Maintaining a lawn care machine requires a solid understanding of its various elements. Each component plays a crucial role in the overall performance and efficiency of the equipment. Familiarity with these parts enables users to troubleshoot issues effectively and ensure optimal functioning.

When dealing with lawn maintenance tools, it is essential to have access to a visual representation that outlines the arrangement and relationship of each element. This knowledge not only simplifies repairs but also aids in the identification of replacement needs, ensuring that your equipment remains in top condition.

Whether you’re a seasoned professional or a novice gardener, comprehending the structure of your machinery can significantly enhance your maintenance routine. Armed with the right information, you can confidently approach any task, ensuring that your lawn remains lush and healthy throughout the seasons.

Understanding Husqvarna YTH18542 Parts

Grasping the components of your lawn machine is crucial for optimal performance and maintenance. Familiarity with each element ensures efficient operation and can help in troubleshooting issues.

Key aspects to consider include:

- Identification of essential components

- Common replacement options

- Maintenance tips for longevity

Here are some primary categories of components:

- Engine and its accessories

- Transmission elements

- Cutting mechanism parts

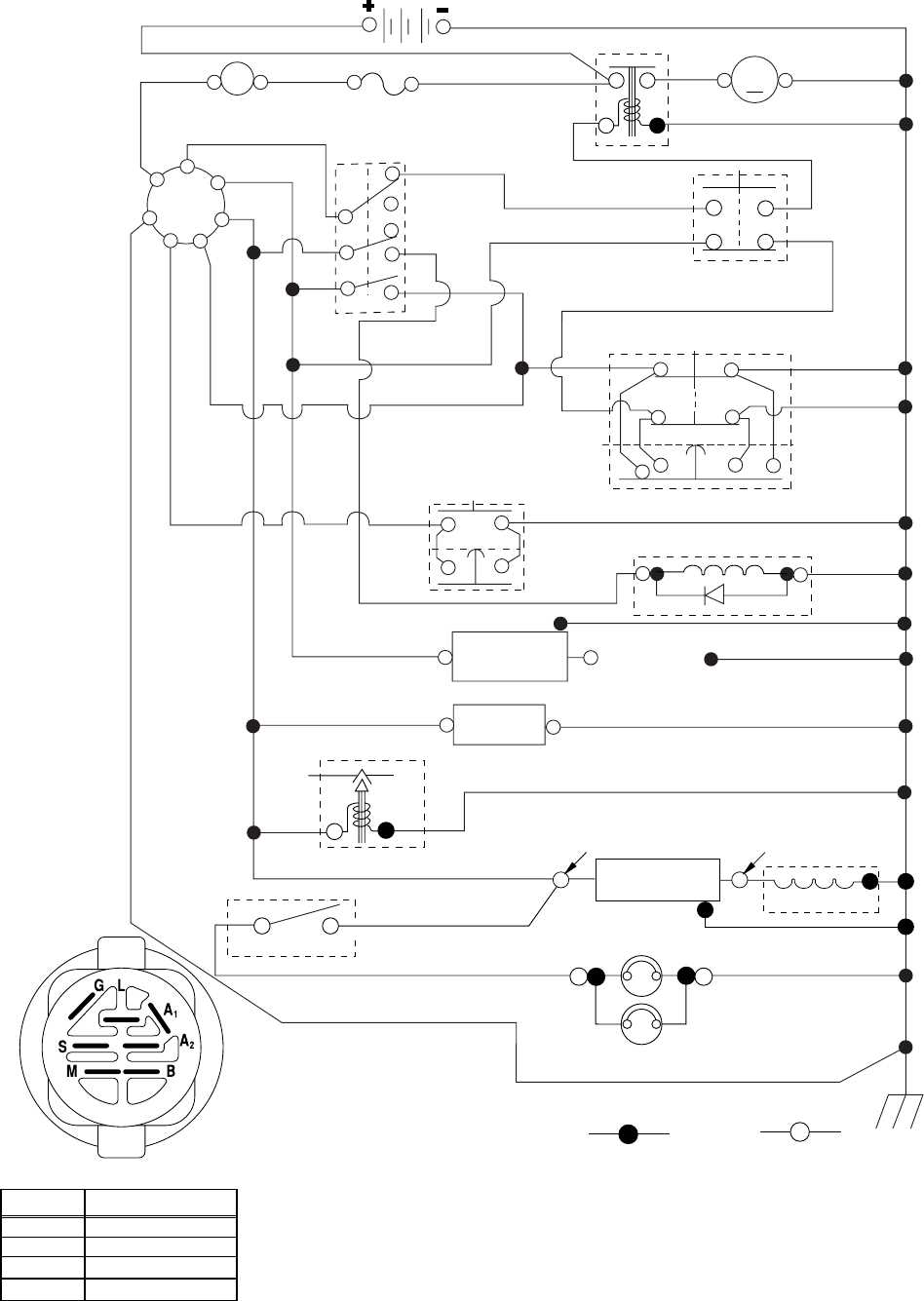

- Electrical systems

Understanding these categories allows for informed decisions during repairs or upgrades, ensuring your equipment remains in peak condition.

Overview of Lawn Mower Components

Lawn mowers consist of various essential elements that work in harmony to achieve efficient grass cutting and maintenance. Understanding these components can enhance performance and simplify troubleshooting when issues arise.

Main Components

- Engine: Powers the mower, available in different sizes and types.

- Deck: The housing that contains the cutting blade.

- Blade: The sharp tool that cuts grass, varying in design for different mowing styles.

- Wheels: Provide mobility and stability, available in various sizes.

Additional Features

- Handles: Used for steering and controlling the mower.

- Grass Collector: Captures clippings for easy disposal.

- Chassis: The frame that supports all components and ensures durability.

Key Features of the YTH18542 Model

This model is designed to provide exceptional performance and reliability, catering to various lawn care needs. It combines advanced technology with user-friendly features, ensuring a smooth and efficient mowing experience.

| Feature | Description |

|---|---|

| Engine Power | Robust engine delivering high torque for effective grass cutting. |

| Cutting Width | Generous deck size allows for wider paths, reducing mowing time. |

| Transmission | Automatic transmission for effortless speed adjustments and maneuverability. |

| Ergonomic Design | Comfortable seating and controls to enhance user experience during operation. |

| Durability | Sturdy construction ensures longevity and reliability under various conditions. |

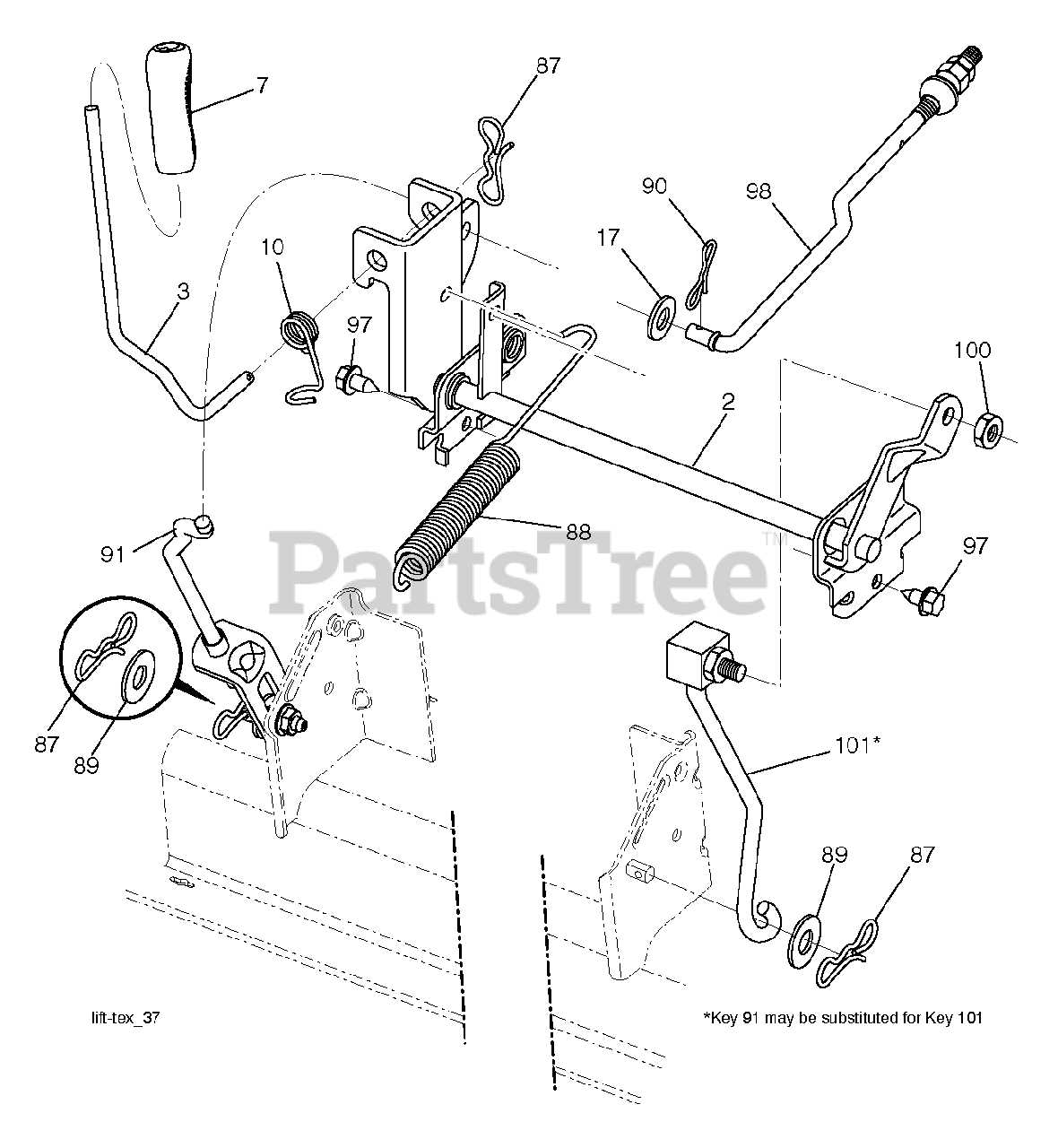

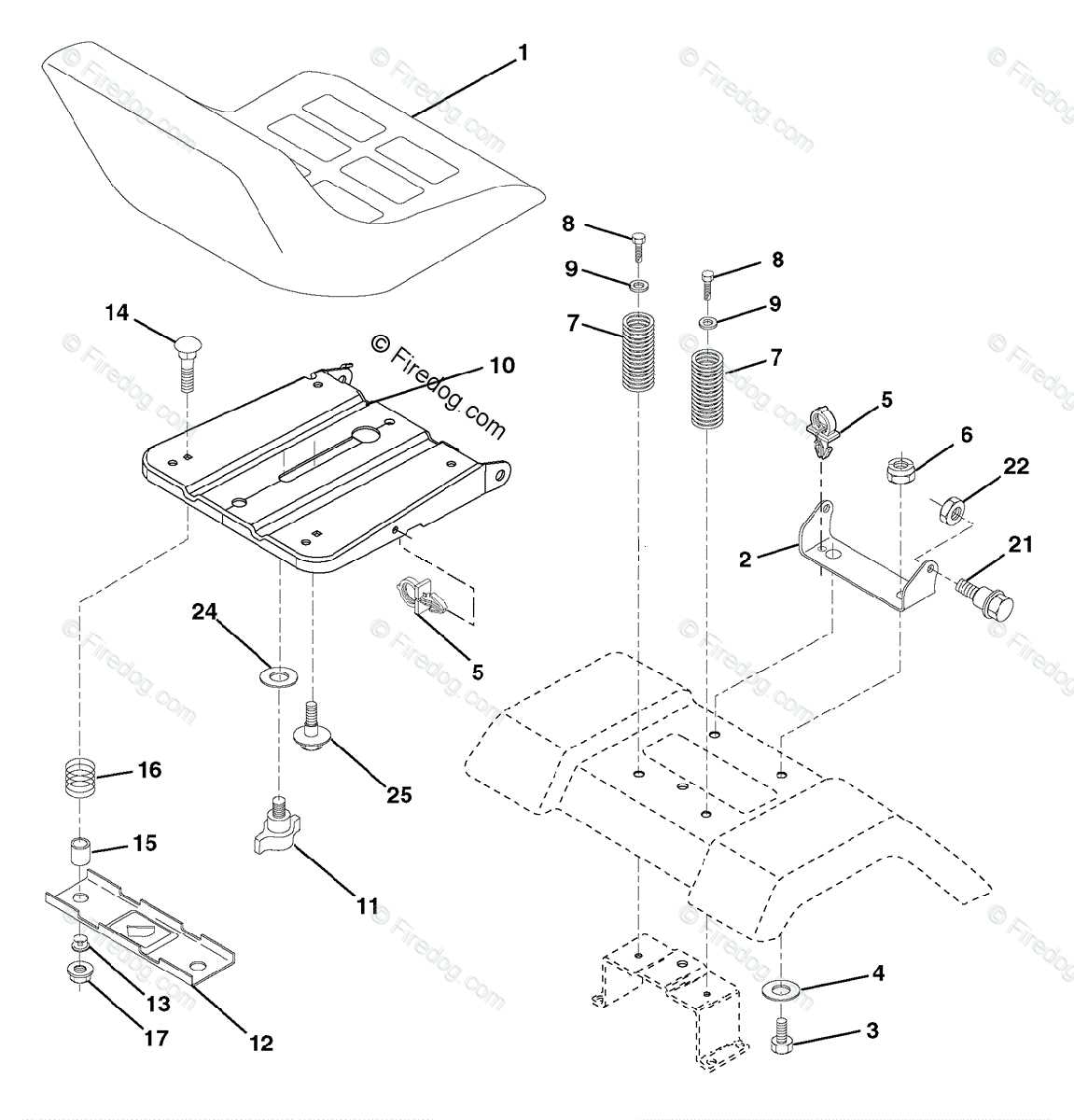

Importance of a Parts Diagram

A visual representation of components plays a crucial role in maintenance and repair tasks. It offers a clear overview, helping users identify various elements and understand their relationships. This clarity is essential for efficient troubleshooting and effective replacement processes.

Enhancing Understanding

Such illustrations enable individuals to grasp the complexity of machinery more easily. By visualizing each part’s placement and function, users can better appreciate how each element contributes to overall performance.

Facilitating Repairs

Having access to a detailed schematic streamlines the repair process. It minimizes confusion, allowing technicians to locate specific parts quickly and execute repairs with confidence. This ultimately leads to reduced downtime and improved operational efficiency.

Common Replacement Parts Explained

Understanding the various components that may need to be replaced can significantly enhance the performance and longevity of outdoor equipment. Each element plays a crucial role in ensuring the machine operates efficiently and reliably.

Key Components

- Blades: Essential for effective cutting, they must be sharp and free of damage.

- Batteries: Vital for powering the equipment; weak or dead batteries can lead to performance issues.

- Filters: Air and fuel filters prevent debris from causing engine problems and maintain optimal performance.

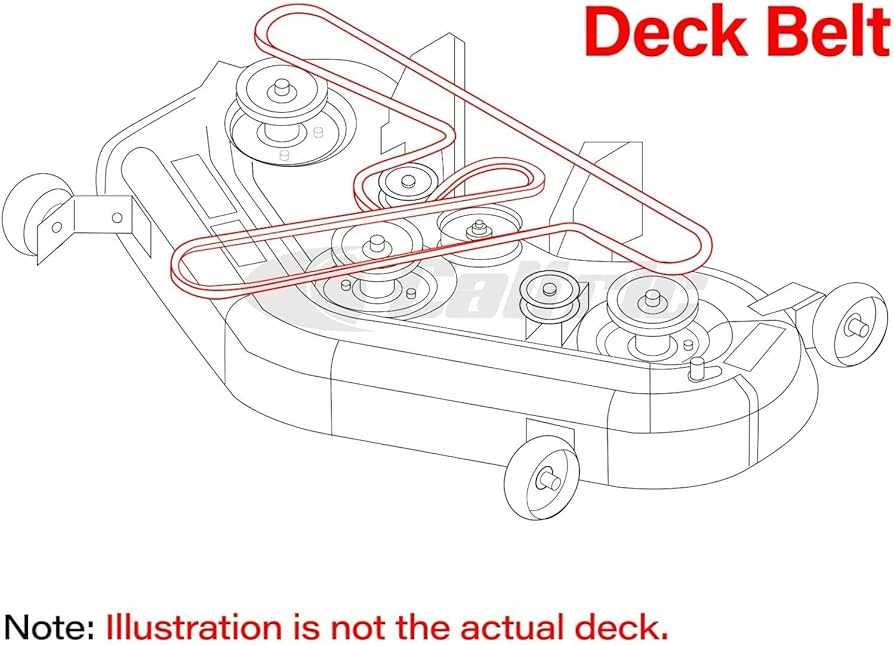

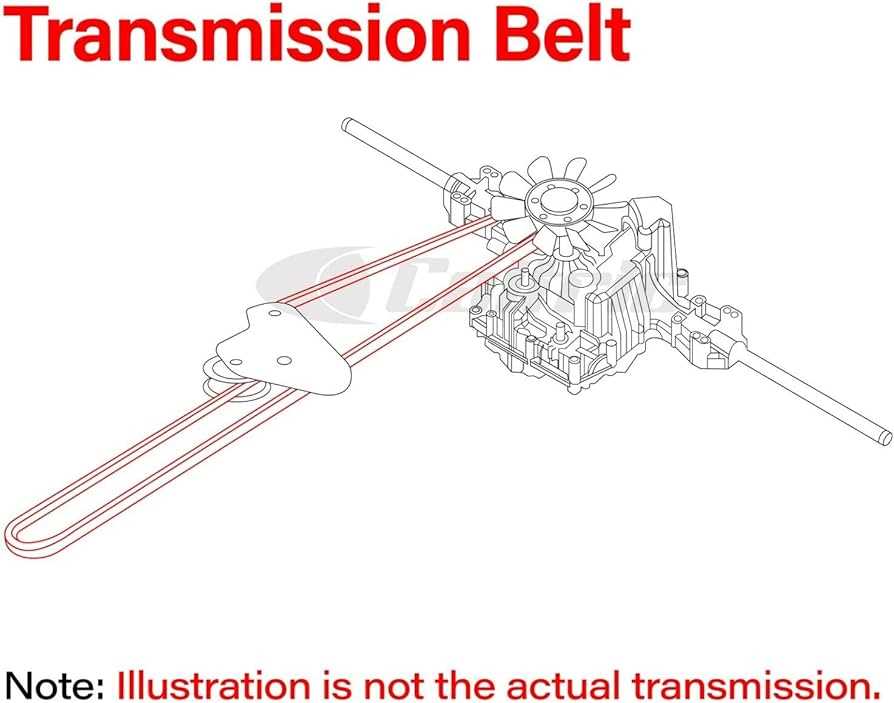

- Belts: These components transmit power; wear and tear can lead to reduced efficiency.

Signs of Wear

- Reduced cutting efficiency indicates dull blades.

- Starting issues may signal battery failure.

- Unusual noises can suggest worn belts.

- Engine performance problems might point to clogged filters.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the schematic layout, allowing you to identify individual elements and their connections within the machine. Familiarity with this illustration can significantly streamline your troubleshooting and restoration processes.

Begin by locating the section that pertains to the specific area of your equipment. Each component will typically be labeled, providing both the part number and a brief description. This information is invaluable when seeking replacements or making adjustments. Pay attention to the arrangement, as it often reflects the assembly sequence, making reassembly after repair much easier.

Once you have identified the necessary elements, cross-reference them with the manufacturer’s catalog or online store to ensure you acquire the correct replacements. It’s also helpful to make notes of any related tools or additional items you may need for installation, as this preparation can save time during the actual work.

Lastly, don’t hesitate to consult community forums or repair guides that may offer further insights into common issues or best practices associated with the components you are working with. Engaging with fellow enthusiasts can provide you with tips that enhance your repair experience.

Tips for Identifying Faulty Components

Recognizing malfunctioning elements in machinery is crucial for maintaining optimal performance and longevity. Understanding the signs of wear or failure can prevent further damage and reduce repair costs. Here are some strategies to effectively identify these issues.

1. Visual Inspection: Regularly examine parts for any obvious signs of damage, such as cracks, rust, or excessive wear. Pay close attention to areas that experience high levels of stress or friction.

2. Listen for Unusual Noises: Strange sounds like grinding, squeaking, or rattling can indicate that components are not functioning correctly. These noises often signify misalignment or deterioration.

3. Monitor Performance: Sudden changes in efficiency or performance, such as reduced power or responsiveness, can be a clear indication of underlying issues. Keeping track of performance over time helps pinpoint when problems arise.

4. Check for Leaks: Fluid leaks are often a sign of faulty seals or gaskets. Inspect the machine for any signs of leaking fluids, which can indicate potential failures in critical areas.

5. Use Diagnostic Tools: Employing specialized tools or equipment can help identify faults that are not immediately visible. Multimeters and pressure gauges can provide valuable insights into the condition of various components.

6. Consult Documentation: Referring to maintenance manuals or technical documentation can provide essential information about normal operating parameters and common issues associated with specific components.

By implementing these techniques, you can effectively identify faulty components, ensuring your machinery runs smoothly and efficiently.

Where to Buy Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Reliable sources offer quality items that meet the exact specifications required for your machinery. Purchasing genuine replacements not only enhances efficiency but also safeguards your investment.

Authorized Dealers: One of the best places to find original components is through authorized retailers. These dealers are officially recognized and typically provide a wide range of items tailored to your specific model. You can expect expert advice and support when purchasing from them.

Manufacturer’s Website: Visiting the official website of the equipment’s manufacturer is another excellent option. Here, you can often find a dedicated section for genuine components, complete with detailed descriptions and part numbers to assist you in making the right choice.

Local Repair Shops: Local repair shops can also be a valuable resource. Many of these establishments have established relationships with suppliers and can help you locate the precise items you need. They often have the added advantage of hands-on experience with your machinery.

Online Marketplaces: Reputable online marketplaces can provide a convenient way to shop for authentic components. Ensure you choose sellers with positive reviews and a return policy to guarantee satisfaction with your purchase.

In summary, seeking out genuine replacements from trusted sources is essential for maintaining the efficiency and durability of your equipment. Whether through authorized dealers, official websites, local shops, or online platforms, ensuring you acquire the right items will lead to better performance and peace of mind.

Maintenance Practices for Longevity

Regular upkeep is essential for extending the lifespan of outdoor machinery. Proper maintenance not only enhances performance but also minimizes the likelihood of breakdowns.

- Routine Cleaning: Keep the exterior free from dirt and debris to prevent rust and corrosion.

- Oil Changes: Regularly replace the oil to ensure smooth operation and reduce wear on internal components.

- Blade Sharpening: Ensure blades are sharp for efficient cutting and reduced strain on the engine.

- Fuel System Maintenance: Use fresh fuel and check filters to maintain optimal performance.

- Check Belts and Cables: Inspect for wear and replace any frayed parts to avoid unexpected failures.

Implementing these practices will significantly contribute to the ultimate durability and reliability of your equipment.