In the realm of pneumatic tools, comprehending the intricacies of machinery is essential for optimal performance and maintenance. Each unit consists of numerous elements that work in harmony to ensure efficiency and reliability. Familiarity with these components empowers users to troubleshoot issues and enhance functionality.

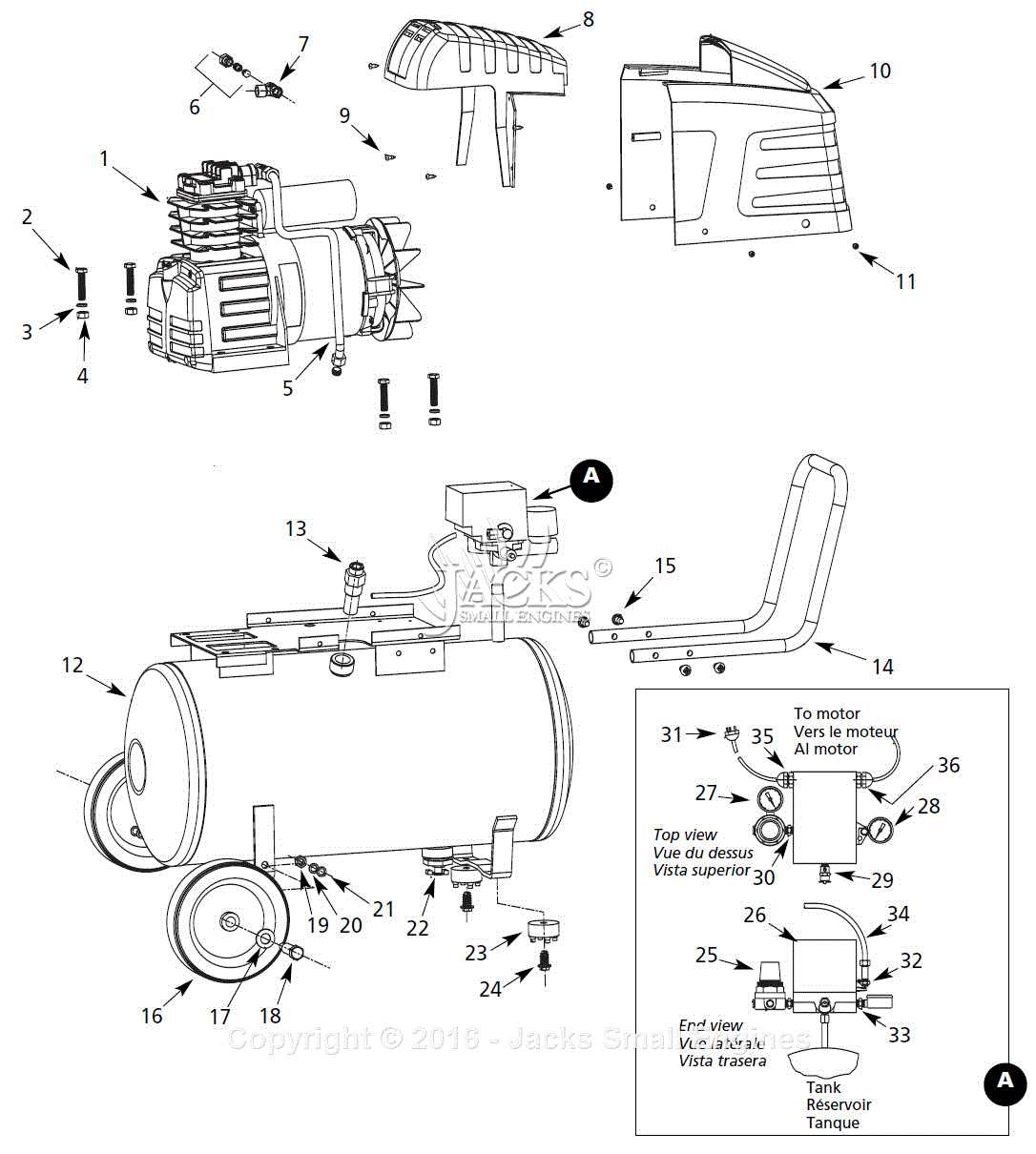

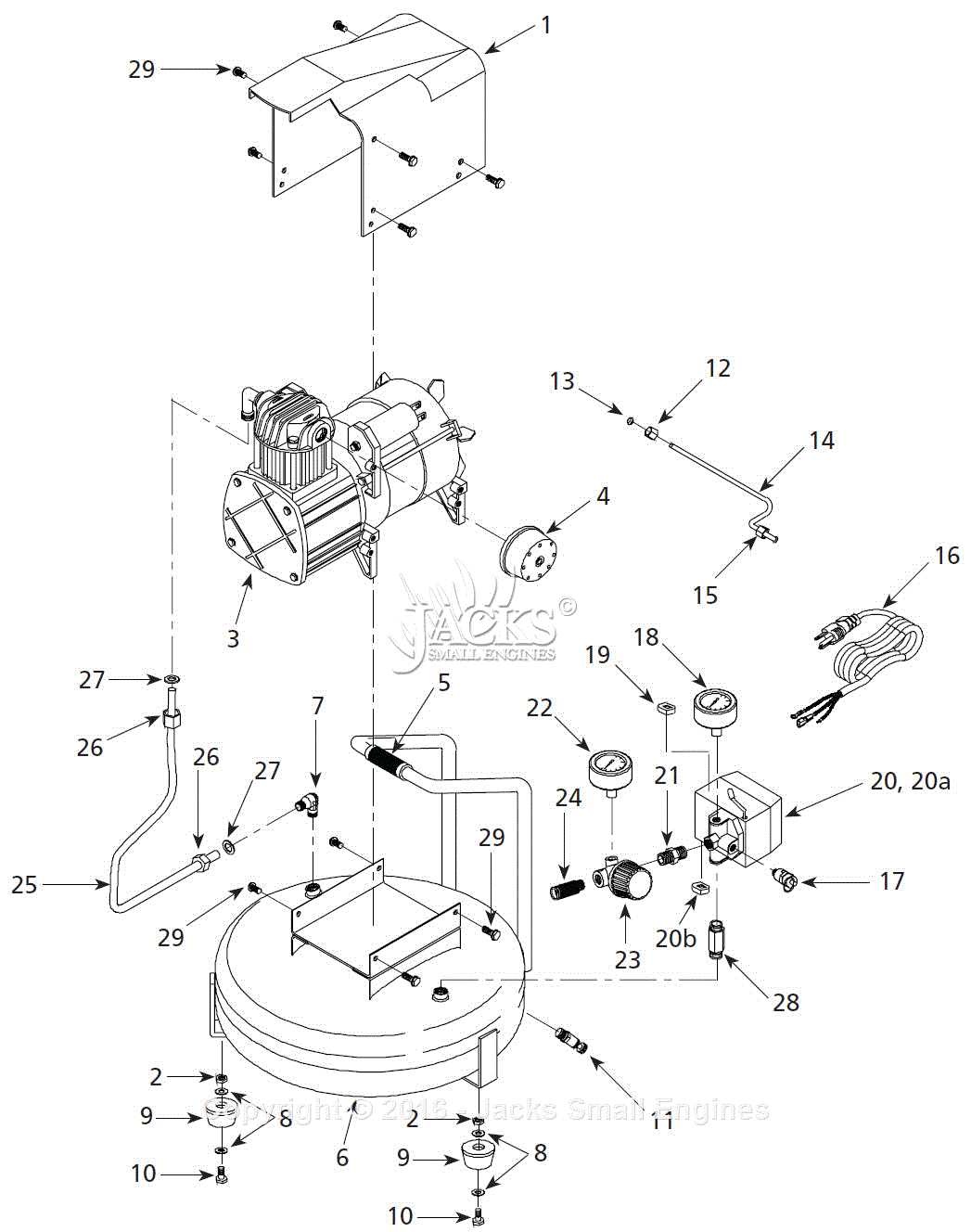

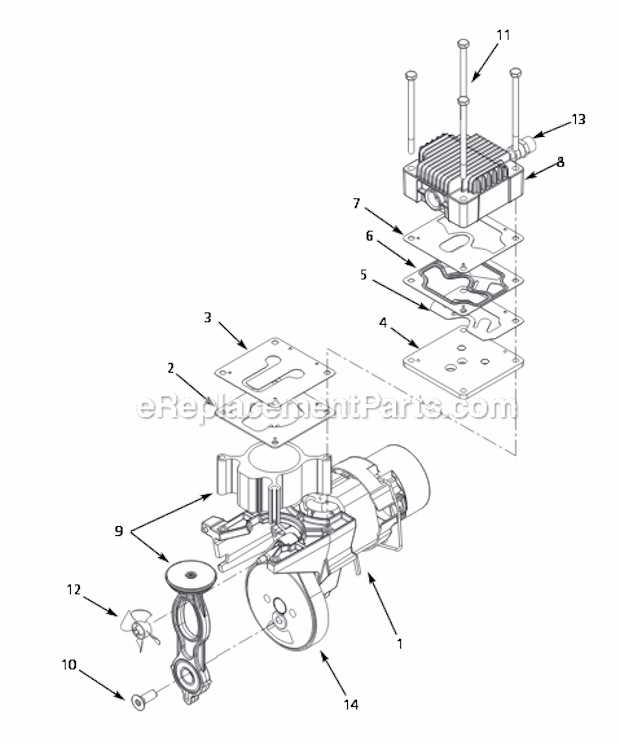

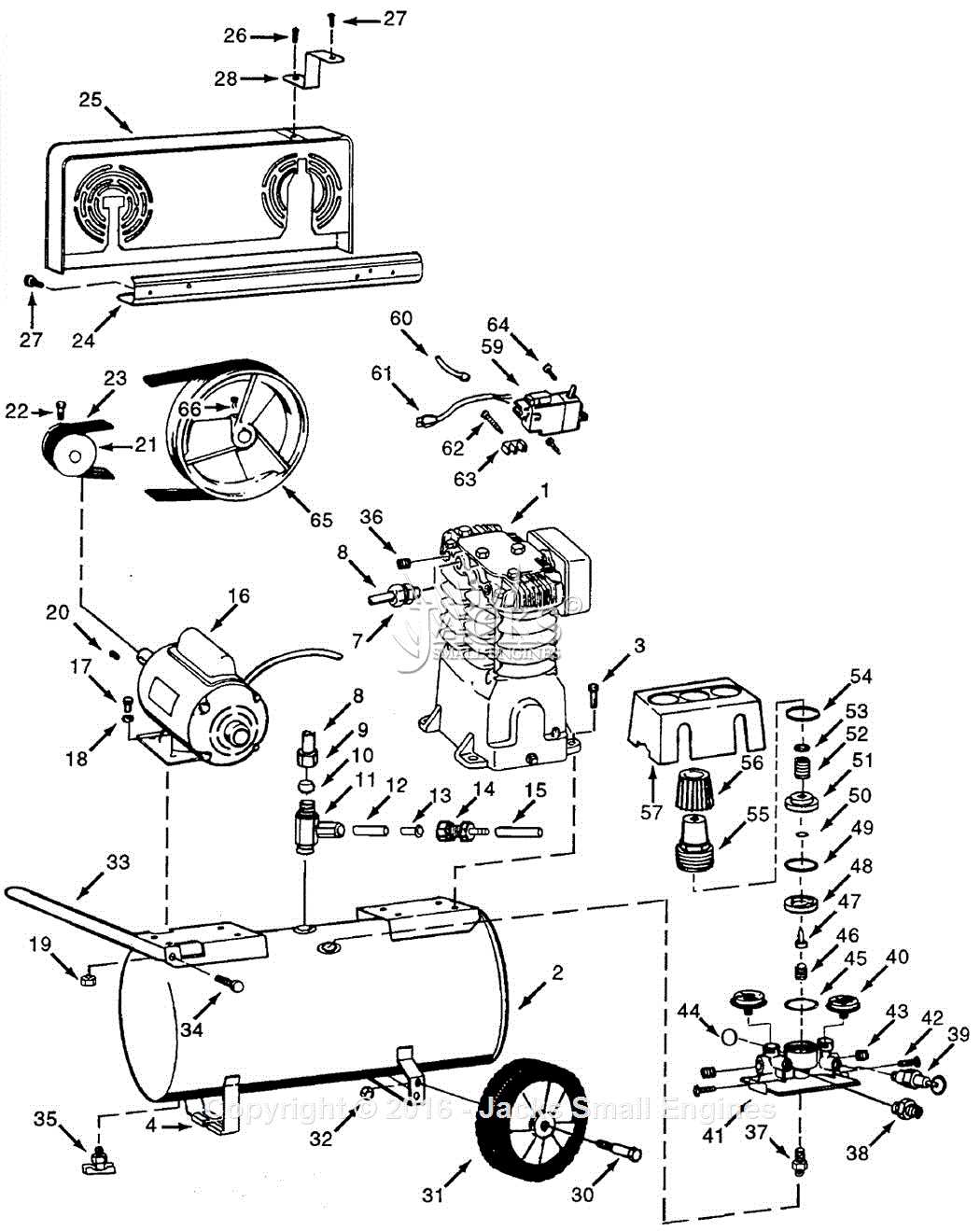

Visual representations play a crucial role in grasping the arrangement and purpose of each section. By examining detailed illustrations, individuals can identify essential features and understand how they contribute to the overall operation. This knowledge is particularly beneficial for DIY enthusiasts and professionals alike.

As we delve into the specifics of these vital systems, we will uncover the ultimate insights that lead to better upkeep and longevity of your equipment. Mastering the layout and role of each part not only simplifies repairs but also optimizes usage, ensuring peak performance in all applications.

Understanding Campbell Hausfeld Compressors

This section explores the intricacies of a renowned brand known for its innovative air management solutions. With a focus on efficiency and reliability, these machines serve a multitude of applications across various industries.

Key Features and Benefits

Featuring advanced technology, these devices provide optimal performance and longevity. Users can expect durability and versatility, making them ideal for both professional and DIY tasks.

Maintenance Essentials

Regular upkeep is crucial for ensuring peak performance. Understanding the essential components and their functions can significantly enhance the lifespan and effectiveness of these units.

Key Components of the Compressor

Understanding the essential elements of an air pressurizing system is crucial for optimal operation and maintenance. Each component plays a vital role in ensuring efficiency and longevity, contributing to the overall performance of the equipment.

| Component | Description |

|---|---|

| Motor | Drives the system, converting electrical energy into mechanical energy. |

| Pump | Responsible for drawing in and compressing air, increasing its pressure. |

| Tank | Stores compressed air, allowing for consistent pressure delivery during use. |

| Regulator | Controls the pressure of the air being released, ensuring it meets the requirements of connected tools. |

| Valves | Manage the flow of air, including intake and discharge, to maintain proper operation. |

| Filter | Removes impurities from the air to protect internal components and enhance performance. |

| Hoses | Transport compressed air from the tank to the tools or equipment being used. |

Importance of Proper Maintenance

Regular upkeep of machinery plays a crucial role in ensuring its longevity, efficiency, and overall performance. Without consistent attention to maintenance, the risk of malfunctions, reduced functionality, and even complete breakdowns increases significantly. A well-maintained system operates more effectively, saving both time and money in the long run. Neglecting routine care, on the other hand, can lead to costly repairs and unnecessary downtime.

Benefits of Routine Care

- Extended Lifespan: Proper maintenance helps avoid wear and tear, allowing the equipment to function optimally for a much longer period.

- Improved Efficiency: Well-maintained machines run more smoothly, requiring less energy to perform the same tasks.

- Cost Savings: Preventative maintenance reduces the likelihood of major breakdowns and the expensive repairs they often entail.

- Safety: Regular checks can identify potential issues that could pose safety risks, ensuring a safer working environment.

Key Maintenance Practices

- Regular Inspections: Frequent visual checks help spot any visible issues early, such as leaks, rust, or damaged components.

- Lubrication: Keeping moving parts properly lubricated minimizes friction and prevents excessive wear.

- Cleaning: Dust and debris buildup can impair performance, so regular cleaning is essential to maintain optimal operation.

- Replacement of Worn Components: Timely replacement of parts that have reached the end of their service life helps avoid sudden failures.

Common Issues and Solutions

This section addresses frequent challenges encountered with air pressure systems and offers practical solutions. Understanding these problems can enhance performance and prolong the lifespan of the equipment.

Frequent Problems

- Insufficient Air Pressure

- Unusual Noises During Operation

- Air Leaks

- Overheating

Effective Solutions

- Check and adjust the pressure settings.

- Inspect for loose components and tighten as needed.

- Apply sealant to identified leak points.

- Ensure proper ventilation and clean filters to prevent overheating.

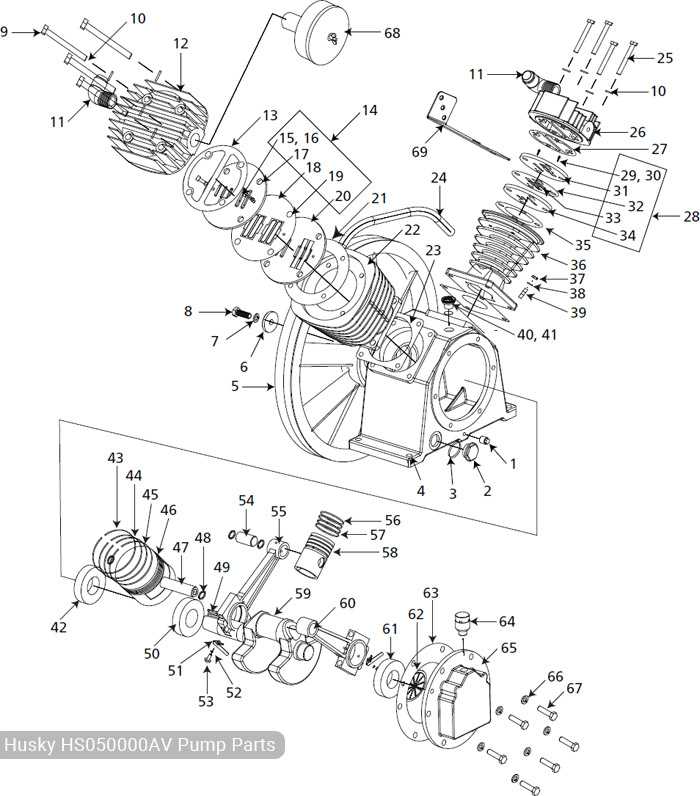

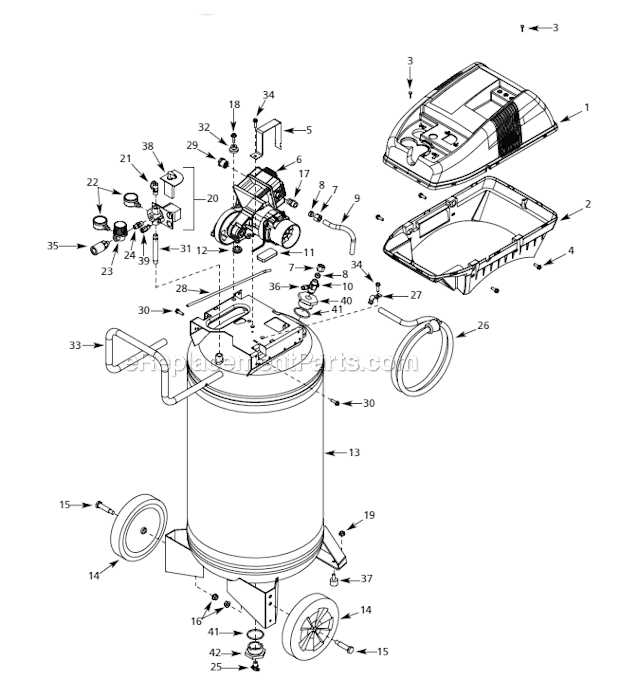

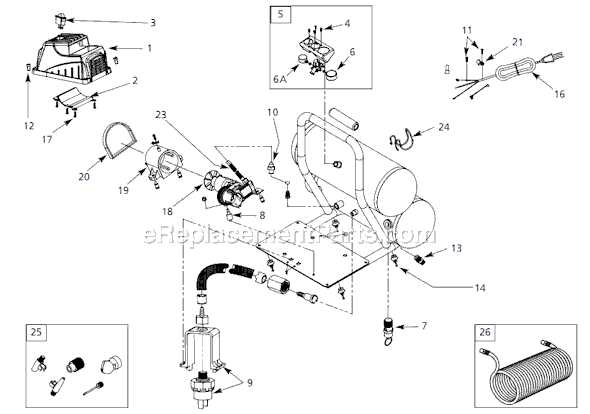

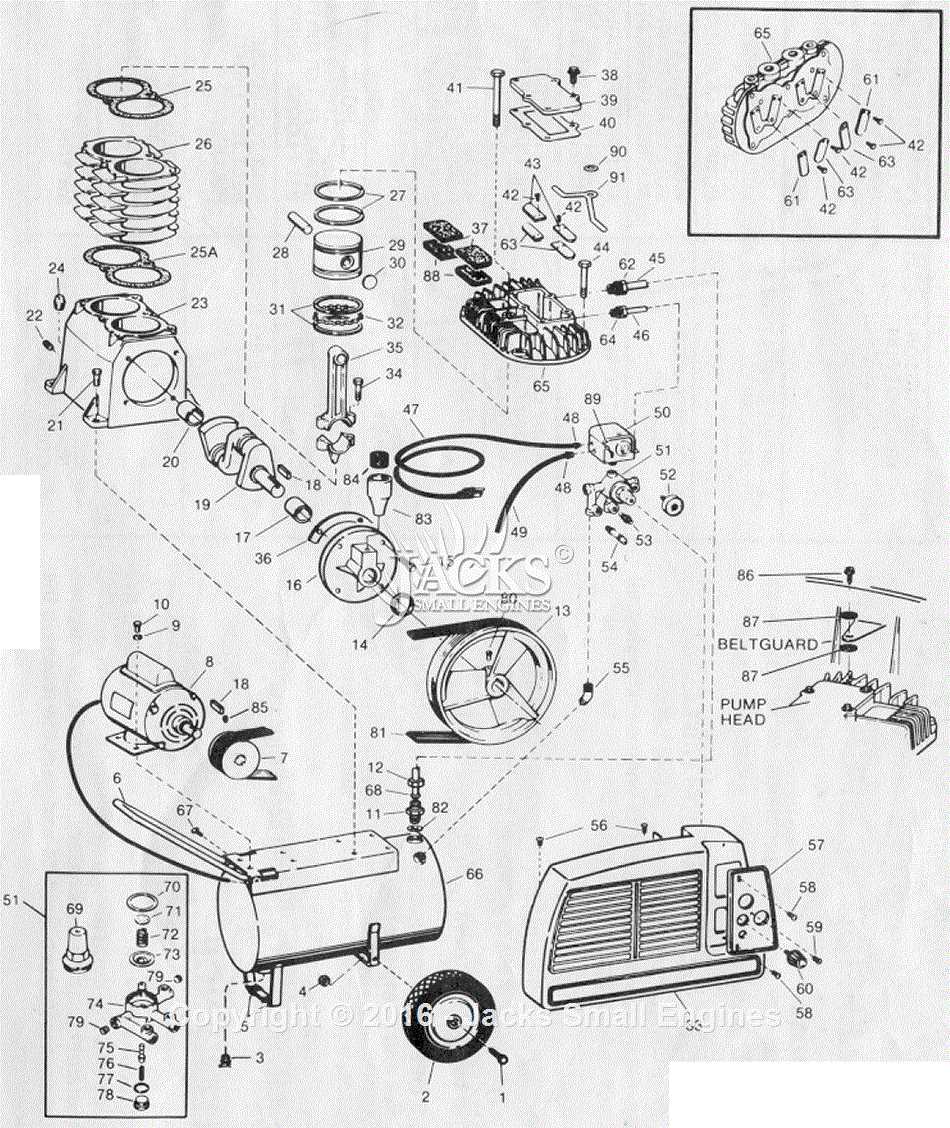

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repairs. These visual guides provide essential information about components and their relationships, enabling users to identify and locate necessary items quickly. Mastering the art of reading these illustrations enhances problem-solving capabilities and ensures efficient workflows.

Identifying Key Elements

To interpret an illustration effectively, begin by familiarizing yourself with its symbols and notations. Each graphic representation typically includes labels indicating specific components, along with numbers corresponding to a legend or list. Pay attention to the orientation and placement of parts, as this often reflects their function and assembly sequence.

Understanding Connections and Flow

Next, analyze the connections depicted in the illustration. Lines or arrows usually indicate how components interact or connect, helping to clarify their roles within the system. Understanding these relationships is vital for troubleshooting issues, as it provides insights into potential failure points or maintenance needs.

Where to Find Replacement Parts

When equipment malfunctions or components wear out, finding the correct replacements is essential for restoring functionality. Whether you need to repair a malfunctioning machine or upgrade a worn-out component, there are several reliable sources to consider for obtaining high-quality replacements.

One of the first places to check is the manufacturer’s official website. Many manufacturers offer a dedicated section for purchasing spare components directly or provide a list of authorized dealers. This ensures you receive parts that are compatible and meet the original specifications.

Alternatively, online marketplaces like eBay, Amazon, and specialized tool retailers often carry a wide range of replacement items. These platforms can provide competitive pricing, along with customer reviews that may help guide your choice.

Local hardware stores or industrial supply shops are also good options. While they may not always stock specific models, they often have a wide variety of universal components and are capable of helping you find what you need through special orders.

For harder-to-find parts, forums and online communities dedicated to equipment repair can be invaluable. These communities often share tips on where to source rare components or provide information about compatible alternatives that may not be immediately obvious from the manufacturer’s catalog.

| Source | Advantages | Considerations |

|---|---|---|

| Manufacturer Website | Direct from the source, ensures compatibility | Prices may be higher, limited selection in some cases |

| Online Marketplaces | Wide selection, often lower prices | Quality can vary, shipping times may be longer |

| Local Stores | Immediate availability, knowledgeable staff | Limited selection, higher local prices |

| Online Communities | Useful advice, rare parts | Reliability of sources can vary |

Upgrading Your Compressor’s Performance

Enhancing the efficiency of your pneumatic system can significantly boost its functionality and lifespan. By focusing on specific upgrades, you can achieve optimal results and ensure consistent operation.

- Invest in high-quality filters to improve air quality and protect internal components.

- Consider upgrading to a more powerful motor to increase output and reduce cycle times.

- Install a pressure regulator to maintain consistent airflow and prevent overloading.

- Evaluate the tank size; a larger tank can provide extended usage without frequent cycling.

Implementing these modifications will allow you to delve deeper into your system’s capabilities, ultimately achieving greater performance and reliability.

Safety Tips for Operation

Ensuring safety during the use of pneumatic equipment is crucial for both the operator and the surrounding environment. Proper precautions can significantly reduce the risk of accidents and injuries, making the work process smoother and more efficient.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and hearing protection. This gear is essential to safeguard against potential hazards, including flying debris and loud noises, which are common during operation.

Proper Maintenance and Inspection

Before using any pneumatic system, conduct a thorough inspection. Check for signs of wear, leaks, or damage. Regular maintenance is key to preventing failures. Ensure that all connections are secure and that safety features are functioning correctly. Neglecting maintenance can lead to unforeseen issues.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and maintenance of air systems. Whether you are looking for guidance on identifying components, understanding their function, or troubleshooting common issues, the following questions provide helpful insights and solutions.

General Questions

- What is the best way to identify a malfunctioning unit?

Check for unusual noises, inconsistent pressure, or visible damage to parts such as hoses or valves. It may also be helpful to test the system’s pressure gauge to ensure accurate readings. - How do I know when to replace specific components?

Most components should be replaced when they show signs of wear, such as cracks, corrosion, or persistent leaks. It’s essential to consult the manufacturer’s recommendations for the expected lifespan of each part. - Can I use third-party parts for my unit?

While third-party parts can sometimes be compatible, it’s best to use original equipment to ensure proper function and avoid warranty issues.

Maintenance and Troubleshooting

- How often should I perform routine maintenance?

Regular maintenance is essential for optimal performance. It is typically recommended to inspect the system monthly, checking for air leaks, tightness of fittings, and wear on moving parts. - What should I do if the system is not reaching the required pressure?

First, check for any air leaks or damage to the hose. If these are fine, inspect the internal components, such as the intake valve and check valve, for blockages or wear. - How can I extend the lifespan of my equipment?

To maximize longevity, ensure that the system is properly stored, kept clean, and regularly serviced. Avoid overuse and always follow the manufacturer’s maintenance schedule.