When it comes to maintaining agricultural machinery, a thorough comprehension of its components is essential for optimal performance. Knowing how various elements fit together can significantly enhance functionality and longevity.

Visual aids play a crucial role in this understanding, offering a clear representation of each part’s position and relationship within the overall structure. These illustrations serve as a valuable resource for both seasoned technicians and novice users alike.

In this exploration, we will delve into the intricate world of machine parts, providing insights that empower users to identify and manage their equipment effectively. The knowledge gained here can lead to the ultimate improvements in maintenance practices and operational efficiency.

Understanding the John Deere 3320

This section delves into the intricacies of a popular compact utility tractor renowned for its versatility and performance. Designed for various tasks, it combines power with user-friendly features, making it a favored choice among both hobbyists and professionals alike. Understanding its components and functionality can significantly enhance the effectiveness of its operation.

The machine is equipped with a robust engine that provides the necessary torque for demanding applications, whether it be landscaping, farming, or construction. Its hydraulic system plays a critical role in facilitating attachments, allowing for seamless transitions between different implements. Familiarity with these systems can empower users to maximize productivity.

Maintenance is vital for ensuring longevity and optimal performance. Regular inspections and servicing of key elements can prevent downtime and costly repairs. By grasping the layout of its inner workings, operators can easily identify potential issues and address them proactively, leading to a smoother experience in the field.

Lastly, an appreciation for the design choices made in this machine can reveal insights into its operational efficiency. Features such as ease of access for repairs and a comfortable operator station contribute to a more pleasant and effective working environment. Understanding these aspects not only aids in operation but also enhances overall satisfaction with the equipment.

Importance of Parts Diagrams

Understanding the intricacies of machinery requires more than just familiarity with its operation. Visual representations that outline the components of a machine serve as invaluable tools for both maintenance and assembly. They facilitate a clearer comprehension of how each element interacts within the system, ultimately leading to enhanced efficiency and longevity of the equipment.

Enhancing Maintenance Efficiency

Accessing detailed illustrations allows technicians to quickly identify specific elements that may require attention. This not only speeds up the troubleshooting process but also minimizes the risk of overlooking critical components that could lead to operational failures. By utilizing these visual guides, maintenance can be performed with greater accuracy and less downtime.

Facilitating Proper Assembly

When it comes to reassembling machinery after repairs, clarity is essential. Diagrams provide a systematic approach to ensuring that every piece is correctly positioned and secured. This meticulous attention to detail helps prevent misalignments that could affect performance and safety, reinforcing the overall reliability of the equipment.

Common Issues with John Deere 3320

Every machinery model comes with its own set of challenges, and the one in question is no exception. Users often encounter various difficulties that can impact performance and efficiency. Understanding these common issues is crucial for maintenance and optimal operation.

Mechanical Failures

One frequent concern is related to mechanical components, which may wear out over time. Issues such as hydraulic leaks and engine performance drops can arise, leading to decreased productivity. Regular inspections can help identify problems before they escalate.

Electrical System Problems

The electrical system is another area where users report challenges. Battery failures and faulty wiring can cause operational delays. Keeping the electrical connections clean and ensuring the battery is in good condition can mitigate these issues. Timely troubleshooting is essential for maintaining reliable functionality.

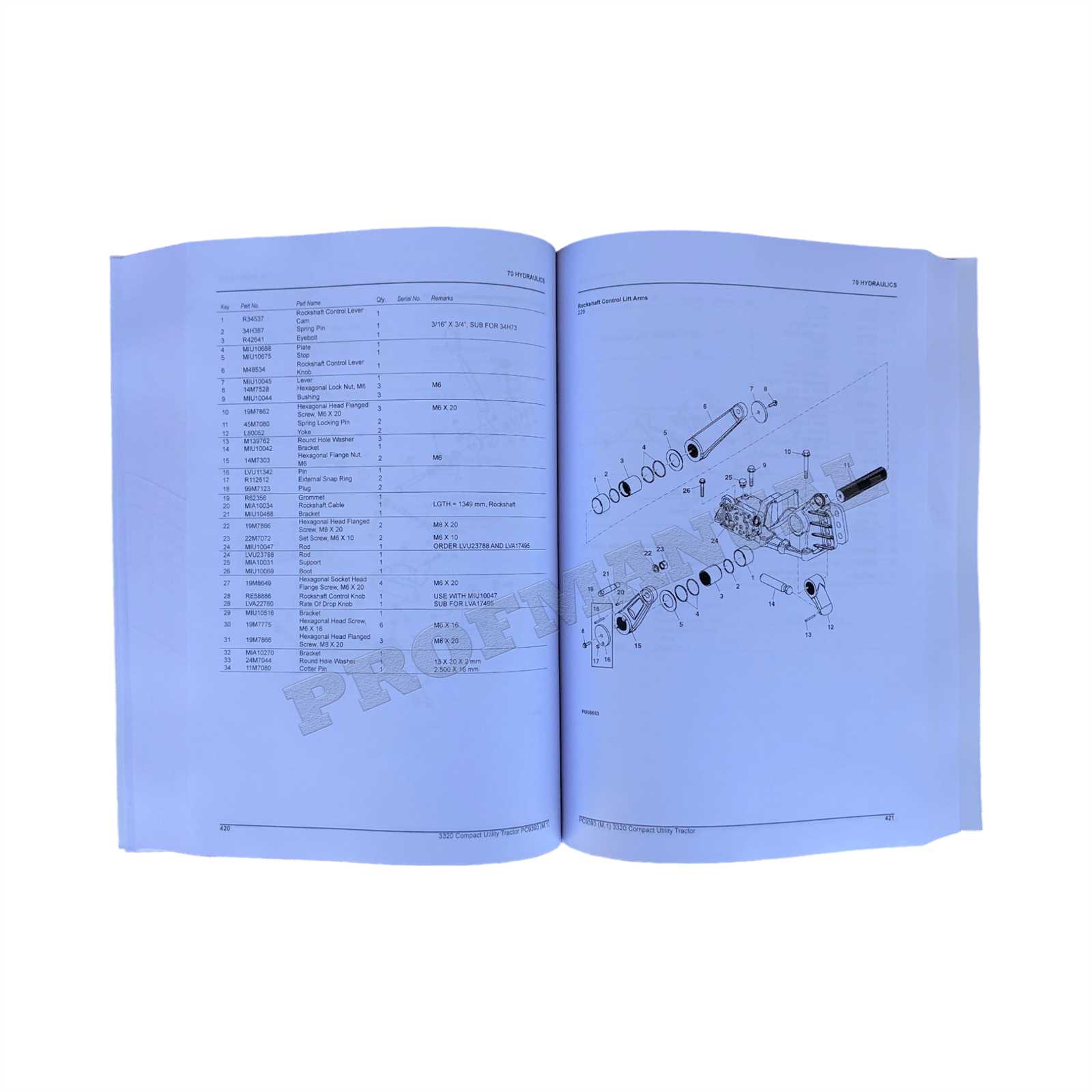

How to Read a Parts Diagram

Understanding an assembly blueprint is crucial for effective maintenance and repairs. This guide will help you navigate through the visual representation of components, ensuring you can identify and locate each piece accurately. Familiarizing yourself with the layout will enhance your ability to tackle any mechanical issue with confidence.

Identifying Components

The first step in interpreting an assembly blueprint is recognizing the various elements depicted. Each item is usually labeled with a unique identifier, allowing you to cross-reference it with a parts list. Take note of any symbols or color codes used, as they often indicate specific functions or categories. Understanding these markers will facilitate quicker identification during repairs.

Understanding Relationships

Another critical aspect is grasping how each element interacts with others. Look for lines or arrows that connect parts; these signify how components fit together or depend on one another. Pay attention to any notes or annotations, as they may provide essential instructions or warnings regarding assembly or disassembly. A clear comprehension of these relationships will streamline your repair process and minimize the risk of errors.

Key Components of the 3320 Model

The efficient operation of agricultural machinery relies on a variety of essential elements that work in harmony to ensure optimal performance. Understanding these critical components is vital for maintenance and troubleshooting, enabling operators to maximize productivity and longevity.

Engine System

The heart of any agricultural machine is its engine, which powers all operations. The engine system includes:

- Fuel injection components

- Cooling system

- Exhaust management

- Oil lubrication system

Transmission and Drive Mechanism

The transmission system facilitates the transfer of power from the engine to the wheels, ensuring efficient movement. Key elements include:

- Gearbox

- Clutch assembly

- Drive shafts

- Hydraulic components

Familiarity with these core parts enhances the understanding of machinery functionality, contributing to more effective operation and care.

Where to Find Replacement Parts

Finding the right components for your machinery can be a daunting task. With various options available, it’s essential to know where to look to ensure you receive quality items that fit your equipment perfectly. Below are some reliable sources for sourcing necessary replacements.

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors often provide genuine items that meet the manufacturer’s specifications. They offer knowledgeable staff to assist with selection. |

| Online Retailers | Numerous e-commerce platforms specialize in machinery components. Reviews and ratings can guide your choices and ensure satisfaction. |

| Local Hardware Stores | Some local shops carry common components or can order them for you. It’s a good idea to check if they have the items you need in stock. |

| Salvage Yards | For those seeking budget-friendly options, salvage yards can offer used components. Just ensure they are in good condition before purchasing. |

| Manufacturer’s Website | Visiting the official site can provide access to catalogs and online ordering systems, making it easy to find the exact components required. |

Tips for Maintaining Your Tractor

Regular upkeep of your agricultural vehicle is essential for ensuring optimal performance and longevity. By following a few key practices, you can keep your machinery running smoothly and efficiently, reducing the risk of unexpected breakdowns.

- Regular Inspections: Frequently check all major components for signs of wear or damage.

- Fluid Levels: Monitor and maintain appropriate levels of oil, coolant, and hydraulic fluids.

- Air Filters: Clean or replace air filters to ensure proper airflow and engine performance.

Implementing a systematic maintenance schedule can help you stay on top of these tasks.

- Daily Checks: Perform quick inspections before each use to identify any immediate issues.

- Weekly Maintenance: Dedicate time each week for more thorough checks and necessary adjustments.

- Seasonal Servicing: Prepare your equipment for seasonal changes by performing in-depth maintenance at the start and end of each season.

Investing time and effort in maintenance not only enhances performance but also prolongs the life of your agricultural equipment.

Benefits of Using Genuine Parts

Opting for authentic components is essential for ensuring optimal performance and longevity of machinery. These items are specifically designed to fit seamlessly, enhancing the efficiency of your equipment.

Quality Assurance: Genuine components are manufactured to strict standards, providing reliability that generic alternatives often lack. This leads to reduced risks of malfunction and breakdown.

Improved Performance: Using authentic replacements ensures that your machinery operates at its best. This not only boosts productivity but also enhances safety during operation.

Long-Term Savings: While initial costs may be higher, the durability of genuine components often results in fewer replacements and repairs over time, ultimately saving you money.

Warranty Protection: Many manufacturers offer warranties on their authentic parts, giving you peace of mind and additional financial protection against unexpected failures.

Investing in genuine components is a decision that pays off in reliability, efficiency, and overall satisfaction with your equipment.

Resources for John Deere Owners

For enthusiasts and operators of agricultural machinery, having access to reliable information and support is essential for optimal maintenance and performance. Numerous resources are available to assist users in finding components, troubleshooting issues, and enhancing their knowledge about equipment. Here, we outline several valuable tools and references to help you get the most out of your machinery.

| Resource Type | Description |

|---|---|

| Official Manuals | Comprehensive guides that provide detailed information on maintenance, operation, and specifications. |

| Online Forums | Communities where users can share experiences, ask questions, and offer solutions. |

| Parts Retailers | Websites and stores that specialize in equipment components, ensuring you find what you need quickly. |

| Tutorial Videos | Visual aids available on various platforms that demonstrate repair and maintenance procedures. |

| Local Dealerships | Authorized service centers that offer expertise and genuine products for your machinery. |