The efficiency of fluid transfer mechanisms is essential in various industries, ensuring that liquids are transported effectively from one location to another. These systems consist of several components that work in harmony to achieve optimal performance. Understanding the arrangement and function of these elements is crucial for both maintenance and operational efficiency.

In this section, we will explore the intricate relationships between different components involved in fluid movement. By examining the specific elements, we can better comprehend how each contributes to the overall functionality of the system. This knowledge can assist in troubleshooting and improving system reliability.

Moreover, having a clear visualization of the configuration allows for easier identification of potential issues and facilitates informed decision-making regarding repairs and upgrades. Gaining insights into the organization of these crucial elements will empower users to enhance the longevity and efficiency of their fluid transfer systems.

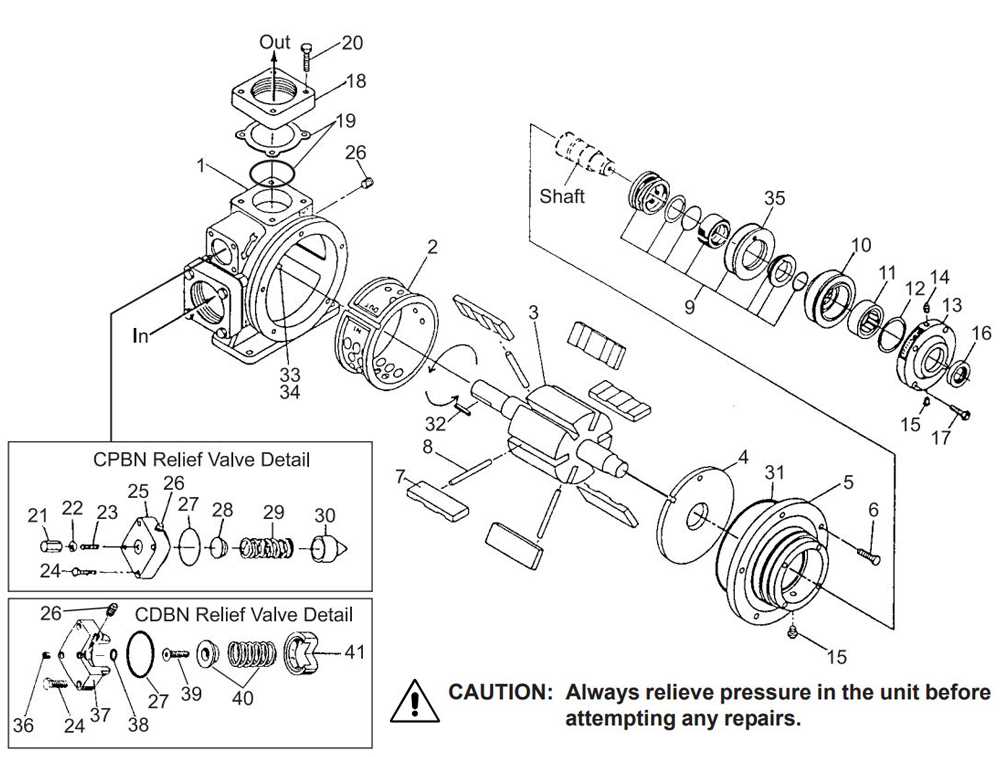

Understanding Roper Pump Components

This section delves into the intricate elements of a fluid transfer system, shedding light on their functionality and interrelationships. Each component plays a pivotal role in ensuring optimal performance, contributing to the overall efficiency and reliability of the machinery.

Key elements of this system include:

- Housing: The protective shell that encases the internal components, providing structural integrity and safeguarding against environmental factors.

- Impeller: A rotating part that imparts energy to the fluid, facilitating its movement through the system.

- Seal: A critical component that prevents leakage and maintains pressure within the system, ensuring fluid integrity.

- Drive Mechanism: The system responsible for transferring energy from the motor to the rotating elements, driving their movement.

- Inlet and Outlet Ports: The entry and exit points for the fluid, designed to optimize flow rates and minimize turbulence.

Understanding these elements is essential for effective maintenance and troubleshooting. Each part interacts with others, contributing to the seamless operation of the system. Regular inspection and knowledge of each component’s function can greatly enhance the longevity and efficiency of the entire assembly.

By familiarizing oneself with the various elements and their roles, operators can better manage performance and address issues that may arise during operation. This understanding not only aids in troubleshooting but also enhances overall system efficiency.

Key Features of Roper Pumps

Innovative fluid transfer systems are crucial in various industrial applications, providing reliable performance and efficiency. These systems are designed with numerous attributes that enhance their functionality and durability, making them a preferred choice in the market. Understanding these distinctive characteristics can help users make informed decisions when selecting a suitable option for their specific needs.

Durability and Reliability

One of the standout qualities of these fluid handling solutions is their robust construction. Crafted from high-quality materials, they are engineered to withstand harsh environments and demanding conditions. This resilience ensures minimal downtime and maintenance, allowing for continuous operation over extended periods.

Versatile Applications

The adaptability of these systems makes them suitable for a wide range of uses across various industries. Whether it’s in chemical processing, food and beverage production, or oil and gas applications, they can efficiently handle different types of fluids, including viscous and abrasive substances. This versatility is complemented by customizable options, enabling users to tailor the equipment to their specific operational requirements.

Common Applications for Roper Pumps

These hydraulic devices are widely utilized across various industries due to their reliability and efficiency. Their design enables them to handle different fluids, making them suitable for diverse operational environments. Below are some common sectors where these mechanisms excel.

- Agriculture: Essential for irrigation systems, ensuring consistent water supply for crops.

- Industrial Processes: Employed in the transfer of chemicals and solvents, facilitating smooth production workflows.

- Food and Beverage: Used for moving viscous liquids, such as oils and syrups, while maintaining hygiene standards.

- Marine Applications: Critical in bilge and ballast systems, aiding in vessel stability and maintenance.

- Oil and Gas: Integral in transporting fuels and lubricants, contributing to energy efficiency in operations.

- Pharmaceuticals: Important for precise fluid handling in the manufacture of medications and health products.

In summary, these versatile devices serve a multitude of roles, enhancing productivity and ensuring the smooth operation of various systems across multiple fields.

Benefits of Using Roper Pumps

Utilizing high-quality fluid transfer systems offers numerous advantages for various applications. These systems are designed to provide efficient performance and reliability, making them essential for industries requiring consistent operations.

- Durability: Constructed with robust materials, these systems are built to withstand harsh conditions, ensuring longevity and reducing the frequency of replacements.

- Efficiency: Advanced engineering allows for optimal fluid movement, leading to lower energy consumption and enhanced productivity.

- Versatility: Suitable for a wide range of fluids, these mechanisms can handle different viscosities and temperatures, making them adaptable to diverse tasks.

- Easy Maintenance: Designed for straightforward servicing, these systems simplify upkeep procedures, minimizing downtime and operational costs.

- High Performance: Capable of maintaining consistent flow rates, these systems contribute to stable operations and improved process management.

In summary, the advantages of utilizing reliable fluid transfer systems enhance operational efficiency, reduce maintenance efforts, and contribute to overall productivity across various sectors.

Maintenance Tips for Roper Pumps

Ensuring the longevity and efficiency of your equipment requires consistent attention and care. By adhering to a regular maintenance routine, you can prevent potential issues and optimize performance over time.

- Regular Inspections: Conduct frequent assessments to identify any signs of wear or damage. Look for leaks, unusual noises, or vibrations that may indicate underlying problems.

- Clean Components: Keep all surfaces free from debris and buildup. Regular cleaning helps maintain functionality and prevents clogs.

- Check Seals and Gaskets: Examine all sealing elements for cracks or degradation. Replace any that show signs of wear to prevent leaks.

- Lubrication: Ensure all moving parts are adequately lubricated according to manufacturer recommendations. Proper lubrication reduces friction and wear.

- Monitor Operating Conditions: Keep an eye on temperature and pressure levels during operation. Abnormal readings may indicate issues that require immediate attention.

By following these guidelines, you can enhance the reliability of your system and extend its operational life. Consistent maintenance not only saves costs in the long run but also ensures smooth and efficient performance.

Diagnosing Pump Issues and Solutions

Identifying and resolving operational challenges in fluid-moving machinery is essential for maintaining efficiency and preventing costly downtime. Understanding the signs of malfunction and implementing effective solutions can significantly enhance performance and reliability. This section outlines common symptoms and corresponding corrective actions to ensure optimal functionality.

When faced with operational difficulties, consider the following symptoms and their possible causes:

- Low Output:

- Check for blockages in the inlet or outlet.

- Examine the integrity of seals and gaskets.

- Assess the rotational speed to ensure proper operation.

- Unusual Noises:

- Inspect for loose components that may be causing vibrations.

- Listen for cavitation, which may indicate inadequate fluid levels.

- Evaluate bearing wear, which can lead to grinding or rattling sounds.

- Overheating:

- Ensure proper lubrication is present.

- Check for excessive friction due to misalignment or wear.

- Monitor the ambient temperature to avoid exceeding operational limits.

- Leaks:

- Identify the source of leakage to determine if it’s a seal or joint failure.

- Examine the mounting hardware for tightness.

- Assess the overall condition of hoses and connectors.

By systematically evaluating these indicators, operators can pinpoint issues and implement timely interventions. Regular maintenance practices, including inspections and part replacements, are also crucial for preventing future complications.

Upgrading Your Roper Pump System

Enhancing the efficiency and performance of your fluid transfer mechanism can lead to significant improvements in overall productivity. Upgrading components not only extends the lifespan of the entire setup but also ensures it meets modern operational standards. This section outlines essential considerations and options for optimizing your existing system.

Evaluate Existing Components: Before making any enhancements, assess the current configuration and identify areas that may benefit from upgrades. Look for signs of wear, inefficiency, or outdated technology that could hinder performance.

Research Compatibility: Ensure that new components are compatible with your current assembly. This includes checking specifications and dimensions to avoid installation issues later.

Consider Performance Upgrades: Explore options such as high-efficiency motors, improved seals, or advanced control systems. These upgrades can drastically improve reliability and energy consumption, leading to cost savings over time.

Consult with Professionals: If uncertain about the best upgrades for your specific situation, seeking advice from industry experts can provide valuable insights. They can guide you in selecting the most suitable enhancements based on your requirements.

Regular Maintenance: Alongside upgrades, implementing a routine maintenance schedule is crucial. Regular checks and timely replacements can help prevent failures and prolong the life of the entire assembly.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its functionality and efficiency. Several resources are available to help you find the right items to ensure optimal performance.

Here are some recommended sources for obtaining these essential components:

- Manufacturer’s Website: Start by visiting the official website of the manufacturer. They often have a dedicated section for components, where you can find detailed listings and specifications.

- Authorized Dealers: Check with authorized distributors who specialize in the equipment. These dealers usually stock genuine components and can provide expert advice.

- Online Retailers: Many online platforms offer a wide selection of components. Look for reputable sites with good customer reviews to ensure quality.

- Local Hardware Stores: Visit local stores that carry hardware and tools. They may have some components available or can order them for you.

- Aftermarket Suppliers: Explore aftermarket suppliers that produce compatible components. While they may not be original, many offer quality alternatives at competitive prices.

- Forums and Community Groups: Engage with online forums or community groups dedicated to your equipment. Members often share tips and recommendations on where to find specific components.

By utilizing these resources, you can efficiently source the necessary components to keep your equipment running smoothly.