Understanding the key elements of a classic agricultural machine is essential for effective maintenance and repair. Properly identifying each system’s parts allows for smoother operation and extended longevity. This section will provide a clear representation of the various mechanical and electrical components that make up these robust vehicles.

The importance of having a detailed visual guide to these elements cannot be overstated. Each part, whether it pertains to the engine, transmission, or hydraulics, plays a pivotal role in ensuring the machinery performs at its best. A comprehensive breakdown of these individual units can help operators and technicians alike in troubleshooting and ensuring the machine runs efficiently.

With a well-organized layout, it becomes easier to pinpoint potential issues and carry out necessary replacements or repairs. This visual aid serves not just as a reference, but as a fundamental tool in maintaining the functionality of a machine that often operates in challenging environments. Proper familiarity with each component’s layout is a crucial step towards achieving optimal performance.

Understanding Massey Ferguson 35 Components

In order to efficiently operate a classic agricultural machine, it is essential to gain a solid grasp of its various key elements. These elements work together to ensure optimal functionality and performance during demanding field operations. Familiarity with these components allows for easier troubleshooting, maintenance, and repairs, ultimately extending the machine’s lifespan.

Key Elements of a Classic Tractor

At the heart of any reliable vehicle designed for heavy-duty tasks is its core assembly. The main segments that make up the structure include the engine, transmission, hydraulics, and control systems. Each of these areas plays a vital role in the overall effectiveness of the machinery, ensuring it operates smoothly across a range of tasks, from plowing fields to hauling equipment.

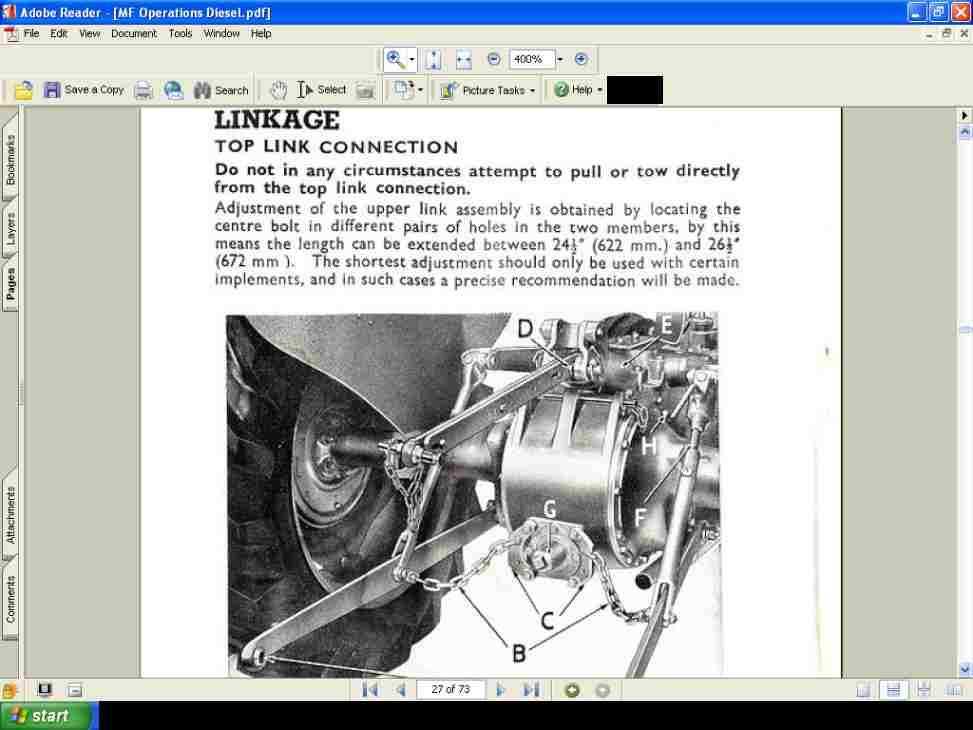

Hydraulic System and Power Transmission

Among the many systems incorporated in a robust tractor design, the hydraulic system stands out as particularly crucial. This system powers a variety of tools and implements, enhancing the versatility of the machine. Additionally, the transmission components are responsible for transferring power from the engine to the wheels, allowing the vehicle to maneuver effectively in diverse terrains.

| Component | Function |

|---|---|

| Engine | Generates power to drive the tractor and attached implements. |

| Transmission | Transfers engine power to the wheels for movement. |

| Hydraulic System | Powers external implements like plows and trailers. |

| Control System | Allows the operator to regulate various functions of the machine. |

Key Features of the MF 35 Tractor

The MF 35 Tractor is renowned for its versatility and reliability, making it a popular choice for a wide range of agricultural and industrial tasks. Its design integrates essential elements that offer both power and efficiency, with a robust engine and user-friendly controls. This machine provides the necessary performance for small to medium-sized farms, capable of handling various attachments and equipment for plowing, hauling, and tilling. The durable construction ensures longevity, even under tough conditions, and the intuitive layout simplifies operation for both experienced operators and novices.

| Feature | Description |

|---|---|

| Engine | Powered by a reliable engine that provides sufficient horsepower for various tasks. |

| Transmission | Equipped with a robust transmission system offering multiple gears for smooth operation in different conditions. |

| Hydraulics | Features an efficient hydraulic system that allows the use of various implements, enhancing productivity. |

| Controls | User-friendly control layout, ensuring easy access to all essential functions for smooth operation. |

| Durability | Constructed with high-quality materials, ensuring long-lasting performance even in challenging environments. |

| Versatility | Designed to accommodate a wide range of attachments and implements, making it adaptable to different farming needs. |

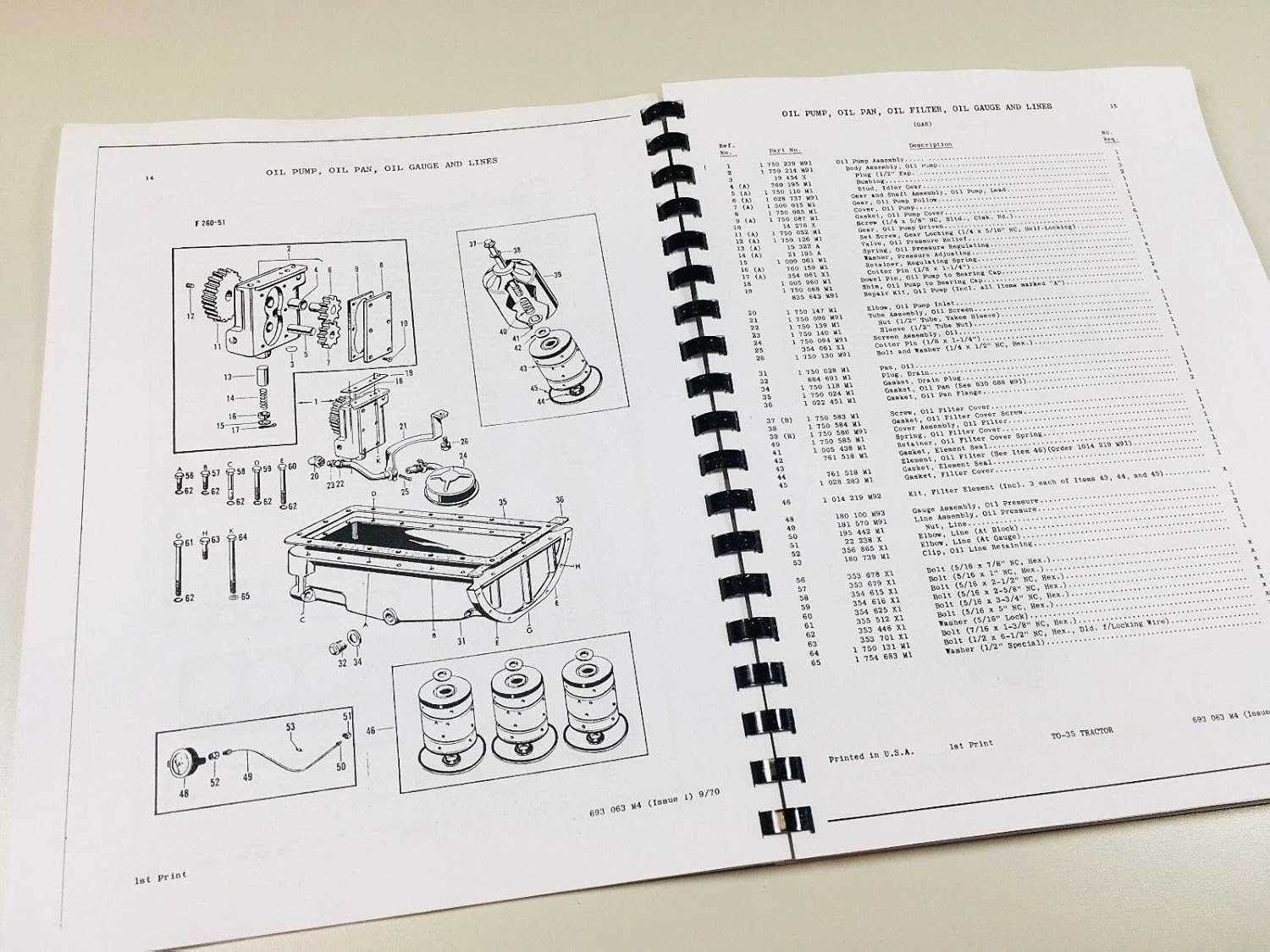

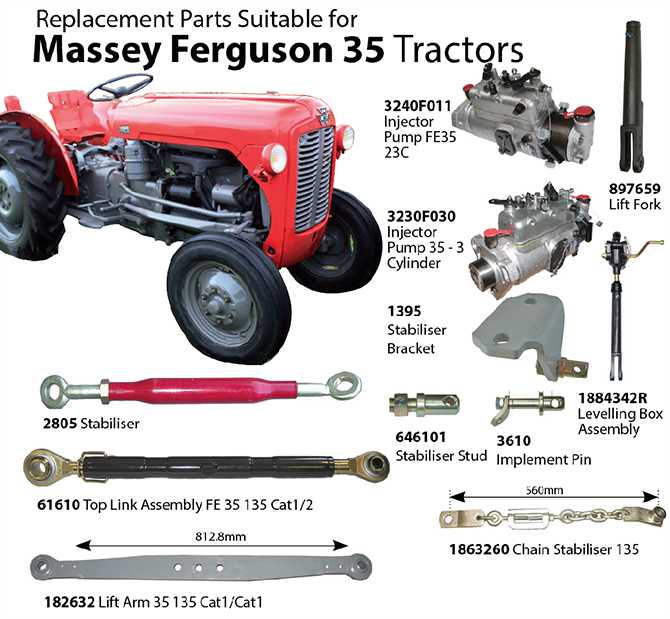

Common Replacement Parts for MF 35

Maintaining a vintage agricultural machine involves regular replacement of key components to ensure its efficient operation. Certain elements, due to their frequent exposure to wear and tear, are more prone to needing replacement than others. Understanding which components tend to degrade over time can help prevent breakdowns and extend the longevity of the equipment.

For this model, several essential elements commonly require replacement as they are vital to the functionality of the tractor. These include the engine, transmission, and hydraulic system components, as well as items such as filters, seals, and belts. Below is a list of frequently needed replacements that are crucial for keeping the machine running smoothly.

| Component | Description | Typical Replacement Interval |

|---|---|---|

| Air Filter | Prevents dust and debris from entering the engine, improving performance and fuel efficiency. | Every 500 hours of operation |

| Oil Filter | Ensures clean engine oil, preventing engine wear. | Every 200 hours of operation |

| Fuel Pump | Delivers fuel from the tank to the engine, maintaining consistent performance. | Every 1,000 hours of operation |

| Hydraulic Pump | Operates the hydraulic system, powering attachments and controlling lifting mechanisms. | Every 1,500 hours of operation |

| Clutch Disc | Engages and disengages the engine from the transmission for smooth operation. | Every 2,000 hours of operation |

| Starter Motor | Crucial for starting the engine, especially in colder climates. | Every 3,000 hours of operation |

How to Identify MF 35 Spare Parts

Identifying replacement components for agricultural machinery is essential for ensuring optimal performance and longevity. Knowing how to distinguish each element allows for efficient repairs and minimizes downtime. This process involves recognizing key features, numbers, and labels associated with each specific item in the equipment system.

Understanding Key Identifiers

Each component typically has unique markings or codes that provide important information, including size, material, and intended function. By examining these identifiers, it becomes easier to match an item with its correct counterpart. Sometimes these details are embossed, stamped, or printed directly onto the surface of the part itself. Other times, you may need to consult manufacturer records for reference.

Using Reference Guides for Accuracy

In addition to markings, consulting reference guides or technical manuals is an important step. These guides often provide comprehensive lists of compatible items and their corresponding numbers. Using these resources can ensure that you select the right replacement, even when the original identifier is unclear or worn down.

| Feature | Description |

|---|---|

| Serial Number | A unique code used to identify the specific item and its production details. |

| Manufacturer Code | Often a stamped or engraved code indicating the maker of the component. |

| Material Markings | Indicates the type of material used, such as steel, aluminum, or composite materials. |

| Model Number | Helps in identifying the exact model the item is compatible with. |

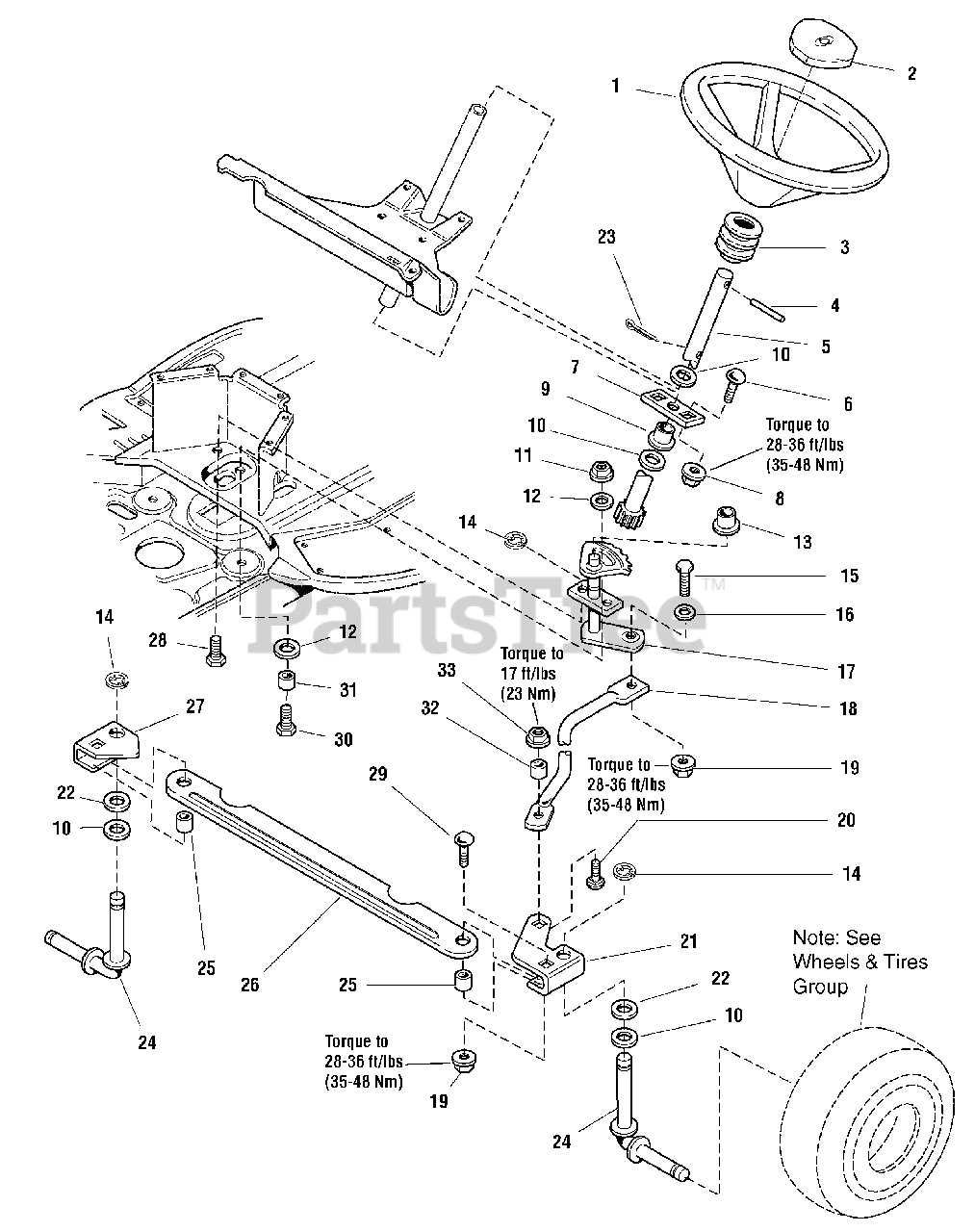

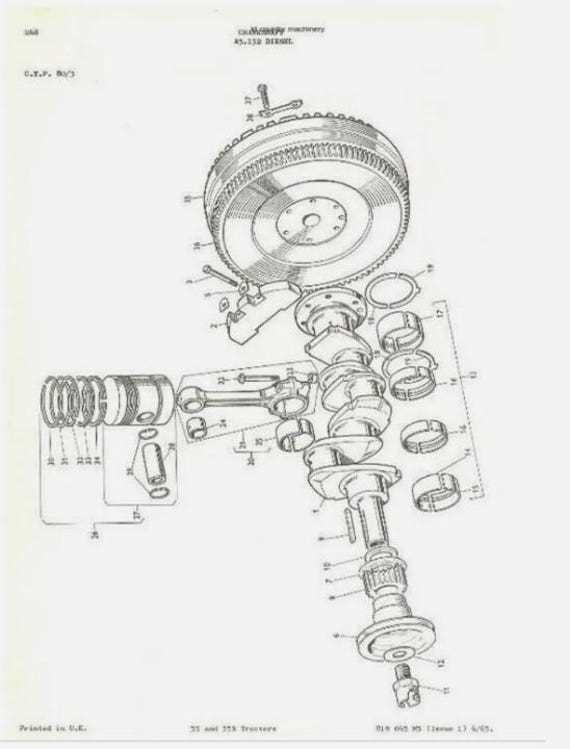

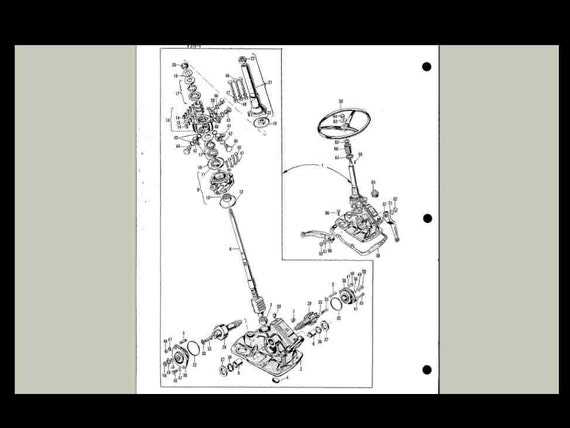

Complete Diagram for Massey Ferguson 35

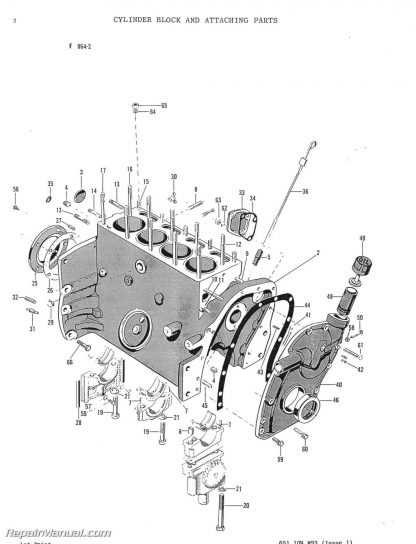

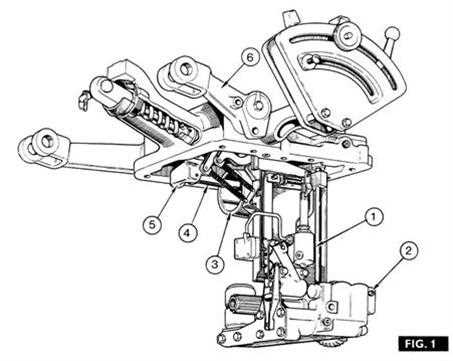

Understanding the structure and key components of agricultural machinery is essential for maintaining optimal functionality. For operators and technicians, a visual representation of the various assemblies and their interconnections can significantly enhance troubleshooting and repair processes. A comprehensive guide showcasing these assemblies provides a clear overview, ensuring that every essential element is properly addressed.

The visual layout breaks down the intricate details of the machine’s construction, from the main engine unit to smaller, auxiliary systems. It offers an in-depth look at how each system interacts, making it easier for users to identify potential issues and solutions.

- Engine and transmission systems

- Hydraulic mechanisms

- Steering and control assemblies

- Electrical components

- Frame and structural elements

Each section is carefully laid out to reflect the complexity of the equipment while maintaining clarity and accessibility. The visual aid ensures a thorough understanding of the machine’s operation, providing valuable insights for both seasoned professionals and those new to the field.

Maintenance Tips for MF 35 Parts

Proper upkeep of machinery components is crucial for ensuring optimal performance and longevity. Regular maintenance can prevent potential issues, minimize downtime, and enhance efficiency. This section will provide essential tips for maintaining your equipment effectively.

Firstly, routine inspections should be carried out to identify any signs of wear or damage. Checking seals, gaskets, and connections for leaks can help avoid more significant problems in the future. Additionally, it is vital to keep all moving parts lubricated to reduce friction and prevent premature wear.

Secondly, ensure that all filters are replaced according to the manufacturer’s recommendations. Clean filters help maintain optimal fluid flow and prevent contaminants from entering vital systems. Regularly flushing fluids and replacing them as needed will also contribute to the health of your machinery.

Furthermore, pay attention to any unusual sounds or vibrations during operation. These can be indicators of underlying issues that require immediate attention. Addressing these problems early can save time and money on repairs.

Lastly, maintain a clean environment around your equipment. Keeping work areas tidy can reduce the risk of accidents and help ensure that tools and materials are easily accessible when needed. By following these tips, you can prolong the life of your machinery and improve overall performance.

Sources for High-Quality Massey Ferguson Spares

When it comes to maintaining agricultural machinery, sourcing reliable components is crucial for ensuring longevity and optimal performance. The right spare parts can make a significant difference in the efficiency of your equipment, minimizing downtime and repair costs. To achieve this, finding reputable suppliers that offer high-quality replacements is essential.

Several options are available for sourcing these essential components, each catering to different needs and preferences. Whether you’re looking for original equipment or durable aftermarket options, it’s important to explore all avenues to ensure you’re getting the best value for your investment.

- Authorized Dealerships: These establishments are the go-to source for genuine components. They offer original equipment manufactured to exact specifications, ensuring compatibility and performance.

- Online Retailers: With the rise of e-commerce, many online platforms now provide a vast range of spares. Reputable websites often carry both original and aftermarket items, making them convenient for quick deliveries.

- Local Suppliers: For those who prefer a hands-on approach, visiting local suppliers can be a practical option. Many of these businesses specialize in agricultural machinery and offer personalized service and support.

- Specialized Manufacturers: Some manufacturers focus solely on producing high-quality replacements. These parts are often made to strict standards and can be a cost-effective alternative to originals.

Choosing the right source will depend on your specific needs, budget, and the urgency of the repair. It’s important to check reviews and verify the authenticity of the items before making a purchase to avoid unnecessary complications down the road.

Benefits of Using Original MF 35 Components

Choosing authentic components for your agricultural machinery ensures longevity and optimal performance. When it comes to maintaining your equipment, using the right materials can prevent frequent breakdowns and costly repairs. The quality of the materials plays a crucial role in how smoothly the system operates, leading to improved efficiency during work.

Durability is one of the most significant advantages of using original materials. Unlike aftermarket alternatives, genuine components are engineered to meet the specific requirements of the machinery, ensuring that each element functions in harmony with the others. This results in extended operational life and reduced wear and tear.

Additionally, precision engineering guarantees that each component fits perfectly, minimizing the chances of malfunctions or damage. Original components are also tested rigorously to comply with safety standards, offering peace of mind for the user. This contributes to better performance and reliability in all conditions.

Investing in authentic materials may be seen as an initial higher expense, but the long-term savings on maintenance and repairs more than make up for the cost. With fewer unexpected issues and reduced downtime, your equipment remains productive and efficient throughout its lifespan.

Step-by-Step Assembly of MF 35 Tractor Components

Assembling a classic agricultural vehicle requires precision and attention to detail. This guide will walk you through the sequential process of putting together the essential elements of a vintage farm machine. Whether you’re restoring or conducting maintenance, following each step closely will ensure optimal functionality and longevity of the equipment.

- Begin by securing the main frame and sub-assemblies. This is the foundation upon which other elements will be mounted.

- Install the engine block, ensuring it aligns properly with the chassis. Verify the placement of key components like pistons and cylinders.

- Next, attach the transmission system. Make sure that the linkage connects smoothly with the drive shaft for proper power transmission.

- Fit the axle components and wheels. Adjust the alignment to guarantee the wheels rotate freely without obstruction.

- Mount the steering mechanism. Double-check the connections to prevent any misalignment during operation.

- Finally, connect the hydraulic system and electrical components. Ensure all hoses and wires are routed safely and correctly to avoid future issues.

Throughout this process, attention to detail is paramount. Each step builds upon the last, contributing to the overall performance of the machine. With patience and careful work, you will achieve a reliable and fully functional unit.