The intricate assembly of agricultural machinery plays a crucial role in enhancing productivity on the farm. Each element, whether mechanical or electronic, contributes to the overall efficiency and functionality of the equipment. A thorough understanding of these components is essential for anyone involved in maintenance or repair tasks.

By exploring the various sections and how they interconnect, operators can gain valuable insights into the workings of their machinery. Recognizing each component’s function allows for more effective troubleshooting and repairs, ultimately leading to reduced downtime and increased yield.

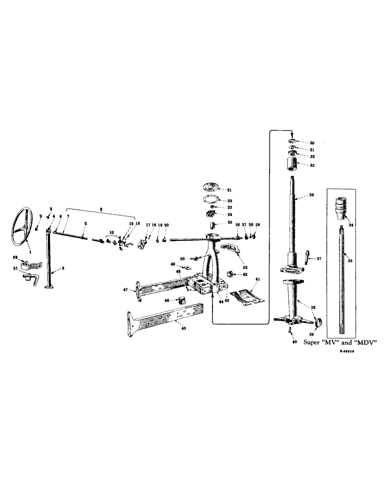

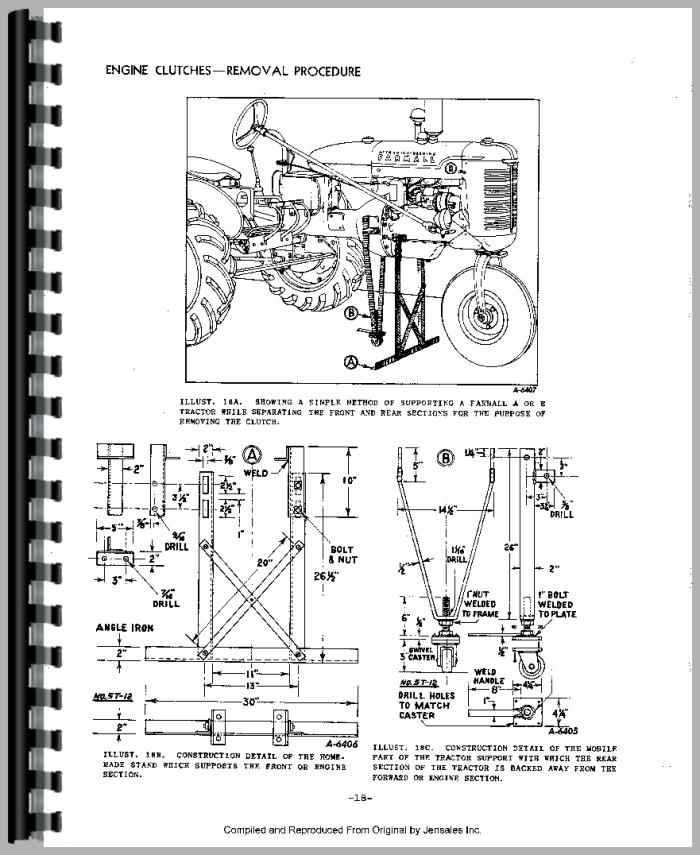

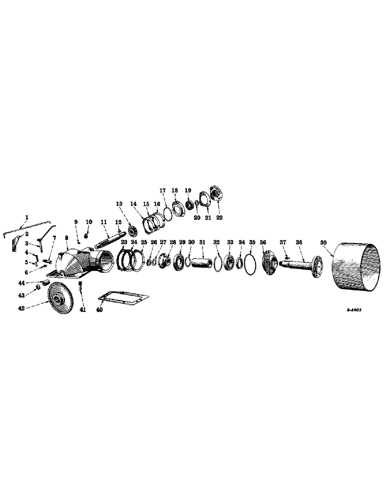

Furthermore, visual representations of these assemblies serve as invaluable resources, providing clarity on how different elements interact within the system. Such illustrations can simplify the learning process, making it easier to identify and address specific issues as they arise. This foundational knowledge is key to sustaining operational efficiency in agricultural practices.

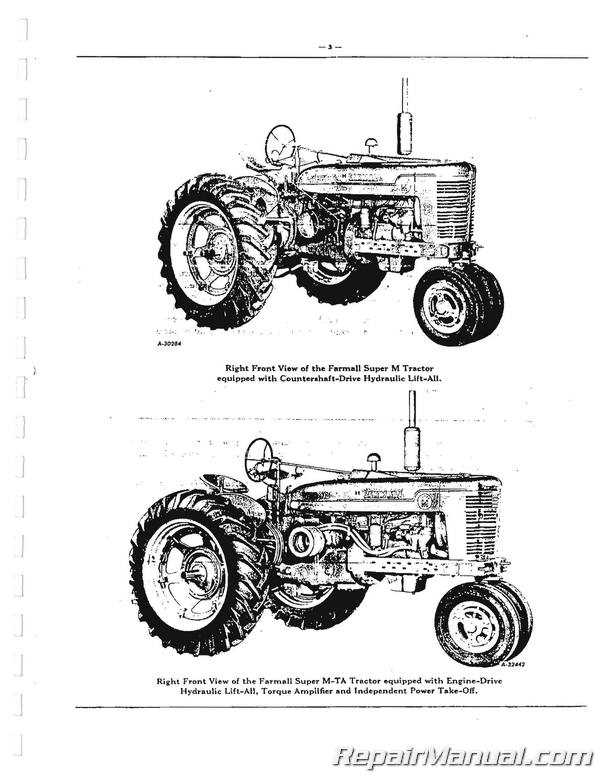

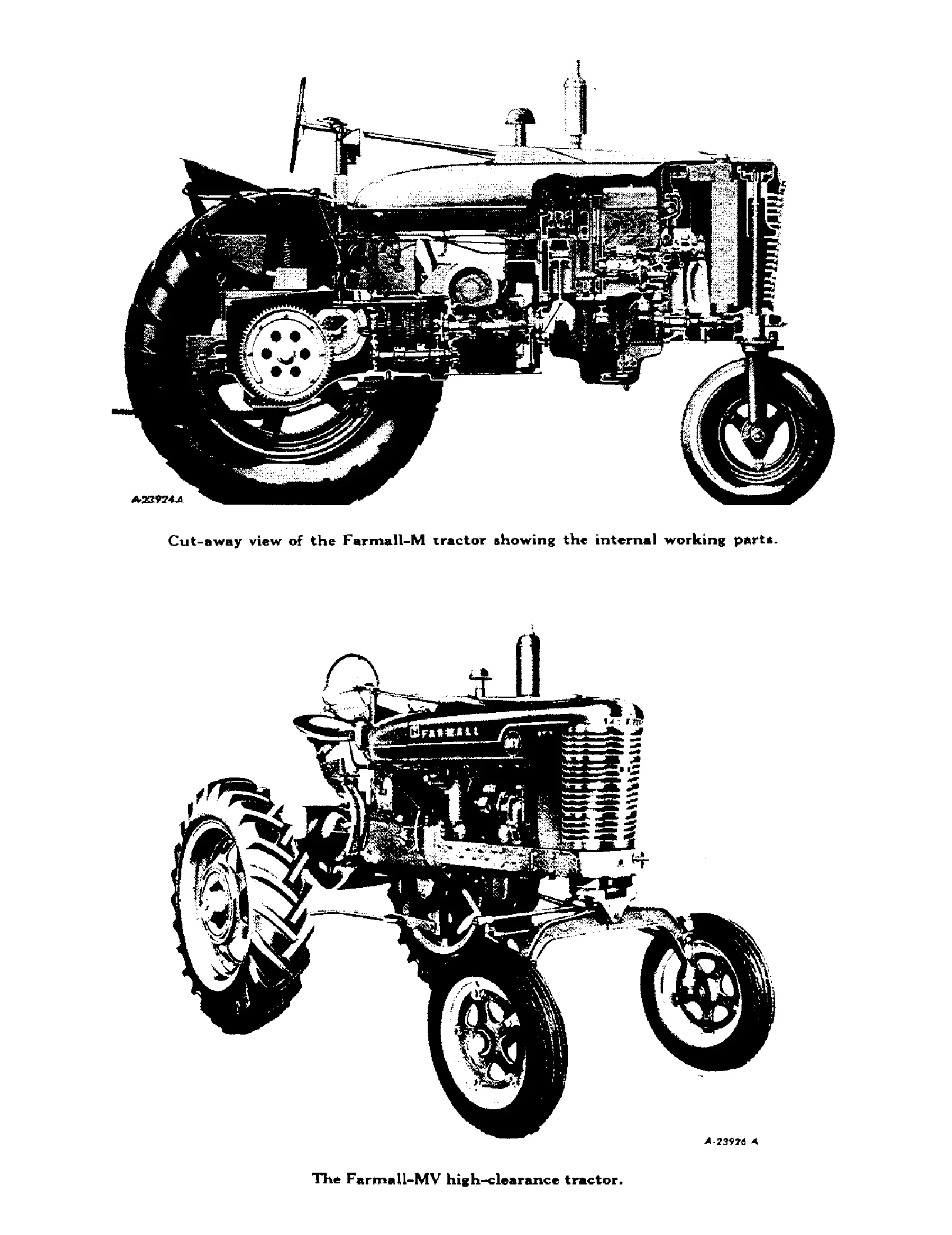

Essential Components of the Farmall M Tractor

The machinery features a variety of crucial elements that contribute to its efficiency and performance in agricultural tasks. Understanding these fundamental components is vital for proper maintenance and operation.

Key Elements

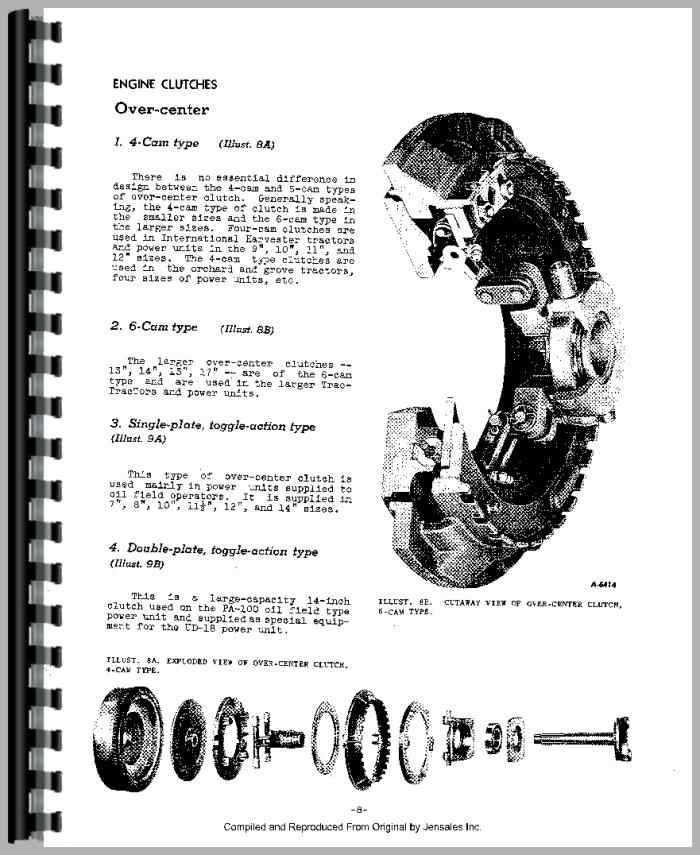

- Engine: The heart of the machine, providing the necessary power for operation.

- Transmission: Facilitates speed and torque adjustments, allowing for smooth movement across different terrains.

- Steering System: Essential for maneuverability, ensuring accurate control of direction.

- Hydraulic System: Powers various attachments and implements, enhancing functionality.

- Electrical System: Manages lighting and ignition, ensuring reliable operation.

Additional Components

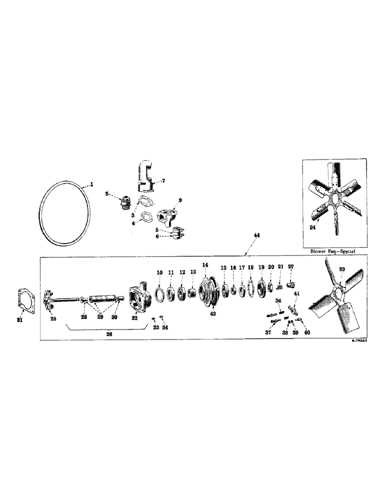

- Cooling System: Maintains optimal engine temperature to prevent overheating.

- Fuel System: Stores and delivers fuel to the engine efficiently.

- Chassis: The framework that supports all other elements, providing stability and durability.

- Tires: Designed for traction and support on various surfaces.

Familiarity with these essential components aids in effective troubleshooting and ensures longevity in operation.

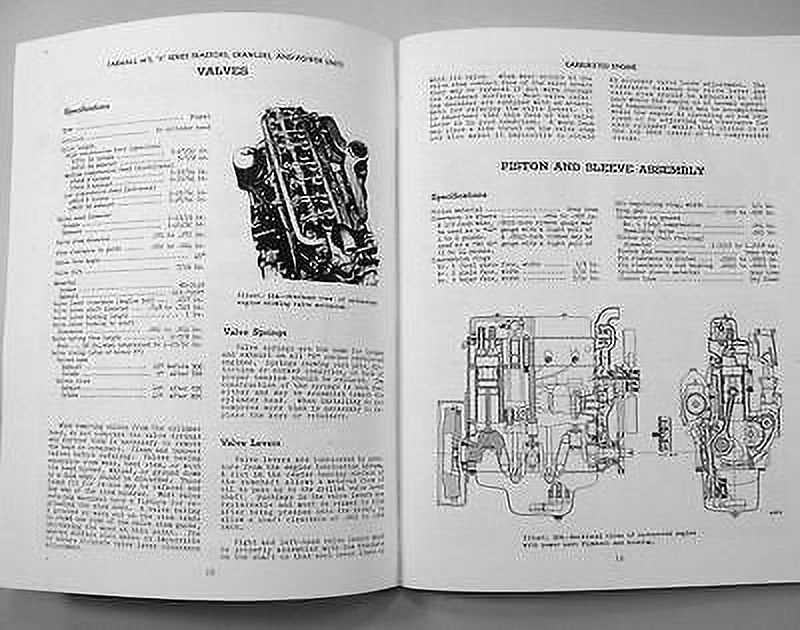

Understanding the Farmall M Engine Parts

Comprehending the components of a vintage tractor’s power unit is essential for enthusiasts and operators alike. Each element plays a crucial role in ensuring optimal performance, reliability, and efficiency. By familiarizing oneself with these key elements, one can effectively maintain and troubleshoot the machinery.

Core Components of the Engine

At the heart of any engine are its vital mechanisms. The cylinder block serves as the main structure, housing the cylinders where combustion occurs. Complementing this are the pistons, which move up and down within the cylinders, converting fuel energy into mechanical force. Additionally, the crankshaft transforms this linear motion into rotational energy, driving the machine’s functions.

Supporting Systems

Beyond the core, several auxiliary systems enhance the engine’s operation. The cooling system prevents overheating, utilizing a radiator and coolant to maintain optimal temperatures. Meanwhile, the fuel delivery system ensures a proper mixture of air and fuel reaches the combustion chamber. Understanding these supporting structures is vital for achieving peak performance and longevity of the equipment.

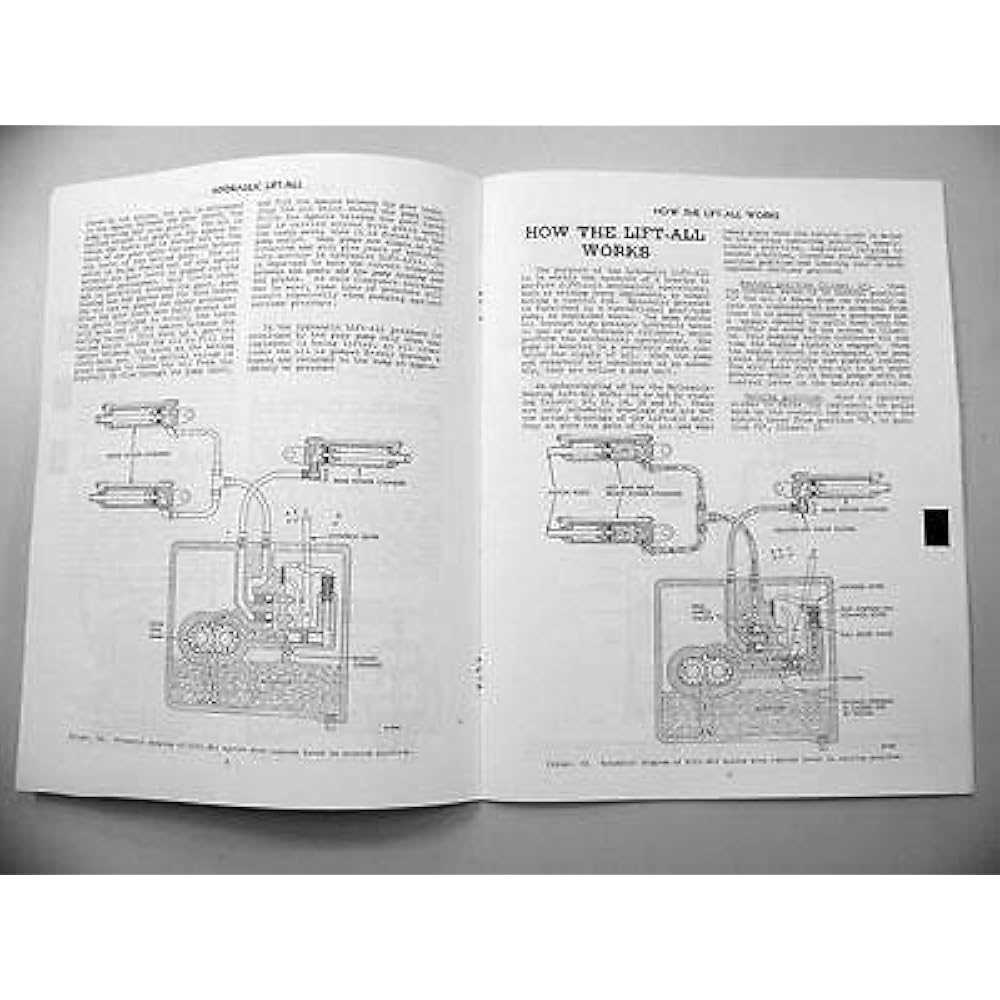

Key Hydraulic System Components for Farmall M

The hydraulic system of a tractor plays a vital role in its functionality, allowing for the efficient operation of various implements and attachments. Understanding the essential elements of this system is crucial for maintenance and effective performance.

| Component | Description |

|---|---|

| Hydraulic Pump | This component generates the flow of hydraulic fluid necessary for powering the system. |

| Control Valve | Regulates the direction and flow of hydraulic fluid to different parts of the system. |

| Hydraulic Cylinder | Converts hydraulic pressure into linear motion, enabling movement of attached implements. |

| Fluid Reservoir | Stores hydraulic fluid, ensuring a steady supply to the system during operation. |

| Hydraulic Lines | These hoses and tubes transport hydraulic fluid between components, facilitating system function. |

Maintaining these key elements ensures optimal performance and longevity, making them integral to the tractor’s operation.

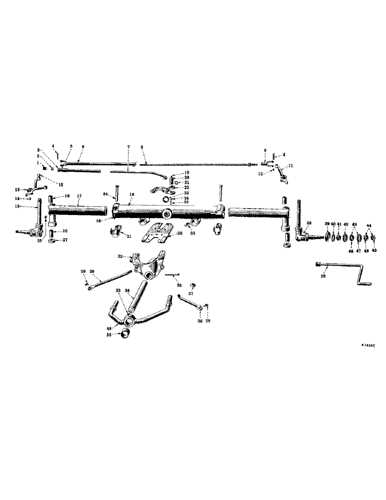

How to Identify Farmall M Transmission Parts

Understanding the components of a specific tractor’s gearbox can enhance your ability to maintain and repair it effectively. Each section plays a crucial role in the overall functioning, and recognizing these elements is essential for troubleshooting and upgrades. This guide will assist you in pinpointing the various elements associated with the transmission system.

Key Components of the Transmission System

- Gearbox Housing: This outer shell protects the inner mechanisms and holds everything in place.

- Shifting Mechanism: Controls gear selection, often consisting of levers and linkages.

- Gears: Various sizes and shapes that facilitate speed changes and torque adjustments.

- Bearings: Support rotating shafts and reduce friction during operation.

- Seals and Gaskets: Prevent fluid leaks and keep contaminants out of the system.

Identifying Each Element

- Refer to a reputable manual or guide specific to the model to familiarize yourself with the layout.

- Inspect the external components for any visible wear or damage, which could indicate the need for replacement.

- Check for identification numbers or markings that can help you confirm the specifications of each component.

- Utilize online resources or forums where enthusiasts share insights and images of various transmission elements.

- Consider consulting with a specialist if you encounter difficulties in recognizing certain components.

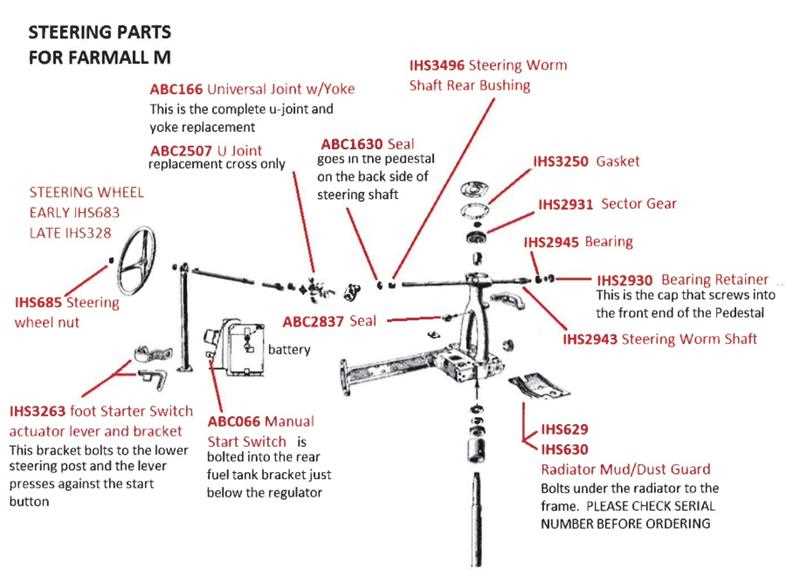

Maintaining the Steering and Suspension System

The steering and suspension components of your machinery are vital for ensuring smooth operation and optimal performance. Regular attention to these systems not only enhances handling but also prolongs the lifespan of your equipment. Proper maintenance practices can prevent issues that may arise from wear and tear, ultimately saving you time and money in the long run.

Key Maintenance Practices

To keep the steering and suspension in excellent condition, several key practices should be followed. Routine inspections are essential to identify any signs of damage or excessive wear. Lubrication of moving parts is equally important to ensure smooth functionality and to prevent rust and corrosion.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Tie Rods | Every 50 hours | Check for bending, wear, or looseness. |

| Lubricate Joints | Every 25 hours | Apply grease to ensure smooth operation. |

| Check Alignment | Every 100 hours | Ensure proper alignment to prevent uneven tire wear. |

| Inspect Shocks | Every 50 hours | Look for leaks and signs of wear. |

Signs of Wear and Tear

Recognizing the symptoms of a failing system is crucial. Common indicators include excessive play in the steering wheel, unusual noises during operation, and an uncomfortable ride. Addressing these issues promptly can prevent more severe problems from developing and ensure your equipment remains reliable.

Farmall M Electrical System Overview

The electrical framework of this agricultural machine plays a crucial role in its overall functionality and efficiency. It serves as the backbone for powering various components, ensuring smooth operation and reliability during agricultural tasks.

At the heart of the system lies the generator, which is responsible for converting mechanical energy into electrical energy. This unit works in conjunction with a battery to store and supply power as needed, enabling the ignition system and other electrical accessories to function effectively.

Wiring harnesses distribute electricity throughout the machine, connecting switches, lights, and gauges. Proper insulation and routing are essential to prevent short circuits and ensure safety during operation. Additionally, the voltage regulator maintains optimal power levels, protecting components from overcurrent and damage.

Understanding the intricacies of this electrical setup is vital for maintenance and troubleshooting. Regular inspections and testing can help identify issues early, ensuring that the machine remains in peak condition for demanding tasks.

Common Wear Parts on the Farmall M

The longevity and efficiency of vintage machinery often hinge on understanding the components that experience the most wear over time. By identifying these crucial elements, operators can ensure smooth operation and maintain performance standards. Regular inspection and timely replacement of these items are vital for optimal functionality.

Engine Components

Critical elements such as pistons and gaskets are prone to deterioration due to continuous usage and heat exposure. Regular checks can help identify leaks or wear, preventing more severe damage.

Transmission and Steering

Components like bearings and seals in the transmission system are also susceptible to wear. Monitoring these parts ensures reliable power transfer and steering control, which are essential for effective operation.

Locating Replacement Parts for Farmall M

Finding the right components for vintage machinery can be a rewarding yet challenging task. It involves understanding the specific requirements of your equipment and knowing where to look for suitable alternatives. Various resources, both online and offline, can help enthusiasts and owners keep their machines running smoothly.

Start by exploring specialized retailers that focus on classic agricultural machinery. These suppliers often have extensive inventories and knowledgeable staff who can assist you in identifying the exact items needed. Additionally, online marketplaces can provide access to a wider range of options, including new and used items from private sellers.

Joining online forums and communities dedicated to vintage equipment can also be invaluable. Members frequently share insights about reliable sources and may even offer spare components for sale or trade. Networking with fellow enthusiasts can lead to discovering hard-to-find pieces that are essential for maintenance and restoration.

Lastly, don’t overlook local salvage yards and antique shops. These locations might have hidden gems that can be refurbished or repurposed for your specific needs. By employing a combination of these strategies, you can effectively track down the components necessary to keep your machinery in optimal condition.

Tips for Repairing Farmall M Parts Diagrams

Understanding and fixing components of vintage machinery can be a rewarding experience. Whether you are working with schematics or just need guidance on maintenance, having a clear approach is essential for effective repairs. Here are some practical suggestions to enhance your skills in tackling these technical illustrations.

1. Familiarize Yourself with the Layout

Before diving into repairs, take time to study the layout of the illustrations. Identify key sections and components that you will be working with. This initial step can save you time and frustration as you proceed. Knowing the arrangement will also help you understand how parts interact with each other.

2. Gather Necessary Tools and Materials

Having the right tools on hand is crucial for successful maintenance. Make a checklist of required instruments and materials before you start. Investing in quality tools can make a significant difference in the ease of your repairs. Additionally, consider organizing your workspace to ensure everything is within reach, facilitating a smoother workflow.