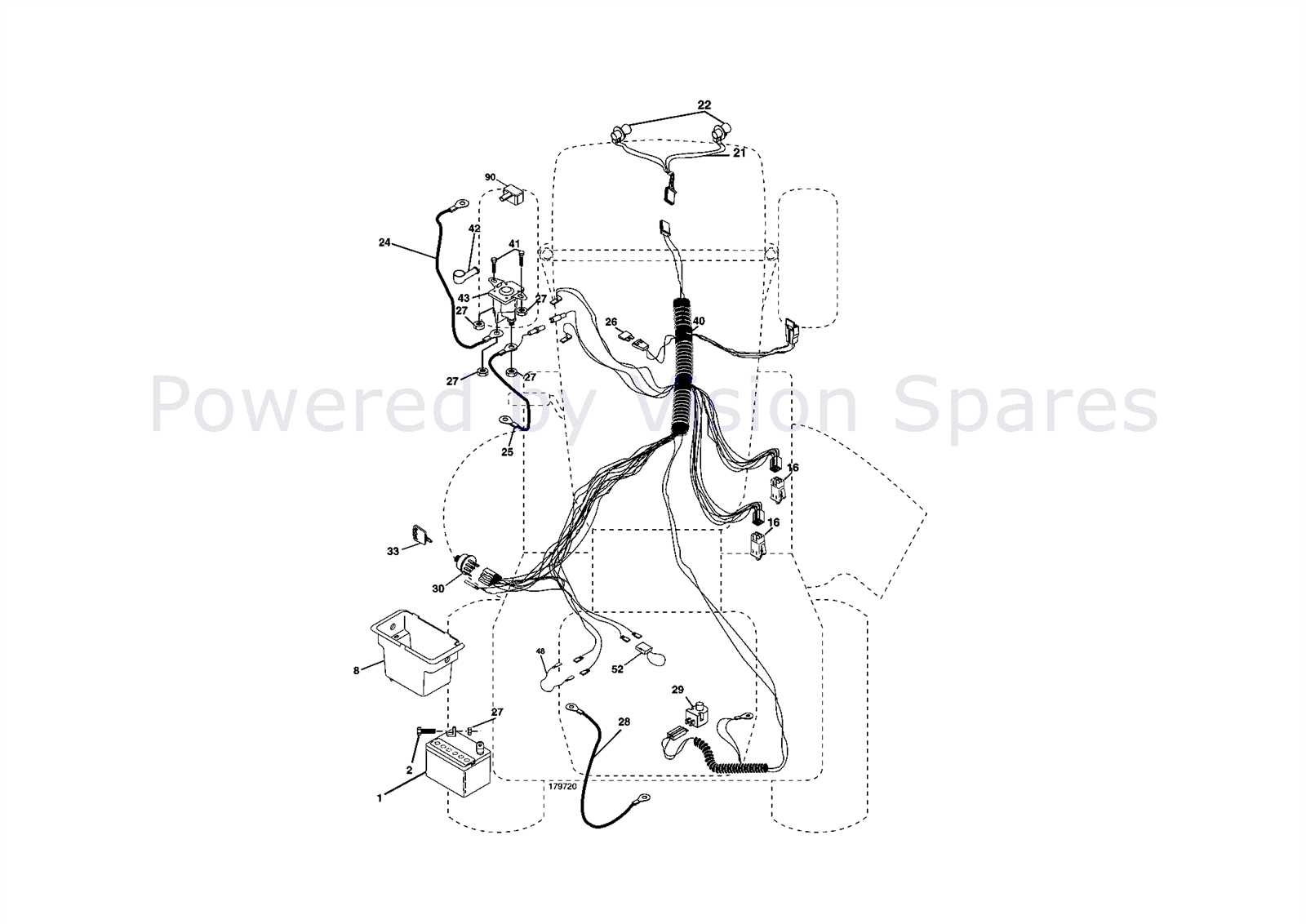

In the realm of outdoor maintenance machines, understanding the intricate layouts of vital components proves essential for any enthusiast or technician. The detailed blueprints unveil the inner workings of these devices, guiding users through the complexities of assembly and repair.

Unveiling these graphical representations of equipment anatomy allows for a deeper grasp of their functionality and interconnections. Each diagram serves as a map, delineating the integration of various parts that harmonize to propel these tools into action.

Through meticulous examination, one can decode the purpose of each element and its contribution to the overall mechanism. These visual aids not only facilitate troubleshooting but also foster a profound appreciation for the engineering marvels that power our outdoor endeavors.

Exploring the Anatomy of the DLT 3000 Equipment Components

In this section, we delve into the intricate details of the components that comprise the DLT 3000 machinery. Our focus lies on dissecting and understanding the internal structure and functioning of these crucial elements, which play a pivotal role in the operational efficiency of the equipment.

Unveiling the Inner Mechanisms

Here, we uncover the internal mechanisms that contribute to the seamless operation of the DLT 3000, highlighting their interconnected roles and functionalities. Each component serves a specific purpose, ensuring optimal performance and durability under various operating conditions.

Emphasizing Structural Integrity

Moreover, we emphasize the importance of structural integrity in these parts, ensuring robustness and reliability throughout their lifespan. Understanding these details provides valuable insights into maintenance and troubleshooting processes, empowering users with the knowledge to effectively manage and optimize equipment performance.

Understanding the Lawn Tractor Parts

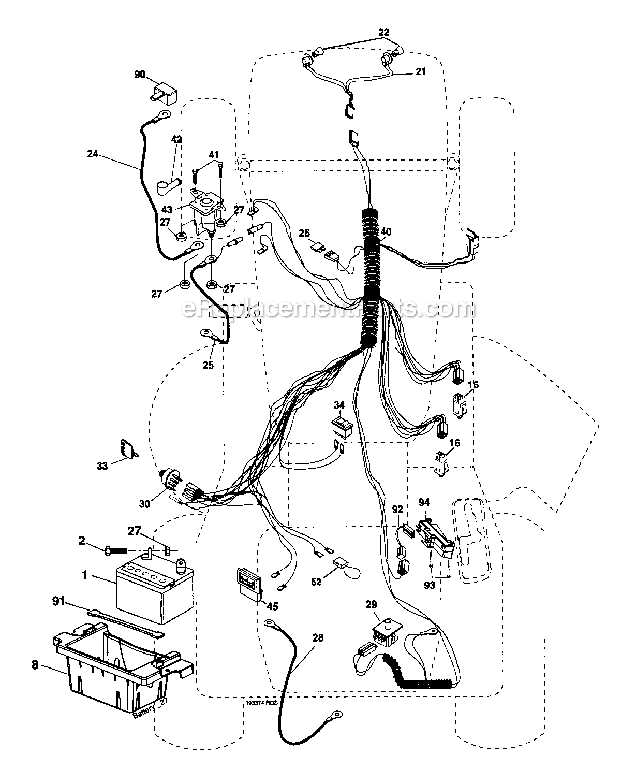

Lawn tractors are essential tools for maintaining large yards, allowing for efficient cutting and trimming of grass. To keep these machines running smoothly, it is important to have a basic understanding of the various components that contribute to their operation. Familiarity with the key elements can help in identifying issues, ensuring proper maintenance, and performing necessary repairs.

Engine and Drive System: The engine powers the tractor, while the drive system transfers this energy to the wheels, enabling movement. Regular inspection and servicing of these components are crucial for optimal performance.

Cutting Mechanism: Th

How to Identify Key Components

Understanding the essential elements of a machine is crucial for effective maintenance and repair. Recognizing these components enables users to troubleshoot issues more efficiently and ensures optimal performance. This guide provides a structured approach to identifying the main parts of your equipment.

Start by familiarizing yourself with the layout and functionality of the device. Here are some steps to help you identify the key components:

- Consult the Manual:

- Locate the user manual that accompanies your equipment.

- Examine the illustrations and descriptions of the various parts.

- Visual Inspection:

- Carefully observe the exterior for labels or markings.

- Take note of any access points that reveal internal components.

- Functionality Testing:

- Power on the device to see which components are actively engaged.

- Listen for sounds or vibrations that may indicate specific parts in operation.

- Research Online:

- Look for forums or websites dedicated to your equipment.

- Seek diagrams or images that can aid in visual identification.

By following these steps, you can develop a clearer understanding of the essential parts that make your device function effectively. This knowledge will empower you to perform maintenance tasks and address issues with confidence.

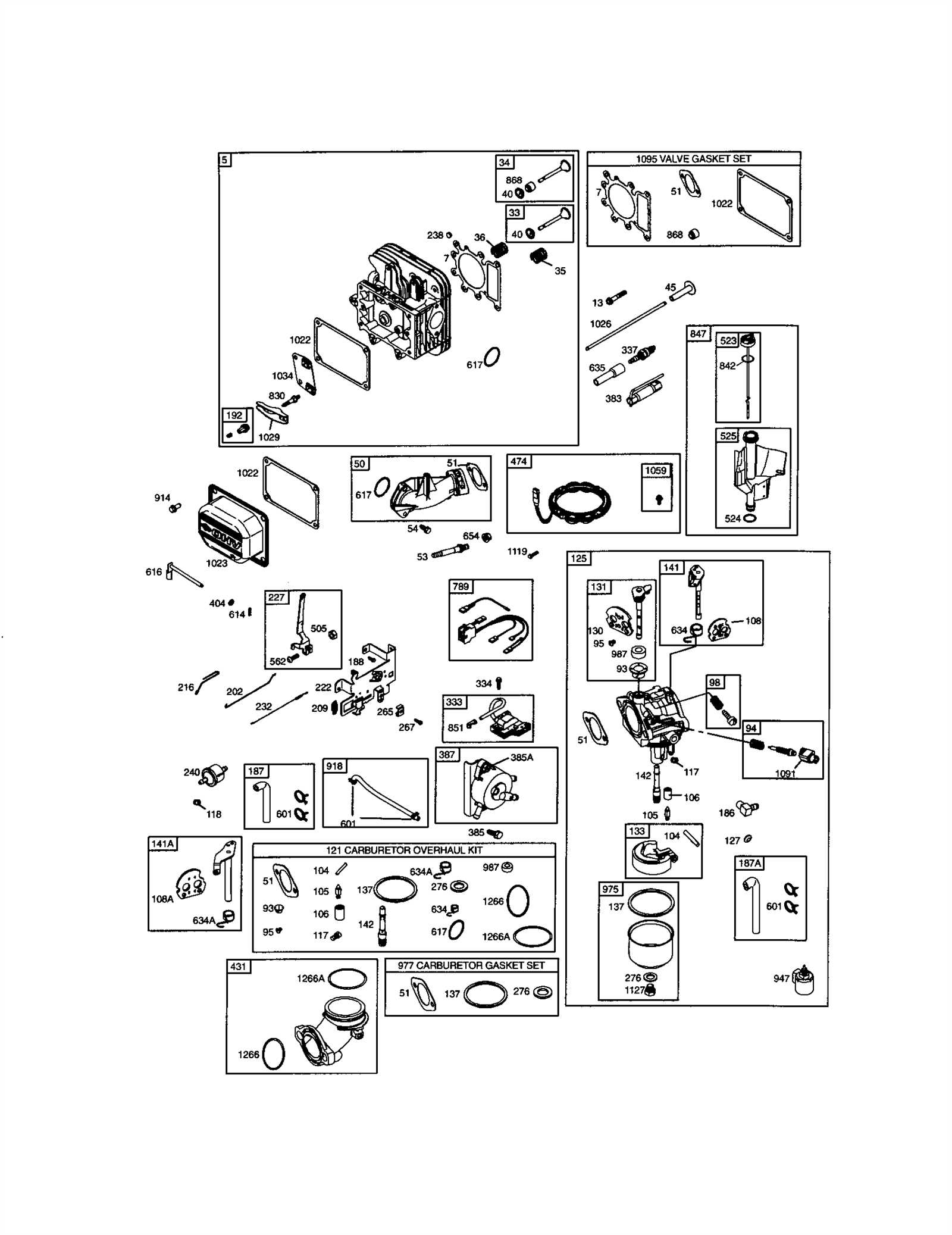

Locating the Engine and Transmission

Understanding the placement of critical components within a machine is essential for maintenance and repair. The engine and transmission serve as the heart and backbone of the system, driving performance and functionality. Their correct positioning ensures optimal operation and ease of access for servicing.

When identifying the locations of these vital elements, it is helpful to consult the assembly layout. The following table provides a brief overview of the typical locations for the engine and transmission in various configurations:

| Component | Common Location |

|---|---|

| Engine | Rear section, aligned with the chassis |

| Transmission | Adjacent to the engine, usually beneath the deck |

Familiarity with the arrangement not only aids in troubleshooting but also facilitates efficient repairs, ensuring that users can keep their equipment running smoothly.

Deck Assembly Breakdown Explained

This section provides a comprehensive overview of the components involved in the construction of a deck assembly. Understanding the various elements is crucial for ensuring optimal performance and longevity. Each part plays a specific role, contributing to the overall functionality and stability of the assembly.

The primary elements include the frame, which serves as the foundation, and the deck itself, providing the surface for operation. Additionally, support brackets enhance structural integrity, while connectors ensure all pieces fit seamlessly together. Identifying these components allows for effective maintenance and troubleshooting, ultimately enhancing user experience.

Moreover, regular inspection of these elements can prevent common issues and prolong the lifespan of the entire system. Knowledge of the assembly process also aids in troubleshooting and repairs, making it easier to address potential problems before they escalate.

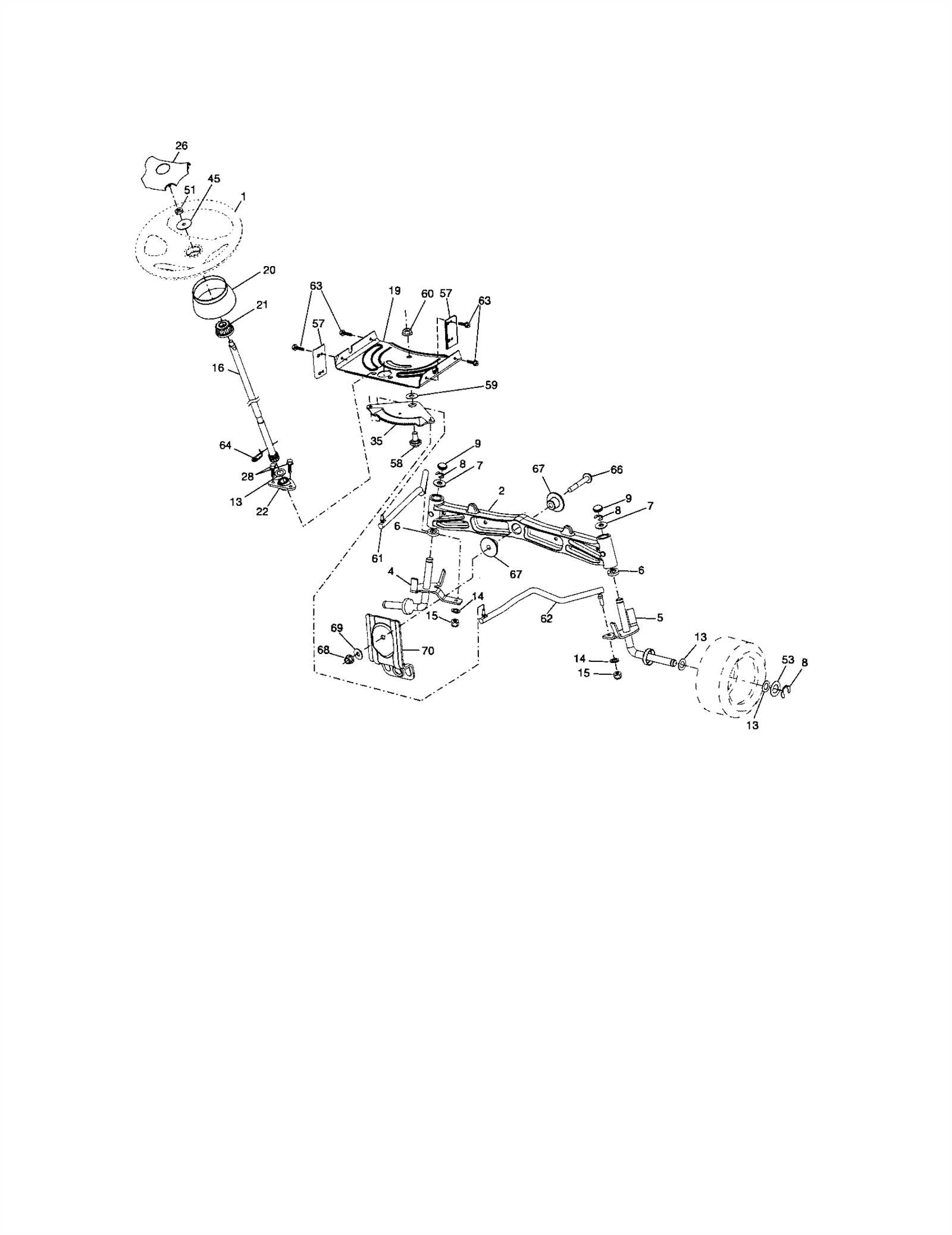

Steering System and Control Layout

The steering mechanism plays a crucial role in ensuring precise maneuverability and operator comfort. Understanding its configuration and the arrangement of controls is essential for effective operation.

| Component | Description |

|---|---|

| Steering Wheel | The primary interface for directional control, allowing for smooth navigation. |

| Throttle Control | Regulates engine speed, providing responsiveness to steering inputs. |

| Brake Pedal | Engages the braking system, essential for stopping or slowing down effectively. |

| Gear Selector | Enables the operator to shift between various operational modes. |

| Indicator Lights | Provides visual feedback on system status and alerts the operator to necessary actions. |

Comprehending the layout of these controls facilitates better handling and enhances safety during operation.

Inspecting the Cutting Blades Area

Regular examination of the cutting implement zone is essential for maintaining optimal performance and ensuring safety. This process involves checking for wear, damage, and proper alignment to prevent operational issues that could lead to inefficient cutting or potential hazards.

Visual Inspection

Begin by visually inspecting the blades for any signs of dullness, chips, or cracks. A thorough look can reveal issues that may not be immediately apparent but could significantly affect functionality.

Functional Checks

After visual assessment, perform functional checks by engaging the blades. Listen for unusual sounds and observe the cutting action to ensure smooth operation. Address any irregularities promptly to maintain the overall efficiency of the machinery.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular upkeep and attention. Proper maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By following a systematic approach, you can keep your tools in optimal condition and avoid costly repairs.

Regular Cleaning

Keeping your machinery clean is essential for efficient operation. Dust, debris, and other contaminants can affect performance and lead to premature wear. Here are some cleaning tips:

- Wipe down surfaces after each use to remove dirt and grime.

- Use compressed air to blow out hard-to-reach areas.

- Inspect and clean filters regularly to ensure proper airflow.

Scheduled Inspections

Conducting periodic inspections helps identify potential issues before they escalate. Create a maintenance schedule to stay on track:

- Check belts and hoses for signs of wear and tear.

- Inspect electrical connections for corrosion or damage.

- Lubricate moving parts to prevent friction-related damage.

Finding Replacement Parts Easily

Locating suitable components for your tools can be a straightforward process with the right approach. Understanding where to search and how to navigate available resources will save time and ensure that you find exactly what you need.

Start by identifying the specific model and features of your equipment. This information is crucial for narrowing down options and ensures compatibility with the item you wish to repair or enhance. Once you have this data, you can proceed to various platforms that offer replacement components.

Consider using the following resources:

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | The official site often has a dedicated section for replacement items, complete with model numbers and installation guides. |

| Online Retailers | Large e-commerce platforms provide extensive catalogs and user reviews, helping you make informed decisions. |

| Local Hardware Stores | Physical stores may have knowledgeable staff who can assist in finding the correct components for your needs. |

| Forums and Communities | Online discussion groups often share insights and recommendations for sourcing parts effectively. |

By utilizing these resources, you can simplify the process of sourcing replacements and ensure your tools remain in optimal working condition.