Understanding the structure and configuration of essential elements in lawn maintenance tools can greatly simplify troubleshooting and upkeep. When working with such machinery, knowing how different sections are connected and how each element functions within the larger system is key to ensuring smooth operation.

Whether you’re dealing with mechanical issues or simply performing routine maintenance, having a clear understanding of the placement of key components can make the process much more efficient. Identifying these elements can also help in replacing or adjusting specific areas when necessary.

Proper maintenance and regular checks will not only prolong the life of the equipment but also ensure its consistent performance. Being familiar with the internal layout and recognizing the roles of different components can significantly ease the maintenance process.

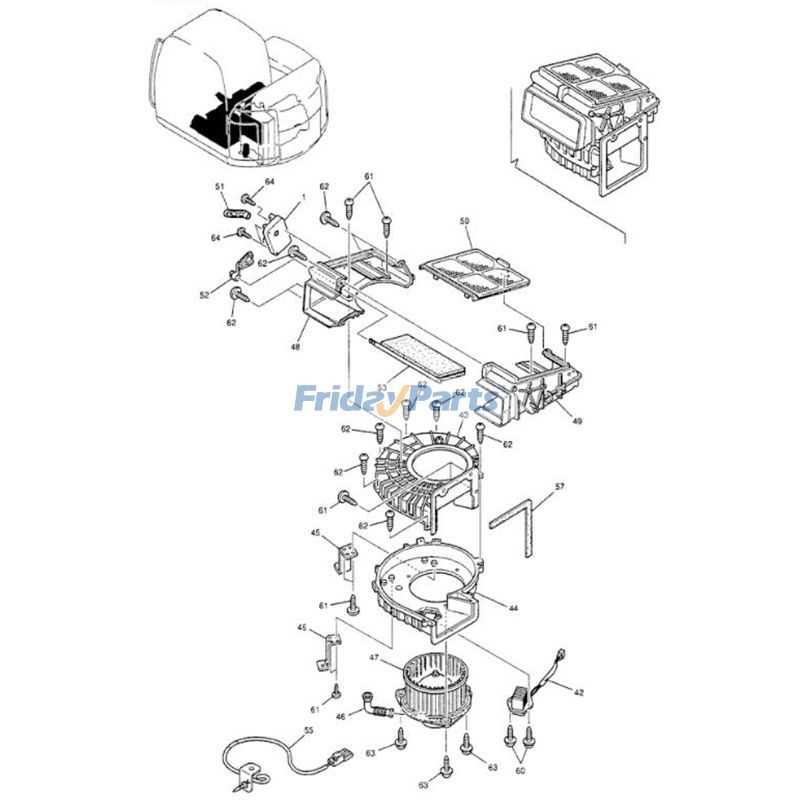

Engine and Transmission System Breakdown

The power and motion system in modern machinery plays a crucial role in ensuring smooth operation. Understanding how energy is transferred and managed within the system is key to maintaining efficiency and prolonging the life of the equipment.

Key Components

The engine and transmission system consists of several critical elements that work together to generate and transfer power. Each part has a specific function that ensures seamless movement and control.

- Power Source: The engine generates the energy needed to drive the system.

- Transmission Gears: These manage speed and torque, ensuring the right balance for various operational conditions.

- Drive Shaft: Transfers the rotational energy from the engine to the transmission.

- Clutch Mechanism: Engages and disengages the transmission to control motion.

Common Issues and

Steering Mechanism and Related Parts

The steering system plays a crucial role in providing precise control over the vehicle, ensuring smooth navigation and maneuverability. The components involved in this system are designed to work together, allowing the operator to steer the vehicle with minimal effort. Proper maintenance of these components is essential for optimal performance and safety.

Main Elements: The key elements of the steering mechanism include linkages, bearings, and various pivots. Each part is responsible for transferring the driver’s input to the wheels, allowing for accurate turning and stability during movement.

Wear and Tear: Over time, the steering components may experience wear due to friction and stress. It is important to regularly inspect and

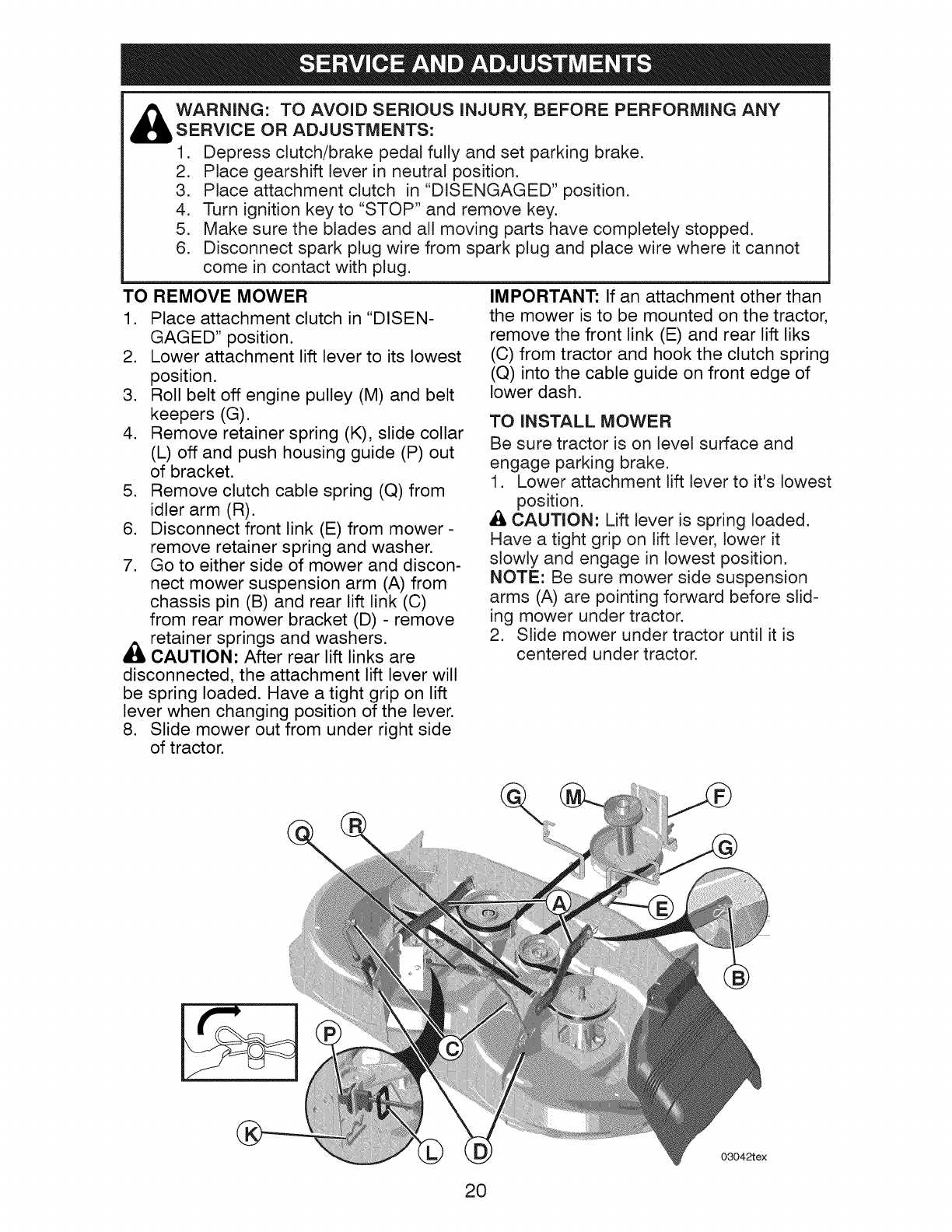

Blade and Cutting Deck Configuration

The setup of the blade and cutting deck is crucial for achieving optimal performance and a clean, even cut. Ensuring proper alignment and maintenance of these components contributes to the machine’s efficiency and extends the lifespan of the equipment. Below, we will cover the key aspects involved in configuring and maintaining the cutting system.

Blade Alignment and Sharpness

A properly aligned and sharp blade is essential for effective mowing. Regular inspection and sharpening prevent uneven cutting, while proper alignment ensures a balanced rotation, reducing strain on the machine.

Cutting Deck

Electrical System and Wiring Details

The electrical system is a crucial part of the machine’s overall functionality. Understanding how the wiring is laid out and connected ensures proper maintenance and troubleshooting when issues arise. In this section, we will look into the key aspects of wiring and how different components are interconnected to supply power where it’s needed.

Main Components

- Battery: Provides power to the entire system, ensuring that the engine and electrical parts function correctly.

- Alternator: Charges the battery while the machine is in use, maintaining a steady flow of power.

- Starter motor: Responsible for turning over the engine to begin operation.

- Ignition switch: Controls the flow of electrical current to various components, including the starter and engine.

Wiring Layout

The wiring connects each component in a specific order

Fuel System Layout and Components

The fuel system is designed to efficiently deliver fuel to the engine, ensuring smooth operation and performance. This section outlines the essential elements involved in the fuel supply process and their arrangement within the machine. Understanding how these components interact can help in maintaining and troubleshooting the system.

Main Components

The fuel system typically includes key elements such as the fuel tank, which stores the fuel, the fuel lines that transport it, and the carburetor or injection system that regulates the flow. Each of these plays a crucial role in the overall function of the system.

Fuel Flow Process

Fuel flows from the tank through the lines, where it’s filtered to remove impurities before reaching the engine. Proper maintenance of this process ensures that the engine receives clean fuel at the correct pressure, contributing to

Seat and Comfort Features Overview

This section provides an insight into the various seating and comfort attributes designed to enhance the user experience. A well-constructed seat is essential for extended periods of use, ensuring both support and relaxation. Features such as adjustable seating positions and ergonomic designs play a crucial role in promoting comfort and reducing fatigue during operation.

| Feature | Description |

|---|---|

| Adjustable Seat | Allows customization of the seat position for optimal comfort based on individual preferences. |

| Ergonomic Design | Designed to provide support to the body, reducing strain and enhancing comfort during use. |

| Padded Armrests | Offers additional support and comfort for the arms, aiding in a more relaxed posture. |

| Suspension System | Helps absorb shocks and vibrations, providing a smoother ride on uneven terrain. |

Tire and Wheel Assembly Guide

Proper assembly of tires and wheels is crucial for optimal performance and safety. This section will provide essential information and steps to ensure that these components are installed correctly and function effectively.

Step-by-Step Assembly Instructions

Begin by gathering all necessary tools and components for the assembly process. Make sure to check that the wheels and tires are compatible with your equipment. Carefully align the tire with the rim, ensuring that it fits snugly. Once aligned, use appropriate fastening techniques to secure the tire in place.

Maintenance Tips

Regular maintenance is vital for extending the lifespan of your tire and wheel assembly. Inspect for any signs of wear or damage, and ensure that the pressure is maintained at the recommended level. Proper care will enhance performance and prevent potential issues during operation.

Maintenance Tips for YT3000 Parts

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent unexpected breakdowns and extends the life of your machinery. Here are some key recommendations to keep in mind.

Regular Inspection: Conduct routine checks on all components to identify any signs of wear or damage. This proactive approach can help catch issues before they escalate.

Cleaning: Keep all surfaces free from dirt and debris. Use a gentle cleaning solution and a soft cloth to wipe down parts, ensuring that no harmful substances accumulate over time.

Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This will reduce friction and prevent premature wear.

Storage: When not in use, store your equipment in a dry, protected area. This minimizes exposure to moisture and other environmental factors that could lead to rust or corrosion.

Replacement: If any part shows significant wear or damage, replace it promptly with a compatible component. Using the correct replacement ensures continued reliability and performance.

By following these maintenance tips, you can ensure your machinery operates smoothly and efficiently, providing you with reliable service for years to come.