Understanding the intricate details of machinery can significantly enhance maintenance and repair efforts. This section delves into the essential elements that contribute to the functionality of a specific model, offering insights into its structure and operation. By examining a visual representation of the components, users can gain a clearer perspective on how each part interconnects.

Through a comprehensive overview of the various sections, this resource aims to simplify the often complex task of identifying and locating specific elements within the system. Detailed illustrations serve as valuable tools for both novice and experienced technicians alike, facilitating a more efficient approach to troubleshooting and repairs.

Whether you are looking to replace worn-out components or simply want to familiarize yourself with the layout of the machine, understanding these visual aids can lead to better-informed decisions and a smoother maintenance process. This guide provides a stepping stone toward mastering the nuances of the equipment’s design.

Understanding the John Deere Hydro 175

This section explores a popular model known for its reliable performance in landscaping and gardening tasks. It combines advanced technology with user-friendly features, making it an ideal choice for both professionals and enthusiasts. A thorough comprehension of its components and functionality is essential for effective maintenance and optimal operation.

Key Features

- Efficient engine design

- Comfortable seating arrangement

- Intuitive control layout

- Versatile attachment compatibility

- Durable construction for longevity

Maintenance Tips

- Regularly check and change the oil to ensure smooth operation.

- Inspect the air filter periodically for optimal engine performance.

- Sharpen or replace blades to maintain cutting efficiency.

- Keep the wheels and tires properly inflated for stability.

- Store in a dry place to prevent rust and corrosion.

Understanding these elements will enhance your experience and extend the lifespan of this remarkable machine.

Key Components of the Hydro 175

This section explores essential elements of a well-known lawn care machine, highlighting their functions and importance. Understanding these components is crucial for effective maintenance and optimal performance.

Power System

The power system is the heart of the machine, providing the necessary energy for various operations. It includes the engine and related accessories that ensure efficient functionality.

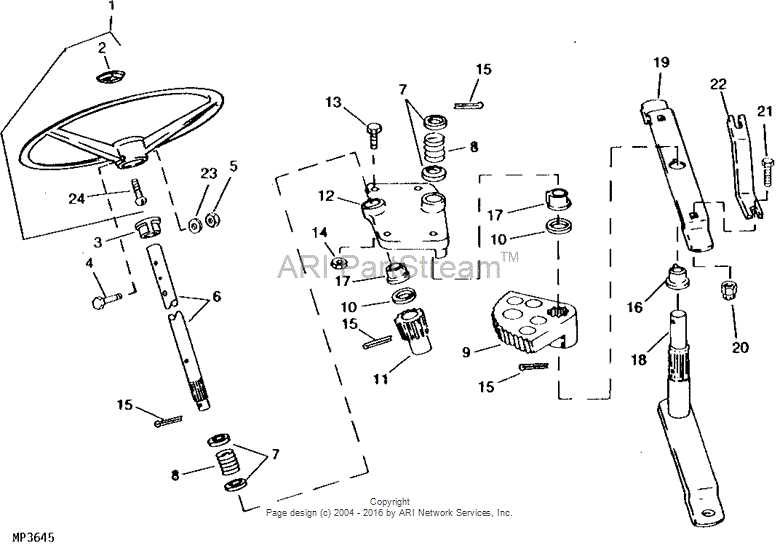

Transmission and Control

The transmission system allows for smooth movement and maneuverability, while control components enable operators to adjust settings and manage speed effectively.

| Component | Function |

|---|---|

| Engine | Powers the machine |

| Transmission | Controls movement and speed |

| Steering System | Enables directional control |

| Cutting Deck | Facilitates grass trimming |

Finding Replacement Parts Efficiently

Locating the necessary components for your machinery can often be a daunting task. However, with the right approach, you can streamline the process significantly. Understanding where to look and how to identify the correct items is crucial for ensuring optimal performance and longevity of your equipment.

Start by researching reputable suppliers. Many online platforms offer extensive inventories, making it easier to find what you need. Look for websites that specialize in machinery components, as they typically provide detailed information about each item, including compatibility and specifications.

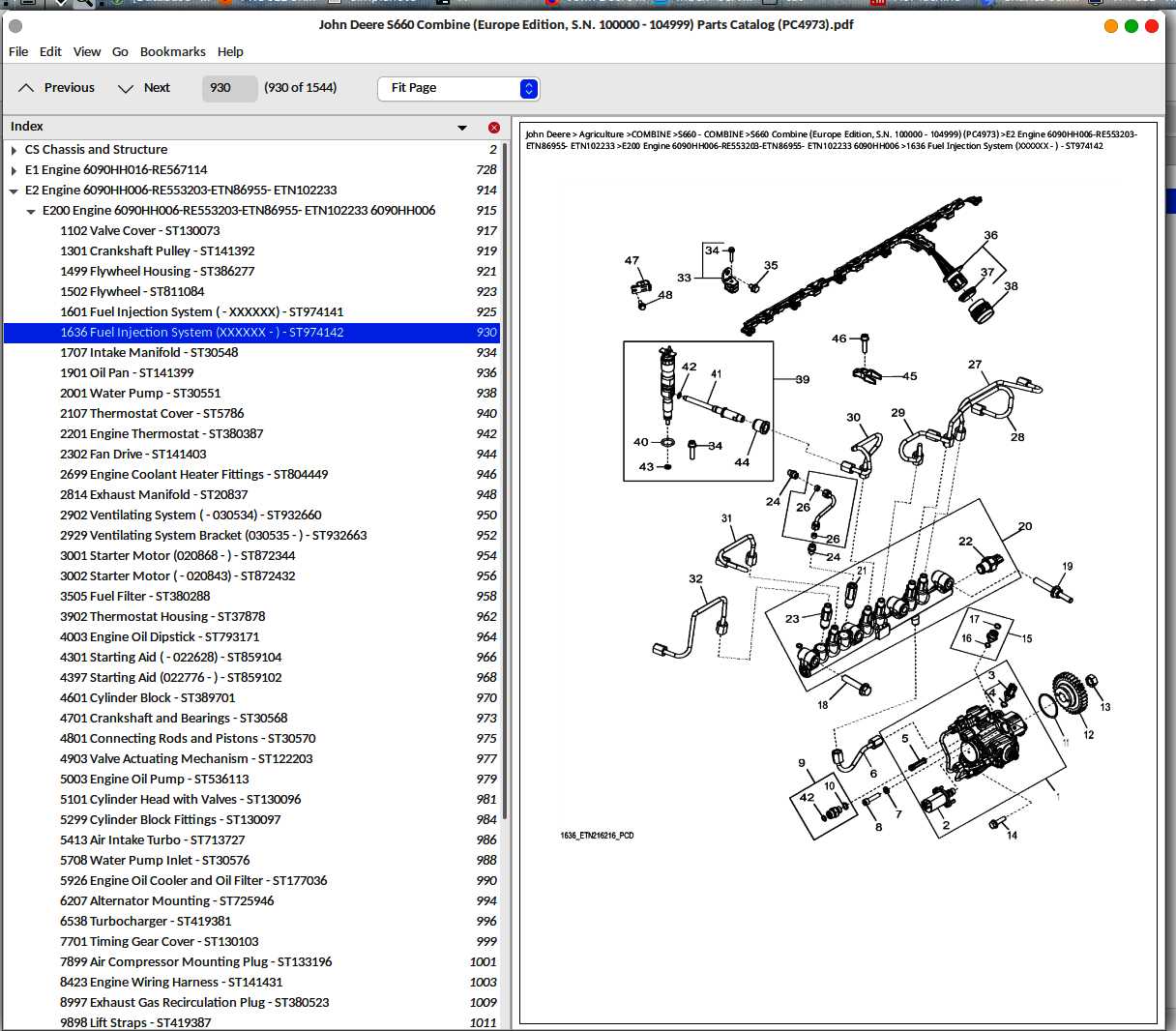

Utilizing manuals and schematics can be incredibly helpful. These resources often contain illustrations that clearly depict the various elements of your machinery. By referencing these materials, you can ensure you are selecting the correct components for your specific model.

Another effective strategy is to join online forums or communities dedicated to equipment enthusiasts. These platforms can provide invaluable insights and recommendations from fellow users who have navigated similar challenges.

Lastly, don’t hesitate to contact customer support. Many suppliers offer assistance in identifying the right components for your needs. They can guide you through the selection process, ensuring you make informed decisions.

Where to Source OEM Parts

Finding original equipment manufacturer components is essential for maintaining the longevity and efficiency of your machinery. Quality and compatibility are paramount when selecting replacement items, ensuring optimal performance.

Here are some reliable sources to consider:

- Authorized Dealers: Local dealerships often carry a wide range of authentic components and can provide expert advice.

- Manufacturer’s Website: The official site usually has a catalog or online store for direct purchasing.

- Specialty Retailers: Look for businesses that focus on specific brands and offer a selection of OEM products.

- Online Marketplaces: Platforms like eBay or Amazon can have listings for genuine items, but verify the seller’s credibility.

- Local Repair Shops: Sometimes, mechanics have spare parts or can order them directly for you.

Prioritizing these avenues will help ensure you acquire the right components for your needs.

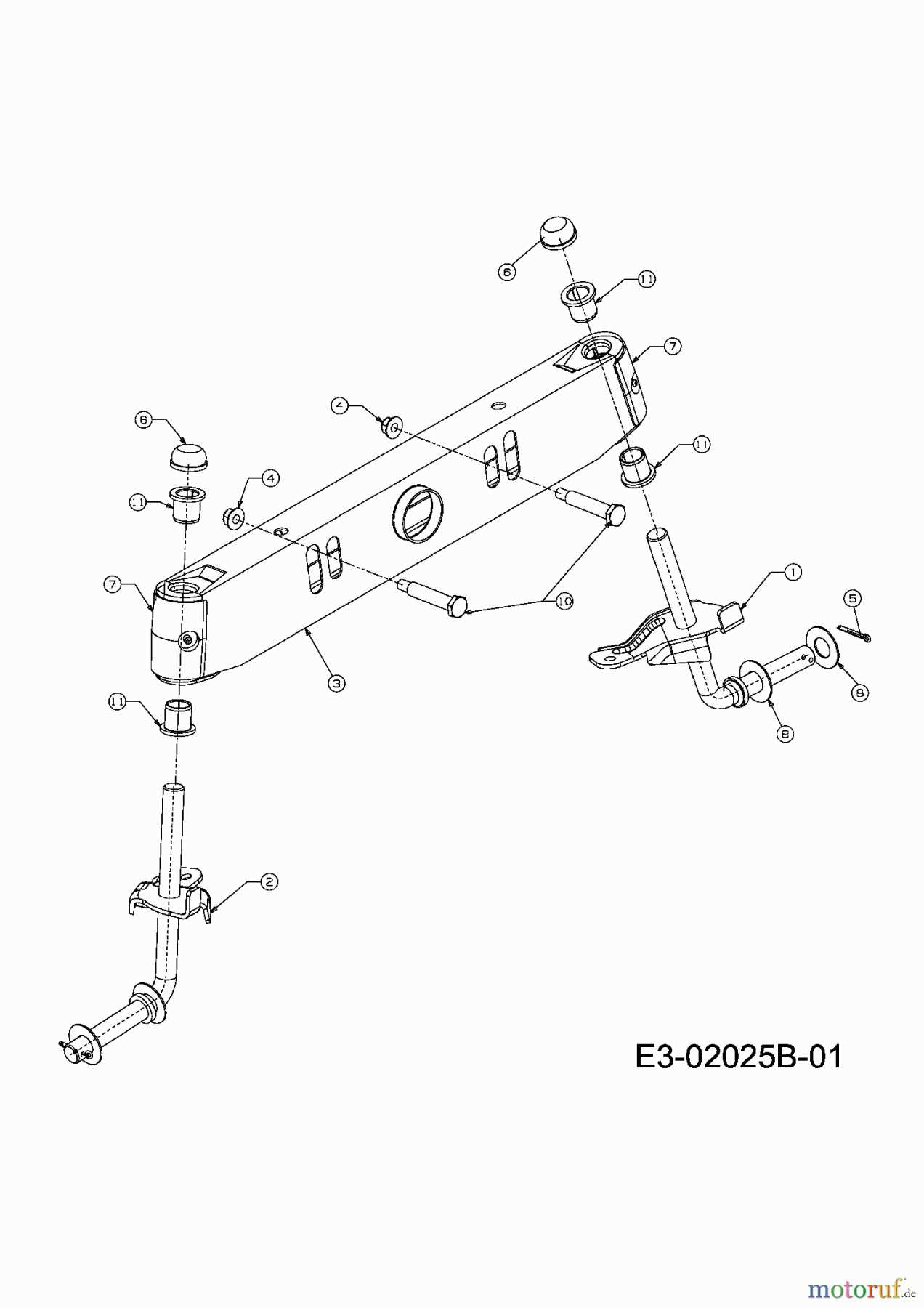

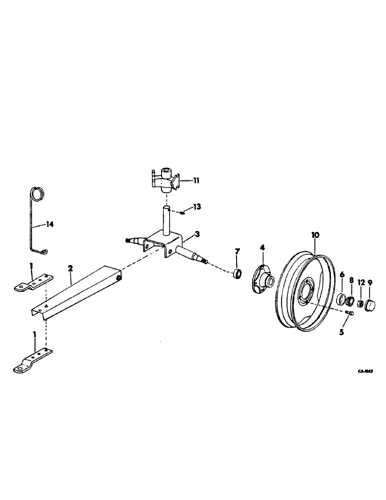

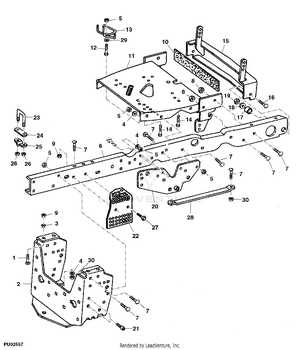

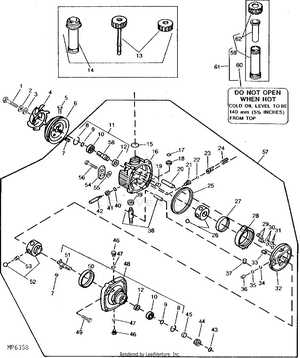

Interpreting the Parts Diagram

Understanding the schematic representation of components is essential for effective maintenance and repair of equipment. Such illustrations provide a visual guide to the various elements involved, helping users identify each part’s location and function. Mastering this visual tool can significantly enhance one’s ability to troubleshoot and perform necessary interventions.

Key Features of the Schematic

These illustrations typically include various symbols and annotations that indicate the specific components and their interconnections. Familiarizing oneself with these features can streamline the repair process and reduce the likelihood of errors.

Reading the Illustration

When examining the representation, pay close attention to the labels and reference numbers associated with each component. This information is crucial for sourcing replacements and understanding the assembly. Below is a simplified table illustrating common elements found in such representations.

| Component Name | Description | Reference Number |

|---|---|---|

| Engine | Power source for the machinery | 01A |

| Transmission | Controls the speed and torque | 02B |

| Deck | Housing for various components | 03C |

| Wheel Assembly | Provides mobility | 04D |

Common Issues and Solutions

In the realm of machinery, encountering challenges is a common experience for users. Identifying these issues and understanding potential remedies can significantly enhance the efficiency and lifespan of equipment. This section will delve into frequent problems and their respective solutions, ensuring optimal performance and reliability.

Engine Performance Problems

One of the most prevalent concerns involves engine performance, which may manifest as difficulty starting or irregular operation. Regular maintenance, such as replacing air filters and ensuring proper fuel quality, can address these issues effectively. Additionally, checking for loose connections and worn components can restore functionality.

Transmission Issues

Another frequent challenge relates to transmission malfunctions, often indicated by unusual noises or failure to shift properly. To remedy this, it’s essential to inspect fluid levels and quality, as well as to examine belts and linkages for wear. Regular lubrication and timely replacements can prevent severe complications.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of various components. Here are essential strategies to keep your machine running smoothly and efficiently.

Regular Inspections

Conducting routine checks is crucial. Look for wear and tear on belts, hoses, and other critical parts. Early detection of issues can prevent more significant problems down the line.

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and wear. Follow the manufacturer’s guidelines for lubricant types and intervals. This practice ensures that moving parts operate seamlessly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Belts | Every 50 hours | Replace if frayed or worn |

| Check Fluid Levels | Every 25 hours | Top up as necessary |

| Clean Air Filters | Monthly | Replace if excessively dirty |

Upgrades and Modifications Available

Enhancing the performance and functionality of your equipment can lead to significant improvements in efficiency and longevity. Various upgrades and modifications are available, allowing users to tailor their machines to better suit specific needs or preferences.

Performance Enhancements

- Engine upgrades for increased horsepower

- Improved air filtration systems for better combustion

- Enhanced transmission options for smoother operation

Functional Additions

- Attachment compatibility for diverse tasks

- Comfort upgrades like ergonomic seating and controls

- Advanced lighting systems for improved visibility

These modifications not only boost productivity but also ensure a more enjoyable user experience, making them worthwhile considerations for any operator.