In the realm of agricultural machinery, the efficiency of cutting tools significantly impacts overall productivity. A comprehensive grasp of these implements is essential for optimal performance and maintenance.

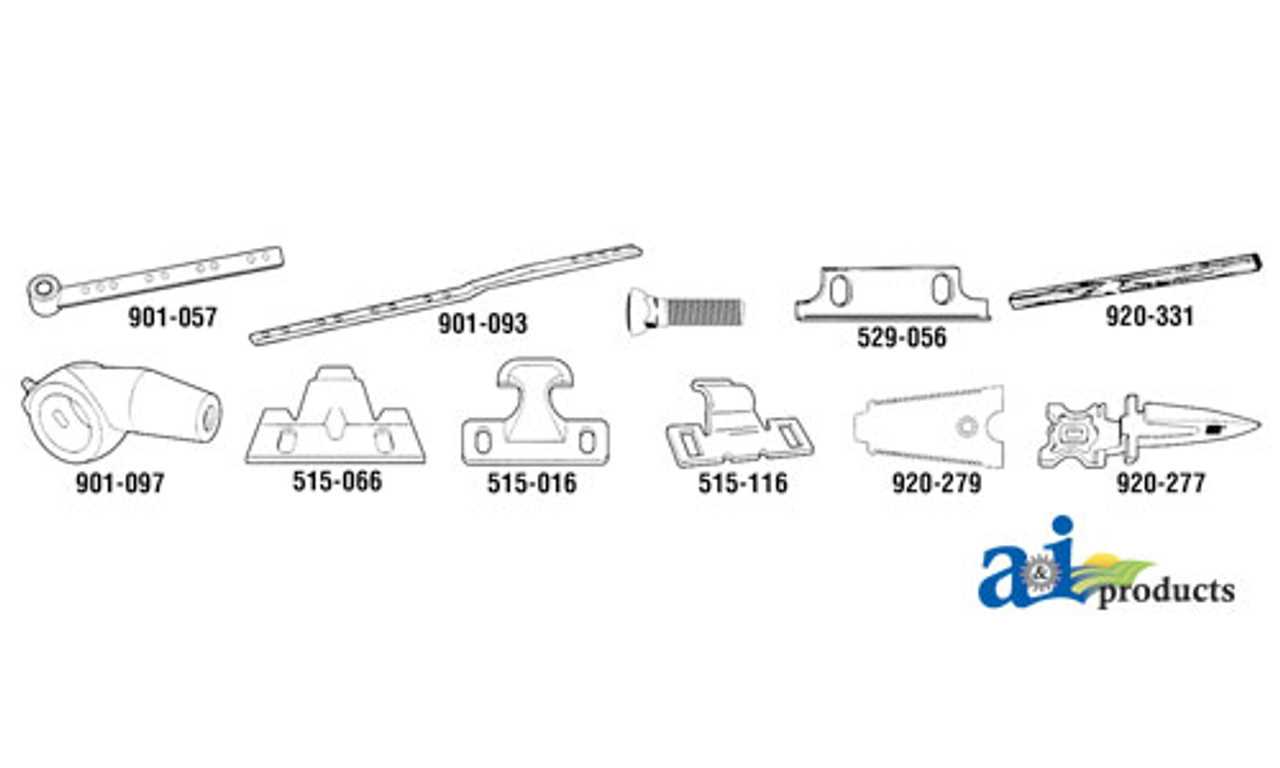

Various elements play a critical role in the functionality of these machines. Identifying and understanding the arrangement and purpose of each component can enhance both operation and longevity.

By delving into the specifics, operators can ensure their equipment remains in peak condition, ultimately leading to better yield and reduced downtime. This guide aims to provide clarity on the intricate layout of these essential tools.

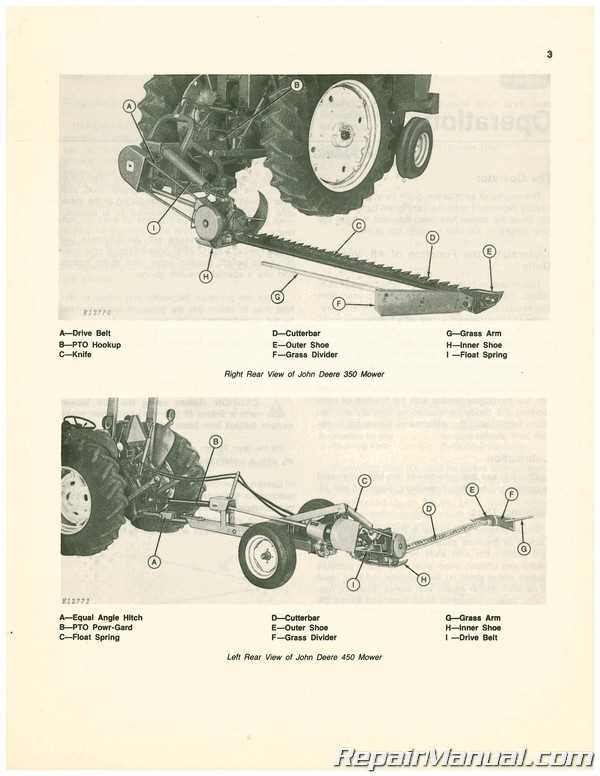

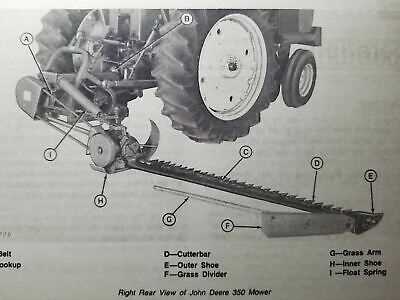

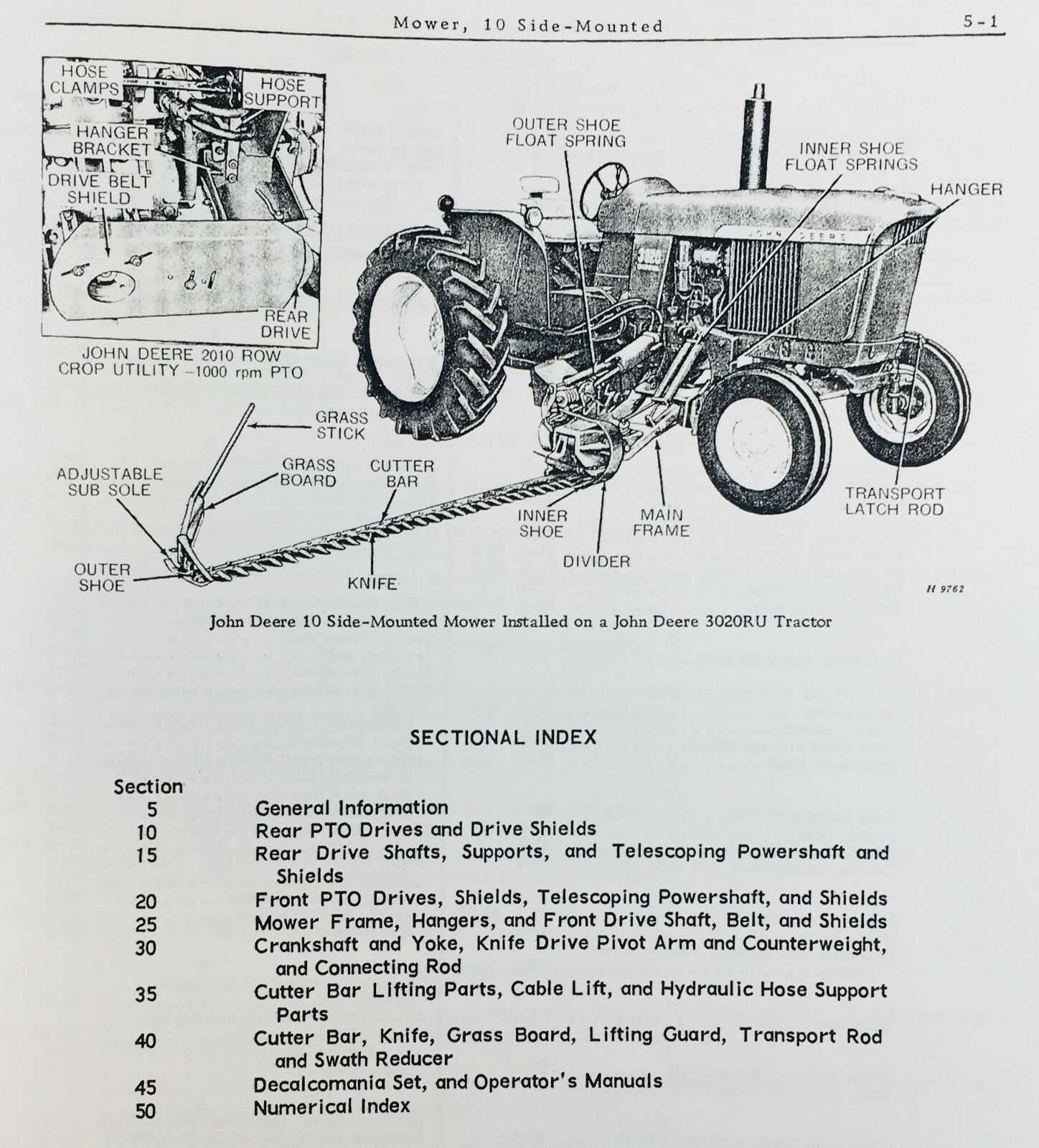

Understanding John Deere Sickle Mowers

This section explores the essential components and functionality of a specific type of agricultural equipment designed for cutting vegetation. By comprehending the intricacies involved, users can enhance their maintenance skills and optimize performance.

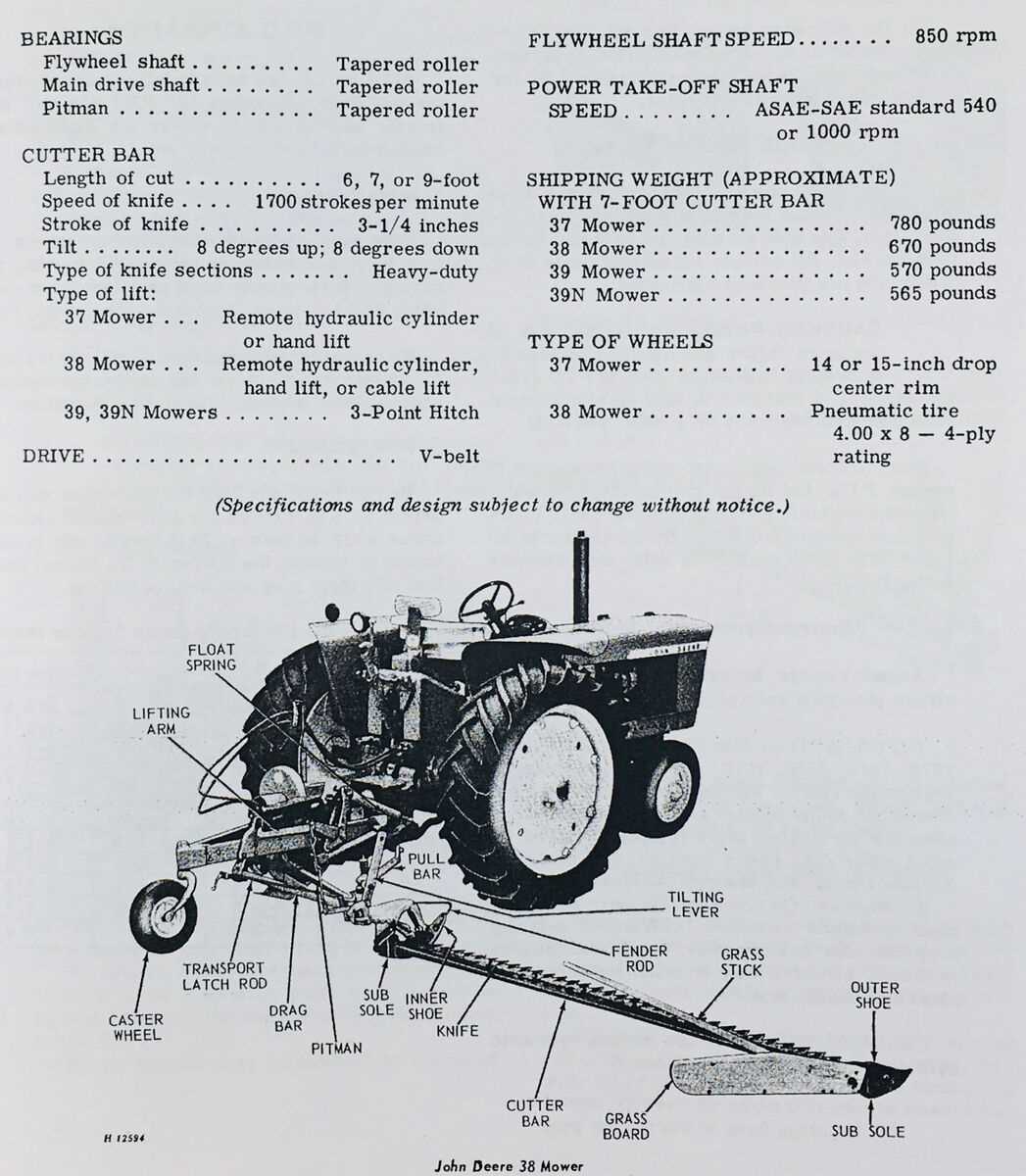

- Components: Familiarize yourself with the main elements, such as the cutting mechanism and drive system.

- Functionality: Learn how this machinery effectively engages with various types of crops.

- Maintenance: Discover tips for keeping your equipment in peak condition for longevity.

- Inspecting blades for sharpness and wear.

- Checking fluid levels and lubricating moving parts.

- Ensuring all connections and adjustments are secure.

By delving into these areas, operators can achieve the ultimate efficiency and productivity from their equipment.

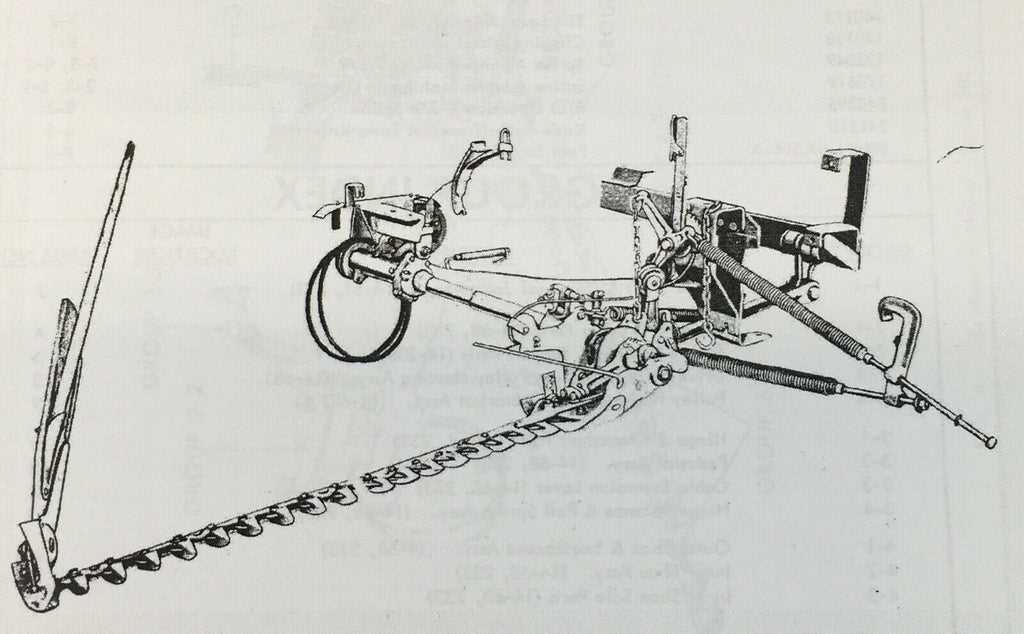

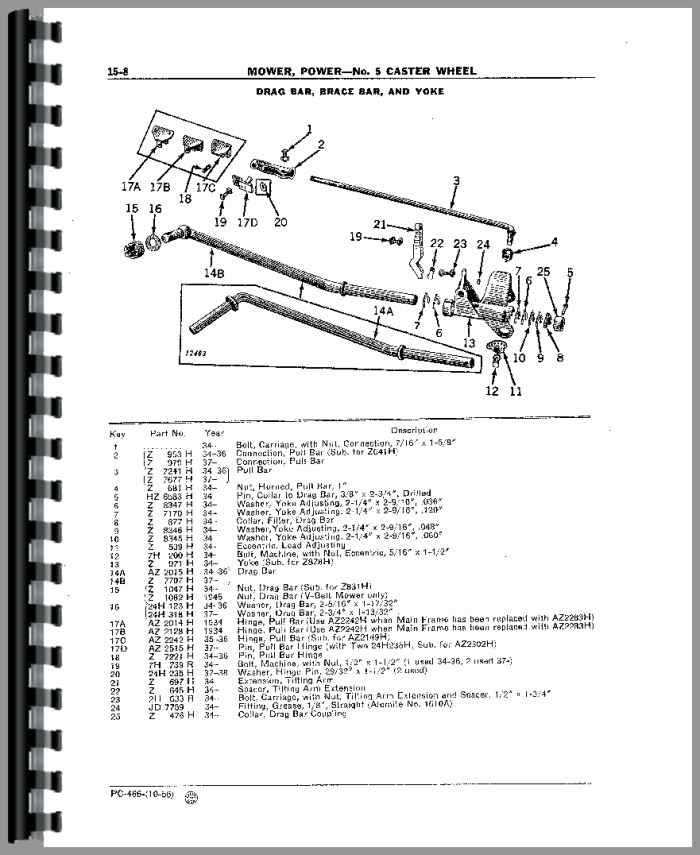

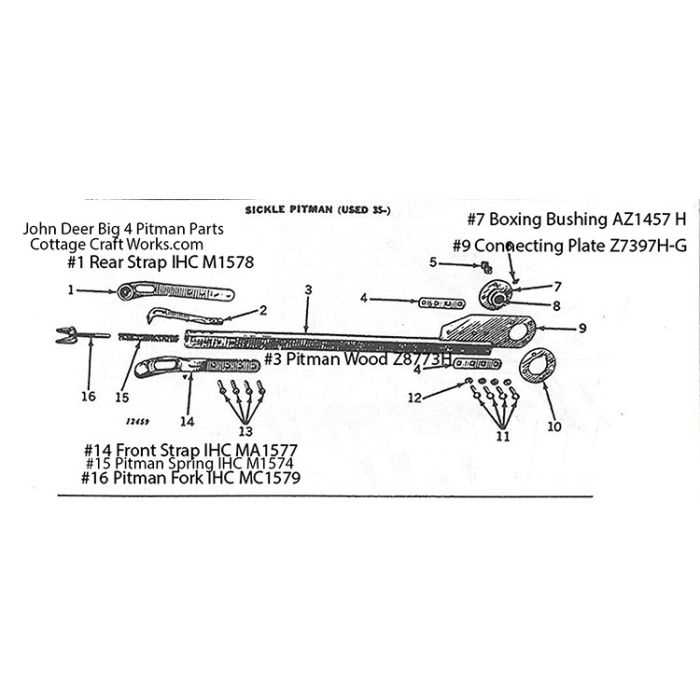

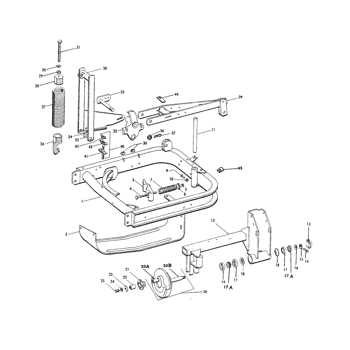

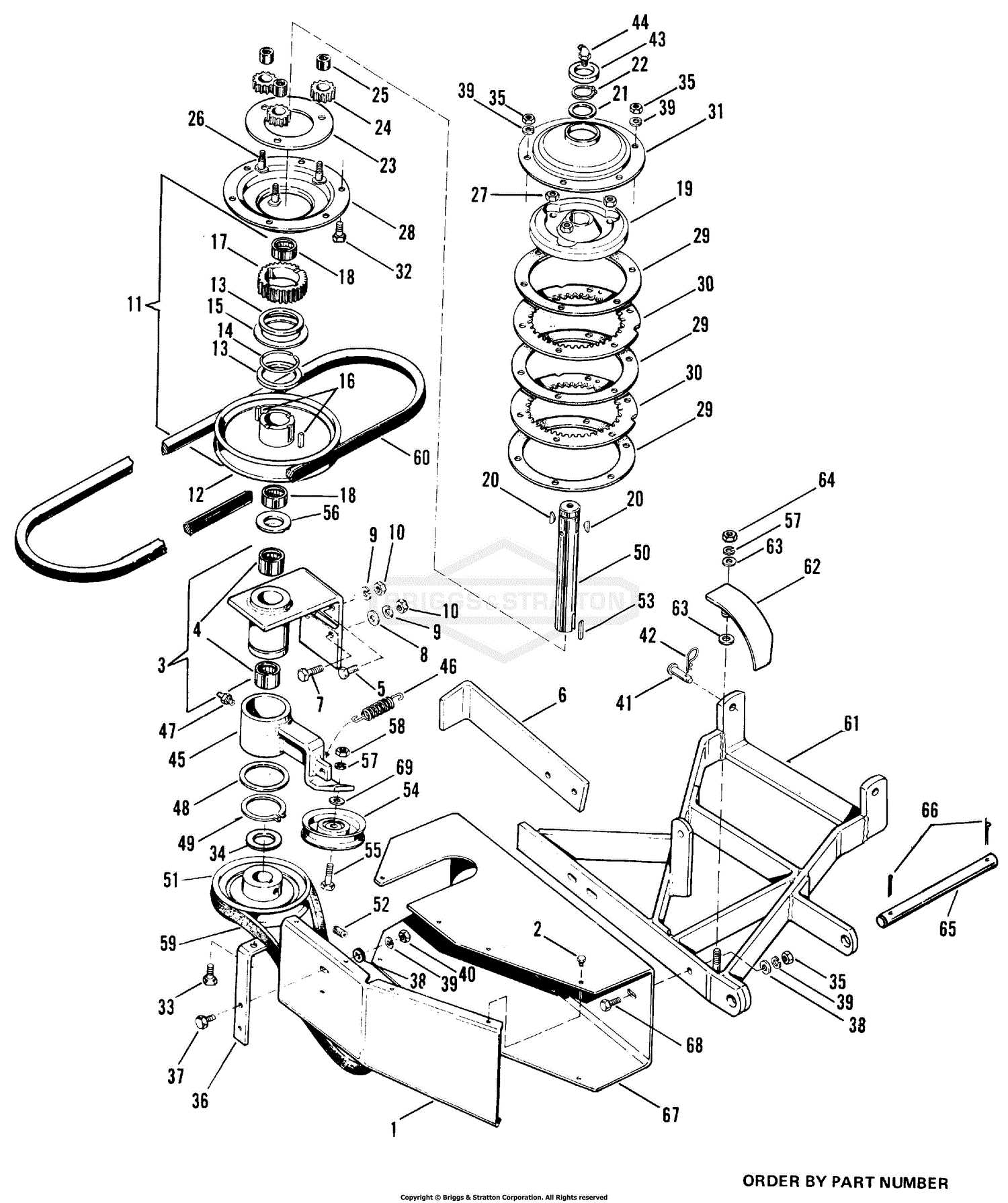

Key Components of Sickle Mowers

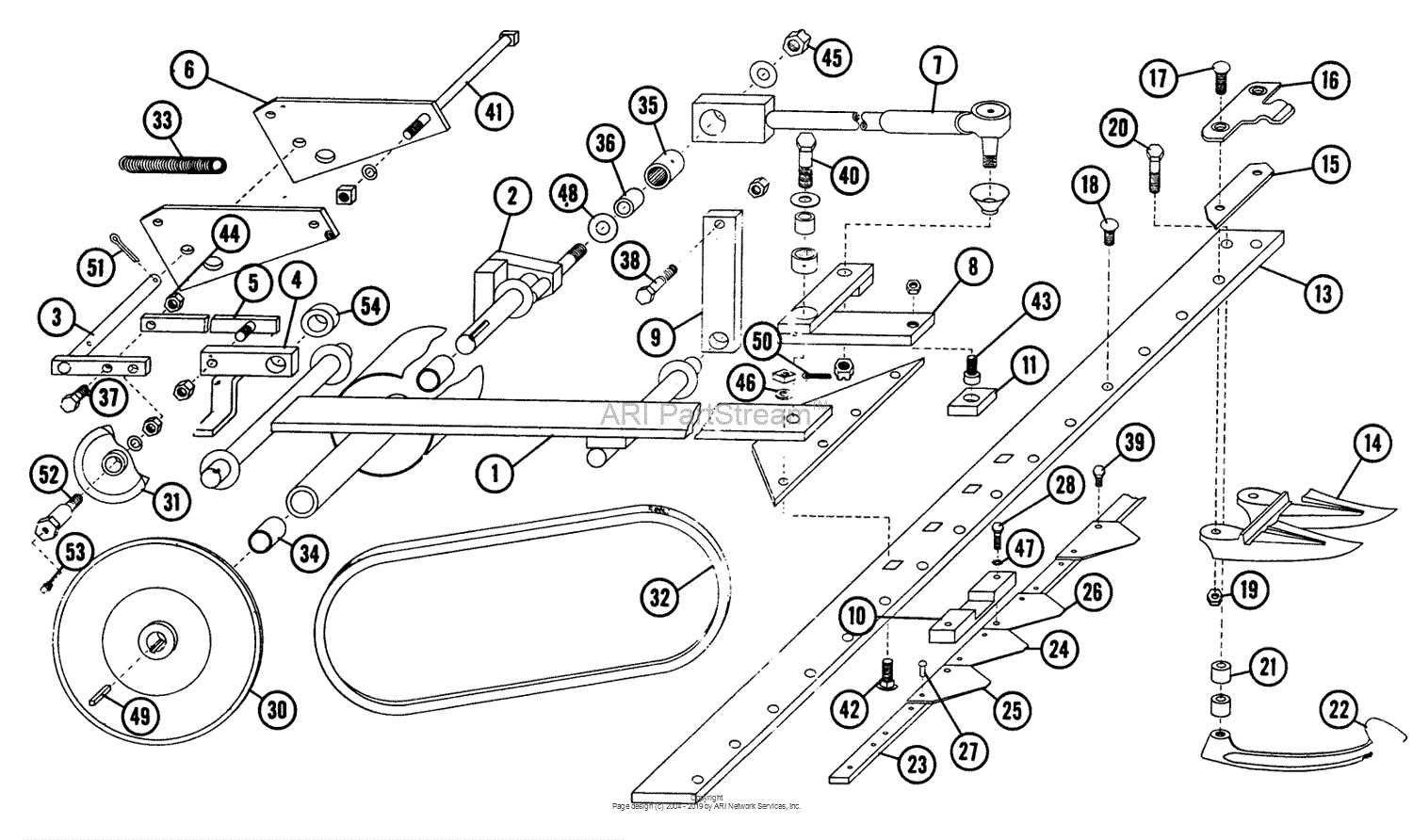

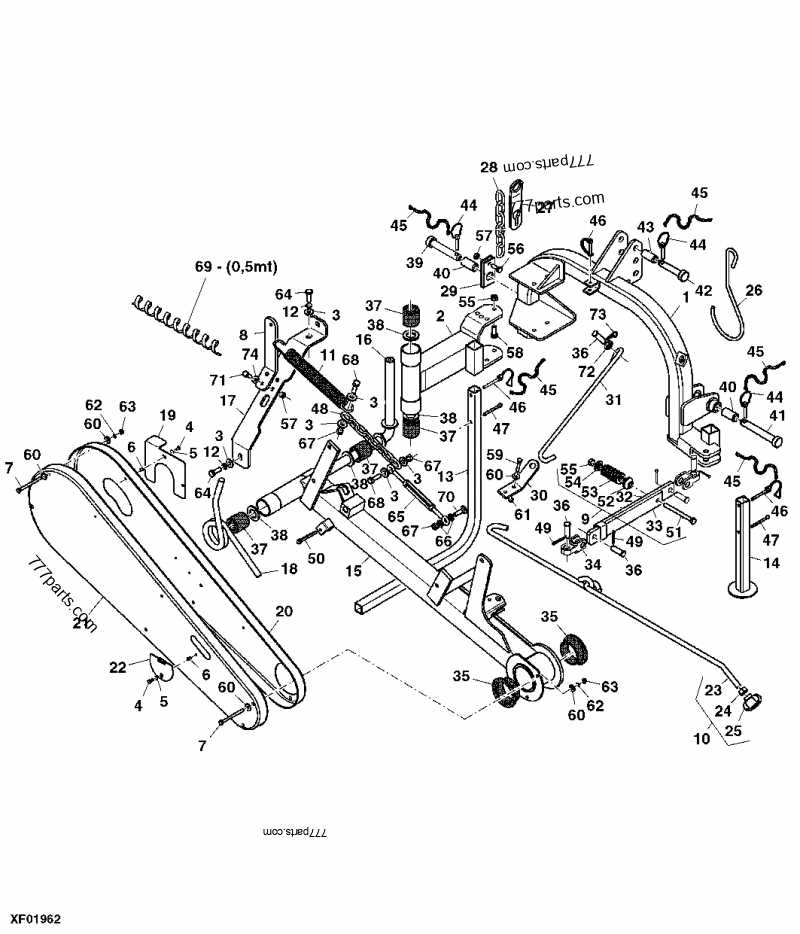

Understanding the core elements of a cutting machine is essential for proper maintenance and efficient operation. Each component plays a vital role in ensuring that the equipment functions smoothly and delivers precise cutting results. These key components work together to make the entire system effective, from cutting to collection.

Primary Cutting Mechanism

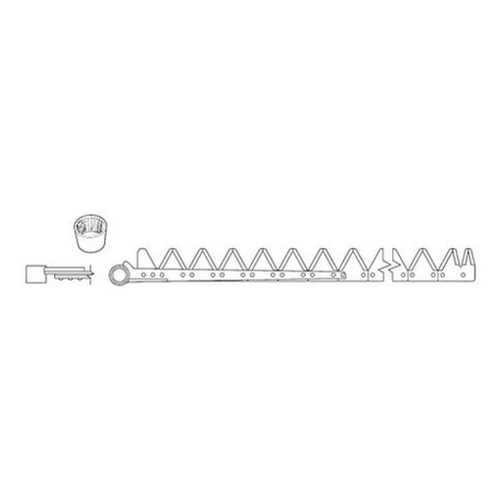

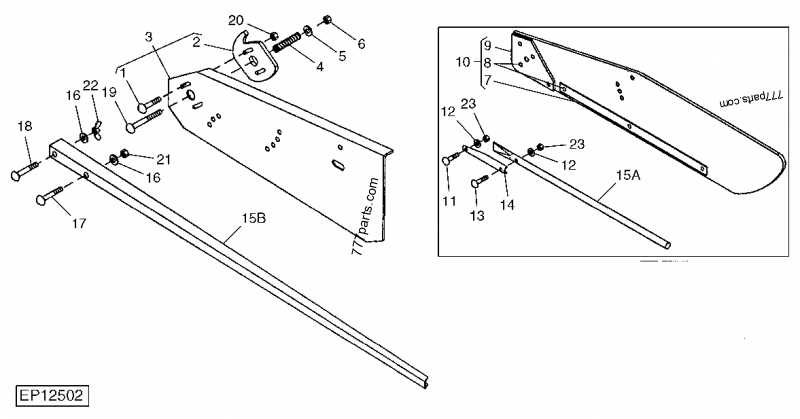

The cutting bar is a fundamental part of the system, as it houses the blades responsible for severing the material. The blades are mounted along this bar and move back and forth in a reciprocating motion, effectively slicing through grass, crops, or other vegetation. The sharpness and alignment of the blades are crucial for achieving a clean and efficient cut.

Support and Drive System

The drive shaft and gears play an integral role in transferring power from the engine to the cutting bar. The motion is usually facilitated through a series of rotating parts that allow the blades to move with precision. Proper lubrication and maintenance of the gears and drive mechanisms ensure smooth operation and prevent wear and tear over time.

Importance of Regular Maintenance

Proper upkeep of equipment is essential to ensure long-lasting performance and prevent unexpected failures. Routine checks and servicing help keep machinery running smoothly, reduce the risk of costly repairs, and extend its operational lifespan. Regular maintenance is the key to avoiding downtime, optimizing efficiency, and preserving the value of the equipment over time.

Enhanced Efficiency

By addressing wear and tear before it becomes a problem, regular maintenance can keep your machine working at peak performance. Well-maintained components operate more smoothly, consuming less energy and reducing the need for frequent repairs. This leads to better fuel efficiency and lower overall operational costs.

Reduced Risk of Breakdown

Timely inspection and lubrication prevent components from wearing out prematurely. Components such as belts, blades, and gears are subject to constant stress, and neglecting them can lead to sudden breakdowns. Regular care ensures that potential issues are identified early, reducing the chances of unexpected downtime.

Proactive maintenance not only prevents breakdowns but also contributes to a safer work environment. By fixing small problems before they escalate, you minimize the risk of accidents that could be caused by malfunctioning equipment.

How to Identify Worn Parts

Recognizing the signs of deterioration in equipment components is crucial for maintaining optimal performance. Regular inspection helps prevent unexpected breakdowns and extends the lifespan of machinery. By knowing what to look for, operators can ensure that their tools remain in peak condition.

Visual Inspection

A thorough visual examination can reveal a lot about the condition of components. Look for any signs of corrosion, cracks, or unusual wear patterns. Pay close attention to areas that experience frequent contact or friction, as these are often the first to show signs of fatigue. Additionally, check for any misalignment or abnormal movement during operation.

Functional Testing

In addition to visual checks, performing functional tests can help identify issues. Listen for unusual sounds, such as grinding or squeaking, which may indicate problems. Assess the performance of the machinery under load; any reduction in efficiency can be a warning sign of underlying issues. Regular monitoring of these factors can lead to early detection of worn elements.

Tools Needed for Repairs

Maintaining and fixing equipment requires a range of essential tools to ensure effective and efficient repairs. Having the right instruments not only simplifies the process but also enhances safety and precision during work. Here’s a look at the primary tools you’ll need for successful maintenance.

Basic Hand Tools

Start with a set of wrenches, screwdrivers, and pliers. These fundamental instruments are crucial for loosening and tightening various components. Additionally, having a reliable hammer can assist in adjustments and alignments.

Specialized Equipment

For more complex tasks, consider investing in a socket set and a torque wrench for precise tightening. A multimeter can also be invaluable for diagnosing electrical issues, while a toolbox keeps everything organized and easily accessible.

Step-by-Step Repair Guide

This guide provides a structured approach to troubleshoot and restore functionality to your agricultural cutting equipment. Following these steps will help ensure efficiency and longevity of your machinery.

1. Preparation and Safety

Before starting any repair, ensure you have the necessary tools and protective gear. Disconnect the power source to prevent accidents, and examine the equipment for any visible damage or wear.

2. Disassembly and Inspection

Carefully dismantle the relevant components, taking note of their arrangement. Document each step with photos if necessary. Inspect for any signs of wear or damage, focusing on critical areas that impact performance. Replace any faulty items to enhance the overall function.

Benefits of Genuine Replacement Parts

When it comes to maintaining agricultural machinery, choosing the right components is essential for ensuring optimal performance and longevity. Opting for authentic replacements rather than generic alternatives provides numerous advantages that contribute to the overall efficiency and reliability of the equipment. These genuine components are designed specifically for the machinery in question, ensuring a perfect fit and seamless operation. Below are some of the key benefits of choosing original replacements over generic ones.

1. Enhanced Durability and Performance

Original components are manufactured with high standards of quality, offering a higher level of durability compared to aftermarket options. They are built to handle the exact demands of the machinery, ensuring consistent performance even under tough working conditions. Using authentic replacements reduces the likelihood of early wear and breakdowns, thereby improving the overall lifespan of the equipment.

- Long-lasting durability

- Maintains peak performance

- Resistant to wear and tear

2. Perfect Fit and Compatibility

Genuine components are designed with precision, ensuring they fit perfectly within the equipment. This compatibility reduces the risk of mechanical issues that may arise from using improperly fitted or inferior parts. With an ideal fit, the machinery operates smoothly, minimizing downtime and costly repairs.

- Precise engineering for seamless integration

- Eliminates compatibility issues

- Reduces the need for frequent adjustments

In conclusion, investing in genuine replacements for your machinery not only guarantees better performance but also provides long-term savings by reducing repair costs and increasing the operational lifespan of your equipment.

Common Issues and Solutions

In the realm of agricultural equipment, various challenges can arise during operation. Understanding these common problems and their respective solutions can enhance efficiency and prolong the lifespan of your machinery. Below are some frequently encountered issues along with practical remedies.

Performance Issues

One of the primary concerns is reduced operational efficiency. This can manifest as uneven cutting or poor performance. Possible causes include dull blades, improper tension, or misalignment of components. Regular maintenance, including sharpening blades and checking for correct alignment, can significantly improve performance.

Mechanical Failures

Another prevalent issue is mechanical breakdowns, which often stem from wear and tear over time. Common signs include unusual noises or vibrations during use. To address these problems, it is crucial to perform routine inspections and replace worn components promptly. Keeping an eye on the lubrication levels can also prevent many mechanical failures.

Where to Find Diagrams Online

When it comes to maintaining and repairing agricultural equipment, having access to detailed schematics is essential. These visual guides can help users identify components, understand their functions, and facilitate troubleshooting. Fortunately, there are multiple platforms and resources available on the internet where one can find these helpful illustrations. This section highlights the best places to access these resources for a variety of machines.

Official Manufacturer Websites

One of the most reliable sources for technical illustrations is the official website of the equipment manufacturer. Most companies offer downloadable resources or interactive guides for their products. These documents are typically organized by model and year of production, ensuring you get the correct visual representation for your machine. Check the support or product section of the manufacturer’s site for links to the relevant documents.

Third-Party Websites and Forums

In addition to official sources, several third-party websites and online communities specialize in equipment repair. These platforms often have extensive collections of free-to-use schematics uploaded by fellow users or collectors. Some of the most popular sites include online marketplaces, repair communities, and agricultural equipment forums where users share their knowledge and diagrams. Ensure the resources are trustworthy and that the diagrams are up-to-date to avoid any errors in repairs.

| Platform | Access Method | Additional Features |

|---|---|---|

| Manufacturer Website | Free Downloads | Model-Specific Guides |

| Third-Party Forums | Community Uploads | Peer Assistance |

| Online Marketplaces | Paid Resources | Product Listings and Reviews |