When working with outdoor equipment, it is crucial to have a clear understanding of how its mechanical components interact to ensure proper functionality. A device designed for trimming grass and weeds relies on a combination of internal mechanisms that work together seamlessly to provide efficiency and power.

This article explores the intricate system behind a four-stroke engine used in lawn equipment. By breaking down the key elements, you will gain insights into how each component contributes to the overall performance and longevity of the machine. Whether you are performing maintenance or seeking to optimize your equipment, having this knowledge is invaluable.

We will guide you through a detailed overview of how the internal elements are configured, helping you to identify and understand their specific roles. This knowledge will empower you to handle repairs or upgrades more effectively, ensuring the equipment runs smoothly over time.

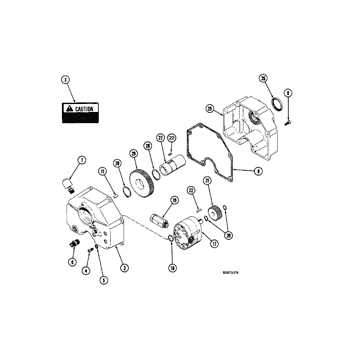

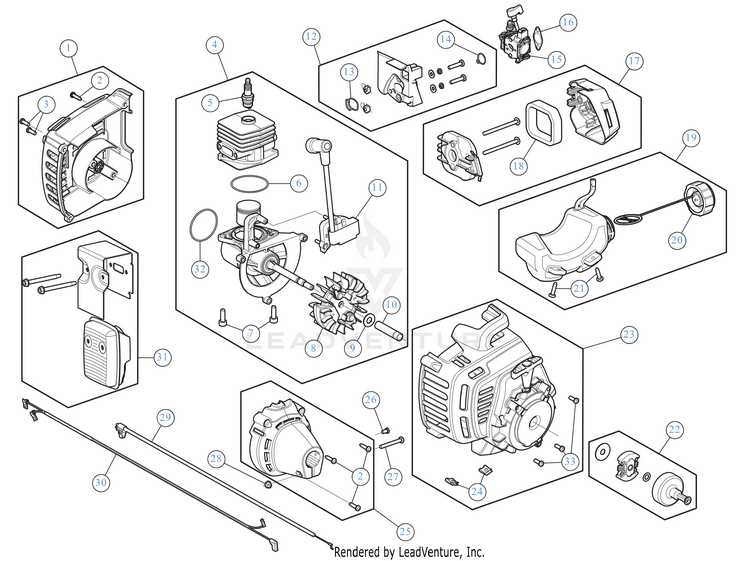

Understanding the 30cc 4 Cycle Engine

The engine in question is designed with precision, combining multiple stages to ensure smooth operation. It’s a well-structured system that optimizes fuel efficiency and power output, making it a reliable choice for various outdoor tasks. This type of motor is built to deliver consistent performance while reducing environmental impact.

At its core, the engine utilizes a series of processes that involve the intake, compression, power, and exhaust stages. These steps work in harmony to convert fuel into the energy required to drive the tool, ensuring maximum efficiency. Each stage is crucial for maintaining a balance between power and fuel consumption, which enhances overall performance.

This kind of motor is valued for its ability to separate the oil and fuel systems, leading to reduced emissions and easier maintenance. The design allows for prolonged usage with minimal interruptions, ensuring that the tool remains operational even during demanding tasks. Understanding how these components interact is key to keeping the motor running smoothly.

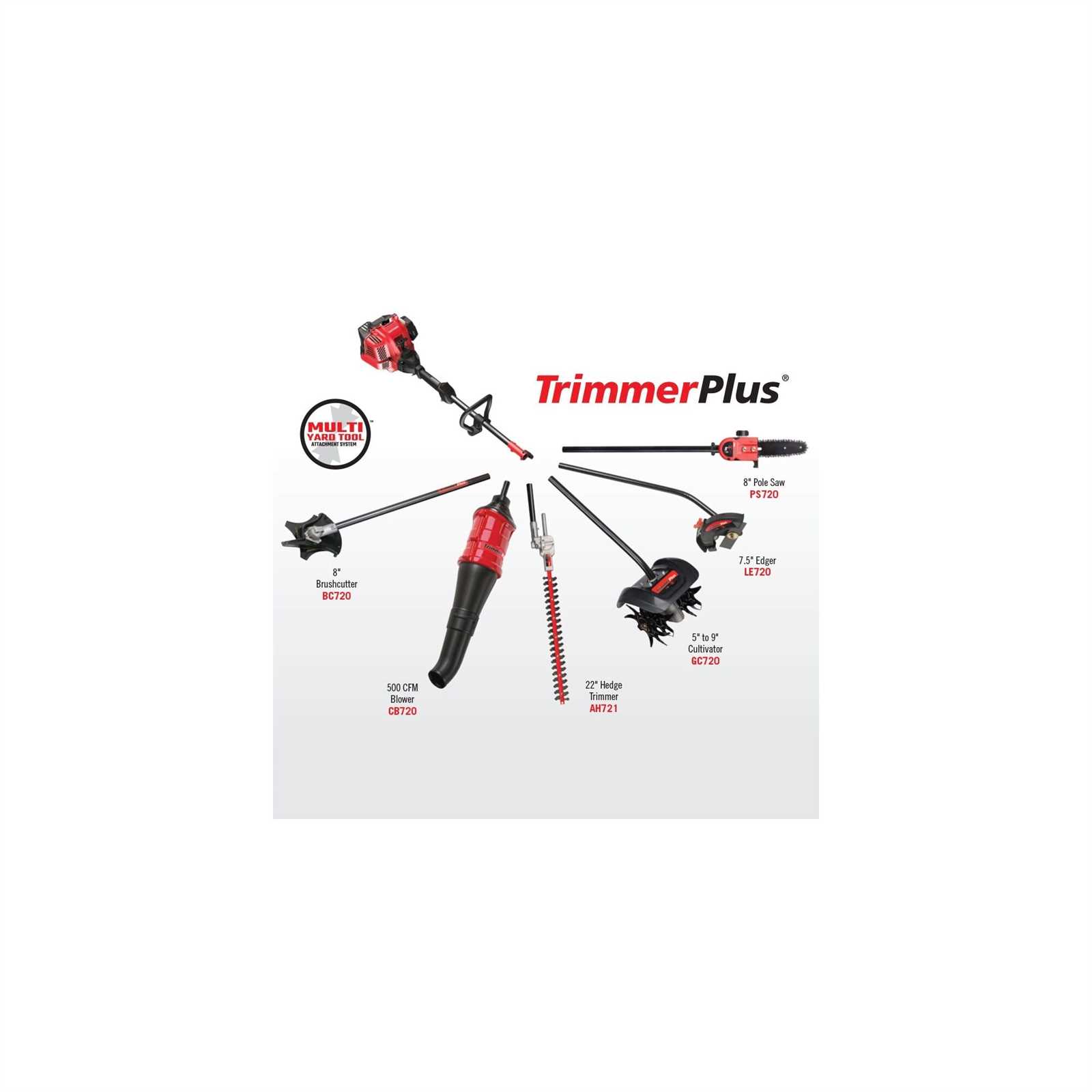

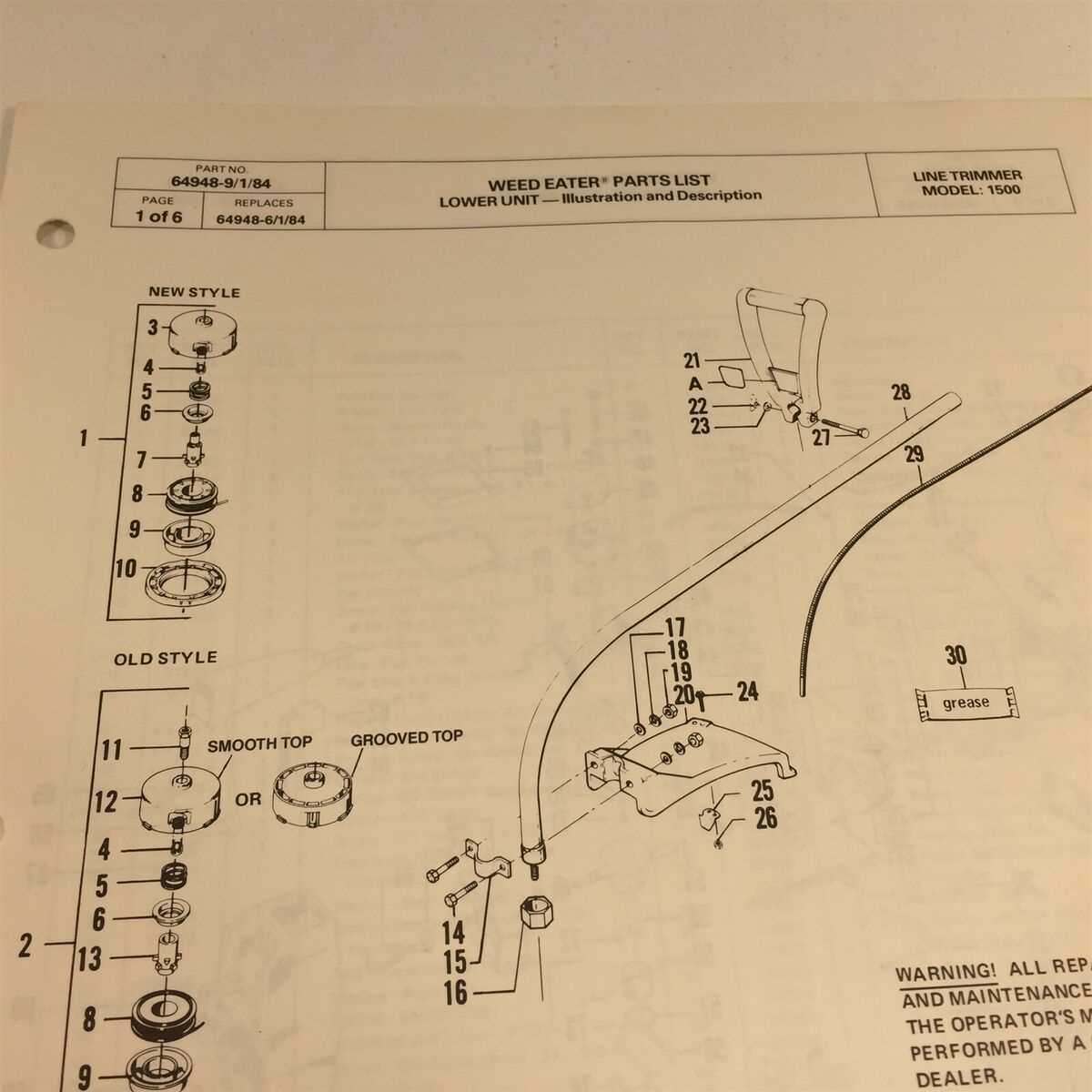

Key Components of a Craftsman Weedwacker

Every efficient outdoor trimming tool relies on a combination of essential elements to ensure smooth operation and optimal performance. These parts work together to deliver the power and precision needed to handle tough landscaping tasks. Understanding the primary components can help maintain the tool and ensure its longevity.

Engine

The power source of the trimmer, the motor, is responsible for driving the cutting head. It generates the energy necessary to rotate the blade or string, allowing the machine to cut through thick grass and weeds. A well-maintained engine ensures consistent performance, making it one of the most critical elements of the equipment.

Cutting Head

The cutting head holds the string or blade used for trimming. Its design is crucial for achieving a clean, even cut. Depending on the model, the head may come equipped with either a string mechanism or a metal blade, each designed for specific trimming tasks. Regular inspection and replacement of the cutting elements ensure optimal results.

How the Fuel System Works

The fuel system plays a crucial role in powering your equipment, ensuring the engine runs smoothly and efficiently. It is designed to store, deliver, and mix the fuel with air before combustion. Understanding how the fuel system operates can help with troubleshooting and maintenance.

Main Components

The system is made up of several key components, including the fuel tank, lines, filter, and carburetor. Each part works together to ensure that the right amount of fuel reaches the engine at the proper time. The filter prevents dirt and debris from entering the system, keeping the fuel clean.

Fuel Delivery Process

Fuel is drawn from the tank and passes through the lines, where it is filtered before entering the carburetor. In the carburetor, it is mixed with air to create the ideal ratio for combustion. This mixture is then fed into the engine, providing the necessary energy for operation.

Efficient Operation of the Weed Trimmer

To ensure optimal performance of your grass-cutting tool, it’s important to follow key principles that enhance its functionality. Understanding the proper use and maintenance of the device will lead to smoother operations, less strain on the engine, and more precise trimming results.

Regular Inspection of the equipment before each use ensures that all components are in working condition, reducing the chance of malfunction. Pay attention to the line feed mechanism and fuel levels, as these can impact the tool’s efficiency.

Another critical aspect is proper handling during operation. Maintaining the right cutting angle and speed will allow you to cover more ground quickly, while also protecting the tool from unnecessary wear and tear.

Finally, keeping the tool clean after each session will prevent debris buildup, ensuring it remains in peak condition over time.

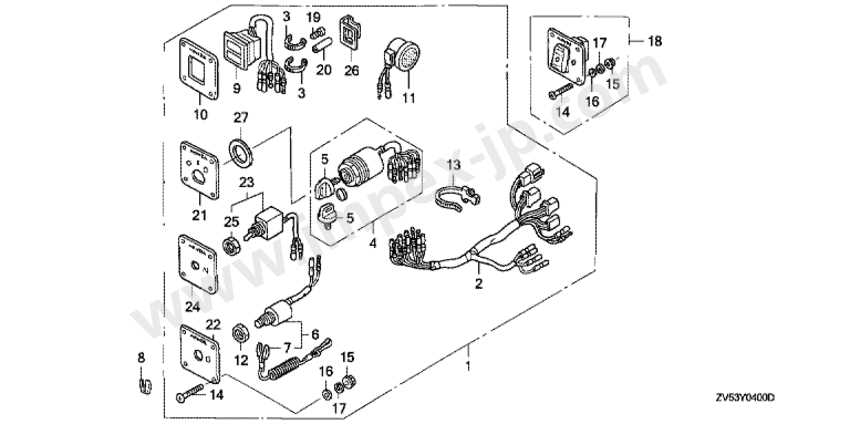

Guide to the Ignition System

The ignition system plays a critical role in ensuring smooth engine operation by generating the necessary spark to ignite the fuel-air mixture. Understanding how this system functions can help maintain and troubleshoot various equipment effectively. This guide will explain the key components involved and their function in the overall process.

Key Components of the Ignition System

At the heart of the system is the spark plug, which receives an electric charge from the ignition coil. The coil amplifies the voltage from the battery, creating the high energy needed to spark the mixture inside the engine. Without this coordinated interaction, the engine would not start or run efficiently.

Common Ignition System Issues

Over time, components like spark plugs can wear out or accumulate carbon buildup, leading to performance problems. Regular inspection and replacement of worn parts are essential for preventing issues such as misfires or hard starts. Keeping the ignition system in good condition ensures reliable performance and prolongs the life of your equipment.

Ensuring a Proper Start Every Time

Achieving a successful ignition of your outdoor equipment is essential for optimal performance and longevity. Whether you’re dealing with garden tools or maintenance devices, understanding the mechanisms involved in starting can make all the difference. This section will explore various strategies and techniques to help you ensure reliable operation every time.

Key Considerations for Starting

Several factors contribute to the efficiency of starting your device. Keeping these elements in mind can help streamline the process:

- Fuel Quality: Always use fresh and clean fuel to prevent starting issues.

- Oil Levels: Ensure that the lubricant levels are adequate and meet the manufacturer’s specifications.

- Air Filter Maintenance: Regularly inspect and clean the air filter to allow for proper airflow.

- Battery Condition: If your device utilizes a battery, check its charge and connections to avoid power failures.

Step-by-Step Starting Procedure

Following a systematic approach can significantly enhance your starting experience. Consider these steps:

- Prepare your equipment by ensuring all components are securely attached and in good condition.

- Fill the tank with appropriate fuel, avoiding overfilling.

- Engage the choke if necessary, depending on the model and environmental conditions.

- Pull the starter cord gently to avoid damage while generating sufficient force.

- After ignition, gradually adjust the choke to allow for smooth operation.

By adhering to these guidelines, you can increase the likelihood of a successful startup and maintain the efficiency of your equipment for years to come.

Maintenance of the Air Filter

Proper upkeep of the air filter is crucial for optimal engine performance and longevity. A clean filter ensures that the engine receives the necessary airflow for efficient operation, preventing potential damage and enhancing fuel efficiency. Regular maintenance not only contributes to better performance but also extends the life of the equipment.

Regular Inspection: It is essential to routinely check the air filter for dirt, debris, and wear. If the filter appears clogged or discolored, it should be cleaned or replaced promptly to maintain proper airflow.

Cleaning Process: To clean the air filter, gently remove it from its housing. Use a soft brush or compressed air to eliminate dust and particles. For more thorough cleaning, wash the filter in warm soapy water, rinse it well, and allow it to dry completely before reinstalling.

Replacement Frequency: Depending on usage conditions, filters may need to be replaced periodically. It is advisable to consult the user manual for specific recommendations on replacement intervals.

Final Checks: After maintenance, ensure that the air filter is securely installed. Regular upkeep will not only enhance performance but also reduce the risk of engine issues, keeping your equipment running smoothly for years to come.

Importance of Clean Air for Performance

Maintaining optimal airflow is crucial for the efficient functioning of small engines. The quality of the air entering the combustion chamber directly impacts the power output and overall effectiveness of the equipment. Clean air ensures that the engine operates smoothly, enhancing its performance and longevity.

Impact on Engine Efficiency

When an engine receives clean air, it operates more efficiently. Contaminants and debris can obstruct airflow, leading to poor combustion and reduced power. A well-maintained air intake system promotes optimal fuel-air mixing, which is essential for maximizing output and minimizing emissions.

Longevity of the Equipment

Engines that are exposed to unclean air are prone to faster wear and tear. Particles can cause damage to internal components, leading to costly repairs or replacements. By ensuring that the air remains free from impurities, the lifespan of the engine can be significantly extended, reducing maintenance costs over time.

| Benefits of Clean Air | Consequences of Dirty Air |

|---|---|

| Improved engine performance | Reduced power output |

| Enhanced fuel efficiency | Increased fuel consumption |

| Lower emissions | Higher environmental impact |

| Extended equipment lifespan | Frequent repairs |

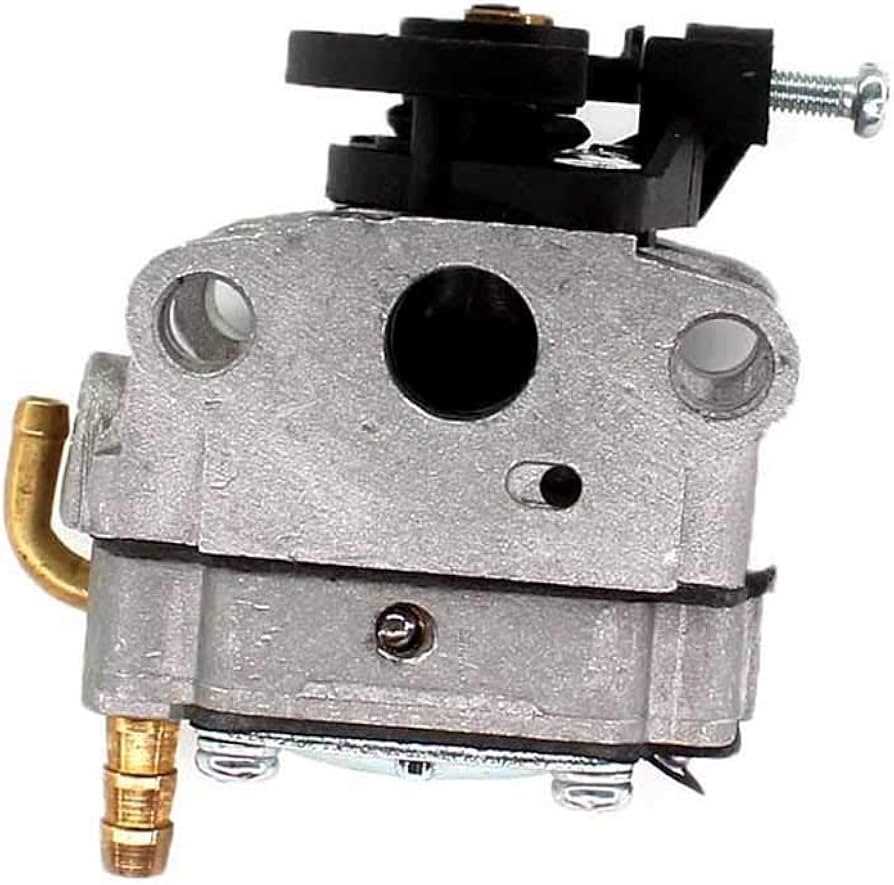

Inspecting and Replacing the Carburetor

Regular examination and replacement of the fuel mixing device is crucial for maintaining the efficiency of small engine machinery. This component is responsible for blending air and fuel in the correct proportions, ensuring optimal performance. Over time, it may accumulate dirt, debris, or become damaged, which can lead to performance issues or starting difficulties.

Steps for Inspection

Begin by safely disconnecting the spark plug to prevent accidental starts. Remove the carburetor from the engine by loosening the screws that hold it in place. Once detached, inspect the exterior for any visible cracks or signs of wear. Additionally, check the internal components for clogs or blockages, especially in the jets and passages. Using a carburetor cleaner can help clear any accumulated residue.

Replacing the Carburetor

If the inspection reveals significant damage or wear, it may be necessary to replace the component. Ensure you obtain a compatible replacement. To install, position the new carburetor in place and secure it with screws. Reattach the fuel lines and make sure all connections are tight to prevent leaks. Finally, reconnect the spark plug and test the equipment to ensure it operates smoothly.

| Inspection Item | Action | Notes |

|---|---|---|

| External Damage | Check for cracks | Replace if any are found |

| Internal Blockages | Clean with carburetor cleaner | Ensure all jets are clear |

| Fuel Connections | Inspect

Improving Fuel Efficiency with a New CarburetorEnhancing fuel efficiency in small engines can significantly reduce operating costs and extend the lifespan of the equipment. One of the most effective methods to achieve this is by upgrading to a more efficient carburetor. A well-designed carburetor optimizes the air-fuel mixture, ensuring the engine runs smoothly and consumes less fuel during operation. When selecting a new carburetor, consider models that offer improved airflow and precise fuel delivery. This can lead to a more complete combustion process, resulting in better performance and lower emissions. Additionally, maintaining proper adjustments and tuning after installation is crucial for maximizing efficiency. Regular maintenance of the carburetor will not only enhance fuel economy but also contribute to the overall reliability of the engine. In summary, investing in a high-quality carburetor can be a game changer for anyone looking to improve their equipment’s fuel efficiency. By ensuring optimal fuel delivery and reducing waste, users can enjoy enhanced performance while minimizing their environmental impact. |