In the world of winter maintenance, having a reliable machine for distributing materials is crucial. These devices are engineered to ensure even application, enhancing safety and efficiency on roadways. A thorough understanding of their individual components can significantly aid in maintenance and troubleshooting, making it easier to address issues that may arise during operation.

The intricate design of these machines comprises various essential elements, each serving a specific function. Recognizing how these components interact with one another is vital for ensuring optimal performance. This knowledge can help operators make informed decisions regarding repairs and replacements, ultimately prolonging the lifespan of the equipment.

Whether you are a seasoned operator or new to the field, familiarizing yourself with the inner workings of these devices will enhance your operational effectiveness. By focusing on the arrangement and functionality of each segment, you can better appreciate the engineering that goes into creating a reliable tool for material distribution.

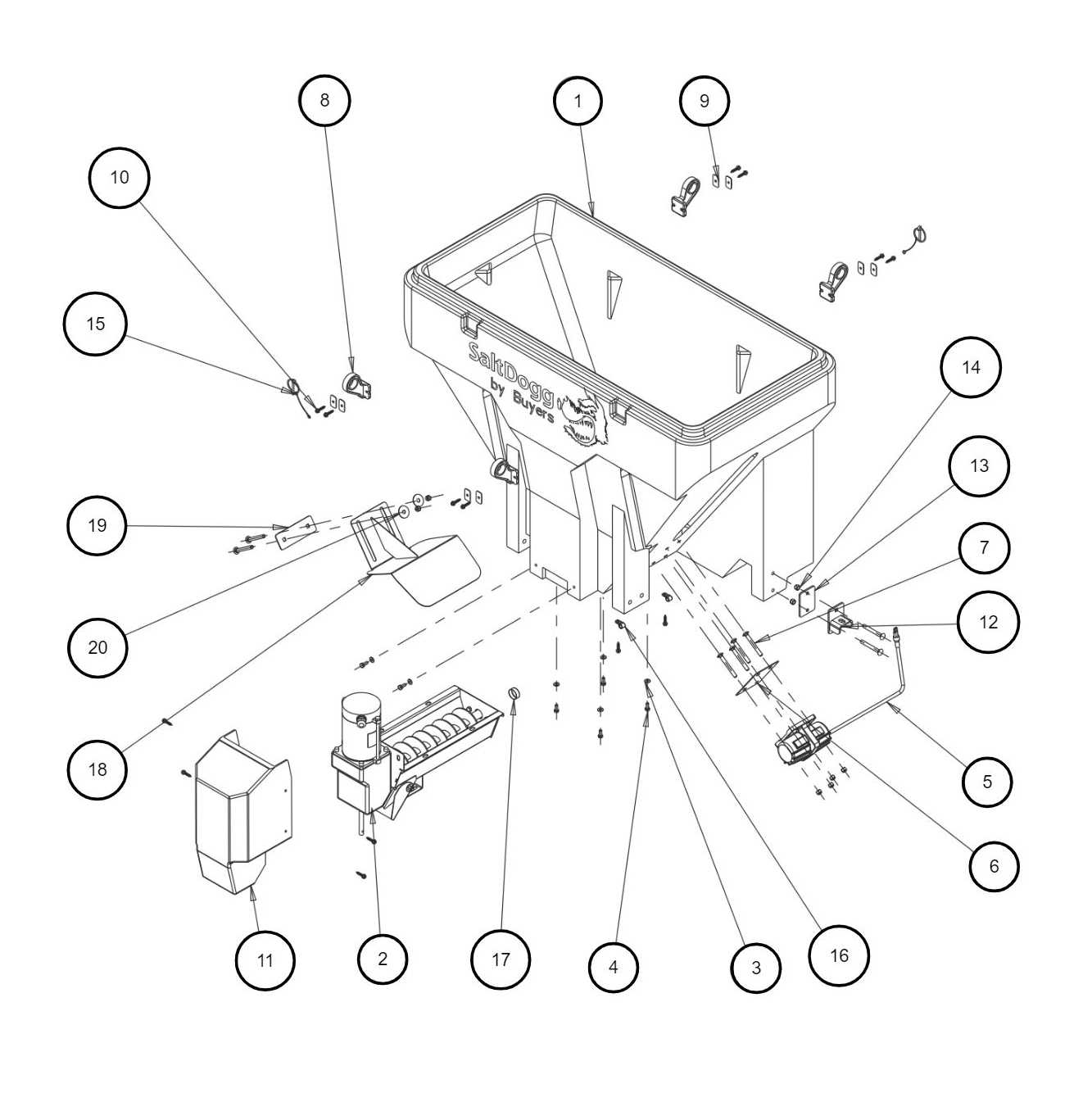

Henderson Salt Spreader Parts Overview

This section provides a comprehensive look at the various components of a winter maintenance device designed for efficient material distribution. Understanding the individual elements is essential for optimal functionality and maintenance.

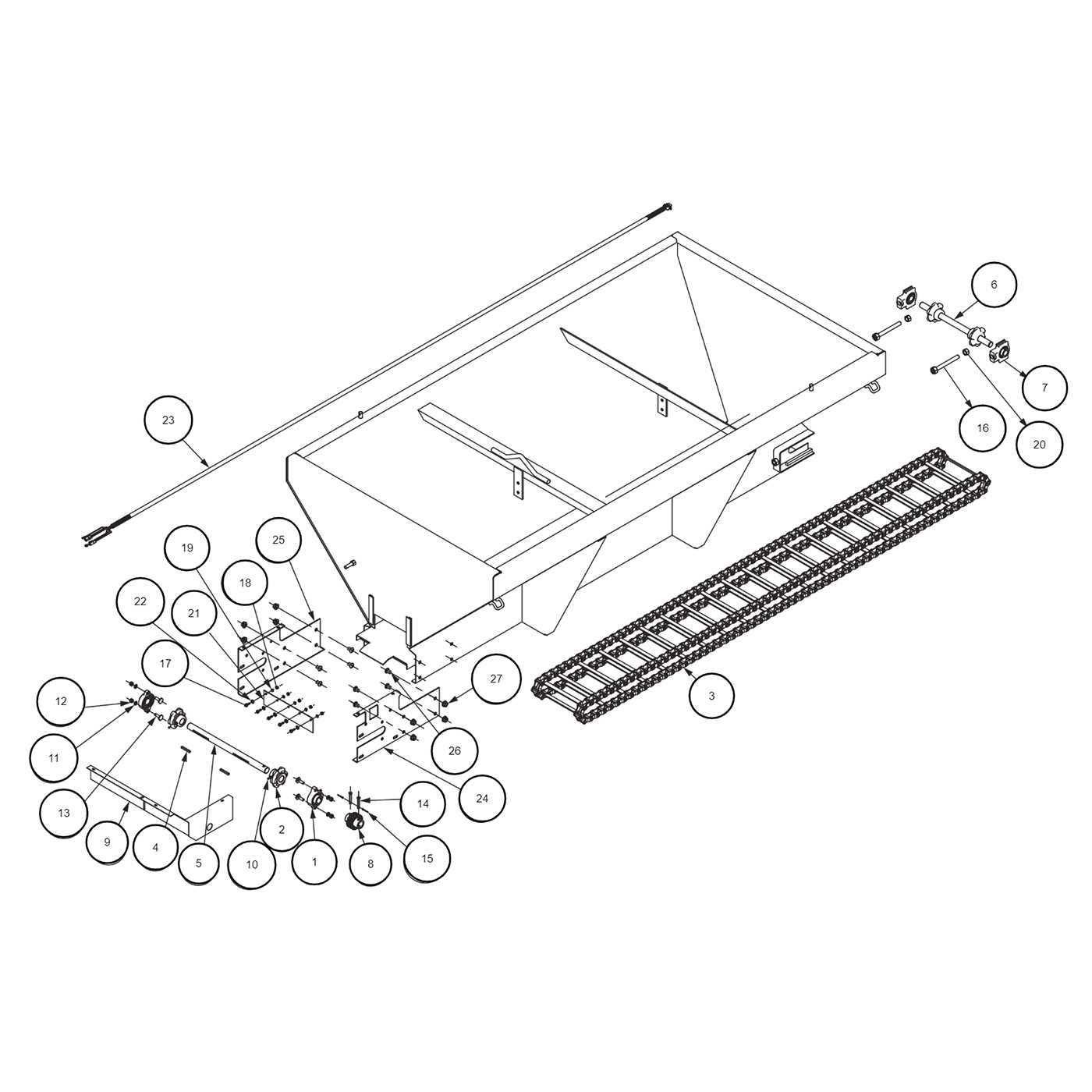

The assembly consists of multiple integral elements, each serving a specific purpose to enhance performance. Key components include the hopper for holding materials, the drive system that facilitates movement, and the distribution mechanism that ensures even application. Additional accessories may include controls for operation and adjustments to suit different conditions.

Familiarity with these components allows users to better appreciate their roles and responsibilities in maintaining effective performance during winter operations. Regular inspection and understanding of each part can significantly impact overall efficiency and longevity.

Main Components of a Salt Spreader

The efficient functioning of a material distributor relies on several essential elements that work together seamlessly. Understanding these components is crucial for proper maintenance and effective usage, ensuring optimal performance during operations. Each part contributes to the overall functionality, influencing the distribution and control of the applied substance.

Control Mechanisms

At the heart of the operation lies the control system, which allows the operator to adjust the flow rate and distribution pattern. This system typically includes a lever or digital interface, providing real-time adjustments to suit varying conditions. The precision offered by these controls ensures that the application remains efficient and effective, minimizing waste.

Distributing Mechanism

The distribution unit is responsible for evenly dispersing the material across the intended area. This mechanism often consists of rotating disks or plates that propel the material outward, ensuring a consistent application. The design of this component can greatly affect the spread width and coverage, making it vital for achieving desired results.

Functions of the Hopper Assembly

The hopper assembly plays a crucial role in the distribution process of granular materials. Its design is intended to facilitate efficient loading, storage, and delivery of substances, ensuring that the application is both effective and uniform. Understanding its functionalities is essential for optimizing performance and achieving desired outcomes.

Key functions of the hopper assembly include:

| Function | Description |

|---|---|

| Storage | Provides a reservoir for holding the material before application, allowing for controlled release. |

| Dispensing | Enables accurate distribution of the substance, ensuring even coverage across the target area. |

| Flow Regulation | Includes mechanisms to control the flow rate, preventing clogs and ensuring a steady output. |

| Material Protection | Designed to shield the contents from environmental factors, maintaining material integrity. |

| Compatibility | Works seamlessly with other components to enhance overall efficiency and functionality of the system. |

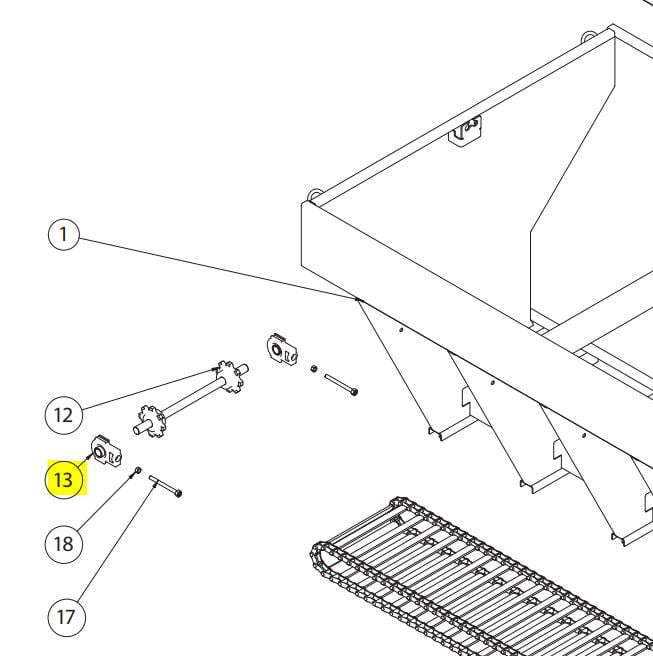

Drive Mechanism and Its Role

The drive system is a crucial component in the operation of various machinery, providing the necessary power and movement to facilitate tasks efficiently. This mechanism converts energy into motion, enabling the equipment to perform its intended functions with precision and reliability.

In essence, the drive mechanism ensures that the machine operates smoothly by transferring energy from the motor to the working parts. This process involves several elements, including gears, belts, or chains, which work together to create the desired movement. The design of this system plays a significant role in determining the overall efficiency and effectiveness of the equipment.

Regular maintenance of the drive mechanism is essential for optimal performance. It helps prevent wear and tear, ensuring that the equipment remains functional over time. Understanding how this system operates allows users to troubleshoot issues effectively and maintain the machine’s reliability.

Spinner and Conveyor System

The spinner and conveyor system plays a crucial role in the effective distribution of materials. This mechanism is designed to ensure that the substance is evenly spread across a designated area, facilitating efficient coverage. The operation involves a coordinated effort between the spinner, which launches the material outward, and the conveyor that delivers the substance to the spinner.

Functionality Overview

This system operates through a combination of rotating elements and a feeding mechanism. The conveyor transports the material from the storage compartment to the spinner. Once the material reaches the spinner, it is propelled outward through centrifugal force, enabling a uniform spread. This process minimizes waste and maximizes coverage, making it essential for various applications.

Maintenance Tips

Regular maintenance is vital for the longevity and efficiency of the spinner and conveyor system. Ensure that all moving components are well-lubricated and free of debris to prevent any operational issues. Additionally, periodically inspect the spinner blades for wear and tear, replacing them as necessary to maintain optimal performance.

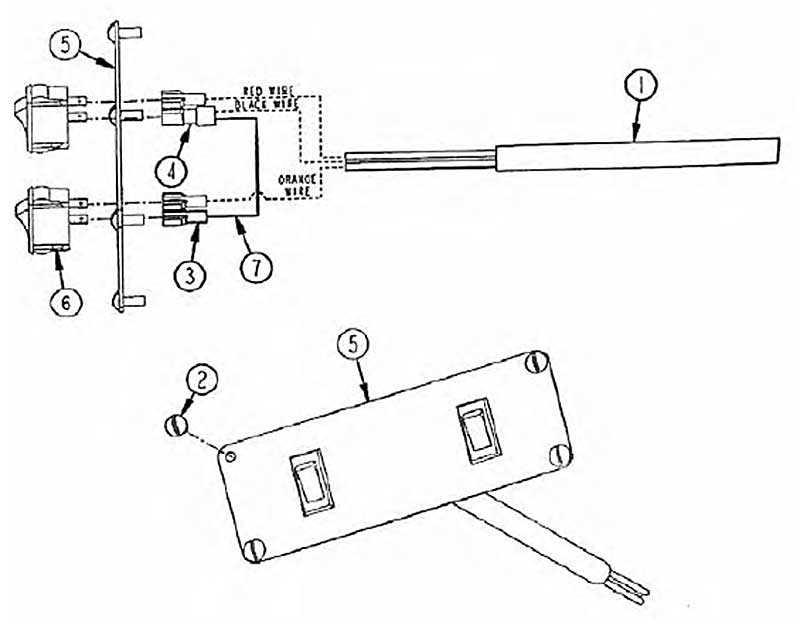

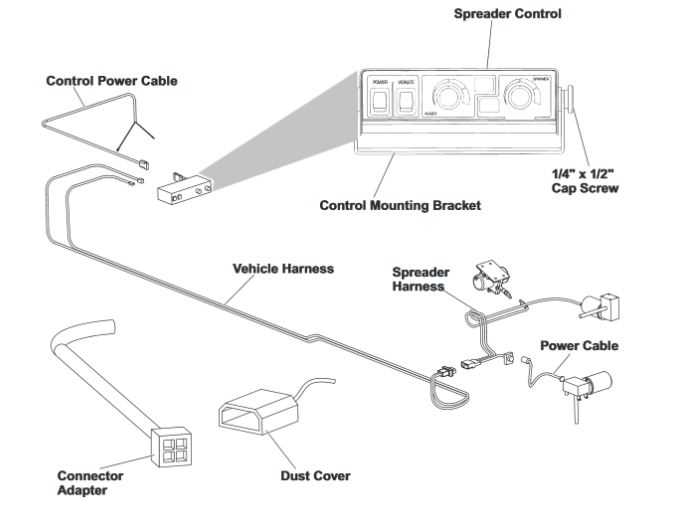

Electronic Controls and Wiring

This section delves into the essential components and wiring systems that govern the operation of the spreading device. Understanding these systems is crucial for ensuring optimal functionality and performance. The electronic controls allow for precise regulation of operations, enhancing efficiency during use.

The wiring configuration connects various elements, facilitating communication between the controller and the mechanisms involved. A thorough knowledge of these connections can aid in troubleshooting and maintenance.

| Component | Description |

|---|---|

| Controller | The unit responsible for processing user input and regulating operations. |

| Wiring Harness | A collection of wires that connects different components, ensuring proper communication. |

| Relay | An electromechanical switch that controls the flow of electricity to various parts. |

| Sensor | A device that detects specific conditions and sends signals to the controller. |

| Fuse | A safety device that protects the system from overload by breaking the circuit if necessary. |

Maintaining these components in good working order is vital for the reliability of the entire system. Regular checks can prevent failures and prolong the lifespan of the equipment.

Maintenance Tips for Key Parts

Proper upkeep of essential components is crucial for ensuring optimal performance and longevity of your equipment. Regular maintenance can help prevent issues and enhance the efficiency of the system. Here are some important practices to consider:

- Regular Cleaning: Keep all components free from debris and build-up. Use appropriate cleaning solutions and tools to maintain cleanliness.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. Follow manufacturer guidelines for recommended products and intervals.

- Inspection: Frequently inspect key components for signs of damage or wear. Look for cracks, rust, or any irregularities that may affect functionality.

- Replacement of Worn Parts: Identify parts that show significant wear and replace them promptly to prevent further damage to the system.

- Storage Practices: During off-season periods, store equipment in a dry, sheltered location. Ensure all components are protected from moisture and extreme temperatures.

Implementing these maintenance practices will help you achieve reliable operation and extend the life of your equipment, saving time and resources in the long run.

Common Issues with Salt Spreaders

When it comes to effective winter maintenance, various challenges can arise with equipment designed for distribution tasks. Understanding these common problems can help ensure optimal performance and longevity.

Frequent Problems Encountered

- Inconsistent material flow, leading to uneven application.

- Blockages caused by moisture or clumping of the distributed material.

- Wear and tear on mechanical components, resulting in decreased efficiency.

- Malfunctions in the control system, affecting operational reliability.

- Inadequate calibration, which can cause improper spread patterns.

Troubleshooting and Solutions

- Regularly inspect and clean components to prevent clogging.

- Lubricate moving parts to minimize wear and enhance performance.

- Adjust the calibration settings to match the required distribution rate.

- Monitor the equipment during operation for any unusual noises or behaviors.

- Consult the user manual for specific troubleshooting guidelines.

Replacement Parts and Installation Guide

This section provides essential information regarding the various components required for maintenance and repair of your equipment. Understanding the available alternatives and their proper installation will ensure optimal performance and longevity. Below, you will find a comprehensive overview of the key elements needed for seamless operation.

| Component | Description | Installation Instructions |

|---|---|---|

| Control Handle | Used for adjusting speed and direction during operation. | Detach the existing handle by unscrewing the bolts. Align the new handle and secure it with the provided screws. |

| Dispersal Mechanism | Ensures even distribution of materials. | Remove the old mechanism and install the new unit, ensuring it locks into place properly. |

| Hopper Assembly | Holds and feeds the material to be distributed. | Disconnect the hopper from the frame and replace it with the new one by following the reverse process. |

| Tires | Provide mobility and stability on various surfaces. | Lift the equipment to access the wheels, remove the old tires, and fit the new ones securely. |