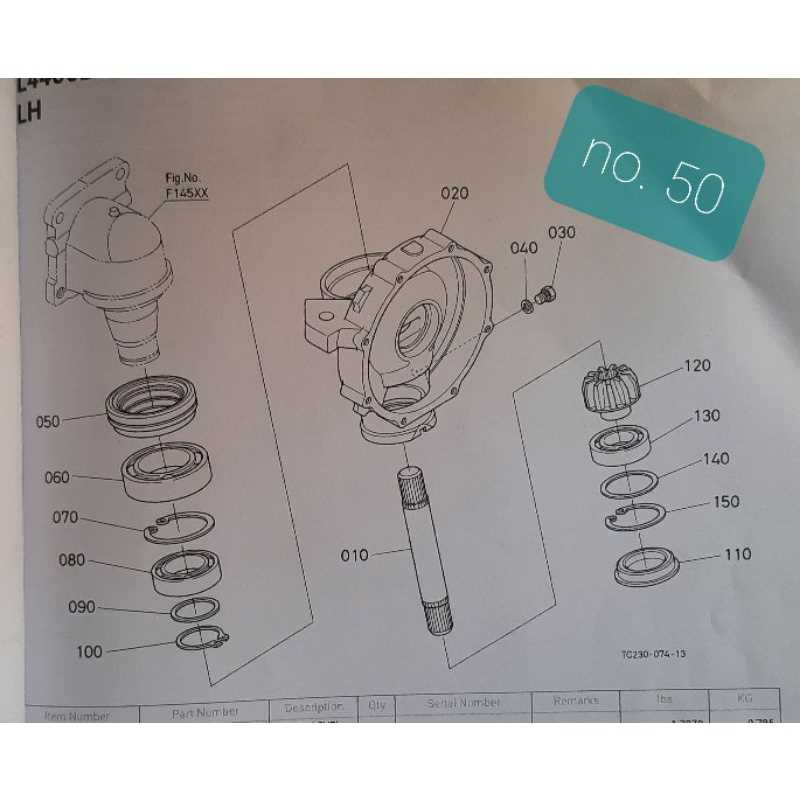

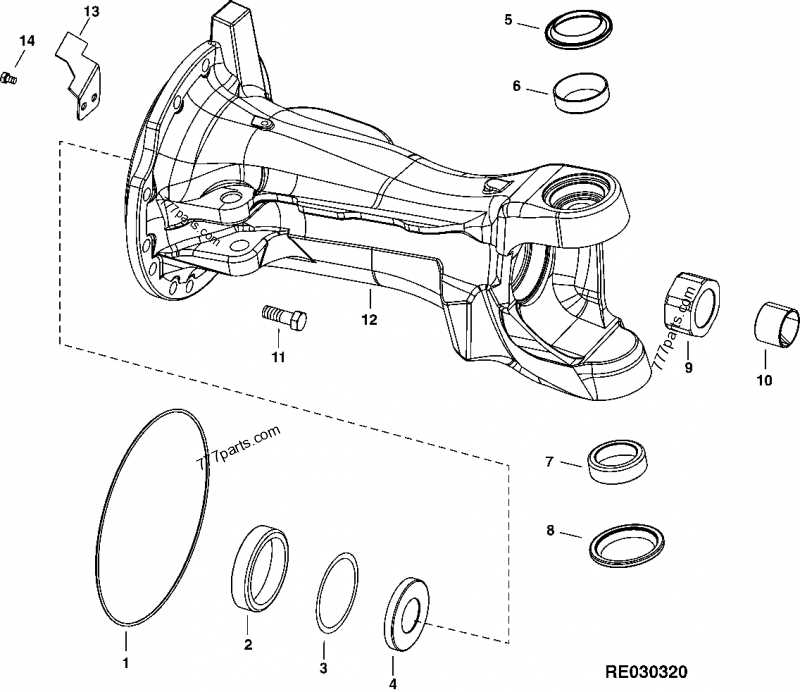

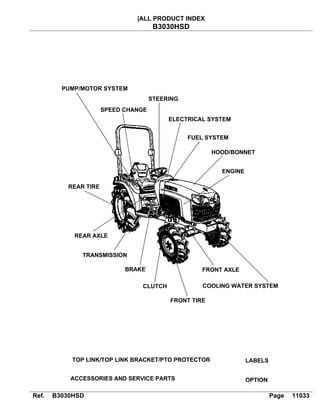

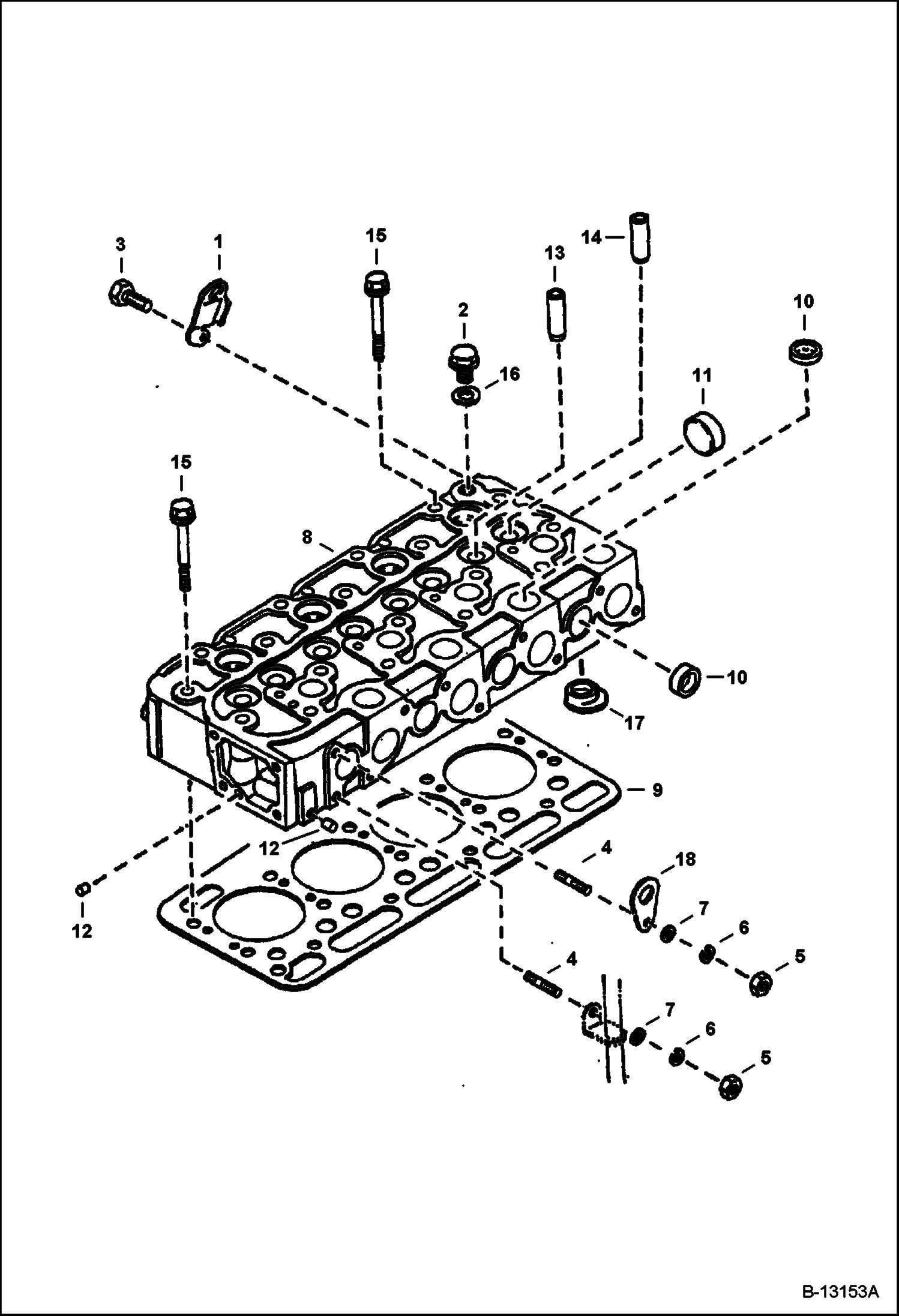

In this section, we delve into the intricate details and inner workings of a notable agricultural vehicle, uncovering the intricate connections and configurations that make up its structure. This exploration goes beyond mere descriptions, providing a visual map that elucidates the interplay of its various components.

Unveiling these blueprints, we illuminate the essential framework that underpins the functionality of this machinery. Through these detailed illustrations, each element’s role becomes evident, from the foundational components to the intricate subsystems that ensure optimal performance in the field.

This comprehensive breakdown doesn’t just reveal the physical attributes; it provides a comprehensive understanding of how each part interacts, fostering a deeper appreciation for the engineering marvel that is the L4400 and its operational prowess.

Kubota L4400 Overview

This section provides an insightful look into a particular model known for its robust performance and versatility in agricultural tasks. Designed to meet the demands of both professional and hobbyist users, this machine exemplifies efficiency and reliability in various applications.

With a powerful engine and user-friendly controls, this model is equipped to handle a wide range of farming and landscaping projects. Its compact size allows for maneuverability in tight spaces, making it ideal for small to medium-sized operations.

Furthermore, the innovative engineering behind this equipment ensures low maintenance costs and prolonged service life. Users can expect enhanced productivity, whether for plowing, tilling, or transporting materials. Overall, this machine stands out as a valuable asset for anyone looking to optimize their agricultural endeavors.

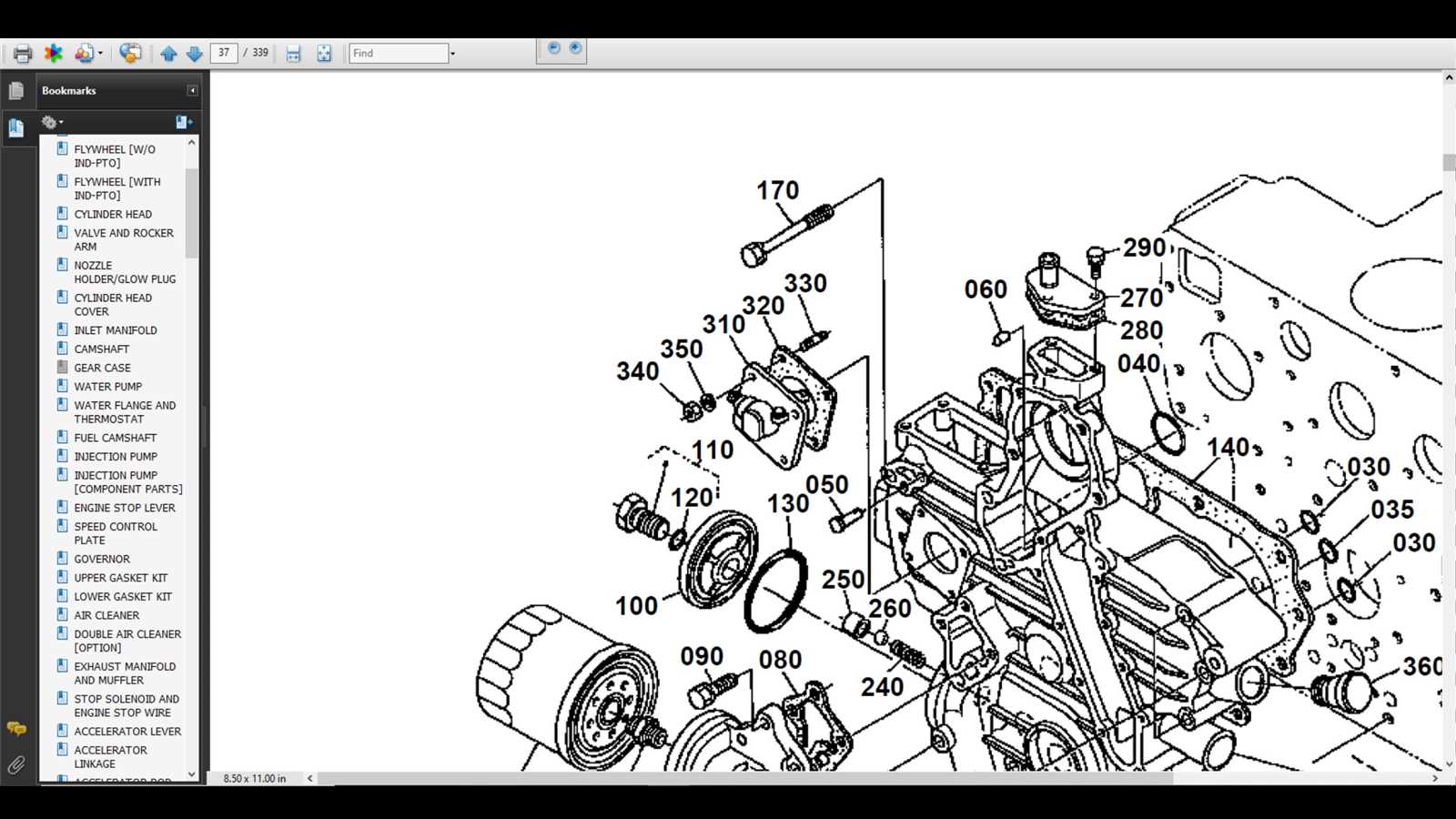

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining complex machinery. They provide clarity and insight into how various elements interact and function together, making it easier for users to diagnose issues, perform repairs, or replace specific elements. This organized depiction facilitates a more efficient workflow, ultimately enhancing the longevity and performance of the equipment.

Enhanced Understanding

Having a clear visual layout aids in grasping the intricate relationships between different components. Users can quickly identify each part’s location and function, which is especially beneficial during maintenance tasks. Comprehension of the assembly allows operators to work with confidence, reducing the likelihood of errors that could lead to further complications.

Streamlined Repairs

When it comes to fixing machinery, having a visual reference can significantly expedite the process. With an accurate representation, individuals can pinpoint the exact components that need attention without unnecessary guesswork. This efficiency not only saves time but also minimizes the risk of damaging other parts during repairs, ensuring a smoother restoration process.

Key Components of L4400

This section focuses on the essential elements that contribute to the functionality and efficiency of this agricultural machinery. Understanding these components is crucial for optimal operation and maintenance, ensuring that users can maximize productivity in their tasks.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power for various operations. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, allowing for smooth movement. |

| Hydraulic System | Enables the operation of attachments and implements, enhancing versatility. |

| Chassis | The framework that supports the entire structure and components, ensuring stability and durability. |

| Steering Mechanism | Allows for precise navigation and control during operation in various terrains. |

| Electrical System | Supports the ignition, lighting, and various electronic controls for better usability. |

Finding Genuine Replacement Parts

When it comes to maintaining agricultural machinery, sourcing authentic components is essential for optimal performance and longevity. Using original items ensures compatibility and reliability, preventing issues that can arise from inferior substitutes.

Here are some tips to help you locate authentic replacements:

- Authorized Dealers: Always check with official distributors. They typically stock genuine items and can offer guidance on your specific needs.

- Manufacturer Websites: Browse the official website of the manufacturer. Many provide resources for locating certified sellers and catalogs of available items.

- Quality Assurance: Look for seals or markings that indicate the item is original. Be wary of prices that seem too good to be true.

Additionally, consider joining forums or communities dedicated to your equipment type. Enthusiasts often share valuable insights on where to find authentic components and can recommend reliable sources.

Lastly, always keep your equipment’s model and serial number handy. This information is crucial when inquiring about specific items, ensuring you get exactly what you need.

Common Issues and Repairs

Understanding the frequent problems encountered with agricultural machinery can significantly enhance maintenance efficiency and prolong the lifespan of the equipment. Addressing these issues promptly not only ensures optimal performance but also minimizes downtime, leading to increased productivity on the farm.

Frequent Mechanical Problems

Operators often report various mechanical challenges that can arise during the operation of their equipment. The following table outlines some of these common issues, their potential causes, and recommended solutions.

| Issue | Possible Causes | Suggested Repairs |

|---|---|---|

| Engine Won’t Start | Faulty battery, fuel blockage, or electrical issues | Check battery connections, inspect fuel lines, and test the starter motor |

| Overheating | Coolant leak, blocked radiator, or faulty thermostat | Inspect for leaks, clean the radiator, and replace the thermostat if necessary |

| Poor Performance | Dirty air filter, clogged fuel filter, or engine misfire | Replace air and fuel filters, and check ignition system components |

Maintenance Tips

Regular maintenance is key to preventing issues. Implementing a schedule for routine checks can help identify potential problems before they escalate. Simple tasks like oil changes, filter replacements, and inspections of belts and hoses can make a substantial difference in the overall health of the machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your machinery. Regular maintenance not only enhances performance but also extends the lifespan of various components. By following a structured routine, you can prevent premature wear and costly repairs, ultimately saving time and resources.

Start by conducting frequent inspections to identify any signs of wear or damage. Look for loose connections, leaks, and unusual sounds during operation. Keeping a close eye on these indicators allows for timely interventions and adjustments.

Regular lubrication of moving parts is crucial. Using the appropriate type of lubricant minimizes friction and reduces the risk of overheating. Consult your manual for recommended products and intervals to maintain optimal performance.

Additionally, ensure that filters are replaced and fluids are topped up according to the schedule. Clean air and fuel filters help maintain efficiency, while proper fluid levels contribute to smooth operation.

Finally, store equipment in a dry, sheltered area when not in use. This prevents rust and corrosion, safeguarding the integrity of various components. By adhering to these maintenance practices, you can significantly enhance the longevity of your machinery and ensure it remains in top working condition for years to come.

Understanding Hydraulic System Layout

The hydraulic system is a crucial component in various machinery, playing a significant role in facilitating movement and power transfer. By harnessing fluid dynamics, these systems enable the operation of different functions, making them essential for efficient performance. A clear understanding of the layout and components involved is vital for troubleshooting and maintenance.

Key Components of the Hydraulic System

At the heart of a hydraulic system are several key elements, including the hydraulic pump, cylinders, hoses, and valves. The pump generates the necessary pressure to move the fluid, while cylinders convert this pressure into mechanical force. Valves control the flow of fluid, directing it to the appropriate components, and hoses connect these parts, ensuring a seamless operation.

Flow Path and Functionality

Understanding the flow path of the hydraulic fluid is essential for diagnosing issues. The fluid travels from the reservoir through the pump, then to the valves and cylinders, before returning to the reservoir. Each section of the system must work harmoniously to maintain efficiency and responsiveness. Any blockage or leak can disrupt this flow, leading to performance issues.

Where to Source Repair Manuals

Finding reliable sources for repair documentation is essential for efficient maintenance and troubleshooting. Whether you’re dealing with agricultural machinery or other equipment, having access to comprehensive manuals can make all the difference in understanding the components and their functions.

Online Resources

- Manufacturer’s Website: Many brands offer downloadable manuals directly on their official sites.

- Online Marketplaces: Websites like eBay or Amazon often have physical copies or digital versions available for purchase.

- Specialized Forums: Enthusiast and professional forums can be great places to find shared resources or recommendations.

Local Options

- Dealerships: Local dealerships often carry manuals and can provide additional support.

- Library Services: Some libraries have technical sections where you might find what you need.

- Repair Shops: Local mechanics might have manuals they are willing to share or sell.