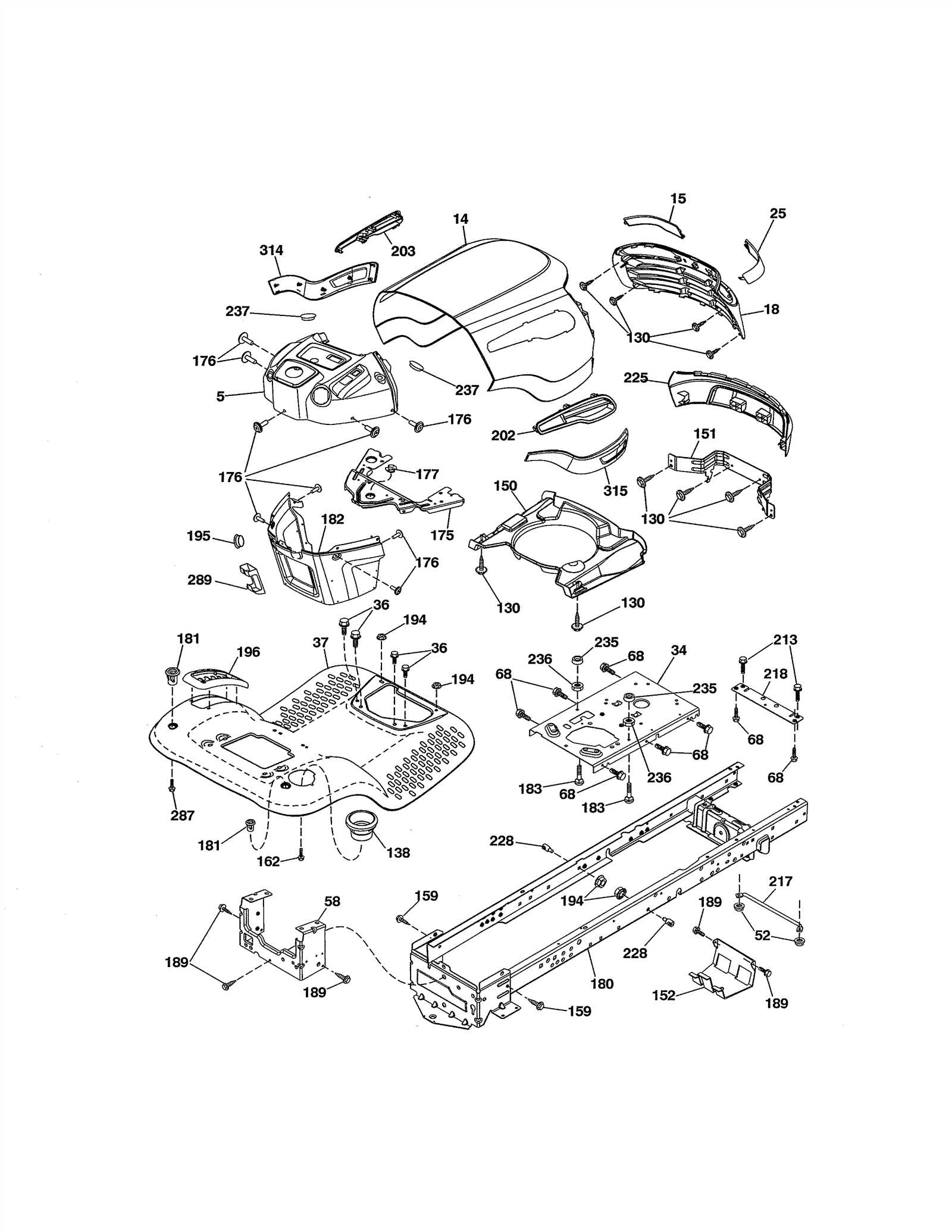

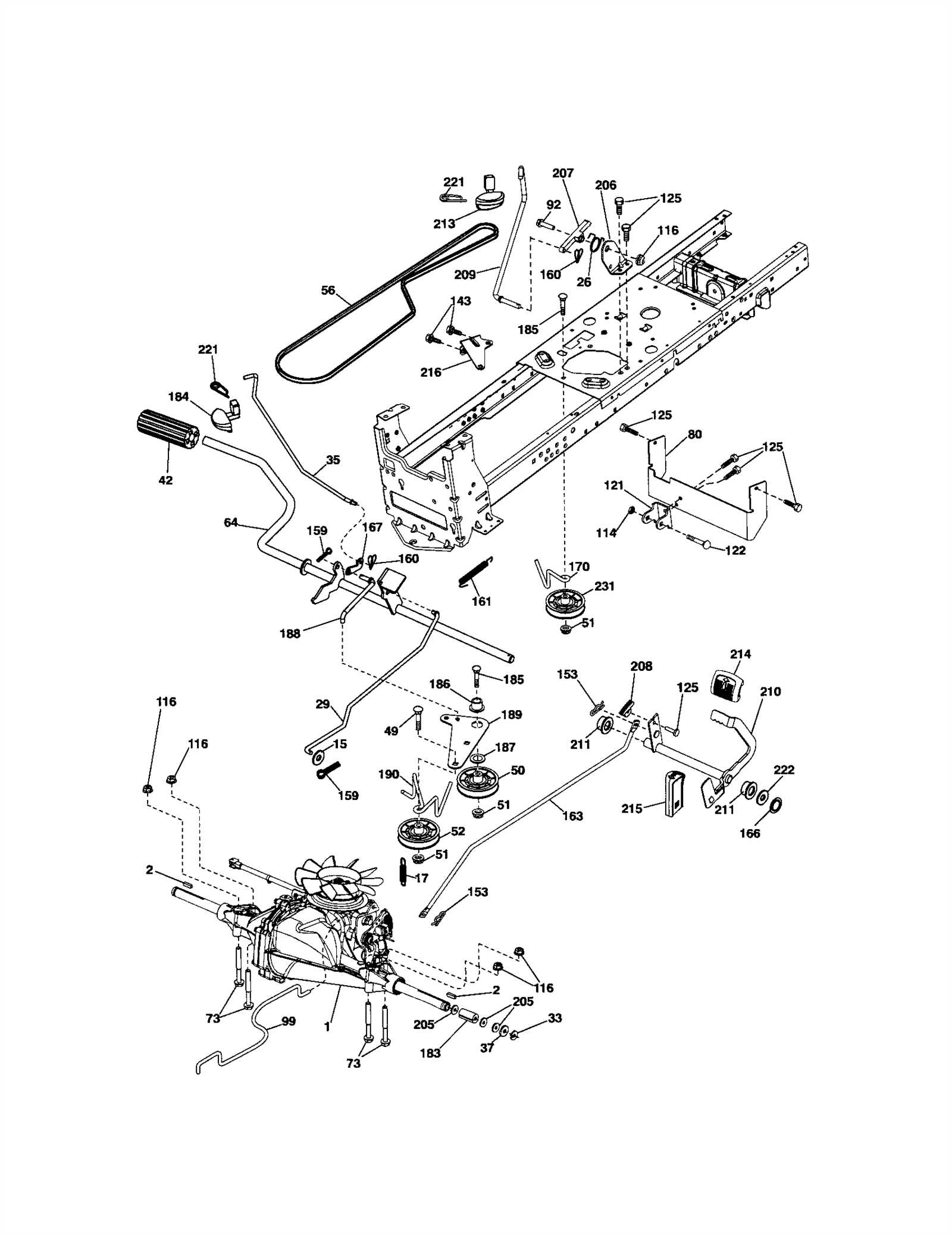

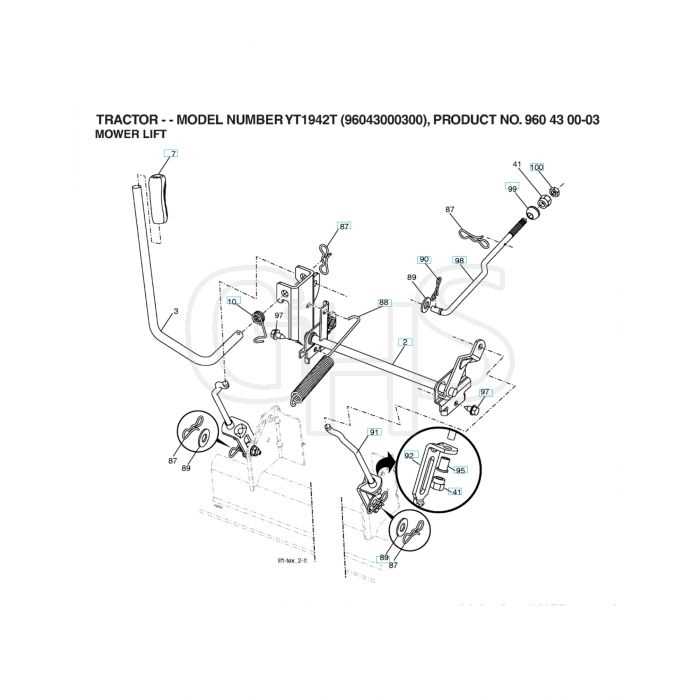

When it comes to maintaining a lawn mower, having a clear visual representation of its elements can significantly enhance your repair and upkeep process. This resource serves as a comprehensive guide to the various components of a popular mowing machine model, allowing users to identify and understand each part’s function and location.

Familiarity with the machine’s structure is essential for anyone looking to troubleshoot issues or perform routine maintenance. By studying the layout of these components, users can gain insights into how different elements work together to ensure optimal performance. Whether you’re a seasoned mechanic or a DIY enthusiast, this visual reference will aid in navigating the complexities of your equipment.

Additionally, knowing the specific roles of each section can empower users to make informed decisions when it comes to repairs or replacements. Understanding what you’re working with is key to achieving a well-functioning device that meets your gardening needs efficiently. With this guide, you’ll be equipped to tackle any challenges that may arise with your mowing machine.

Understanding the Craftsman YTS3000

This section aims to provide a comprehensive overview of a specific lawn care machine, emphasizing its components and functionality. By examining its features and design, users can gain valuable insights into how this equipment operates effectively in various gardening tasks.

Familiarizing oneself with the essential elements of this machinery allows operators to enhance their maintenance practices. Each component plays a vital role, contributing to the ultimate performance of the equipment.

Furthermore, analyzing the various sections of the machine helps identify potential issues, ensuring a smoother operation and longer lifespan. Understanding the intricacies of its construction empowers users to make informed decisions during upkeep and repairs.

Key Features of YTS3000 Model

This model stands out due to its exceptional functionality and robust design, making it a favorite among users seeking reliability and efficiency. A blend of innovative technology and user-friendly features ensures that it meets the demands of various tasks with ease.

Robust Performance

One of the most notable attributes is its impressive operational capability. This unit is engineered to deliver consistent power output, allowing users to tackle even the most challenging projects without interruption. The advanced mechanism ensures smooth functionality, enhancing overall productivity.

User-Centric Design

Designed with the end-user in mind, this model boasts intuitive controls that simplify operation. Features such as an ergonomic handle and adjustable settings contribute to a comfortable user experience. Furthermore, the compact size facilitates easy storage and transport, making it a practical choice for both professionals and hobbyists alike.

In summary, this model offers a remarkable combination of power and usability, ensuring it remains a top choice for a variety of applications.

Common Issues and Solutions

Understanding frequent challenges that arise with machinery can greatly enhance its longevity and performance. By recognizing these common problems and implementing effective solutions, users can ensure a smoother operation and reduce downtime.

Engine Starting Difficulties

Problem: A machine may struggle to start due to various factors, including fuel issues or electrical failures.

Solution: First, check the fuel level and quality. If the fuel is stale, replace it with fresh fuel. Additionally, inspect the battery connections and replace any corroded cables.

Unusual Noises During Operation

Problem: Strange sounds can indicate underlying issues, such as loose components or mechanical wear.

Solution: Carefully examine all parts for looseness or damage. Tighten any loose bolts and consider lubricating moving parts to minimize friction. If the issue persists, consult a professional for further assessment.

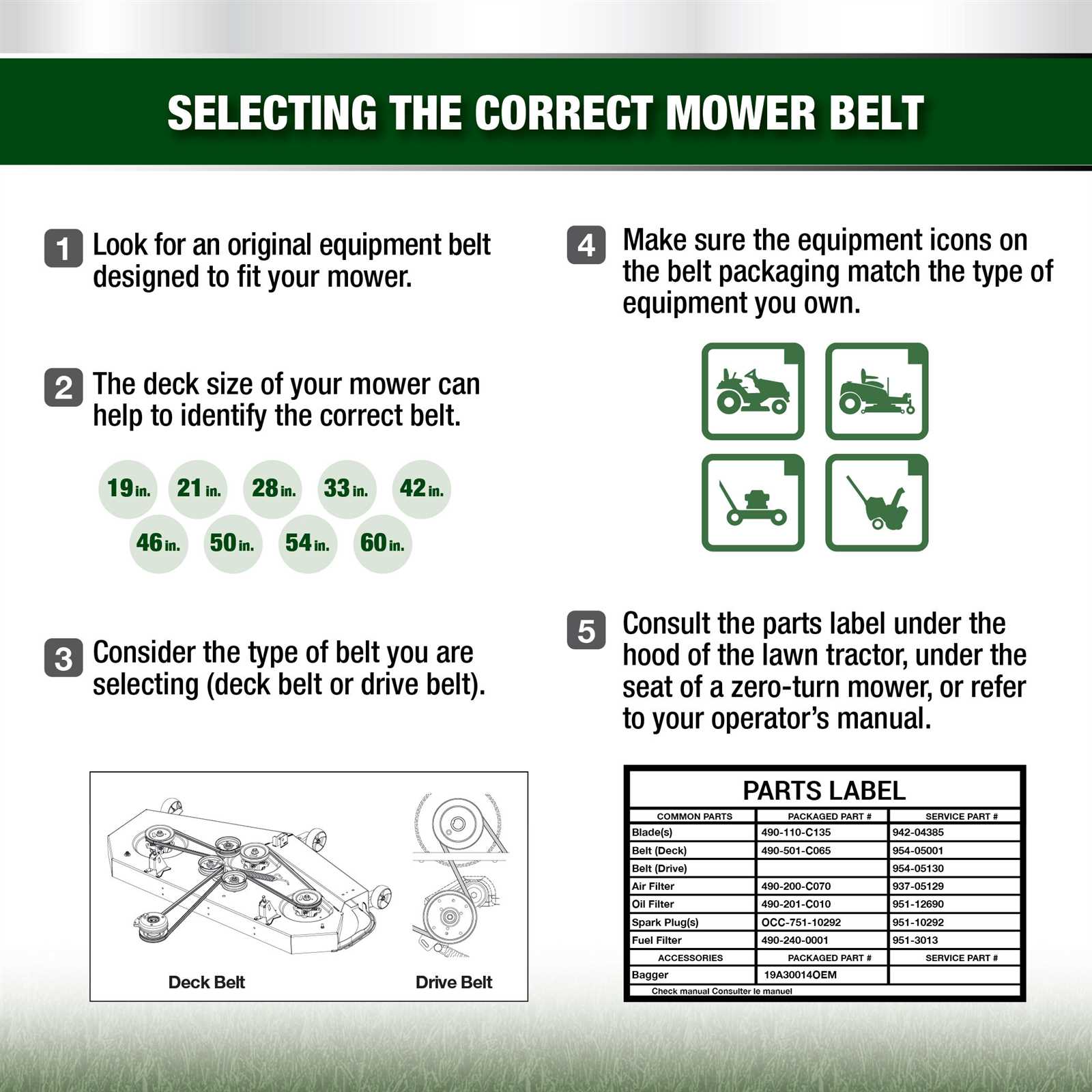

Parts Availability and Sourcing

Ensuring the accessibility of components is crucial for effective maintenance and repair. Availability can significantly influence the overall functionality and longevity of equipment. Understanding where to find these essential elements helps users keep their machines running smoothly without unnecessary downtime.

Reliable Sources

When searching for replacement items, it’s vital to consider various reliable sources. Authorized dealers often provide genuine components, ensuring quality and compatibility. Additionally, online marketplaces offer a wide range of options, including aftermarket alternatives that may suit budget-conscious individuals. It’s advisable to verify the reputation of the seller to ensure a satisfactory purchasing experience.

Local vs. Online Options

Local hardware stores can be an excellent starting point for immediate needs, providing the advantage of direct inspection before purchase. However, for hard-to-find elements, online resources can expand choices significantly. Many websites specialize in hard-to-source items, often featuring customer reviews and detailed specifications to assist in making informed decisions.

In conclusion, understanding where to source components effectively can enhance the maintenance process and ensure that equipment remains in peak condition for years to come. Prioritizing quality and reliability during the selection process will ultimately contribute to a more efficient and satisfying experience.

Step-by-Step Assembly Guide

This section provides a comprehensive walkthrough for piecing together your equipment efficiently. Following these instructions will help ensure that every component fits perfectly, contributing to optimal performance.

Preparation

Before starting, gather all necessary tools and components. Familiarize yourself with each piece to facilitate a smoother assembly process. Read through the instructions carefully to understand the sequence of assembly.

Assembly Process

Begin by attaching the main body to the chassis, ensuring all connectors align properly. Next, secure each section with the appropriate fasteners, checking for stability as you progress. Once the primary structure is complete, proceed to install additional features, double-checking each connection for accuracy.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. A proactive maintenance routine not only enhances functionality but also extends the lifespan of your tools. Here are some essential practices to help you achieve this goal.

Regular Cleaning: Keeping your machinery clean is fundamental. Dust, debris, and grime can accumulate and lead to malfunctions. After each use, take a moment to wipe down surfaces and remove any build-up.

Lubrication: Proper lubrication is crucial for moving parts. Use appropriate oils or greases as specified in the manual. Regularly lubricating components helps reduce friction and wear, ensuring smooth operation.

Inspection: Frequently check for signs of wear or damage. Look for cracks, rust, or loose connections. Addressing these issues promptly can prevent larger problems in the future.

Storage: When not in use, store your equipment in a dry, protected area. Avoid exposure to harsh weather conditions which can lead to deterioration. Use covers or cases to shield against dust and moisture.

Professional Servicing: Consider periodic professional inspections. Experts can identify potential issues that may not be immediately apparent and provide necessary repairs or adjustments to maintain optimal performance.

By implementing these maintenance strategies, you can ensure that your tools remain reliable and efficient for years to come.

Upgrading Components for Better Performance

Enhancing machinery often involves replacing or improving specific elements to boost overall efficiency and effectiveness. By focusing on key components, users can experience significant gains in productivity and durability, ultimately leading to a more satisfying experience with their equipment.

Selecting High-Quality Alternatives

Choosing superior alternatives can make a remarkable difference. Investing in premium materials and innovative designs ensures longevity and reliability, helping to prevent frequent breakdowns and maintenance issues.

Customization allows for tailored upgrades that align with specific needs. By analyzing performance metrics and understanding individual requirements, one can select modifications that elevate the functionality of their machinery.

Comparing YTS3000 with Other Models

This section explores the distinctions between a specific model and its counterparts, focusing on performance, features, and user satisfaction. Understanding these differences can guide potential buyers in making informed decisions based on their needs.

Performance Analysis

- Power output comparison

- Efficiency ratings

- Durability in various conditions

Feature Set Overview

- Unique functionalities

- Ergonomic design elements

- Technological advancements

By examining these aspects, users can identify which model aligns best with their requirements and preferences.

User Experiences and Testimonials

This section captures the voices of individuals who have engaged with their machinery and equipment, sharing insights into their journeys. By exploring their feedback, potential users can gain valuable perspectives on performance, reliability, and ease of use.

Many users express satisfaction with the functionality and durability of their tools. One user noted, “After using my machine for several seasons, I can confidently say it’s been a reliable companion. It handles various tasks effortlessly, and maintenance is straightforward.” This sentiment reflects a common theme among those who prioritize longevity and usability.

Another testimonial highlights the importance of customer support. “I had a minor issue and reached out for assistance. The response was prompt and helpful, ensuring that I was back to work in no time.” Such experiences underline the significance of a supportive service network in enhancing user confidence and satisfaction.

Additionally, users appreciate the accessibility of replacement components, making repairs and upgrades manageable. As one enthusiast shared, “Finding the right parts is crucial, and the availability makes it easy to keep everything in top shape.” This ease of access contributes to a positive overall experience.