In the realm of machinery, comprehending the intricate layout of essential elements is crucial for effective maintenance and repairs. This guide explores the various components that constitute a specific model, providing insights into their functions and relationships.

Identifying each piece within the assembly is vital for anyone seeking to enhance their operational knowledge. By analyzing the layout, users can better grasp how each element contributes to the overall performance of the equipment.

Whether you’re a seasoned technician or a curious enthusiast, delving into these schematics will empower you with the ultimate understanding needed for efficient troubleshooting and servicing.

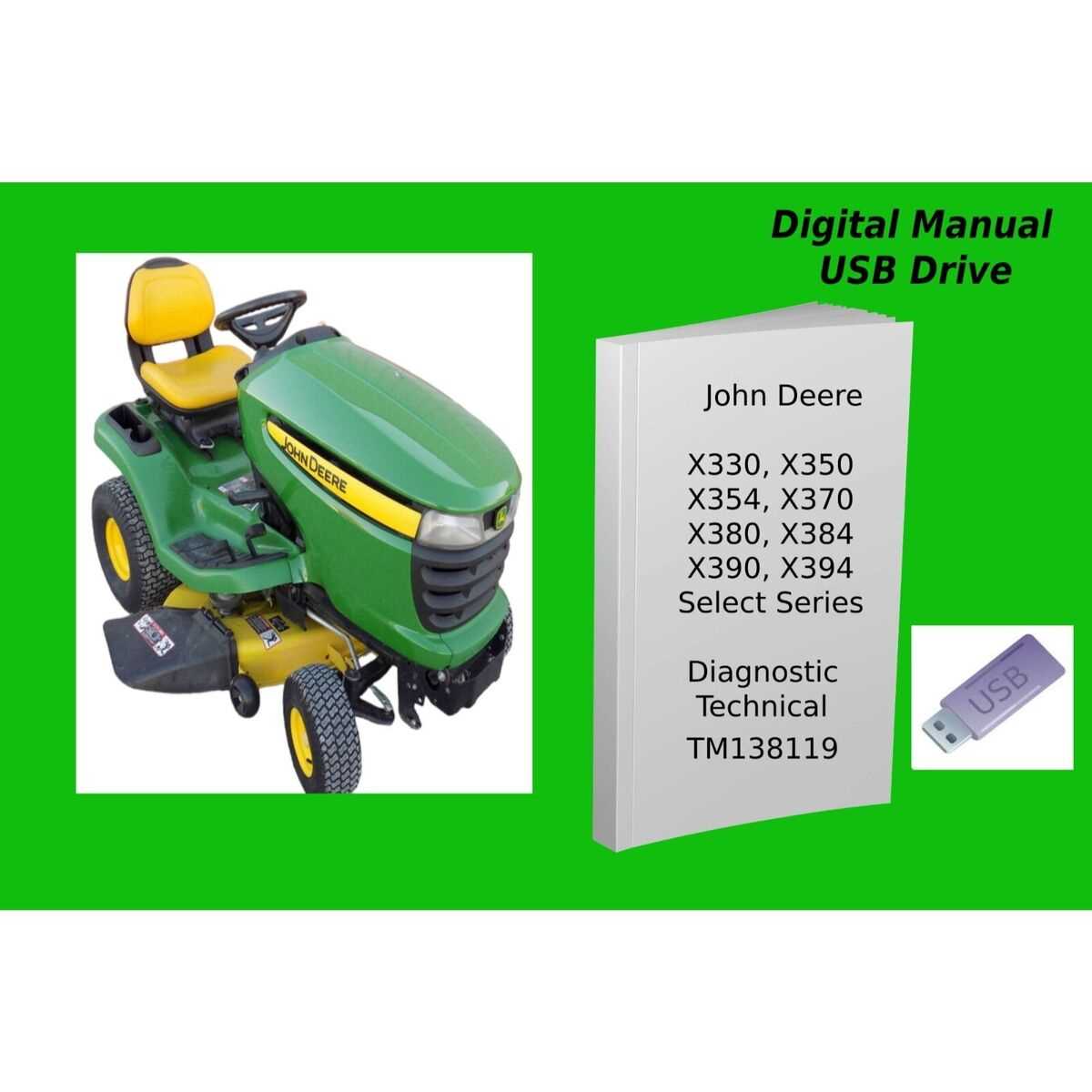

Understanding the John Deere JS30

This section aims to provide insights into a specific model renowned for its efficiency and performance. With its robust design and innovative features, this machine stands out in the realm of outdoor equipment, making lawn maintenance easier and more effective.

Key Features

One of the standout attributes of this model is its powerful engine, which ensures reliable operation even in challenging conditions. Coupled with a user-friendly interface, operators can easily navigate through various settings, enhancing their overall experience. Additionally, the ergonomic design promotes comfort during extended use, reducing fatigue.

Maintenance and Care

Proper upkeep is essential to prolong the lifespan of this equipment. Regular inspections and timely replacements of essential components will ensure optimal performance. Understanding the layout of the machine aids users in identifying parts that may require attention, contributing to a seamless maintenance routine.

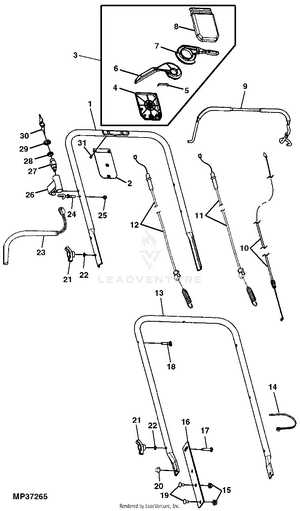

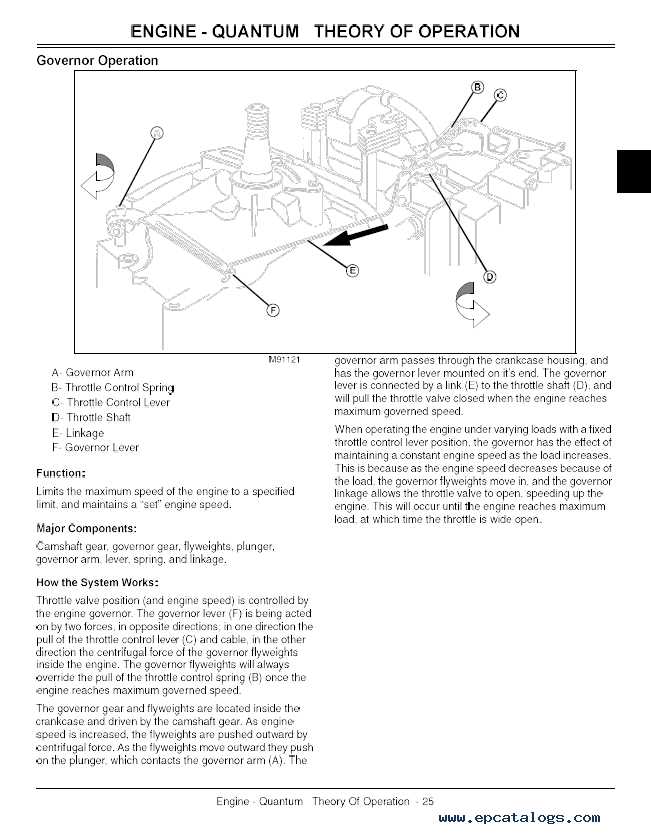

Importance of Parts Diagrams

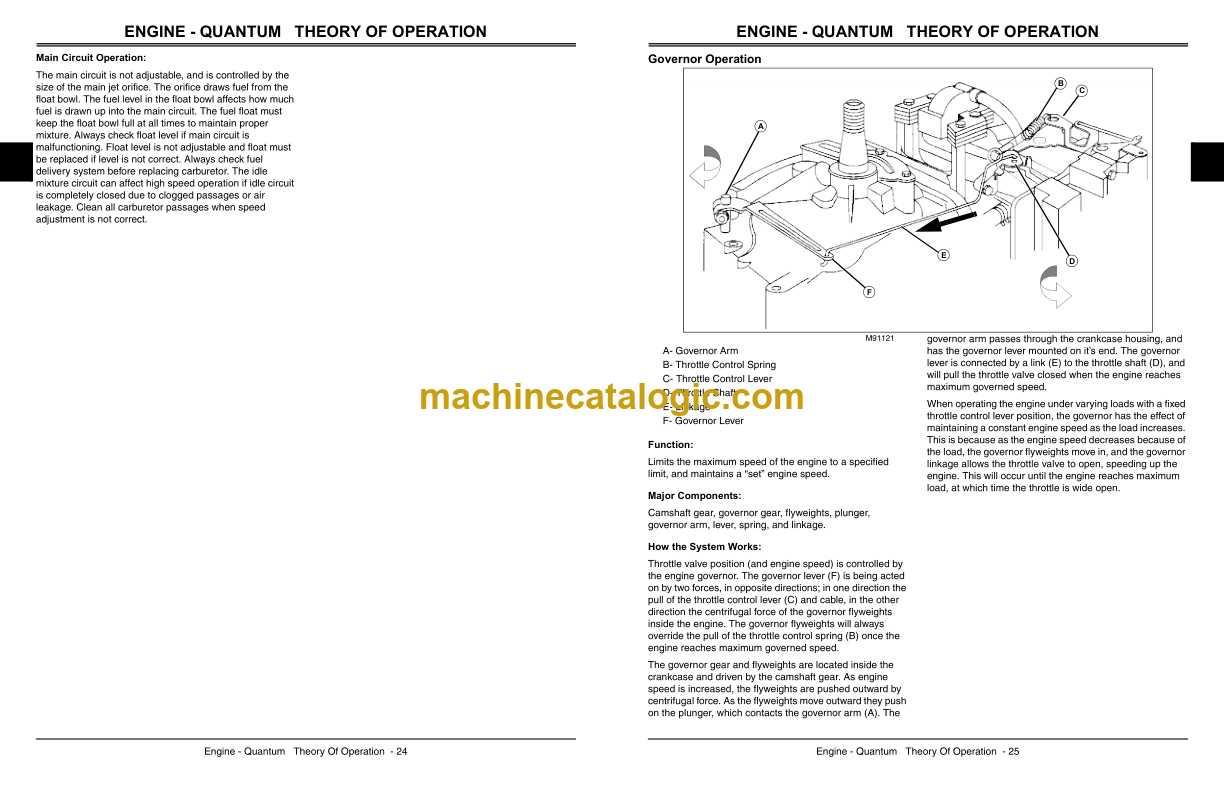

The availability of visual schematics plays a crucial role in understanding the intricacies of machinery. These representations not only enhance comprehension but also facilitate efficient maintenance and repair processes. By providing a clear view of components and their relationships, they serve as essential tools for both professionals and enthusiasts alike.

Enhanced Clarity: Visual guides eliminate ambiguity, allowing users to identify and locate specific elements quickly. This clarity minimizes errors during assembly or disassembly, ultimately saving time and resources.

Improved Maintenance: Regular upkeep is vital for longevity. Having detailed visuals aids technicians in pinpointing wear and tear, ensuring timely interventions that prevent further damage.

Streamlined Repairs: When a malfunction occurs, understanding the layout of a machine is paramount. Visual aids help in diagnosing issues efficiently, enabling quicker resolutions and reducing downtime.

In summary, the significance of visual representations in machinery cannot be overstated. They not only empower users with knowledge but also enhance operational efficiency.

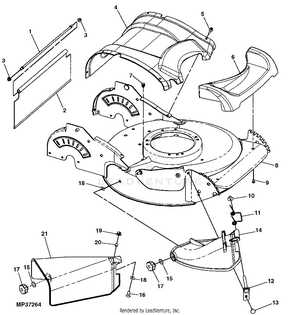

Key Components of JS30 Mower

The functionality and efficiency of a mower rely heavily on its essential elements, which work in unison to deliver optimal performance. Understanding these components is crucial for effective maintenance and operation, ensuring that the equipment runs smoothly and reliably throughout its lifespan.

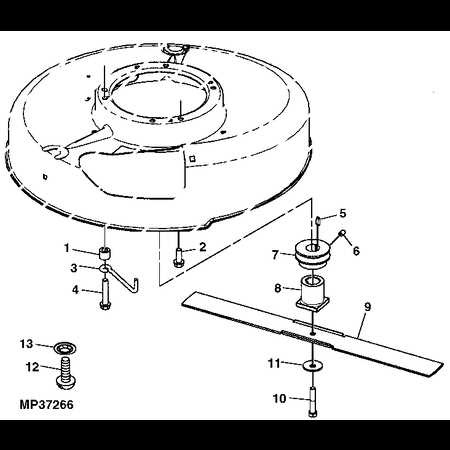

Engine: The heart of any mower, the engine provides the necessary power to propel the machine and drive the cutting blades. A well-maintained engine contributes to a longer operational life and improved fuel efficiency.

Cutting Deck: This component houses the blades and is responsible for delivering a clean, even cut. The design and material of the cutting deck can significantly influence durability and cutting performance, especially in varying terrain.

Blades: Sharp and well-balanced blades are essential for achieving a precise cut. Regular inspection and sharpening of the blades not only enhance performance but also reduce strain on the engine.

Wheels: The wheels affect the maneuverability and stability of the mower. Quality wheels provide better traction and ease of movement, allowing the operator to navigate different types of landscapes effortlessly.

Chassis: The frame of the mower supports all other components and contributes to overall durability. A robust chassis is vital for withstanding the rigors of outdoor use and ensuring longevity.

By familiarizing oneself with these critical components, operators can better manage their equipment, leading to enhanced performance and a more satisfying mowing experience.

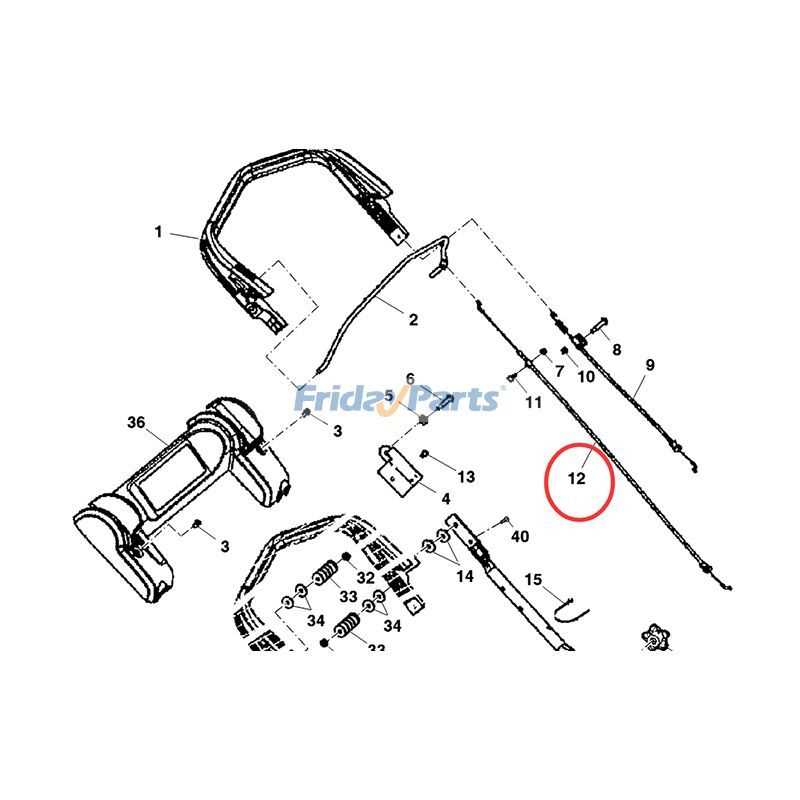

How to Access the Parts Diagram

Accessing an illustrative guide for components is essential for maintenance and repairs. This resource provides a visual representation, making it easier to identify individual elements and their configurations.

Steps to Access the Resource

- Visit the manufacturer’s official website.

- Navigate to the support or service section.

- Search for your specific model.

- Look for a link or section dedicated to component illustrations.

Utilizing Online Platforms

- Check forums and user communities for shared resources.

- Explore third-party websites that specialize in machinery documentation.

- Consider downloading maintenance manuals that include visual guides.

Common Issues and Solutions

When operating machinery, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their corresponding solutions is essential for maintaining optimal functionality. Below are some frequent issues faced by operators and practical tips to resolve them.

Frequent Problems

- Engine starting difficulties

- Uneven cutting performance

- Overheating during operation

- Unresponsive controls

- Excessive vibrations

Solutions

-

Engine Starting Difficulties:

- Check fuel levels and quality.

- Inspect the battery for corrosion or low charge.

- Ensure that the ignition system is functioning properly.

-

Uneven Cutting Performance:

- Sharpen or replace the cutting blades.

- Adjust the height settings for even results.

- Examine tire pressure for balanced traction.

-

Overheating:

- Clean the cooling fins and ensure proper airflow.

- Check coolant levels and refill if necessary.

- Inspect for any blockages in the cooling system.

-

Unresponsive Controls:

- Inspect the wiring for frays or disconnections.

- Test the fuses and replace any that are blown.

- Ensure that all levers and buttons are functioning correctly.

-

Excessive Vibrations:

- Check for loose bolts or components.

- Ensure blades and attachments are properly secured.

- Inspect for any damage to the frame or wheels.

By identifying and addressing these issues promptly, users can enhance the performance and longevity of their equipment.

Replacing JS30 Parts Effectively

Maintaining your equipment in optimal condition is essential for ensuring its longevity and performance. When components begin to show signs of wear, timely replacement is crucial. This section will guide you through effective strategies for swapping out worn-out elements, enhancing both efficiency and durability.

1. Identify the Components Needing Replacement

Before initiating any replacements, conduct a thorough inspection to determine which elements require attention. Look for signs of damage or deterioration, such as cracks, rust, or irregular functionality.

2. Gather Necessary Tools and Supplies

Having the right tools at hand will facilitate a smoother replacement process. Make sure you have all necessary implements ready, including wrenches, screwdrivers, and safety gear. Additionally, source high-quality replacements to ensure reliability and compatibility.

3. Follow a Systematic Approach

Adopt a step-by-step methodology when removing and installing new components. Document each step to keep track of the process and avoid confusion. This structured approach will not only save time but also prevent potential errors.

4. Consult Reference Materials

Utilize manuals or online resources to understand the specifics of the replacement procedure. These resources can provide valuable insights, including diagrams and tips that can simplify the task.

5. Test Functionality Post-Replacement

After completing the installation, it’s important to test the equipment to ensure everything operates smoothly. Conduct a thorough evaluation to confirm that the new components are functioning as intended.

By following these guidelines, you can effectively replace essential elements, keeping your machinery running at its best for years to come.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long life and optimal performance of your equipment. Regular maintenance can prevent costly repairs and extend the operational lifespan significantly. Here are some essential tips to keep in mind:

- Regular Cleaning: Keep the machine free from dirt and debris to prevent wear and tear.

- Fluid Checks: Regularly inspect and replace fluids such as oil and coolant to maintain performance.

- Inspect Belts and Cables: Check for any signs of wear and replace them as needed to avoid breakdowns.

- Tire Maintenance: Keep tires properly inflated and check for any damage to ensure stability and safety.

- Scheduled Servicing: Follow the manufacturer’s recommendations for service intervals to address potential issues proactively.

By incorporating these practices into your routine, you can significantly enhance the durability and reliability of your machinery.

Finding Authentic Replacement Parts

Ensuring optimal performance of machinery requires sourcing genuine components. This is crucial for maintaining the efficiency and longevity of your equipment. Identifying trustworthy suppliers and understanding the features of authentic elements can significantly enhance operational reliability.

Here are some key strategies for locating genuine components:

- Research Reputable Suppliers: Look for dealers with a strong reputation in the industry. Check online reviews and testimonials.

- Verify Authenticity: Always request documentation or certificates that confirm the legitimacy of the components.

- Consult Manufacturer Resources: Utilize official manuals or websites for recommendations on certified vendors.

- Network with Professionals: Engage with industry groups or forums to share insights on reliable sources for components.

By following these guidelines, you can ensure that your machinery remains in top condition, reducing the risk of malfunctions and enhancing overall performance.

Customer Support and Resources

Accessing reliable assistance and valuable materials is essential for ensuring optimal performance of your equipment. Support services not only help resolve technical issues but also enhance user experience through informative resources. This section aims to provide guidance on where to find expert help and useful documentation to keep your machinery running smoothly.

Expert Assistance

For personalized support, reaching out to trained professionals can be incredibly beneficial. Many companies offer dedicated hotlines and online chat services where knowledgeable staff can assist with troubleshooting, maintenance tips, and operational inquiries. Additionally, local dealerships often provide in-person consultations, ensuring that users receive tailored solutions for their specific needs.

Documentation and Guides

Comprehensive manuals and instructional videos serve as valuable tools for users at all experience levels. These resources cover everything from basic operation to advanced maintenance techniques. Online forums and community groups also offer a platform for sharing insights and experiences, enabling users to learn from one another and access a wealth of shared knowledge.