The intricate design of a widely-used garden device plays a crucial role in its performance and reliability. Understanding its structure is essential for effective maintenance and optimal functionality. This section aims to provide a comprehensive overview of the various elements that make up this essential machinery.

By examining the layout of these individual components, users can enhance their familiarity with the equipment and ensure proper care. Such knowledge not only extends the lifespan of the tool but also empowers users to tackle minor repairs confidently.

Ultimately, gaining insight into the assembly of this equipment will enrich the user experience, allowing for a more informed approach to gardening tasks. With this foundational understanding, one can delve deeper into specific functionalities and troubleshooting techniques.

Understanding Stihl FS 38 Components

Familiarizing oneself with the various elements of a grass trimmer is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring optimal performance, and understanding their functions can enhance the overall user experience.

Key Elements of the Grass Trimmer

- Engine: The heart of the device, responsible for powering the machine.

- Cutting Head: This part houses the line or blade that performs the trimming.

- Handle: Provides control and comfort during operation.

- Shaft: Connects the engine to the cutting head, transmitting power effectively.

- Fuel System: Comprises the tank and lines that deliver fuel to the engine.

Importance of Each Component

- The engine needs to be well-maintained to ensure reliable starts and sustained performance.

- The cutting head should be regularly inspected for wear and tear to maintain cutting efficiency.

- Comfortable handles reduce fatigue, allowing for longer use without discomfort.

- A sturdy shaft ensures durability and efficient power transfer from the engine to the cutting mechanism.

- A clean fuel system is essential for optimal engine function and longevity.

Benefits of Using Original Parts

When it comes to maintaining and enhancing the performance of your equipment, the choice of components plays a crucial role. Opting for authentic components ensures reliability and efficiency, which are vital for the longevity and functionality of any machinery. Original items are designed specifically for your equipment, providing a seamless fit and optimal performance.

Enhanced Performance

Using genuine components significantly improves the overall efficiency of your machinery. These items are crafted to meet exact specifications, which means they work harmoniously with existing systems. This precision leads to better performance, ensuring that your equipment operates at its best and reducing the risk of malfunctions.

Long-Term Cost Savings

Investing in original components may seem more expensive upfront, but it can save you money in the long run. Authentic items tend to have a longer lifespan and lower failure rates compared to generic alternatives. By reducing the need for frequent replacements and repairs, you can achieve substantial savings over time, making it a wise financial decision.

How to Access Parts Diagram PDF

Finding the right visual reference for equipment components can greatly enhance your understanding and maintenance tasks. This guide will help you navigate the process of obtaining essential resources for your machinery.

Follow these steps to locate the necessary reference material:

- Visit the manufacturer’s official website.

- Use the search function to find the model of your equipment.

- Look for sections labeled as support or resources.

- Select the appropriate documentation for your model.

- Download the visual reference for your needs.

By following these steps, you can ensure that you have the ultimate resource for effective maintenance and repair.

Common Repairs for Stihl FS 38

Maintaining a reliable trimmer involves addressing several frequent issues that may arise during its operation. Understanding these common repairs can help users troubleshoot problems effectively and ensure their equipment runs smoothly. This section outlines typical maintenance tasks and repairs that can enhance the performance and longevity of the machine.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Starting Problems | Engine won’t start or is difficult to start. | Check fuel mixture, inspect spark plug, and clean or replace the air filter. |

| Loss of Power | Engine runs weakly or stalls under load. | Examine fuel lines for clogs, clean the carburetor, and ensure the air filter is clear. |

| Excessive Vibration | Unit vibrates excessively during operation. | Check for loose components, inspect the cutting head, and ensure the cutting line is properly installed. |

| Fuel Leaks | Visible fuel pooling or smell of gasoline. | Inspect fuel lines and connections for damage, and replace any worn or cracked components. |

| Cutting Head Issues | Line does not advance or cuts unevenly. | Ensure the spool is loaded correctly, check for line jams, and replace worn cutting line. |

Maintaining Your Trimmer’s Performance

To ensure optimal functionality and longevity of your cutting tool, regular maintenance is essential. A well-maintained device not only performs better but also enhances safety and efficiency during operation. Here are key practices to keep your equipment running smoothly.

Regular Cleaning

Debris can accumulate in various parts, leading to decreased performance. Follow these steps for effective cleaning:

- After each use, wipe down the exterior to remove grass and dirt.

- Inspect and clean the air filter to prevent airflow blockage.

- Check the cutting head for any obstructions or build-up.

Routine Inspections

Conducting regular checks on your equipment can help identify issues before they escalate. Focus on the following components:

- Inspect the spark plug for wear and replace if necessary.

- Examine the fuel lines for any cracks or leaks.

- Check the cutting line for proper length and replace when worn.

By adhering to these maintenance practices, you can ensure your tool remains in peak condition, allowing for efficient and effective performance throughout its lifespan.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, understanding how to locate the necessary components can significantly enhance efficiency. Whether for repairs or upgrades, recognizing the right elements is crucial for optimal performance. This guide will assist in simplifying the process of finding what you need.

Familiarize Yourself with the Equipment

Begin by thoroughly understanding the machine’s structure and functions. Refer to the user manual or online resources to gain insight into various components and their roles. This knowledge will empower you to identify specific items when needed.

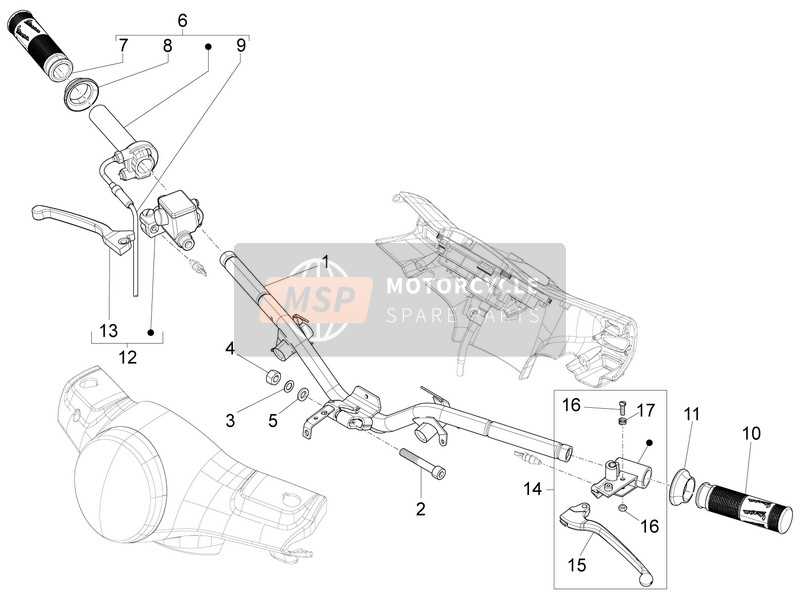

Utilize Visual References

Visual aids can be invaluable. Look for annotated illustrations or images that showcase the arrangement and identification of different pieces. These references help to clarify the specific components required for replacement, making the process more straightforward.

Consult Reliable Sources

Engage with reputable retailers or online platforms specializing in equipment. They often provide detailed information and assistance regarding the components you might be searching for. Additionally, user forums can offer insights and experiences from others who have tackled similar issues.

Keep a Record

Documenting the details of components, such as model numbers and specifications, can save time in future repairs. Create a personal inventory that includes vital information for quick reference whenever necessary.

By implementing these strategies, locating the required items becomes a more efficient and less daunting task, ensuring your equipment remains in top condition.

Tips for Ordering Parts Online

When it comes to purchasing components online, ensuring a smooth experience can make all the difference. Understanding how to navigate the digital marketplace effectively can help you save time and avoid potential pitfalls. Here are some essential guidelines to enhance your online ordering process.

| Tip | Description |

|---|---|

| Research Thoroughly | Before making a purchase, spend some time gathering information about the specific item you need. Look for user reviews and comparisons to confirm the quality and suitability. |

| Verify Seller Reputation | Check the credibility of the online retailer. Look for ratings, customer feedback, and any certifications that demonstrate reliability. |

| Double-Check Compatibility | Ensure the component you are ordering is compatible with your equipment. Refer to specifications and model numbers to avoid mismatches. |

| Understand Return Policies | Familiarize yourself with the seller’s return policy before finalizing your order. Knowing the process for returns can save you from headaches later on. |

| Keep an Eye on Shipping Costs | Review shipping options and fees. Sometimes, opting for a slightly higher-priced item with free shipping can be more economical. |

By following these strategies, you can enhance your online purchasing experience, ensuring that you receive the correct components efficiently and effectively.

Safety Precautions During Repairs

When undertaking maintenance or repairs on any equipment, prioritizing safety is essential. Proper precautions help prevent accidents and injuries, ensuring that the task can be completed effectively. Familiarizing yourself with safety measures can greatly enhance the repair process and protect everyone involved.

Here are some critical safety guidelines to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and ear protection, to shield against debris and noise. |

| Disconnect Power Sources | Ensure that all power sources are disconnected before starting any repairs to prevent accidental startups. |

| Work in a Well-Ventilated Area | Perform repairs in a space with adequate airflow to minimize exposure to harmful fumes or gases. |

| Keep Workspace Organized | A tidy work area reduces the risk of accidents by minimizing hazards and helping you locate tools quickly. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s instructions for repairs and maintenance to ensure proper handling and safety. |

By implementing these safety measures, you can create a secure environment for performing repairs, allowing you to focus on the task at hand with peace of mind.