The inner workings of lawn maintenance machinery can often seem complex, yet understanding their composition is crucial for effective upkeep. This section aims to explore the intricate elements that make up these machines, offering insights into their functionality and maintenance.

Familiarizing oneself with these components not only enhances the ability to troubleshoot issues but also empowers users to perform necessary repairs. Each segment plays a vital role in the overall performance, contributing to the ultimate efficiency of the equipment.

By examining these elements closely, enthusiasts and professionals alike can delve deeper into the mechanics, leading to improved longevity and reliability of their tools. This knowledge is invaluable for anyone dedicated to maintaining a pristine outdoor space.

Understanding Craftsman Zero-Turn Mowers

The modern mowing equipment designed for efficiency and maneuverability has transformed the way we maintain our lawns. These machines offer enhanced control, allowing users to navigate tight spaces with ease while achieving a professional-quality cut. Understanding the components and mechanisms of this innovative machinery is crucial for effective operation and maintenance.

At the heart of this equipment lies a robust engine system, providing the necessary power to handle various terrains. Coupled with an advanced transmission, these machines ensure swift and precise movements, making them ideal for both residential and commercial use. Regular maintenance of these systems is essential for longevity and optimal performance.

Additionally, the cutting deck is engineered for efficiency, featuring sharp blades that create a clean cut. Users can customize the height settings to achieve the desired grass length, which is vital for lawn health. Understanding the different adjustments and care routines for the cutting deck can significantly enhance the overall performance of the equipment.

Lastly, familiarity with the control features and safety mechanisms is imperative. These machines often include intuitive steering and safety options designed to protect users during operation. By mastering these aspects, operators can maximize their mowing experience while ensuring safety on the job.

Essential Components of Zero-Turn Mowers

The effective operation of a specialized lawn care machine relies on a variety of key elements, each serving a distinct purpose to ensure optimal performance. Understanding these fundamental components is crucial for maintenance, troubleshooting, and enhancing the overall efficiency of the equipment.

Engine: The heart of any mowing apparatus, the engine provides the necessary power to drive the blades and propel the unit forward. A reliable engine is vital for achieving the desired cutting speed and efficiency.

Transmission: This mechanism transfers power from the engine to the wheels. An efficient transmission allows for smooth maneuverability, enabling quick turns and precise movements in tight spaces.

Deck: The cutting deck houses the blades and determines the width of the mowing path. A well-designed deck ensures an even cut and can influence the machine’s overall cutting ability.

Blades: Sharp and durable blades are essential for achieving a clean and even cut. Regular maintenance and replacement are necessary to maintain their effectiveness and prolong the lifespan of the machine.

Wheels: The size and type of wheels affect traction and stability. Properly sized wheels provide better control, especially on uneven terrain, enhancing the overall user experience.

Controls: User-friendly controls allow for precise adjustments in speed and direction, making operation intuitive. Ergonomic designs enhance comfort during extended use.

Each of these components plays a pivotal role in the functionality and performance of the machine. A thorough understanding of these elements empowers users to maintain their equipment effectively and address any issues that may arise during operation.

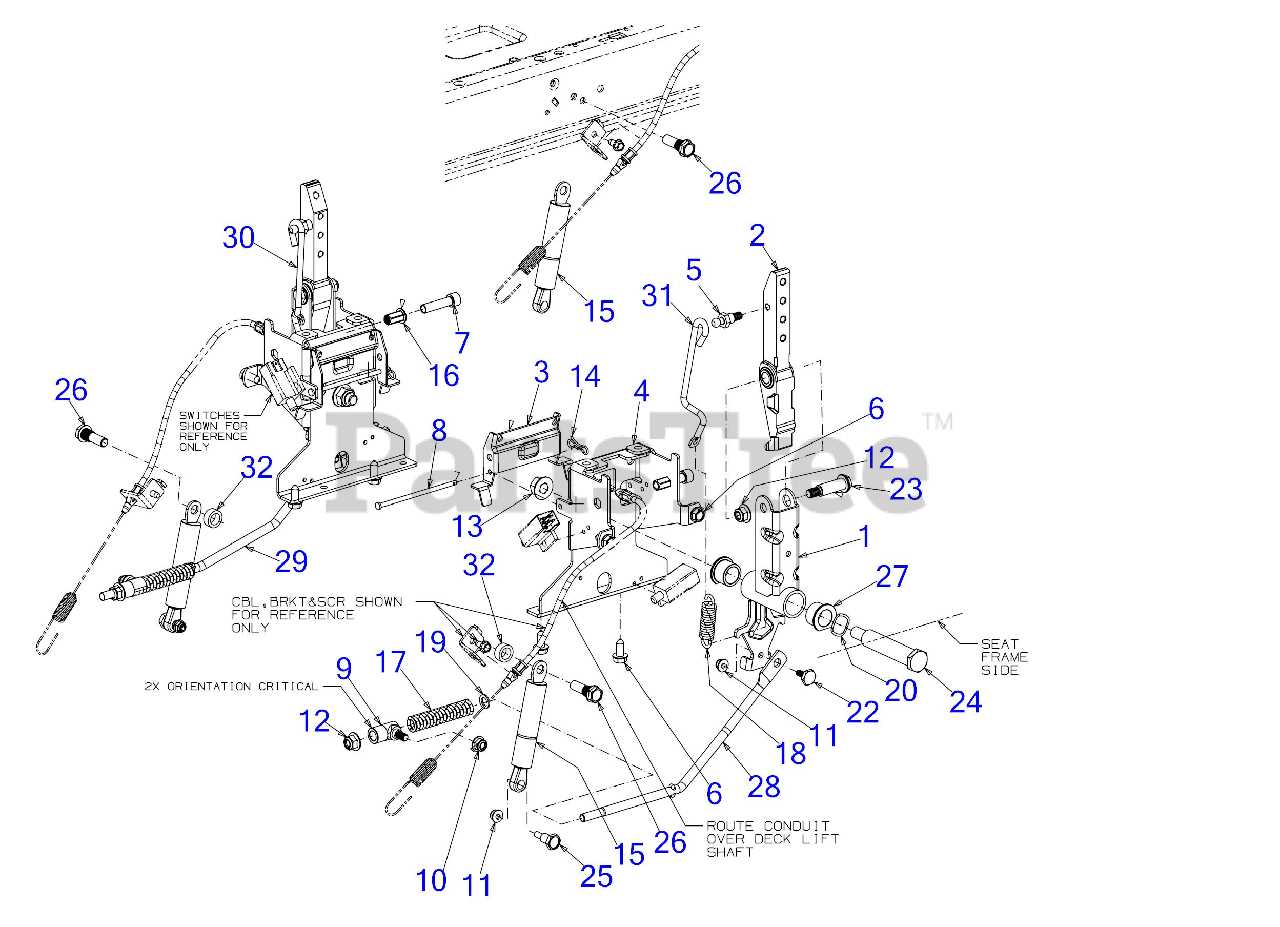

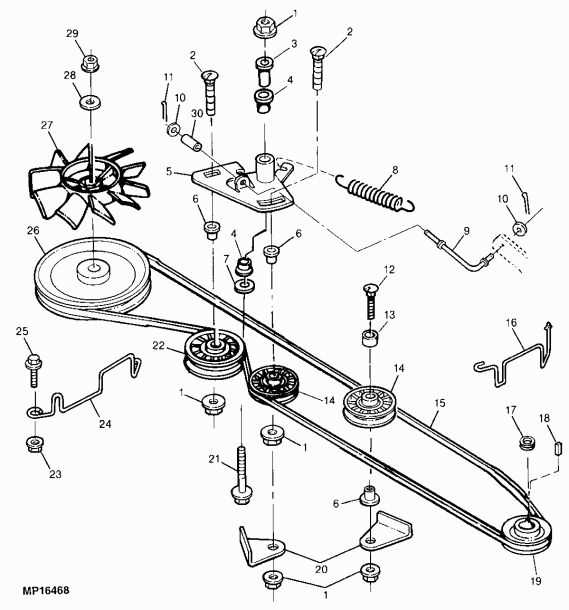

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs. These visual representations provide detailed information about the components and their arrangement, enabling users to identify and source the necessary elements for their equipment. Familiarity with this type of graphic can greatly enhance your ability to troubleshoot and execute repairs efficiently.

Identify the Components: Start by examining each labeled section. Each part is typically accompanied by a reference number, which corresponds to a list that includes descriptions and specifications. This will help you to recognize the various elements and their functions within the whole system.

Follow the Connections: Pay attention to how the components are interconnected. Arrows or lines may indicate relationships or the flow of operation. Understanding these connections can assist in diagnosing issues or determining the sequence of assembly.

Consult the Key: Most illustrations include a key or legend that explains the symbols and notation used. Familiarizing yourself with this information is crucial, as it clarifies any ambiguous elements in the graphic.

Use the Information: Once you grasp the layout and meaning of the illustration, use it as a reference while performing maintenance tasks. This resource can guide you in selecting the right items when ordering replacements or making modifications.

By mastering the interpretation of these visuals, you can significantly streamline your repair processes and ensure your equipment remains in optimal working condition.

Common Issues with Craftsman Mowers

Lawn maintenance equipment is essential for keeping your outdoor spaces tidy and well-kept. However, various challenges can arise with these machines, affecting their performance and longevity. Understanding typical problems can help users troubleshoot effectively and maintain their equipment better.

Frequent Problems Encountered

- Engine Starting Issues:

- Dead battery

- Clogged fuel lines

- Faulty spark plugs

- Cut Quality Problems:

- Dull blades

- Incorrect cutting height

- Uneven tire pressure

- Overheating:

- Low oil levels

- Clogged air filters

- Blocked cooling fins

Maintenance Tips

- Regularly check and replace the oil.

- Sharpen or replace the cutting blades as needed.

- Inspect the air filter and clean or replace it periodically.

- Ensure the fuel system is clear and functioning properly.

By addressing these common issues and following maintenance guidelines, users can enhance the performance and lifespan of their lawn care machines.

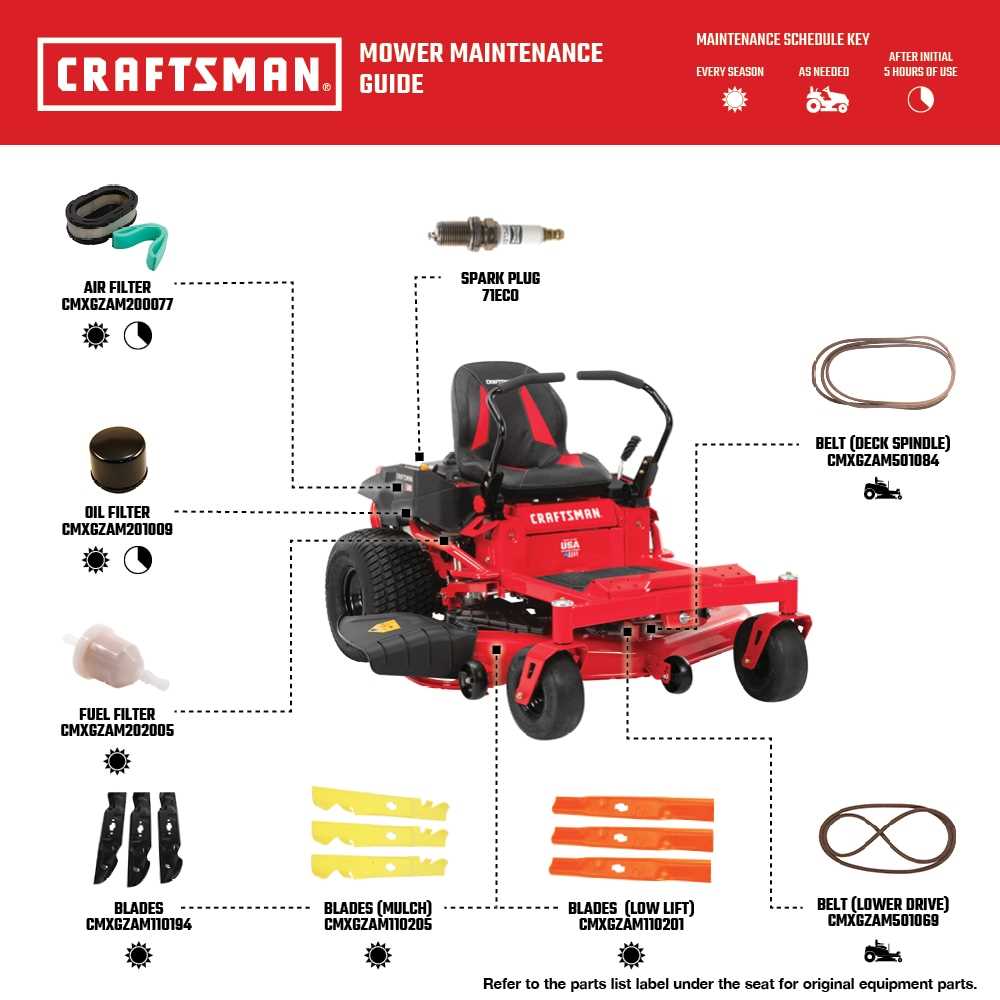

Identifying Replacement Parts Easily

Understanding how to locate and identify necessary components can significantly enhance the maintenance of your equipment. A clear approach to distinguishing the correct elements will not only save time but also ensure the longevity and performance of your machinery. By familiarizing yourself with the specific terminology and references, you can streamline the process of finding what you need.

Start by consulting the manufacturer’s documentation, which often includes detailed visuals and descriptions. These resources typically highlight the different sections and elements, making it easier to pinpoint what requires attention. Additionally, leveraging online forums and community discussions can provide insights and advice from experienced users who may have faced similar challenges.

Using reference numbers can also facilitate identification. When looking for a replacement, having the original code at hand allows you to quickly cross-reference and verify compatibility with the required item. It’s advisable to create a list of common components to keep track of their specifications and availability.

Lastly, consider reaching out to customer support from the retailer or manufacturer. They often possess valuable expertise and can assist in ensuring you acquire the correct replacements. This combined approach will help you navigate the process with confidence and efficiency.

Benefits of Using OEM Parts

Opting for original manufacturer components offers several advantages that enhance performance and longevity. These elements are specifically designed to fit and function seamlessly within the equipment, ensuring reliability and optimal operation.

- Quality Assurance: Original items undergo rigorous testing to meet high standards.

- Perfect Compatibility: Designed for specific models, they guarantee a precise fit.

- Longevity: Built from durable materials, they often outlast aftermarket alternatives.

- Warranty Protection: Using genuine parts usually maintains warranty coverage.

- Resale Value: Maintaining equipment with original components can enhance its market value.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor machinery requires regular upkeep and attention to detail. Implementing a consistent maintenance routine can significantly extend the lifespan of your equipment and enhance its performance.

Here are essential maintenance tips to keep your machine in optimal condition:

- Regular Inspections: Check for wear and tear on all components. Look for loose bolts, worn belts, and signs of rust.

- Cleanliness: Keep the exterior and undercarriage clean. Debris buildup can lead to overheating and mechanical failure.

- Oil Changes: Change the oil at recommended intervals to ensure smooth operation. This helps in reducing friction and preventing engine damage.

- Air Filter Maintenance: Inspect and replace the air filter as needed. A clean filter promotes better airflow and engine efficiency.

In addition to these tips, consider the following recommendations:

- Blade Care: Sharpen blades regularly to ensure a clean cut. Dull blades can stress the engine and affect performance.

- Tire Maintenance: Check tire pressure frequently. Properly inflated tires enhance stability and handling.

- Fuel Quality: Use fresh fuel and add a stabilizer if storing the equipment for an extended period. This prevents fuel degradation.

- Winter Storage: Prepare the machine for winter by cleaning it thoroughly, draining the fuel, and storing it in a dry location.

By following these maintenance practices, you can enjoy reliable operation and extend the life of your outdoor equipment for many seasons to come.

DIY Repairs for Zero-Turn Mowers

Maintaining and repairing your mower can save you time and money while ensuring optimal performance. Tackling minor issues on your own not only enhances your skills but also extends the life of your machine. This guide will walk you through common fixes and preventative measures that you can easily manage at home.

Before starting any repairs, it’s important to gather the necessary tools and materials. This will streamline the process and help you stay organized. Below is a simple table of essential tools and their purposes:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts |

| Screwdrivers | For adjusting or removing screws |

| Pliers | For gripping and manipulating components |

| Oil Filter Wrench | For changing oil filters |

| Jack Stands | For safely lifting the mower |

Regular inspections are crucial for identifying potential issues early. Common areas to check include the blades, belts, and battery connections. Keeping these components in good condition can prevent more serious repairs down the line.

In summary, by equipping yourself with the right tools and knowledge, you can confidently address many common issues. This proactive approach will ensure your equipment runs smoothly, providing reliable service for years to come.

Where to Purchase Replacement Parts

Finding quality components for your equipment can significantly enhance its performance and longevity. Various options are available to ensure you have access to reliable replacements when needed.

Authorized Dealers

Visiting certified retailers is often the best way to obtain genuine components. These locations guarantee authenticity and typically offer a selection of high-quality items that match your machine’s specifications.

Online Marketplaces

Exploring e-commerce platforms can provide a wide range of alternatives. Websites that specialize in machinery supplies often have competitive prices and user reviews, helping you make informed decisions. Be sure to verify the seller’s reputation for a secure purchase.