serve as excellent resources for training new technicians, providing a clear reference for understanding complex systems.

- Documentation: Comprehensive visuals contribute to better record-keeping and provide valuable references for future maintenance tasks.

In summary, the role of accurate visual representations in machinery maintenance is vital. They not only enhance operational efficiency but also contribute to overall equipment longevity by ensuring that each component is handled correctly and with care.

Common Issues with D170 Machinery

In the realm of agricultural equipment, certain challenges frequently arise, affecting performance and efficiency. Understanding these common problems can aid in timely maintenance and ensure smooth operation over time.

Mechanical Failures

- Engine Overheating: Often caused by coolant leaks or blocked radiators.

- Transmission Issues: Slipping gears or delayed engagement can hinder mobility.

- Hydraulic Failures: Problems may include leaks or unresponsive controls.

Electrical Malfunctions

- Battery Drain: Frequent discharges can indicate faulty wiring or aging components.

- Starter Problems: Difficulty in starting may stem from a worn-out starter motor.

- Lighting Failures: Flickering or non-functioning lights can reduce visibility and safety.

By being aware of these prevalent issues, operators can take proactive measures to maintain their equipment in optimal condition, minimizing downtime and maximizing productivity.

Where to Find Replacement Parts

Locating suitable components for your machinery can enhance performance and extend its lifespan. Several avenues exist for sourcing these essential items, ensuring you can maintain your equipment effectively.

Online Retailers

- Specialized e-commerce websites offer a wide variety of options.

- General online marketplaces often have third-party vendors providing quality components.

- Manufacturer’s official sites frequently list available items and accessories.

Local Suppliers

- Authorized dealers can provide original equipment with reliable warranties.

- Local hardware stores might carry compatible components suitable for various models.

- Salvage yards can offer used but functional items at a reduced price.

Consider comparing prices and checking reviews to ensure the best choice for your needs.

Maintaining Your John Deere D170

Proper upkeep of your lawn equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. This guide outlines key practices to ensure your machinery remains in top condition throughout its operational life.

Regular Inspections

Conducting frequent inspections is vital. Check for any signs of wear and tear, particularly in the engine and moving components. Ensure that all fasteners are tight and that there are no leaks. Cleaning the exterior regularly helps prevent rust and corrosion, while also allowing for easier detection of any issues that may arise.

Fluid Changes and Filter Replacements

Routine fluid changes are crucial for maintaining the internal mechanisms of your equipment. Regularly replace the oil and ensure that the fuel system is clean. Additionally, changing the air and fuel filters at specified intervals keeps the engine running smoothly. A well-maintained engine not only performs better but also consumes fuel more efficiently.

Tools Required for Parts Replacement

When undertaking maintenance or repairs on your equipment, having the right tools at your disposal is essential for a smooth and efficient process. Properly selected instruments not only enhance performance but also ensure safety and accuracy during the task.

Wrenches are fundamental for loosening and tightening fasteners. Both standard and adjustable options will provide versatility for different sizes. Additionally, screwdrivers, including both flathead and Phillips, are necessary for securing various components.

For more intricate tasks, socket sets can offer greater leverage and accessibility to hard-to-reach bolts. An impact wrench can also be invaluable for stubborn fasteners that require extra torque.

Lastly, having a multimeter can assist in diagnosing electrical issues, while pneumatic tools may be beneficial for specific applications. Ensuring your toolkit is well-equipped will facilitate a more efficient repair experience.

Tips for DIY Repairs

Embarking on repair tasks can be both rewarding and challenging. With the right approach, you can tackle various maintenance projects effectively, saving time and money. Here are some essential tips to guide you through the process.

- Understand Your Equipment: Familiarize yourself with the specific model and its components. Knowing how everything fits together is crucial for effective repairs.

- Gather Necessary Tools: Ensure you have all required tools before starting. This includes wrenches, screwdrivers, pliers, and any specialized equipment that may be needed.

- Consult Manuals: Use user manuals or online resources to gain insights into the repair process. Diagrams and instructions can provide valuable guidance.

- Work in a Clean Area: Maintain an organized workspace to avoid losing small parts and to ensure safety while working.

- Take Notes: Document each step of the disassembly process. This will make it easier to reassemble everything correctly.

By following these tips, you can enhance your DIY repair skills and ensure that your maintenance tasks are carried out smoothly and efficiently.

Resources for Further Information

For those seeking in-depth knowledge about machinery components and their maintenance, a variety of resources are available to enhance understanding and assist in repairs. These resources can provide valuable insights, including specifications, troubleshooting guides, and community support. Utilizing these tools effectively can lead to improved performance and longevity of equipment.

Online Forums and Communities

Engaging with online communities can be incredibly beneficial. Platforms such as specialized forums and social media groups allow enthusiasts and professionals to share their experiences, ask questions, and provide advice. Participating in these discussions can deepen your understanding and connect you with knowledgeable individuals in the field.

Manufacturer Resources

Official websites often offer a wealth of information, including manuals, installation guides, and customer support services. These resources are essential for obtaining accurate and detailed information directly from the source. Make sure to explore these options for the most reliable guidance regarding your equipment.